Abstract

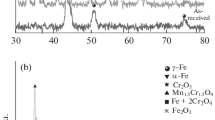

This study investigated the corrosion behavior and mechanism of 42CrMoE LAS in boric acid solutions with varying concentrations (2500-37000 mg/l) and temperatures (25-97.5 °C) using electrochemical measurement and weight loss immersion experiment. Results revealed that at a low boric acid concentration, the corrosion rate initially increased and subsequently decreased with increasing temperature. While at higher concentrations, the corrosion rate exhibited a monotonic increase with increasing temperature. Additionally, the steel displayed pitting corrosion, which intensified with increasing boric acid concentrations. However, at high temperature, pits corrosion transformed toward uniform corrosion. The interrelated effects of temperature and boric acid concentration primarily modulated the pH and dissolved oxygen content, consequently impacting the corrosion behavior. With escalating temperature and concentration, corrosion products transformed from protective Fe2O3 and Fe3O4 to inadequately protective FeOOH, ultimately resulting in an increased corrosion rate of 42CrMoE LAS.

Similar content being viewed by others

References

L. Tian, P. Zhizhen, and F. Yancheng, Boric Acid Corrosion in the Primary System of PWRs, in Materials Science and Advanced Technologies in Manufacturing II: Selected, Peer Reviewed Papers from the 4th International Conference on Materials Science and Engineering (ICMSE 2014), December 27–28, 2014, Jiujiang, Chinaed, 2014, p 58–62

J. Park, O. Chopra, K. Natesan, W. Shack, and W. Cullen, Jr., Boric acid corrosion of light water reactor pressure vessel materials, in Proceedings of the 12th International Conference on Environmental Degradation of Materials in Nuclear Power System-Water Reactors, 2005, pp 459–468

S. Fyfitch and H. Xu, Boric acid Corrosion Laboratory Investigation of Carbon and Low-Alloy Steels in PWR Systems (2007)

H.L. Dai, S.W. Shi, C. Guo, and X. Chen, Pits Formation and Stress Corrosion Cracking Behavior of Q345R in Hydrofluoric Acid, Corros. Sci., 2020, 166, 108443.

E. Hunt, Boric Acid Corrosion Guidebook, Revision 1: Managing Boric Acid Corrosion Issues at PWR Power Stations, EPRI Final Rep., 2001, 6, p 1000–975.

S.-W. Kim, D.-J. Kim, and H.-P. Kim, Evaluation of Galvanic Corrosion Behavior of Sa-508 Low Alloy Steel and Type 309l Stainless Steel Cladding of Reactor Pressure Vessel under Simulated Primary Water Environment, Nucl. Eng. Technol., 2012, 44(7), p 773–780.

Q. Xiao, Z. Lu, J. Chen, M. Yao, Z. Chen, and A. Ejaz, The Effects of Temperature and Aeration on the Corrosion of A508III Low Alloy Steel in Boric Acid Solutions at 25–95 °C, J. Nucl. Mater., 2016, 480, p 88–99.

Y.S. Lim, S.S. Hwang, D.J. Kim, and J.Y. Lee, Corrosion Behavior of SA508 Low Alloy Steels Exposed to Aerated Boric Acid Solutions, Nucl. Eng. Technol., 2020, 52(6), p 1222–1230.

L. Wang, M. Wang, M. Zhong, X. Li, and Z. Cui, Degradation of Thermal Oxide Film on Pure Titanium in an Acidic Environment Containing Fluoride, npj Mater. Degrad., 2022, 6(1), p 65.

Q. Zhu, J. Chen, G. Gou, H. Chen, and P. Li, Ameliorated Longitudinal Critically Refracted—Attenuation velocity method for Welding Residual Stress Measurement, J. Mater. Process. Technol., 2017, 246, p 267–275.

J.X. Fang, S.Y. Dong, S.B. Li, Y.J. Wang, B.S. Xu, J. Li, B. Liu, and Y.L. Jiang, Direct Laser Deposition as Repair Technology for a Low Transformation Temperature Alloy: Microstructure, Residual Stress, and Properties, Mater. Sci. Eng. A, 2019, 748, p 119–127.

Z.Y. Zhu, Y.L. Liu, G.Q. Gou, W. Gao, and J. Chen, Effect of Heat Input on Interfacial Characterization of the Butter Joint of Hot-Rolling CP-Ti/Q235 Bimetallic Sheets by Laser + CMT, Sci. Rep., 2021, 11(1), p 10020.

Y. Pan, L. Song, Z. Liu, J. Hu, and X. Li, Effect of Hydrogen Charging on SCC of 2205 Duplex Stainless Steel with Varying Microstructures in Simulated Deep-Sea Environment, Corros. Sci., 2022, 196, p 66.

Y. Pan, B. Sun, Z. Liu, W. Wu, and X. Li, Hydrogen Effects on Passivation and SCC of 2205 DSS in Acidified Simulated Seawater, Corros. Sci., 2022, 208, p 66.

W. Wu, Z. Liu, Q. Wang, and X. Li, Improving the Resistance of High-Strength Steel to SCC in a SO2-Polluted Marine Atmosphere through Nb and Sb Microalloying, Corros. Sci., 2020, 170, p 66.

B. Sun, Y. Pan, J. Yang, J. Guo, B. Zhao, X. Liu, Z. Liu, and X. Li, Microstructure Evolution and SSCC Behavior of Strain-Strengthened 304 SS Pre-strained at Room Temperature and Cryogenic Temperature, Corros. Sci., 2023, 210, p 66.

