Abstract

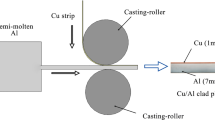

Corrugated cold roll bonding (CCRB) produces metal composite plate with improved mechanical properties compared with conventional methods, but the interfacial mechanism is not fully understood. Here, Cu/Al composite plate with good plate shape was produced by CCRB, and the bonding mechanism and strength along the corrugated interface were studied by experiments and finite element simulations. The results showed that the average bonding strength of Cu/Al composite plate produced by CCRB was nearly twice that of conventional composite plate at an average reduction of 40% during rolling. Strong friction shear stresses occurred at the interface of the corrugated composite plate, which promoted the plastic deformation of the metals and accelerated the rupture of the brittle interfacial layer. Electron backscattered diffraction analysis showed that higher degrees of grain elongation and refinement occurred in the matrices at the front waist and trough due to the stronger normal and shear stresses. Energy-dispersive spectroscopy line scans showed that the thickest atomic diffusion layer occurred at the front waist. The present combination of experimental and computational analyses provides insights into the underlying mechanism of mechanically improved metal composites prepared by CCRB.

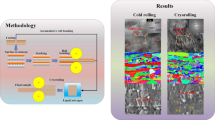

Graphic Abstract

Similar content being viewed by others

References

Li XB, Yang Y, Xu YS, Zu GY. Deformation behavior and crack propagation on interface of Al/Cu laminated composites in uniaxial tensile test. Rare Met. 2020;39(3):296.

Li Z, Zhao J, Jia F, Zhang Q, Liang X, Jiao S, Jiang Z. Numerical and experimental investigation on the forming behaviour of stainless/carbon steel bimetal composite. Int J Adv Manuf Technol. 2019;101:1075.

Li Z, Zhao J, Jia F, Zhang Q, Liang X, Jiao S, Jiang Z. Analysis of bending characteristics of bimetal steel composite. Int J Mech Sci. 2018;148:272.

Yang YX, Wu YH, Zhang Q, Cao GS, Zhao XB. Enhanced thermoelectric performance of Bi2Se3/TiO2 composite. Rare Met. 2020;39(8):887.

Cheng XL, Bai BZ, Gao YM, Feng C. Microstructural characterization of the Al/Cu/steel diffusion bonded joint. Rare Met. 2009;28(5):478.

Zhang L, Meng L, Zhou SP, Yang FT. Behaviors of the interface and matrix for the Ag/Cu bimetallic laminates prepared by roll bonding and diffusion annealing. Mater Sci Eng A. 2004;371(1–2):65.

Mohebbi MS, Akbarzadeh A. Fabrication of Cu/Al composite tubes by spin-bonding process: experiments and modeling. Int J Adv Manuf Technol. 2011;54(9–12):1043.

Abbasi M, Toroghinejad MR. Effects of processing parameters on the bond strength of Cu/Cu roll-bonded strips. J Mater Process Technol. 2010;210(3):560.

Nie H, Liang W, Yang F, Zheng L, Li X, Fan H. Texture evolution of single-pass hot-rolled 5052/AZ31/5052 clad sheets. JOM. 2016;68(8):2274.

Gao C, Li L, Chen X, Zhou D, Tang C. The effect of surface preparation on the bond strength of Al-St strips in CRB process. Mater Des. 2016;107:205.

Xu RC, Tang D, Ren XP, Wang XH, Wen YH. Improvement of the matrix and the interface quality of a Cu/Al composite by the MARB process. Rare Met. 2007;26(3):230.

Durgutlu A, Gülenç B, Findik F. Examination of Cu/stainless steel joints formed by explosive welding. Mater Des. 2005;26(6):497.

Chen TP, Lin WB. Optimal FSW process parameters for interface and welded zone toughness of dissimilar aluminium–steel joint. Sci Technol Weld Join. 2013;15(4):279.

Shi W, Yuan L, Xu F, Zheng Z, Shan D. Refining whisker size of 2024Al/Al18B4O33w composite through extrusion and its effects on the material’s micro-structures and mechanical properties. Mater Charact. 2018;138:98.

Saito Y, Utsunomiya H, Tsuji N, Sakai T. Novel ultra-high straining no process for bulk materials-development of the accumulative roll-bonding (ARB) process. Acta Mater. 1999;47(2):579.

Li X, Zu G, Wang P. Interface strengthening of laminated composite produced by asymmetrical roll bonding. Mater Sci Eng A. 2013;562:96.

Lu J-S, Harrer O-K, Schwenzfeier W, Fischer FD. Analysis of the bending of the rolling material in asymmetrical sheet rolling. Int J Mech Sci. 2000;42(1):49.

Wang C, Jiang Y, Xie J, Zhou D, Zhang X. Interface formation and bonding mechanism of embedded Al-steel composite sheet during cold roll bonding. Mater Sci Eng A. 2017;708:50.

