Abstract

Metal corrosion is one of the key challenges for materials scientists. This natural process creates loses in a variety of industries and necessitates enormous efforts to mitigate its effects. Organic coatings are still the most commonly utilised technique for protecting metallic materials against corrosion. They have opened a new field of research for obtaining coatings with better performance, lifetime, and customized features. While they have excellent anticorrosive characteristics, they must be updated by more environment friendly technology. As a result, there is a need to develop new and more cost-effective methods for creating and applying smart and environmentally friendly organic coatings to reduce corrosion. Anticorrosion research and implementations have progressed as a result of the functionality gained from these coatings at the metal-solution interface in harsh conditions. Smart coatings can react quickly to changes in the environment, cure coating flaws, and prevent additional corrosion. They possess better anticorrosion potential than the traditional anticorrosive coatings. This review discusses self-healing, corrosion sensing, anti-fouling, self-cleaning and anti-microbial organic coatings. It also provides a discussion on selected groups of smart anticorrosive organic coatings such as bio-based and water-borne epoxy resins, hyper branched polyesters and waterborne and bio-based polyurethanes. Moreover, this review outlines different approaches for applying organic coating. Finally, protection mechanisms of organic coatings are summarized.

Similar content being viewed by others

Data availability

Not applicable.

References

Cui G, Bi Z, Wang S, Liu J, Xing X, Li Z, Wang B (2020) A comprehensive review on smart anti-corrosive coatings. Prog Org Coatings 148:105821. https://doi.org/10.1016/j.porgcoat.2020.105821

Honarvar Nazari M, Zhang Y, Mahmoodi A, Xu G, Yu J, Wu J, Shi X (2022) Nanocomposite organic coatings for corrosion protection of metals: A review of recent advances. Prog Org Coatings 162:106573. https://doi.org/10.1016/j.porgcoat.2021.106573

de Almeida Bino MC, Eurídice WA, Gelamo RV et al (2021) Structural and morphological characterization of Ti6Al4V alloy surface functionalization based on Nb2O5 thin film for biomedical applications. Appl Surf Sci 557:149739. https://doi.org/10.1016/j.apsusc.2021.149739

Zhang F, Liu W, Wang S et al (2021) Ke Pi: InvestigationSurface functionalization of Ti3C2Tx and its application in aqueous polymer nanocomposites for reinforcing corrosion protection. Compos Part B Eng 217:108900. https://doi.org/10.1016/j.compositesb.2021.108900

Gonzalez AS, Riego VV et al (2021) Functional antimicrobial surface coatings deposited onto nanostructured 316l food-grade stainless steel. Nanomaterials 11:1055. https://doi.org/10.3390/nano11041055

Baig N, Saleh TA (2021) A facile development of superhydrophobic and superoleophilic micro-textured functionalized mesh membrane for fast and efficient separation of oil from water. J Environ Chem Eng 9:105825. https://doi.org/10.1016/j.jece.2021.105825

Guo Q, Wang G, Batista ER et al (2021) Two-Dimensional Nanomaterials as Anticorrosion Surface Coatings for Uranium Metal: Physical Insights from First-Principles Theory. ACS Appl Nano Mater 4:5038–5046. https://doi.org/10.1021/acsanm.1c00525

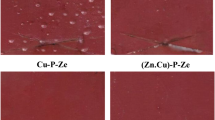

Deyab MA, El Bali B, Mohsen Q, Essehli R (2021) Design new epoxy nanocomposite coatings based on metal vanadium oxy-phosphate M0.5VOPO4 for anti-corrosion applications. Sci Rep 11:1–8. https://doi.org/10.1038/s41598-021-87567-3

Olajire AA (2018) Recent advances on organic coating system technologies for corrosion protection of offshore metallic structures. J Mol Liq 269:572–606

Kao WH, Su YL, Horng JH, Wu WC (2021) Mechanical, tribological, anti-corrosion and anti-glass sticking properties of high-entropy TaNbSiZrCr carbide coatings prepared using radio-frequency magnetron sputtering. Mater Chem Phys 268:124741. https://doi.org/10.1016/J.MATCHEMPHYS.2021.124741

Chen W, Hu T, Wang C et al (2020) The effect of microstructure on corrosion behavior of a novel AlCrTiSiN ceramic coating. Ceram Int 46:12584–12592. https://doi.org/10.1016/J.CERAMINT.2020.02.022

Židov B, Lin Z, Stojanović I, Xu L (2021) Impact of inhibitor loaded mesoporous silica NPs on waterborne coating performance in various corrosive environments. J Appl Polym Sci 138:49614. https://doi.org/10.1002/APP.49614

Adibzadeh E, Mirabedini SM, Behzadnasab M, Farnood RR (2021) A novel two-component self-healing coating comprising vinyl ester resin-filled microcapsules with prolonged anticorrosion performance. Prog Org Coatings 154:106220. https://doi.org/10.1016/j.porgcoat.2021.106220

