Abstract

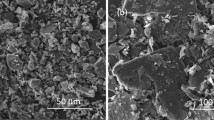

The composites consisting of similar or dissimilar metallic layers with different physical properties are vastly applicable. Among various methods for producing these composites, cold roll bonding (CRB) is considered to be more efficient and more cost-effective than other bonding processes. Nowadays, Al-Cu layer composite bonds are favorable in different industries due to their low price, well conductibility, high corrosion resistance, high deformation, and good electrical conduction. This review paper deals with the investigations of the Al-Cu cold rolling process, of the bonding mechanism of metallic layers during CRB, and of the effect of the roll bond strength parameters such as initial thickness, for one. Roll bonding has three levels: (1) physical touch; (2) activating surfaces in touch; (3) interaction between bonding metals. CRB is supposed to be an in-plane strain, and the normal stress distributed on the top and bottom rollers is homogeneous. Annealing before and after rolling, the direction and speed of rolling, the amount of thickness reduction, and the lubrication conditions on the Al–Cu bond through the roll bonding process were studied. The effect of different annealing conditions on the produced intermetallic compounds at the Al–Cu rolling bond interface and the growth of the intermetallic phases and their impact on the CRB parameters was examined. The thickness of intermetallic compounds, thickness reduction under the rolling process, the rolling speed, the annealing temperature, and time affected the bond strength. The effect of the rolling speed on the bond strength depends on the touching time between the sheets during rolling, which means that the touching time between two surfaces of Al and Cu sheets reduces at higher rolling speeds. As a result, the chance for proper bonding is lost, and, therefore, the bond strength is decreased.

Similar content being viewed by others

REFERENCES

Uscinowicz, R., The effect of rolling direction on the creep process of Al–Cu bimetallic sheet, Mater. Des., 2013, vol. 49, p. 693. https://doi.org/10.1016/j.matdes.2013.02.012

Shiran, M.R.K.G., Bakhtiari, H., Mousavi, S.A.A., Khalaj, G., et al., Effect of stand-off distance on the mechanical and metallurgical properties of explosively bonded 321 austenitic stainless steel-1230 aluminum alloy tubes, Mater. Res., 2017, vol. 20, p. 291. https://doi.org/10.1590/1980-5373-mr-2016-0516

Sheng, L.Y., Yang, F., Xi, T.F., Lai, C., et al., Influence of heat treatment on the interface of Cu/Al bimetal composite fabricated by cold rolling, Composites, Part B, 2011, vol. 42, p. 1468–1473. https://doi.org/10.1016/j.compositesb.2011.04.045

Jamaati, R. and Toroghinejad, M.R., Cold roll bonding bond strengths: Review, Mater. Sci. Technol., 2011, vol. 27, p. 1101. https://doi.org/10.1179/026708310X12815992418256

Roostaei, M. and Darabi, R., Investigation on formability of three-layer joined Al/Cu/Al sheets annealed at different temperature, Mater. Sci. Technol., 2020, vol. 36, no. 13, p. 1476. https://doi.org/10.1080/02670836.2020.1792637

Bagheri, A., Toroghinejad, M.R., and Taherizadeh, A., Investigation of formability of three-layered brass-IF steel-brass composite, J. Weld. Sci. Technol., Iran, 2018, vol. 3, p. 68.

Danesh Manesh, H. and Shahabi, H.Sh., Effective parameters on bonding strength of roll bonded Al/St/Al multilayer strips, J. Alloys Compd., 2009, vol. 476, nos. 1–2, p. 292. https://doi.org/10.1016/j.jallcom.2008.08.081

Jamaati, R. and Toroghinejad, M.R., Investigation of the parameters of the cold roll bonding (CRB) process, Mater. Sci. Eng., A, 2010, vol. 527, p. 2320. https://doi.org/10.1016/j.msea.2009.11.069

Acoff, V.L., Wilkerson, S., and Arenas, M., The effect of rolling direction on the weld structure and hardness of gamma-TiAl sheet material, Mater. Sci. Eng., A, 2002, vol. 329, p. 763. https://doi.org/10.1016/S0921-5093(01)01657-4

Tsuji, N., To, Y.I., Saito, Y., and Minamino, Y., Strength and ductility of ultrafine-grained aluminum and iron produced by ARB and annealing, Scr. Mater., 2002, vol. 47, p. 893. https://doi.org/10.1016/S1359-6462(02)00282-8

