Abstract

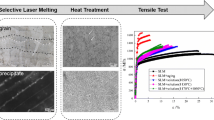

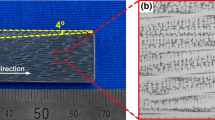

The solidification microstructure of 4716MA0 Ni-based superalloy was studied by ultrasonic treatment. The precipitation behavior of 4716MA0 were observed by means of optical microscopy, scanning electron microscope (SEM + EDS) and X-ray diffraction, and the reasons for the change of microstructure were explained. The results show that the coarse dendrites change into the equiaxed crystals, and the grain size is refined from 266 to 102 μm. It mainly consists of γ matrix phase, γ′ reinforced phase, γ/γ′ eutectic and MC carbides. The area fraction of shrinkage cavities, carbides and γ/γ′ eutectic are decreased from 3.26 to 0.67%, 12.66 to 6.24%, and 15.38 to 7.88%, respectively. The cavitation effect and acoustic streaming effect of ultrasonic can improve the undercooling of melt components, promote grain nucleation and prevent grain growth, at the same time, the composition segregation is inhibited and the number of carbides and γ/γ′ eutectic is reduced.

Similar content being viewed by others

References

Zhang J, Wang L, Wang D, Xie G, and Lou L H, Acta Metall Sin 55 (2019) 1077. https://doi.org/10.11900/0412.1961.2019.00122

Haghayeghi R, Heydari A, and Kapranos P, Mater Lett 153 (2015) 175.

Jian X, Xu H, Meek T T, and Han Q, Mater Lett 59 (2005) 190.

Patel B, Chaudhari G P, and Bhingole PP, Mater Lett 66 (2012) 335.

Nagasivamuni B, and Ravi K R, Trans Indian Inst Met 68 (2015) 1161.

Hong X L, Xiu F G, Sen F Z, Liang W, and Li P N, Int J Miner Metall Mater 27 (2020) 943.

Li Q Q, Zhang Y, Chen J, Guo B G, and Liu Y, J Mater Sci Technol 70 (2021) 185.

Zhu L D, Yang Z C, Xin B, Wang S H, and Xue P S, J Mater Sci Technol 410 (2021) 126964. org/https://doi.org/10.1016/j.surfcoat.2021.126964.

Neeraj S and Chaudhari G P, Mater Sci Technol 35 (2019) 1239.

Li Q, Xie J, Yu J J, Shu D L, and Zhou Y Z, J Alloy Compd, 854 (2021) 156027.

Li X X, Jia C L, Jiang Z H, Zhang Y, and Lv S M, JOM J Miner Met Mater Soc 72 (2020) 4139.

Gong L, Chen B, Du Z H, Zhang M S, and Liu K, J Mater Sci Technol 34 (2018) 541.

Moreira M F, Fantin L B, and Azevedo C R F, Int J Met, 15 (2021) 676. https://doi.org/10.1007/s40962-020-00496-1

Du B N, Hu Z Y, Sheng L Y, Cui C Y, and Sun X F, J Mater Sci Technol, 34 (2018) 1805.

Kang M D, Wang J, Gao H Y, Han Y F, and He S X, Materials 10 (2017) 250.

Kwak S Y, Cheng J, and Choi J K, China Foundry 8 (2011) 112.

Cheng H, Kang L, Pang J C, Xue, B C, and Chang B H, Opt Laser Technol 139 (2021) 106962.

Liang G, Shi C, Zhou Y J, and Mao D H, Metals 6 (2016) 260. https://doi.org/10.3390/met6110260

Martorano M A, Beckermann C, and Gandin C A, Metall Mater Trans A Phys Metall Mater Sci 35A (2004) 1915. https://doi.org/10.1007/s11661-004-0101-0

Martorano M A and Biscuola V B, Acta Mater 57 (2009) 607.

Leighton T G, Ultrason Sonochem 2 (1995) S123.

Sri Harini R, Raj B, and Ravi K R, Trans Indian Inst Met 68 (2015) 1059.

Raghu R, Jayakrishnan N, Kumar S T, and Subramanian R, Trans Indian Inst Met 72 (2019) 1013.

Rajagopal S, J Appl Metalwork 1 (1981) 3.

Hilpert K, Kobertz D, and Venugopal V, Sect A-J Phys Sci 42 (1987) 1327. https://doi.org/10.1515/zna-1987-1117

Kim D K, Kim D H, Choo D K, and Moon H K, Met Mater Int 2 (1996) 211.

Zhang W G and Liu L, Rare Metals 31 (2012) 541.

Dai W L, Mater Lett 57 (2003) 2447

Li X T, Li T J, Li X M, and Jin J Z, Ultrason Sonochem 13 (2006) 121.

Acknowledgements

Supported by the fund of State Key Laboratory of Long-life High Temperature Materials (DTCC28EE200795) and Technology Project of Nanchong and Southwest Petroleum University (SWPU) Cooperation (No. SXQHJH032).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, H., Wen, P., Gong, X. et al. Effect of Ultrasonic Treatment on Solidification Microstructure of a New Nickel-Based Superalloy 4716MA0. Trans Indian Inst Met 75, 2107–2115 (2022). https://doi.org/10.1007/s12666-022-02588-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02588-4