Ji S, Gui H, Guan G et al (2021) Molecular design and copolymerization to enhance the anti-corrosion performance of waterborne acrylic coatings. Prog Org Coatings 153:106140. https://doi.org/10.1016/j.porgcoat.2021.106140

Verma C, Olasunkanmi LO, Akpan ED, et al (2020) Epoxy resins as anticorrosive polymeric materials: A review. React Funct Polym 156:104741. https://doi.org/10.1016/j.reactfunctpolym.2020.104741

Akbarzadeh S, Ramezanzadeh M, Ramezanzadeh B, Bahlakeh G (2020) A green assisted route for the fabrication of a high-efficiency self-healing anti-corrosion coating through GO nanoplatform reduction by Tamarindus indiaca extract. J Hazard Mater 390:122147. https://doi.org/10.1016/j.jhazmat.2020.122147

Yu M, Lu Q, Cui Z et al (2020) Siloxane-epoxy composite coatings for enhanced resistance to large temperature variations. Prog Org Coatings 139:105457. https://doi.org/10.1016/J.PORGCOAT.2019.105457

Pourhashem S, Saba F, Duan J et al (2020) Polymer/Inorganic nanocomposite coatings with superior corrosion protection performance: A review. J Ind Eng Chem 88:29–57. https://doi.org/10.1016/J.JIEC.2020.04.029

Harb SV, Trentin A, Uvida MC, Hammer P (2020) Advanced organic nanocomposite coatings for effective corrosion protection. In: Corrosion protection at the nanoscale. Elsevier 315–343. https://doi.org/10.1016/B978-0-12-819359-4.00017-9

Jena G, Anandkumar B, Sofia S et al (2020) Fabrication of silanized GO hybrid coating on 316L SS with enhanced corrosion resistance and antibacterial properties for marine applications. Surf Coatings Technol 402:126295. https://doi.org/10.1016/J.SURFCOAT.2020.126295

Lyon SB, Bingham R, Mills DJ (2017) Advances in corrosion protection by organic coatings: What we know and what we would like to know. Prog Org Coatings 102:2–7

Burghardt TE, Pashkevich A (2018) Emissions of Volatile Organic Compounds from road marking paints. Atmos Environ 193:153–157. https://doi.org/10.1016/j.atmosenv.2018.08.065

Zafar F, Ghosal A, Sharmin E et al (2019) A review on cleaner production of polymeric and nanocomposite coatings based on waterborne polyurethane dispersions from seed oils. Prog Org Coatings 131:259–275

Ataei S, Khorasani SN, Neisiany RE (2019) Biofriendly vegetable oil healing agents used for developing self-healing coatings: A review. Prog Org Coatings 129:77–95. https://doi.org/10.1016/J.PORGCOAT.2019.01.012

Jing LC, Wang T, Cao WW et al (2020) Water-based polyurethane composite anticorrosive barrier coating via enhanced dispersion of functionalized GO in the presence of acidified multi-walled carbon nanotubes. Prog Org Coatings 146:105734. https://doi.org/10.1016/j.porgcoat.2020.105734

Khanjani J, Hanifpour A, Pazokifard S, Zohuriaan-Mehr MJ (2020) Waterborne acrylic-styrene/PDMS coatings formulated by different particle sizes of PDMS emulsions for outdoor applications. Prog Org Coatings 141:105267. https://doi.org/10.1016/j.porgcoat.2019.105267

Wang S, Wu Y, Dai J et al (2020) Making organic coatings greener: Renewable resource, solvent-free synthesis, UV curing and repairability. Eur Polym J 123:109439. https://doi.org/10.1016/j.eurpolymj.2019.109439

Faccini M, Bautista L, Soldi L et al (2021) Environmentally friendly anticorrosive polymeric coatings. Appl Sci 11:3446

Li J, Ding Y, Gao Q et al (2020) Ultrathin and flexible biomass-derived C@CoFe nanocomposite films for efficient electromagnetic interference shielding. Compos Part B Eng 190:107935. https://doi.org/10.1016/j.compositesb.2020.107935

Thomas J, Singh V, Jain R (2020) Synthesis and characterization of solvent free acrylic copolymer for polyurethane coatings. Prog Org Coatings 145:105677. https://doi.org/10.1016/j.porgcoat.2020.105677

de Wit JHW, van der Weijde DH, Ferrari G (2011) Organic coatings. In: Corrosion mechanisms in theory and practice: Third Edition. Elsevier 863–906. https://doi.org/10.1201/b11020

Ulaeto SB, Rajan R, Pancrecious JK et al (2017) Developments in smart anticorrosive coatings with multifunctional characteristics. Prog Org Coatings 111:294–314

Stankiewicz A, Szczygieł I, Szczygieł B (2013) Self-healing coatings in anti-corrosion applications. J Mater Sci 48:8041–8051

