Abstract

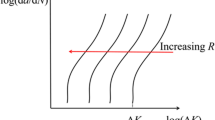

Interpretable machine learning (ML) has become a popular tool in the field of science and engineering. This research proposed a domain knowledge combined with ML method to increase interpretability while ensuring the accuracy of ML models and verifies the generality of the ML approach in fatigue crack growth (FCG) modelling. LZ50 steel single edge notch tension (SENT) specimens were tested for short crack (SC) growth rate and microstructure characterization under various R-controls. Based on the test results, the SC growth process was divided into 3 stages: microstructural short crack (0–145 μm), physical short crack (145–1000 μm), and long crack (1000 μm–fracture). Following the analysis of 8 semi-empirical FSCG rate equations with different driving forces, 6 impact variables that may affect the FCG rate characteristics were identified. Random forest and Pearson correlation analysis were used to investigate the influence of each feature on the FCG rate and the relationships among the features. The main influential features for the short crack symbolic regression (SCSR) model were found to be |ΔK–ΔKat|, Δγxy, |a–at|, and eα(1−R). After considering these 4 input features, the predicted FSCG rate equation generated by the SR model has a concise mathematical structure. Finally, an elastic net multiple linear regression method was proposed to determine the parameters of the predicted equation, while retaining the physical characteristics of each parameter. The SCSR model for SC demonstrated good prediction performance on various metallic materials.

Graphical Abstract

Similar content being viewed by others

Data and Code Availability

Data will be made available on reasonable request.

References

G. Huang, Z.H. Li, L.M. Sun, X.W. Li, K. Wen, L.Z. Yan, B.Q. Xiong, Y.A. Zhang, Rare Met. 40, 2523–2529 (2021)

V. Monfared, S. Ramakrishna, N. Nasajpour-Esfahani, D. Toghraie, M. Hekmatifar, S. Rahmati, Met. Mater. Int. 29, 3442–3470 (2023)

S. Blasón, J.A.F.O. Correia, N. Apetre, A. Arcari, A.M.P. De Jesus, P. Moreira, A. Fernández-Canteli, Procedia Struct. 1, 110–117 (2016)

J.E. Kim, Y.J. Kim, J.H. Bae, B.S. You, S.H. Park, Met. Mater. Int. 29, 3511–3520 (2023)

K. Wang, F. Wang, W. Cui, T. Hayat, B. Ahmad, Fatigue Fract. Eng. Mater. Struct. 37, 1075–1086 (2014)

K.J. Miller, A.S.T.M. Spec, Tech. Publ. 1296, 267–286 (1997)

D.L. McDowell, K. Gall, M.F. Horstemeyer, J. Fan, Eng. Fract. Mech. 70, 49–80 (2003)

G.M. Castelluccio, D.L. McDowell, Mater. Sci. Eng. A 598, 34–55 (2014)

D. Tatlor, J.F. Knott, Fatigue Fract. Eng. Mater. Struct. 4, 147–155 (1981)

W. Zhang, L. Chai, L. Ren, L. Cai, Eng. Fract. Mech. 271, 108650 (2022)

M.H. Hashmi, S.S.R. Koloor, M.F. Abdul-Hamid, M.N. Tamin, Eng. Fract. Mech. 270, 108589 (2022)

E. Natkowski, P. Sonnweber-Ribic, S. Münstermann, Int. J. Fatigue 156, 106621 (2022)

M.L. Su, C. Feng, C.T. Peng, L.Y. Xu, Y.D. Han, L. Zhao, Int. J. Fatigue 166, 107258 (2023)

M.L. Su, L.Y. Xu, C.T. Peng, Y.D. Han, L. Zhao, Int. J. Fatigue 156, 106689 (2022)

Z. Liao, B. Yang, Y. Qin, S. Xiao, G. Yang, T. Zhu, N. Gao, Int. J. Fatigue 132, 105366 (2020)

Y.X. Zhao, B. Yang, W.H. Zhang, Key Eng. Mater. 324–325, 571–578 (2006)

G.M. Castelluccio, D.L. McDowell, Int. J. Fract. 176, 49–64 (2012)

B.O. Kong, M.S. Kim, B.H. Kim, J.H. Lee, Met. Mater. Int. 29, 1334–1345 (2023)

J.F. Durodola, Prog. Mater. Sci. 123, 100797 (2022)

M.B. Gorji, A. de Pannemaecker, S. Spevack, Int. J. Mech. Sci. 215, 106949 (2022)

X. Peng, S.C. Wu, W.J. Qian, J.G. Bao, Y.N. Hu, Z.X. Zhan, G.P. Guo, P.J. Withers, Int. J. Mech. Sci. 221, 107185 (2022)

H. Liu, X. Yang, S. Li, D. Shi, H. Qi, Int. J. Mech. Sci. 178, 105625 (2020)

D.H. Le Nguyen, Q.B. Tao, V.H. Nguyen, M. Abdel-Wahab, H. Nguyen-Xuan, Eng. Fract. Mech. 235, 107085 (2020)

X. Ma, X. He, Z.C. Tu, Eng. Fract. Mech. 241, 107402 (2021)

Z.H. Lian, M.J. Li, W.C. Lu, Int. J. Fatigue 157, 106716 (2022)

M. Jimenez-Martinez, M. Alfaro-Ponce, Int. J. Fatigue 124, 42–47 (2019)

L. Gan, H. Wu, Z. Zhong, Int. J. Fatigue 156, 106666 (2022)

J.A. Esterhuizen, B.R. Goldsmith, S. Linic, Nat. Catal. 5, 175–184 (2022)