Tsuji, N., Saito, Y., Utsunomiya, H., and Tanigawa, S., Ultra-fine grained bulk steel produced by accumulative roll-bonding (arb) process, Scr. Mater., 1999, vol. 40, no. 7, p. 795. https://doi.org/10.1016/S1359-6462(99)00015-9

Hwang, Y.-M. and Tzou, G.-Y., An analytical approach to asymmetrical hot-sheet rolling considering the effects of the shear stress and internal moment at the roll gap, J. Mater. Process. Technol., 1995, vol. 52, p. 399. https://doi.org/10.1016/0924-0136(94)01731-F

Pan, S.C., Huang, M.N., Tzou, G.Y., and Syu, S.W., Analysis of asymmetrical cold and hot bond rolling of the unbounded clad sheet under constant shear friction, J. Mater. Process. Technol., 2006, vol. 177, p. 114. https://doi.org/10.1016/j.jmatprotec.2006.04.071

McQueen, H.J., Pressure welding, solid state: role of hot deformation, Can. Metall. Q., 2012, vol. 51, p. 239. https://doi.org/10.1179/1879139512y.0000000011

Woznika, H., The results of the so far performed investigations of Al–Cu butt cold pressure welding by the method of upsetting, Arch. Civil. Mech. Eng., 2009, vol. 9, p. 135. https://doi.org/10.1016/s1644-9665(12)60046-6

Sim, K.S. and Lee, Y.S., A bonding map for cu and al plates by pressure welding at cold and warm temperatures, Mater. Sci. Forum, 2005, vol. 475, p. 2667. https://doi.org/10.4028/www.scientific.net/MSF.475-479.2667

Abbasi, M., Salehi, M.T., and Karimi Taheri, A., An investigation on cold roll welding of copper to aluminum using electrical resistivity, Z. Metallknd., 2001, vol. 92, no. 5, p. 423.

Khanzadeh, M.R., Khalaj, G.R., Pouraliakbar, H., Jandaghi, M.R., et al., Multilayer Cu/Al/Cu explosive welded joints: characterizing heat treatment effect on the interface microstructure and mechanical properties, J. Manuf. Process., 2018, vol. 35, p. 657. https://doi.org/10.1016/j.jmapro.2018.09.014

Li, Y.T. and Yu, D.M., Interfacial energy and match of cold pressure welded Ag/Ni and Al/Cu, Trans. Nonferrous Met. Soc. China, 2002, vol. 12, no. 5, p. 814.

Vamsi Krishn, B., Venugopal, P., and Prasad Rao, K., Optimization of process parameters in cold solid state joining of sintered steel and copper P/M preforms, Trans. Indian Inst. Met., 2003, vol. 56, no. 4, p. 363.

Sahin, M. and Erol Akata, H., Joining with friction welding of plastically deformed steel, J. Mater. Process. Technol., 2003, vol. 142, p. 239. https://doi.org/10.1016/S0924-0136(03)00589-2

Sahin, M. and Ozel, K., Mechanical and metallurgical properties of aluminum and copper sheets joined bycold pressure welding, J. Mech. Eng., 2008, vol. 54, no. 11, p. 796.

Korzhyk, V., Khaskin, V., Voitenko, O., Sydorets, V., et al., Welding technology in additive manufacturing processes of 3D objects, Mater. Sci. Forum, 2017, vol. 906, p. 121. https://doi.org/10.4028

Iordachescu, M., Iordachescu, D., Scutelnicu, E., and Ocaña, J.L., FEM model of butt cold welding, Sci. Technol. Weld. Joining, 2007, vol. 12, no. 5, p. 402. https://doi.org/10.1179/174329313X13789830157140

Wei, Y., Li, H., Sun, F., and Zou, J., The interfacial characterization and performance ofcu/al-conductive heads processed by explosion welding, cold pressure welding, and solid-liquid casting, Metals, 2019, vol. 9, p. 237. https://doi.org/10.3390/met9020237

Xia, Q., Wang, J., Yao, K., Hou, D., et al., Interface bonding properties of multi-layered metal composites using material composition method, Tribol. Int., 2019, vol. 131, p. 251. https://doi.org/10.1016/j.triboint.2018.10.024

Okumura, Y., Saji, S., and Anada, H., Titanium-flake reinforced aluminum-matrix composite prepared from multilayer foils by cold pressure welding, Adv. Eng. Mater., 2000, vol. 2, no. 12, p. 818. https://doi.org/10.1002/352760622X.ch52