Sauvant-Moynot V, Gonzalez S, Kittel J (2008) Self-healing coatings: An alternative route for anticorrosion protection. Prog Org Coatings 63:307–315. https://doi.org/10.1016/J.PORGCOAT.2008.03.004

Nardeli JV, Fugivara CS, Taryba M et al (2020) Self-healing ability based on hydrogen bonds in organic coatings for corrosion protection of AA1200. Corros Sci 177:108984. https://doi.org/10.1016/j.corsci.2020.108984

Harb SV, Trentin A, de Souza TAC, et al (2020) Effective corrosion protection by eco-friendly self-healing PMMA-cerium oxide coatings. Chem Eng J 383:1-11. https://doi.org/10.1016/j.cej.2019.123219

Karpakam V, Kamaraj K, Sathiyanarayanan S et al (2011) Electrosynthesis of polyaniline-molybdate coating on steel and its corrosion protection performance. Electrochim Acta 56:2165–2173. https://doi.org/10.1016/j.electacta.2010.11.099

Yabuki A, Yamagami H, Noishiki K (2007) Barrier and self-healing abilities of corrosion protective polymer coatings and metal powders for aluminum alloys. Mater Corros 58:497–501. https://doi.org/10.1002/maco.200604041

Andreeva DV, Fix D, Möhwald H, Shchukin DG (2008) Buffering polyelectrolyte multilayers for active corrosion protection. J Mater Chem 18:1738–1740. https://doi.org/10.1039/b801314d

Dello Iacono S, Martone A, Amendola E (2018) Corrosion-resistant self-healing coatings. In: AIP Conference Proceedings. 1990:020010. https://doi.org/10.1063/1.5047764

Zulkifli F, Ali N, Yusof MSM et al (2017) Henna leaves extract as a corrosion inhibitor in acrylic resin coating. Prog Org Coatings 105:310–319. https://doi.org/10.1016/j.porgcoat.2017.01.017

Wang H, Zhou Q (2018) Evaluation and failure analysis of linseed oil encapsulated self-healing anticorrosive coating. Prog Org Coatings 118:108–115. https://doi.org/10.1016/j.porgcoat.2018.01.024

Samadzadeh M, Boura SH, Peikari M et al (2011) Tung oil: An autonomous repairing agent for self-healing epoxy coatings. Prog Org Coatings 70:383–387. https://doi.org/10.1016/j.porgcoat.2010.08.017

Baharom Z, Baba NB, Ramli R, et al (2019) Microencapsulation of natural self-healing agent as corrosion coating. In: AIP conference proceedings. American Institute of Physics Inc 2068(1):020103. https://doi.org/10.1063/1.5089402

Bagale UD, Sonawane SH, Bhanvase BA et al (2018) Green synthesis of nanocapsules for self-healing anticorrosion coating using ultrasound-assisted approach. Green Process Synth 7:147–159. https://doi.org/10.1515/gps-2016-0160

Li J, Feng Q, Cui J et al (2017) Self-assembled GO microcapsules in Pickering emulsions for self-healing waterborne polyurethane coatings. Compos Sci Technol 151:282–290. https://doi.org/10.1016/j.compscitech.2017.07.031

Daradmare S, Pradhan M, Raja VS, Parida S (2016) Encapsulating 8-hydroxyquinoline in GO-stabilized polystyrene containers and its anticorrosion performance. J Mater Sci 51:10262–10277. https://doi.org/10.1007/s10853-016-0254-4

Wang W, Wang H, Zhao J et al (2019) Self-healing performance and corrosion resistance of GO–mesoporous silicon layer–nanosphere structure coating under marine alternating hydrostatic pressure. Chem Eng J 361:792–804. https://doi.org/10.1016/j.cej.2018.12.124

Bryant DE, Greenfield D (2006) The use of fluorescent probes for the detection of under-film corrosion. Prog Org Coatings 57:416–420. https://doi.org/10.1016/j.porgcoat.2006.09.027

Tian Z, Shi H, Liu F et al (2015) Inhibiting effect of 8-hydroxyquinoline on the corrosion of silane-based sol-gel coatings on AA 2024–T3. Prog Org Coatings 82:81–90. https://doi.org/10.1016/j.porgcoat.2015.01.018

Langer E, Waśkiewicz S, Kuczyńska H (2019) Application of new modified Schiff base epoxy resins as organic coatings. J Coatings Technol Res 16:1109–1120. https://doi.org/10.1007/s11998-019-00185-7

Maia F, Tedim J, Bastos AC, et al (2013) Nanocontainer-based corrosion sensing coating. Nanotechnology 24 https://doi.org/10.1088/0957-4484/24/41/415502

Dhole GS, Gunasekaran G, Naik R et al (2020) Fluorescence based corrosion detecting epoxy coating. Prog Org Coatings 138:105425. https://doi.org/10.1016/j.porgcoat.2019.105425

Zhang J, Frankel GS (1999) Investigation of the corrosion-sensing behavior of an acrylic-based coating sys. Corrosion 55:957