Y.Q. Wang, N. Wagner, J.M. Rondinelli, Mrs Commun. 9, 793–805 (2019)

H. Shao, F. Villaescusa-Navarro, S. Genel, D.N. Spergel, D. Anglés-Alcázar, L. Hernquist, R. Davé, D. Narayanan, G. Contardo, M. Vogelsberger, Astrophys. J. 927, 85 (2022)

B.C. Weng, Z.L. Song, R.L. Zhu, Q.Y. Yan, Q.D. Sun, C.G. Grice, Y.F. Yan, W.J. Yin, Nat. Commun. 11, 3513 (2020)

J. Craven, V. Jejjala, A. Kar, J. High Energ. Phys. 2021, 40 (2021)

M.A. Ziatdinov, Y. Liu, A.N. Morozovska, E.A. Eliseev, X. Zhang, I. Takeuchi, S.V. Kalinin, Adv. Mater. 34, 2201345 (2022)

A. Singh, Z. Gu, X. Hou, Y. Liu, D.J. Hughes, Compos. Struct. 282, 115107 (2022)

B. Cao, S. Yang, A.K. Sun, Z.Q. Dong, T.Y. Zhang, J. Mater. Inf. 2, 4 (2022)

Z. Zojaji, M.M. Ebadzadeh, H. Nasiri, Appl. Soft Comput. 122, 108825 (2022)

L. Gan, H. Wu, Z. Zhong, Int. J. Fatigue 161, 106889 (2022)

S. Zhou, B. Yang, S. Xiao, G. Yang, T. Zhu, Chin. J. Mech. Eng. 36, 40 (2023)

F. Bachmann, R. Hielscher, H. Schaeben, Ultramicroscopy 111, 1720–1733 (2011)

E. Natkowski, A.R. Durmaz, P. Sonnweber-Ribic, S. Münstermann, Int. J. Fatigue 152, 106418 (2021)

K. Tokaji, T. Ogawa, O. Shuji, Fatigue Fract. Eng. Mater. Struct. 11, 331–342 (1988)

A. Rovinelli, Y. Guilhem, H. Proudhon, R.A. Lebensohn, W. Ludwig, M.D. Sangid, Model. Simul. Mater. Sci. Eng. 25, 45010 (2017)

W.D. Musinski, D.L. McDowell, Acta Mater. 112, 20–39 (2016)

P.D. Hobson, Fatigue Fract. Eng. Mater. Struct. 5, 323–327 (1982)

K.J. Miller, Mater. Sci. Technol. 9, 453–462 (1993)

M. Goto, K. Kamil, S.Z. Han, K. Euh, S.S. Kim, Y. Yokoho, Int. J. Fatigue 50, 63–71 (2013)

K.S. Chan, J. Lankford, Scripta Metal. 17, 529–532 (1983)

B. Yang, Y.X. Zhao, Int. J. Fatigue 35, 71–78 (2012)

C. Santus, D. Taylor, Int. J. Fatigue 31, 1356–1365 (2009)

M.F. Guan, H. Yu, Sci. China Technol. Sci. 56, 71–79 (2013)

J.C. Liang, Z. Wang, H.F. Xie, H.J. Shi, X.D. Li, Int. J. Fatigue 128, 105195 (2019)

W.A. Herman, R.W. Hertzberg, R. Jaccard, Fatigue Fract. Eng. Mater. Struct. 11, 303–320 (1988)

P. López-Crespo, R.L. Burguete, E.A. Patterson, A. Shterenlikht, P.J. Withers, J.R. Yates, Exp. Mech. 49, 551–559 (2009)

B. Yang, Z. Wei, Z. Liao, S. Zhou, S. Xiao, T. Zhu, G. Yang, M. Wang, Chin. J. Mech. Eng. 34 (2021).

S. Wang, B. Yang, J. Li, S. Zhou, S. Xiao, Eng. Fract. Mech. 289, 109430 (2023)

A. Antoniadis, S. Lambert-Lacroix, J. Poggi, Reliab. Eng. Syst. Saf. 206, 107312 (2021)

M. Kishino, K. Matsumoto, Y. Kobayashi, R. Taguchi, N. Akamatsu, A. Shishido, Int. J. Fatigue 166, 107230 (2023)

A.R. Durmaz, E. Natkowski, N. Arnaudov, P. Sonnweber-Ribic, S. Weihe, S. Münstermann, C. Eberl, P. Gumbsch, Int. J. Fatigue 160, 106824 (2022)

Y.F. Huang, X.B. Ye, B.R. Hu, L.J. Chen, Int. J. Fatigue 88, 217–226 (2016)

H. Zou, T. Hastie, J. Royal. Statistical. Soc. B 67, 301–320 (2005)

W. Zhan, N. Lu, C. Zhang, Eng. Fract. Mech. 119, 85–96 (2014)

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant No. 52375159), the Sichuan Science and Technology Program (Grant No. 2022YFH0075), the National Railway Administration of the P.R.C (KF2023-025), and the Independent Research Project of State Key Laboratory of Traction Power (Grant No. 2022TPL_T03). The first author would like to acknowledge the financial support of the China Scholarship Council (CSC).

Author information

Authors and Affiliations

Contributions

SZ: Investigation, Writing—original draft. BY: Supervision, review & editing. SX: Supervision. GY: Resources. Tao Zhu: Data curation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, S., Yang, B., Xiao, S. et al. Interpretable Machine Learning Method for Modelling Fatigue Short Crack Growth Behaviour. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01628-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-024-01628-6