Y. Xiao, J. Tang, Y. Wang, B. Lin, Z. Nie, Y. and Li, B. Normand and H. Wang, Corrosion Behavior of 2205 Duplex Stainless Steel in NaCl Solutions Containing Sulfide Ions, Corros. Sci., 2022, 200, p 66.

E. Huttunen-Saarivirta, E. Isotahdon, Z. Que, M. Lindgren, A. Mardoukhi, J.B. Jorcin, P. Mocnik, T. Kosec, Y.E. Ouazari, S.H. Mameng, and L. Wegrelius, Pitting Corrosion on Highly Alloyed Stainless Steels in Dilute Sulphuric Acid Containing Sodium Chloride, Electrochimica Acta, 2023, 457, p 66.

T. Zhao, S. Wang, Z. Liu, C. Du, and X. Li, Effect of Cathodic Polarization on Stress Corrosion Cracking Behavior of a Ni(Fe, Al)-Maraging Steel in Artificial Seawater, Corros. Sci., 2021, 179, p 66.

B.Z. Sun, Z.Y. Liu, Y.D. He, F.H. Cao, and X.G. Li, A New Study for Healing Pitting Defects of 316L Stainless Steel Based on Microarc Technology, Corros. Sci., 2021, 187, 109505.

H. Tian, Z. Cui, H. Ma, P. Zhao, M. Yan, X. Wang, and H. Cui, Corrosion Evolution and Stress Corrosion Cracking Behavior of A Low Carbon Bainite Steel in the Marine Environments: Effect of the Marine Zones, Corros. Sci., 2022, 206, p 66.

L. Wang, J. Liang, H. Li, L. Cheng, and Z. Cui, Quantitative Study of the Corrosion Evolution and Stress Corrosion Cracking of High Strength Aluminum Alloys in Solution and Thin Electrolyte Layer Containing Cl, Corros. Sci., 2021, 178, p 66.

B. Sun, Q. Wang, Y. Pan, Z. Liu, C. Du, and X. Li, Understanding the Non-steady Electrochemical Mechanism on SCC of 304 SS under Applied Polarization Potentials, Corros. Sci., 2024, 227, p 66.

Z. Li, B. Sun, Q. Liu, Y. Yu ,and Z. Liu, Fundamentally Understanding the Effect of Non-stable Cathodic Potential on Stress Corrosion Cracking of Pipeline Steel in Near-Neutral pH Solution, Constr. Build. Mater., 2021, 288, p 66.

B. Sun, X. Zuo, X. Cheng, and X. Li, The Role of Chromium Content in the Long-Term Atmospheric Corrosion Process, npj Mater. Degrad., 2020, 4(1), p 66.

X. Xu, H. Cheng, W. Wu, Z. Liu, and X. Li, Stress Corrosion Cracking Behavior and Mechanism of Fe-Mn-Al-C-Ni High Specific Strength Steel in the Marine Atmospheric Environment, Corros. Sci., 2021, 191, p 66.

J. Soltis, Passivity Breakdown, Pit Initiation and Propagation of Pits in Metallic Materials—Review, Corros. Sci., 2015, 90, p 5–22.

E. Mahdi, A. Rauf, and E.O. Eltai, Effect of Temperature and Erosion on Pitting Corrosion of X100 Steel in Aqueous Silica Slurries Containing Bicarbonate and Chloride Content, Corros. Sci., 2014, 83, p 48–58.

S. Ahn, H. Kwon, and D.D. Macdonald, Role of Chloride Ion in Passivity Breakdown on Iron and Nickel, J. Electrochem. Soc., 2005, 152(11), p B482–B490.

B.T. Lu, Z.K. Chen, J.L. Luo, B.M. Patchett, and Z.H. Xu, Pitting and Stress Corrosion Cracking Behavior in Welded Austenitic Stainless Steel, Electrochim. Acta, 2005, 50(6), p 1391–1403.

B. Meng, J. Wang, M. Chen, S. Zhu, and F. Wang, Study on the Oxidation Behavior of a Novel Thermal Barrier Coating System Using the Nanocrystalline Coating as Bonding Coating on the Single-Crystal Superalloy, Corros. Sci., 2023, 225, 111591.

R. Kodým, D. Šnita, V. Fíla, K. Bouzek, and M. Kouřil, Investigation of Processes Occurring at Cathodically Protected Underground Installations: Mathematical Modeling of Reaction Transport Processes in Soil, Corros. Sci., 2017, 120, p 28–41.

Y. Dou, S. Han, L. Wang, X. Wang, and Z. Cui, Characterization of the Passive Properties of 254SMO Stainless Steel in Simulated Desulfurized Flue Gas Condensates by Electrochemical Analysis, XPS and ToF-SIMS, Corrosion Science, 2020, 165, 108405.

H. Huang, M. Huang, W. Zhang, S. Pospisil, and T. Wu, Experimental Investigation on Rehabilitation of Corroded RC Columns with BSP and HPFL under Combined Loadings, J. Struct. Eng., 2020, 146(8), p 04020157.

Z. Zhang, Y. Han, X. Lu, T. Zhang, Y. Bai, and Q. Ma, Effects of N2 Content in Shielding Gas on Microstructure and Toughness of Cold Metal Transfer and Pulse Hybrid Welded Joint for Duplex Stainless Steel, Mater. Sci. Eng. A, 2023, 872, 144936.

Acknowledgments

The authors acknowledge the support of the Natural Science Foundation of China (No. U22B2065).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, W., Zhang, Y., Miao, X. et al. Effect of Temperature and Concentration on the Corrosion Behavior of 42CrMoE Low Alloy Steel in Boric Acid Solution. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09520-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09520-5