Li Y (2020) Temperature and humidity sensors based on luminescent metal-organic frameworks. Polyhedron 179:114413. https://doi.org/10.1016/j.poly.2020.114413

Salaluk S, Jiang S, Viyanit E et al (2021) Design of Nanostructured Protective Coatings with a Sensing Function. ACS Appl Mater Interfaces 13:53046–53054. https://doi.org/10.1021/ACSAMI.1C14110/SUPPL_FILE/AM1C14110_SI_001.PDF

Zhang M, Ma L, Wang L et al (2018) Insights into the Use of Metal-Organic Framework As High-Performance Anticorrosion Coatings. ACS Appl Mater Interfaces 10:2259–2263. https://doi.org/10.1021/acsami.7b18713

Dhole GS, Gunasekaran G, Ghorpade T, Vinjamur M (2017) Smart acrylic coatings for corrosion detection. Prog Org Coatings 110:140–149. https://doi.org/10.1016/j.porgcoat.2017.04.048

Exbrayat L, Salaluk S, Uebel M et al (2019) Nanosensors for Monitoring Early Stages of Metallic Corrosion. ACS Appl Nano Mater 2:812–818. https://doi.org/10.1021/acsanm.8b02045

Buchheit RG, Guan H, Mahajanam S, Wong F (2003) Active corrosion protection and corrosion sensing in chromate-free organic coatings. In: Progress in Organic Coatings. 174–182. https://doi.org/10.1016/j.porgcoat.2003.08.003

Li W, Calle LM (2007) Controlled release microcapsules for smart coatings. In: NACE - International Corrosion Conference Series. OnePetro 072281–0722811

Mathiazhagan A, Joseph R (2011) Nanotechnology-a new prospective in organic coating-review. Int J Chem Eng Appl 225–237. https://doi.org/10.7763/ijcea.2011.v2.108

Basu S, Hanh BM, Ismail MH et al (2020) Laboratory and Field Testing Assessment of Next Generation Biocide-Free, Fouling-Resistant Slippery Coatings. ACS Appl Polym Mater 2:5147–5162. https://doi.org/10.1021/ACSAPM.0C00916/SUPPL_FILE/AP0C00916_SI_013.AVI

Han X, Wu J, Zhang X et al (2021) Special issue on advanced corrosion-resistance materials and emerging applications. The progress on antifouling organic coating: From biocide to biomimetic surface. J Mater Sci Technol 61:46–62. https://doi.org/10.1016/j.jmst.2020.07.002

Mohanan S, Maruthamuthu S, Kalaiselvi N et al (2005) Role of quaternary ammonium compounds and ATMP on biocidal effect and corrosion inhibition of mild steel and copper. Corros Rev 23:425–444. https://doi.org/10.1515/corrrev.2005.23.4-5-6.425

Guo J, Yuan S, Jiang W et al (2018) Polymers for combating biocorrosion Front Mater 5:10

Jin H, Wang J, Tian L et al (2022) Recent advances in emerging integrated antifouling and anticorrosion coatings. Mater Des 213:110307. https://doi.org/10.1016/j.matdes.2021.110307

Regina VR, Søhoel H, Lokanathan AR et al (2012) Entrapment of subtilisin in ceramic sol-gel coating for antifouling applications. ACS Appl Mater Interfaces 4:5915–5921. https://doi.org/10.1021/am301554m

Selim MS, Shenashen MA, Elmarakbi A et al (2017) Synthesis of ultrahydrophobic and thermally stable inorganic–organic nanocomposites for self-cleaning foul release coatings. Chem Eng J 320:653–666. https://doi.org/10.1016/j.cej.2017.03.067

Szleifer I (1997) Protein adsorption on surfaces with grafted polymers: A theoretical approach. Biophys J 72:595–612. https://doi.org/10.1016/S0006-3495(97)78698-3

Khalil F, Franzmann E, Ramcke J et al (2014) Biomimetic PEG-catecholates for stabile antifouling coatings on metal surfaces: Applications on TiO2 and stainless steel. Colloids Surfaces B Biointerfaces 117:185–192. https://doi.org/10.1016/j.colsurfb.2014.02.022

Carpenter AW, Worley BV, Slomberg DL, Schoenfisch MH (2012) Dual action antimicrobials: Nitric oxide release from quaternary ammonium-functionalized silica NPs. Biomacromol 13:3334–3342. https://doi.org/10.1021/bm301108x

Yuan H, Yu B, Fan L-H et al (2016) Multiple types of hydroxyl-rich cationic derivatives of PGMA for broad-spectrum antibacterial and antifouling coatings. Polym Chem 7:5709–5718. https://doi.org/10.1039/C6PY01242F

Josphine JS, Manjusha WA, (2021) Evaluation of antifouling potential of staphylococcus sp. isolated from marine sea water. Ann Rom 25:6650–6661. https://www.annalsofrscb.ro.