Xiao H, Qi Z, Yu C, Xu C. Preparation and properties for Ti/Al clad plates generated by differential temperature rolling. J Mater Process Technol. 2017;249:285.

Zhang XP, Yang TH, Castagne S, Wang JT. Microstructure; bonding strength and thickness ratio of Al/Mg/Al alloy laminated composites prepared by hot rolling. Mater Sci Eng A. 2011;528(4–5):1954.

Liu HS, Zhang B, Zhang GP. Microstructures and mechanical properties of Al/Mg alloy multilayered composites produced by accumulative roll bonding. J Mater Sci Technol. 2011;27(1):15.

Wang T, Li S, Ren Z, Han J, Huang Q. A novel approach for preparing Cu/Al laminated composite based on corrugated roll. Mater Lett. 2019;234:79.

Huang QX, Zhang J, Zhu L, Jiang L, Gao XY. Velocity field analysis of bonding interface on cold-rolled Cu/Al composite plate. Rare Met Mater Eng. 2017;46(7):1749.

Bay N, Clemensen C, Juelstorp O, Wanheim T. Bond strength in cold roll bonding. Cirp Ann Manuf Technol. 1985;34(1):221.

Wu B, Li L, Xia C, Guo X, Zhou D. Effect of surface nitridingtreatment in a steel plate on the interfacial bonding strength of the Al/steel clad sheets by the cold roll bonding process. Mater Sci Eng A. 2017;682:270.

Mehr VY, Toroghinejad MR, Rezaeian A. The effects of oxide film and annealing treatment on the bond strength of Al–Cu strips in cold roll bonding process. Mater Des. 2014;53:174.

Eizadjou M, Manesh HD, Janghorban K. Investigation of roll bonding between Al alloy strips. Mater Des. 2008;29(4):909.

Zhang W, Bay N, Wanheim T. Influence of hydrostatic pressure in cold-pressure welding. Cirp Ann Manuf Technol. 1992;41(1):293.

Li L, Nagai K, Yin F. Progress in cold roll bonding of metals. Sci Technol Adv Mater. 2008;9(2):023001.

Lee KS, Yoon DH, Kim HK, Kwon YN, Lee YS. Effect of annealing on the interface microstructure and mechanical properties of a STS–Al–Mg 3-ply clad sheet. Mater Sci Eng A. 2012;556:319.

Le HR, Sutcliffe MP, Wang PZ, Burstein GT. Surface oxide fracture in cold aluminium rolling. Acta Mater. 2004;52(4):911.

Lukaschkin ND, Erlikh AI, Borissow AP. The system analysis of metal forming technique in welding processes. J Mater Process Technol. 1997;66(1–3):264.

Lapovok R, Ng HP, Tomus D, Estrin Y. Bimetallic copper–aluminium tube by severe plastic deformation. Scripta Mater. 2012;66(12):1081.

Govindaraj NV, Lauvdal S, Holmedal B. Tensile bond strength of cold roll bonded aluminium sheets. J Mater Process Technol. 2013;213(6):955.

Kim I-K, Hong SI. Mechanochemical joining in cold roll-cladding of tri-layered Cu/Al/Cu composite and the interface cracking behavior. Mater Des. 2014;57:625.

Li XB, Zu GY, Wang P. Asymmetry in interface and bending property of Al/Cu/Al bimetallic laminates. Rare Met. 2014;33(5):556.

Valiev RZ, Estrin Y, Horita Z, Langdon TG, Zehetbauer MJ, Zhu YT. Producing bulk ultrafine-grained materials by severe plastic deformation. JOM. 2006;58(4):33.

Hill A, Wallach ER. Modelling solid-state diffusion bonding. Acta Metall. 1989;37(9):2425.

Naya S, Cao R, Ullibarri IL, Artiaga R, Barbadillo F, García A. Logistic mixture model versus Arrhenius for kinetic study of material degradation by dynamic thermogravimetric analysis. J Chemom. 2006;20(3–4):158.

Sato K, Yoshiie T, Satoh Y, Xu Q, Kiritani M. Simulation of vacancy migration energy in Cu under high strain. Mater Sci Eng A. 2003;350(1–2):220.

Acknowledgements

This study was financially supported by the Major Program of National Natural Science Foundation of China (No. U1710254), Shanxi Province Science and Technology Major Projects (No. 20181101008), the Scientific and Technological Progress of Shanxi Province Colleges and Universities (No. 2017132), and the National Natural Science Foundation of China (Nos. 51974196, 51975398, and 51905372).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, T., Gao, XY., Zhang, ZX. et al. Interfacial bonding mechanism of Cu/Al composite plate produced by corrugated cold roll bonding. Rare Met. 40, 1284–1293 (2021). https://doi.org/10.1007/s12598-020-01660-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01660-6