Kim, C. and Forrest, S., Fabrication of organic light-emitting devices by low-pressure cold welding, Adv. Mater., 2003, vol. 15, no. 6, p. 541. https://doi.org/10.1002/adma.200390127

Kim, C., Burrows, P.E., and Forrest, S.R., Micropatterning of organic electronic devices by cold-welding, Science, 2000, vol. 288, p. 831. https://doi.org/10.1126/science.288.5467.831

Danesh Manesh, H., Assessment of surface bonding strength in Al clad steel strip using electrical resistivity and peeling tests, Mater. Sci. Technol., 2006, vol. 22, no. 6, p. 634. https://doi.org/10.1179/174328406X83914

Lee, K.S., Lee, S.E., and Kwon, Y.N., Interface characterization of Al/Cu 2-ply composites under various loading conditions, Trans. Nonferrous Met. Soc. China, 2014, vol. 24, p. 36. https://doi.org/10.1016/S1003-6326(14)63285-4

Kim, I.K. and Hong, S.I., Effect of heat treatment on the bending behavior of tri-layered Cu/Al/Cu composite plates, Mater. Des., 2013, vol. 47, p. 590. https://doi.org/10.1016/j.matdes.2012.12.070

Li, X., Zu, G., and Wang, P., Effect of strain rate on the tensile performance of Al/Cu/Al laminated composites produced by asymmetrical roll bonding, Mater. Sci. Eng., A, 2013, vol. 575, p. 61. https://doi.org/10.1016/j.msea.2013.03.056

Chen, C.Y., Chen, H.L., and Hwang, W.S., Influence of interfacial structure development on the fracture mechanism and bond strength of aluminum/copper bimetal plate, Mater. Trans., 2006, vol. 47, no. 4, p. 1232. https://doi.org/10.2320/matertrans.47.1232

Kim, I.K. and Hong, S.I., Mechanochemical joining in cold roll-cladding of tri-layered Cu/Al/Cu composite and the interface cracking behavior, Mater. Des., 2014, vol. 57, p. 625. https://doi.org/10.1016/j.matdes.2014.01.054

Peng, X.K., Wuhrer, R., Heness, G., and Yeung, W.Y., Rolling strain effect on the interlaminar properties of roll bonded copper/aluminum metal laminates, J. Mater. Sci., 2000, vol. 35, p. 4357. https://doi.org/10.1023/A:1004852806390

Li, X., Zu, G., Ding, M., Mu, Y., et al., Interfacial microstructure and mechanical properties of Cu/Al clad sheet fabricated by asymmetrical roll bonding and annealing, Mater. Sci. Eng., A, 2011, vol. 529, p. 485. https://doi.org/10.1016/j.msea.2011.09.087

Yousefi Mehr, V., Toroghinejad, M.R., and Rezaeian, A., The effects of the oxide film and annealing treatment on the bond strength of Al–Cu strips in cold roll bonding process, Mater. Des., 2014, vol. 53, p. 174. https://doi.org/10.1016/j.matdes.2013.06.028

Guo, Y., Liu, G., Jin, H., Shi, Z., et al., Intermetallic phase formation in diffusion-bonded Cu/Al laminates, J. Mater. Sci., 2011, vol. 46, no. 8, p. 2467. https://doi.org/10.1007/s10853-010-5093-0

Pfeifer, S., Großmann, S., Freudenberger, R., Willing, H., et al., Characterization of intermetallic compounds in Al–Cu-bimetallic interfaces, Proc. 2012 IEEE 58th Holm Conf. on Electrical Contacts (Holm), Red Hook, NY: Curran Assoc., 2012, pp. 1–6. https://doi.org/10.1109/HOLM.2012.6336554

Kouters, M.H.M., Gubbels, G.H.M., and Dos Santos Ferreira, O., Characterization of intermetallic compounds in Cu–Al ball bonds: Mechanical properties, interface delamination and thermal conductivity, Microelectron. Reliab., 2013, vol. 53, p. 1068. https://doi.org/10.1016/j.microrel.2013.02.020

Cheng, H., Lu, Y.J., and Chen, M., Interdiffusion in liquid Al–Cu and Ni–Cu alloys, J. Chem. Phys., 2009, vol. 131, p. 44. https://doi.org/10.1063/1.3184614