Kyei SK, Darko G, Akaranta O (2020) Chemistry and application of emerging ecofriendly antifouling paints: a review. J Coatings Technol Res 17:315–332

Pinteus S, Lemos MFL, Alves C et al (2021) The marine invasive seaweeds Asparagopsis armata and Sargassum muticum as targets for greener antifouling solutions. Sci Total Environ 750:141372. https://doi.org/10.1016/j.scitotenv.2020.141372

Jin H, Tian L, Bing W et al (2022) Bioinspired marine antifouling coatings: Status, prospects, and future. Prog Mater Sci 124:100889. https://doi.org/10.1016/j.pmatsci.2021.100889

Chen L, Duan Y, Cui M, et al (2021) Biomimetic surface coatings for marine antifouling: Natural antifoulants, synthetic polymers and surface microtopography. Sci Total Environ 766:144469. https://doi.org/10.1016/j.scitotenv.2020.144469

Xu Y, He H, Schulz S et al (2010) Potent antifouling compounds produced by marine Streptomyces. Bioresour Technol 101:1331–1336. https://doi.org/10.1016/j.biortech.2009.09.046

Parkin IP, Palgrave RG (2005) Self-cleaning coatings. J Mater Chem 15:1689–1695

Wang S, Wang Y, Zou Y et al (2020) A self-adjusting PTFE/TiO2 hydrophobic double-layer coating for corrosion resistance and electrical insulation. Chem Eng J 402:126116. https://doi.org/10.1016/j.cej.2020.126116

Dhoke SK, Mangal Sinha TJ, Khanna AS (2009) Effect of nano-Al2O3 particles on the corrosion behavior of alkyd based waterborne coatings. J Coatings Technol Res 6:353–368. https://doi.org/10.1007/s11998-008-9127-3

Pawar PG, Xing R, Kambale RC et al (2017) Polystyrene assisted superhydrophobic silica coatings with surface protection and self-cleaning approach. Prog Org Coatings 105:235–244. https://doi.org/10.1016/j.porgcoat.2017.01.016

Wu X, Yang F, Gan J et al (2021) A flower-like waterborne coating with self-cleaning, self-repairing properties for superhydrophobic applications. J Mater Res Technol 14:1820–1829. https://doi.org/10.1016/j.jmrt.2021.07.096

Selim MS, Yang H, El-Safty SA et al (2019) Superhydrophobic coating of silicone/β–MnO 2 nanorod composite for marine antifouling. Colloids Surfaces A Physicochem Eng Asp 570:518–530. https://doi.org/10.1016/j.colsurfa.2019.03.026

Ganesh VA, Raut HK, Nair AS, Ramakrishna S (2011) A review on self-cleaning coatings. J Mater Chem 21:16304–16322

Patil CK, Jirimali HD, Paradeshi JS et al (2019) Functional antimicrobial and anticorrosive polyurethane composite coatings from algae oil and silver doped egg shell hydroxyapatite for sustainable development. Prog Org Coatings 128:127–136. https://doi.org/10.1016/j.porgcoat.2018.11.002

El-Fattah MA, El Saeed AM, Azzam AM et al (2016) Improvement of corrosion resistance, antimicrobial activity, mechanical and chemical properties of epoxy coating by loading chitosan as a natural renewable resource. Prog Org Coatings 101:288–296. https://doi.org/10.1016/j.porgcoat.2016.09.002

Sharmin E, Ashraf SM, Ahmad S (2007) Synthesis, characterization, antibacterial and corrosion protective properties of epoxies, epoxy-polyols and epoxy-polyurethane coatings from linseed and Pongamia glabra seed oils. Int J Biol Macromol 40:407–422. https://doi.org/10.1016/j.ijbiomac.2006.10.002

Xu R, Li J, Xiong Z et al (2020) Antibacterial waterborne epoxy coatings containing poly m-aminophenol-deposited GO. Prog Org Coatings 147:105802. https://doi.org/10.1016/j.porgcoat.2020.105802

Zheng H, Li Z, Liu L et al (2021) Superhydrophobic composite coatings in bacterial culture media: Durable antibacterial activity and enhanced corrosion resistance. Compos Commun 27:100857. https://doi.org/10.1016/j.coco.2021.100857

Kausar A (2020) Performance of corrosion protective epoxy blend-based nanocomposite coatings: a review. Polym Technol Mater 59:658–673

Tator KB (2018) Epoxy resins and curatives. In: Protective organic coatings. ASM International, 63–79

Marotta A, Faggio N, Ambrogi V et al (2021) Biobased furan-based epoxy/TiO2 nanocomposites for the preparation of coatings with improved chemical resistance. Chem Eng J 406:127107. https://doi.org/10.1016/j.cej.2020.127107

Pouladi J, Mirabedini SM, Eivaz Mohammadloo H, Rad NG (2021) Synthesis of novel plant oil-based isocyanate-free urethane coatings and study of their anti-corrosion properties. Eur Polym J 153:110502. https://doi.org/10.1016/j.eurpolymj.2021.110502

Baroncini EA, Kumar Yadav S, Palmese GR, Stanzione JF (2016) Recent advances in bio-based epoxy resins and bio-based epoxy curing agents. J Appl Polym Sci 133: 4103. https://doi.org/10.1002/app.44103

Alam M, Akram D, Sharmin E et al (2014) Vegetable oil based eco-friendly coating materials: A review article. Arab J Chem 7:469–479. https://doi.org/10.1016/J.ARABJC.2013.12.023

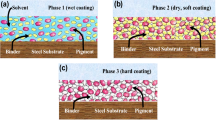

Dehan V, Bourgeat-Lami E, D’Agosto F et al (2017) High-performance water-based barrier coatings for the corrosion protection of structural steel. Steel Constr 10:254–259. https://doi.org/10.1002/stco.201710034

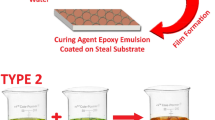

Elmore JD, Kincaid DS, Komar PC, Nielsen JE (2002) Waterborne epoxy protective coatings for metal. J Coatings Technol 74:63–72. https://doi.org/10.1007/bf02697969

Galgoci EC, Komar PC, Elmore JD (1999) High performance waterborne coatings based on dispersions of a solid epoxy resin and an amine-functional curing agent. J Coatings Technol 71:45–52. https://doi.org/10.1007/bf02697895

Dou B, Xiao H, Lin X et al (2021) Investigation of the anti-corrosion properties of fluorinated graphene-modified waterborne epoxy coatings for carbon steel. Coatings 11:1–16. https://doi.org/10.3390/coatings11020254

Wang N, Zhang Y, Chen J et al (2017) Dopamine modified metal-organic frameworks on anti-corrosion properties of waterborne epoxy coatings. Prog Org Coatings 109:126–134. https://doi.org/10.1016/j.porgcoat.2017.04.024

Wang C, Wang Z, Liu S et al (2021) Anti-corrosion and wear-resistant coating of waterborne epoxy resin by concrete- like three-dimensional functionalized framework fillers. Chem Eng Sci 242:116748. https://doi.org/10.1016/j.ces.2021.116748

Wu Y, Yu J, Zhao W et al (2019) Investigating the anti-corrosion behaviors of the waterborne epoxy composite coatings with barrier and inhibition roles on mild steel. Prog Org Coatings 133:8–18. https://doi.org/10.1016/j.porgcoat.2019.04.028

Kausar A (2020) High performance epoxy/polyester-based nanocomposite coatings for multipurpose applications: A review. J Plast Film Sheeting 36:391–408. https://doi.org/10.1177/8756087920910481

Guo T, Li H, Ma X et al (2020) Hyperbranched polyester modified GO on anti-corrosion performance of epoxy composite coatings for electric power system. Plast Rubber Compos 49:245–253. https://doi.org/10.1080/14658011.2020.1735180

Patil AM, Jirimali HD, Jagtap RN (2020) Study of coating performance of bio-based hyperbranched polyester polyol/GO composites in PU-coating. J Macromol Sci Part A Pure Appl Chem 58:81–89. https://doi.org/10.1080/10601325.2020.1826330

Patil AM, Gite VV, Jirimali HD, Jagtap RN (2021) Fully Biobased Nanocomposites of Hyperbranched-Polyol and Hydroxyapatite in Coating Applications. J Polym Environ 29:799–810. https://doi.org/10.1007/s10924-020-01903-8

Gurunathan T, Mohanty S, Nayak SK (2016) Hyperbranched Polymers for Coating Applications: A Review. Polym - Plast Technol Eng 55:92–117. https://doi.org/10.1080/03602559.2015.1021482

Pathak SS, Khanna AS (2009) Investigation of anti-corrosion behavior of waterborne organosilane-polyester coatings for AA6011 aluminum alloy. Prog Org Coatings 65:288–294. https://doi.org/10.1016/j.porgcoat.2008.12.006

Ikladious NE, Asaad JN, Emira HS, Mansour SH (2017) Alkyd resins based on hyperbranched polyesters and PET waste for coating applications. Prog Org Coatings 102:217–224. https://doi.org/10.1016/j.porgcoat.2016.10.015

Hadzich A, Gross GA, Leimbach M, et al (2020) Effect of polyalcohols on the anticorrosive behaviour of alkyd coatings prepared with drying oils. Prog Org Coatings 145 https://doi.org/10.1016/j.porgcoat.2020.105671

Bat E, Gündüz G, Kisakürek D, Akhmedov IM (2006) Synthesis and characterization of hyperbranched and air drying fatty acid based resins. Prog Org Coatings 55:330–336. https://doi.org/10.1016/j.porgcoat.2006.01.005

Singh AP, Suryanarayana C, Baloji Naik R, Gunasekaran G (2016) Development of hyperbranched polyester polyol-based waterborne anticorrosive coating. J Coatings Technol Res 13:41–51. https://doi.org/10.1007/s11998-015-9720-1