Hannech, E.B., Lamoudi, N., Benslim, N., and Makhloufi, B., Intermetallic formation in the aluminum/copper system, Surf. Rev. Lett., 2003, vol. 10, no. 4, p. 677. https://doi.org/10.1142/S0218625X03005396

Abbasi, M., Karimi Taheri, A., and Salehi, M.T., Growth rate of intermetallic compounds in Al/Cu bimetal produced by cold roll welding process, J. Alloy Compd., 2001, vol. 319, nos. 1–2, p. 233. https://doi.org/10.1016/S0925-8388(01)00872-6

Lee, W.B., Bang, K.S., and Jung, S.B., Effects of the intermetallic compound on the electrical and mechanical properties of friction welded Cu/Al bimetallic joints during annealing, J. Alloy Compd., 2005, vol. 390, p. 212. https://doi.org/10.1016/j.jallcom.2004.07.057

Zhang, B., Wang, T., Cong, Y., Zhao, M., et al., Properties of Cu–Al intermetallic compounds in copper wire bonding, Proc. 2010 11th Int. Conf. on Electronic Packaging Technology and High Density Packaging, Red Hook, NY: Curran Assoc., 2010, pp. 213–216. https://doi.org/10.1109/ICEPT.2010.5582439

Heydari, Vini, M., Daneshmand, S., and Forooghi, M., Roll bonding properties of Al/Cu imetallic laminates fabricated by the roll bonding technique, Technologies, 2017, vol. 5, p. 1. https://doi.org/10.3390/technologies5020032

Li, L., Nagai, K., and Yin, F., Progress in cold roll bonding of metals, Sci. Technol. Adv. Mater., 2008, vol. 9, art. ID 023001. https://doi.org/10.1088/1468-6996/9/2/023001

Jamaati, R. and Toroghinejad, M.R., Effect of friction, annealing conditions and hardness on the bond strength of Al/Al strips produced by cold roll bonding process, Mater. Des., 2010, vol. 31, no. 9, p. 4508. https://doi.org/10.1016/j.matdes.2010.04.022

Ghalehbandi, S.M., Malaki, M., and Gupta, M., Accumulative roll bonding—a review, Appl. Sci., 2019, vol. 9, p. 3627. https://doi.org/10.3390/app9173627

Movahedi, M., Kokabi, A.H., and Madaah Hosseini, H.R., An investigation on the soldering of Al 3003/Zn sheets, Mater. Charact., 2009, vol. 60, p. 441. https://doi.org/10.1016/j.matchar.2008.11.010

Alizadeh, M. and Paydar, M.H., Study on the effect of the presence of TiH2 particles on the roll bonding behavior of aluminum alloy strips, Mater. Des., 2009, vol. 30, p. 82. https://doi.org/10.1016/j.matdes.2008.04.058

Jamaati, R. and Toroghinejad, M.R., Microstructure and mechanical properties of Al/Al2O3MMC produced by anodizing and cold roll bonding, Mater. Sci. Technol., 2011, vol. 27, no. 11, p. 1648. https://doi.org/10.1179/1743284710Y.0000000011

Luo, J.G. and Acoff, V.L., Using cold roll bonding and annealing to process Ti/Al multi-layered composites from elemental foils, Mater. Sci. Eng., A, 2004, vol. 379, p. 164. https://doi.org/10.1016/j.msea.2004.01.021

Madaah Hosseini, H.R. and Kokabi, A.H., Cold roll bonding of 5754-aluminum strips, Mater. Sci. Eng., A, 2002, vol. 335, p. 186. https://doi.org/10.1016/S0921-5093(01)01925-6

Danesh Manesh, H. and Karimi Taheri, A., An investigation of deformation behavior and bonding strength of bimetal strip during rolling, Mech. Mater., 2005, vol. 37, p. 531. https://doi.org/10.1016/j.mechmat.2004.04.004

ACKNOWLEDGMENTS

The authors would like to thank the staff of Rahyaft Advanced Sciences and Technologies, (http://www.a-sciences.com/en/), especially K. Asgari, for their technical support.

Funding

The present research was financially supported by the Rahyaft Advanced Sciences and Technologies, (http://www.a-sciences.com/en/).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

About this article

Cite this article

Shajari, Y., Akbari, A., Seyedraoufi, Z.S. et al. Formation of Intermetallic Compounds in Al–Cu Interface via Cold Roll Bonding: Review. Surf. Engin. Appl.Electrochem. 58, 41–50 (2022). https://doi.org/10.3103/S1068375522010112

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068375522010112