Haghdadeh P, Ghaffari M, Ramezanzadeh B et al (2018) The role of functionalized GO on the mechanical and anti-corrosion properties of polyurethane coating. J Taiwan Inst Chem Eng 86:199–212. https://doi.org/10.1016/j.jtice.2018.02.009

Tsai PY, Chen TE, Lee YL (2018) Development and characterization of anticorrosion and antifriction properties for high performance polyurethane/graphene composite coatings. Coatings 8:250. https://doi.org/10.3390/coatings8070250

Naik RB, Malvankar NG, Mahato TK et al (2014) Novel moisture-cured hyperbranched urethane alkyd resin for coating application. J Coatings Technol Res 11:575–586. https://doi.org/10.1007/s11998-013-9561-8

Li J, Cui J, Yang J et al (2016) Reinforcement of graphene and its derivatives on the anticorrosive properties of waterborne polyurethane coatings. Compos Sci Technol 129:30–37. https://doi.org/10.1016/j.compscitech.2016.04.017

Xiao L, Shi J, Wu K, Lu M (2020) Self-healing supramolecular waterborne polyurethane based on host–guest interactions and multiple hydrogen bonds. React Funct Polym 148:104482. https://doi.org/10.1016/j.reactfunctpolym.2020.104482

Lee DK, Tsai HB, Da YZ, Tsai RS (2012) Polyurethane dispersions derived from polycarbonatediols by a solvent-free process. J Appl Polym Sci 126:E275–E282. https://doi.org/10.1002/app.36812

Li Y, Yang Z, Qiu H et al (2014) Self-aligned graphene as anticorrosive barrier in waterborne polyurethane composite coatings. J Mater Chem A 2:14139–14145. https://doi.org/10.1039/c4ta02262a

Marathe R, Tatiya P, Chaudhari A et al (2015) Neem acetylated polyester polyol-Renewable source based smart PU coatings containing quinoline (corrosion inhibitor) encapsulated polyurea microcapsules for enhance anticorrosive property. Ind Crops Prod 77:239–250. https://doi.org/10.1016/j.indcrop.2015.08.054

Ismail EA, Motawie AM, Sadek EM (2011) Synthesis and characterization of polyurethane coatings based on soybean oil–polyester polyols. Egypt J Pet 20:1–8. https://doi.org/10.1016/j.ejpe.2011.06.009

Kathalewar M, Sabnis A, D’Melo D (2014) Polyurethane coatings prepared from CNSL based polyols: Synthesis, characterization and properties. Prog Org Coatings 77:616–626. https://doi.org/10.1016/j.porgcoat.2013.11.028

Araújo RCS, Pasa VMD (2004) New Eucalyptus tar-derived polyurethane coatings. Prog Org Coatings 51:6–14. https://doi.org/10.1016/j.porgcoat.2004.04.002

Siyanbola TO, Neelambaram P, Mohanty S et al (2019) The effects of carbonized Eucalyptus globulus leaves on castor seed oil based urethane coating system. Prog Org Coatings 131:42–48. https://doi.org/10.1016/j.porgcoat.2019.02.018

Edavan RP, Kopinski R (2009) Corrosion resistance of painted zinc alloy coated steels. Corros Sci 51:2429–2442. https://doi.org/10.1016/j.corsci.2009.06.028

Bayliss D, Deacon D (2002) Steelwork corrosion control. Spon. 2nd Edition, Kindle Edition, pp 432

Dumain ED, Agawa T, Goel S et al (1999) Cure behavior of polyester-acrylate hybrid powder coatings. J Coatings Technol 71:69–75. https://doi.org/10.1007/bf02697908

Lafabrier A, Fahs A, Louarn G et al (2014) Experimental evidence of the interface/interphase formation between powder coating and composite material. Prog Org Coatings 77:1137–1144. https://doi.org/10.1016/j.porgcoat.2014.03.021

Iwamura G, Agawa T, Maruyama K, Takeda H (2000) A novel acrylic/polyester system for powder coatings. JOCCA - Surf Coatings Int 83:285–288. https://doi.org/10.1007/BF02692728

Farshchi N, Gedan-Smolka M (2020) Polyurethane powder coatings: A review of composition and characterization. Ind Eng Chem Res 59:15121–15132. https://doi.org/10.1021/acs.iecr.0c02320

Boccaccini AR, Zhitomirsky I (2002) Application of electrophoretic and electrolytic deposition techniques in ceramics processing. Curr Opin Solid State Mater Sci 6:251–260. https://doi.org/10.1016/S1359-0286(02)00080-3

Zhang J, Wu C (2009) Corrosion protection behavior of AZ31 magnesium alloy with cathodic electrophoretic coating pretreated by silane. Prog Org Coatings 66:387–392. https://doi.org/10.1016/j.porgcoat.2009.09.001

Li GY, Lian JS, Niu LY et al (2007) Effect of zinc-phosphate-molybdate conversion precoating on performance of cathode epoxy electrocoat on AZ91D alloy. Surf Eng 23:56–61. https://doi.org/10.1179/174329407X161663

Park JH, Park JM (2014) Electrophoretic deposition of GO on mild carbon steel for anti-corrosion application. Surf Coatings Technol 254:167–174. https://doi.org/10.1016/j.surfcoat.2014.06.007

Singh S, Singh G, Bala N (2019) Corrosion behavior and characterization of HA/Fe3O4/CS composite coatings on AZ91 Mg alloy by electrophoretic deposition. Mater Chem Phys 237:121884. https://doi.org/10.1016/j.matchemphys.2019.121884

Zheludkevich ML, Salvado IM, Ferreira MGS (2005) Sol-gel coatings for corrosion protection of metals. J Mater Chem 15:5099–5111. https://doi.org/10.1039/b419153f

Barranco V, Carmona N, Galván JC et al (2010) Electrochemical study of tailored sol-gel thin films as pre-treatment prior to organic coating for AZ91 magnesium alloy. Prog Org Coatings 68:347–355. https://doi.org/10.1016/j.porgcoat.2010.02.009

Liu L, Mandler D (2015) Sol-gel coatings by electrochemical deposition. In: The sol-gel handbook. John Wiley & Sons Ltd 373–414. https://doi.org/10.1002/9783527670819.ch12

Qi K, Sun Y, Duan H, Guo X (2015) A corrosion-protective coating based on a solution-processable polymer-grafted GO nanocomposite. Corros Sci 98:500–506. https://doi.org/10.1016/j.corsci.2015.05.056

Di H, Yu Z, Ma Y et al (2016) Corrosion-resistant hybrid coatings based on GO–zirconia dioxide/epoxy system. J Taiwan Inst Chem Eng 67:511–520. https://doi.org/10.1016/j.jtice.2016.08.008

Dos Santos FC, Harb SV, Menu MJ et al (2015) On the structure of high performance anticorrosive PMMA-siloxane-silica hybrid coatings. RSC Adv 5:106754–106763. https://doi.org/10.1039/c5ra20885h

Torrico RFAO, Harb SV, Trentin A et al (2018) Structure and properties of epoxy-siloxane-silica nanocomposite coatings for corrosion protection. J Colloid Interface Sci 513:617–628. https://doi.org/10.1016/j.jcis.2017.11.069

Maya-Visuet E, Gao T, Soucek M, Castaneda H (2015) The effect of TiO2 as a pigment in a polyurethane/polysiloxane hybrid coating/aluminum interface based on damage evolution. Prog Org Coatings 83:36–46. https://doi.org/10.1016/j.porgcoat.2015.02.001

Brusciotti F, Snihirova DV, Xue H et al (2013) Hybrid epoxy–silane coatings for improved corrosion protection of Mg alloy. Corros Sci 67:82–90. https://doi.org/10.1016/J.CORSCI.2012.10.013

Sellaiyan S, Hughes AE, Smith SV et al (2014) Leaching properties of chromate-containing epoxy films using radiotracers, PALS and SEM. Prog Org Coatings 77:257–267. https://doi.org/10.1016/j.porgcoat.2013.09.014

Visser P, Lutz A, Mol JMC, Terryn H (2016) Study of the formation of a protective layer in a defect from lithium-leaching organic coatings. Prog Org Coatings 99:80–90. https://doi.org/10.1016/j.porgcoat.2016.04.028

Trentin A, Harb SV, Uvida MC et al (2019) Dual Role of Lithium on the Structure and Self-Healing Ability of PMMA-Silica Coatings on AA7075 Alloy. ACS Appl Mater Interfaces 11:40629–40641. https://doi.org/10.1021/acsami.9b13839

Syrek-Gerstenkorn B, Paul S, Davenport AJ (2020) Sacrificial thermally sprayed aluminium coatings for marine environments: A review. Coatings 10:1–19. https://doi.org/10.3390/coatings10030267

Acknowledgements

Reshmy R (SR/WOS-B/587/2016) acknowledges Department of Science and Technology for sanctioning projects under DST WOS-B scheme.

Funding

Reshmy R (SR/WOS-B/587/2016) acknowledges Department of Science and Technology for sanctioning projects under DST WOS-B scheme.

Author information

Authors and Affiliations

Contributions

Deepa Thomas, Eapen Philip: Collecting articles and Writing original draft.

Reshmy R, Mukesh Kumar Awasthi: Project Administration, Conceptualization and Visualization.

Raveendran Sindhu: Reviewing and Editing.

Sarah B. Ulaeto: Reviewing and Editing.

Arivalagan Pugazhendhi: Supervision, Reviewing and Editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Thomas, D., R, R., Philip, E. et al. Developments in smart organic coatings for anticorrosion applications: a review. Biomass Conv. Bioref. 12, 4683–4699 (2022). https://doi.org/10.1007/s13399-022-02363-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02363-x