Abstract

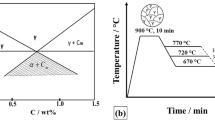

The purpose of this study was to describe the roles of microstructure types and grain boundary characteristics in fatigue crack propagation behavior in ferrite-pearlite steel and ferrite-bainite steel. The ferrite-bainite dual-phase steel was obtained by intermediate heat treatment conducted on ferrite-pearlite low carbon steel. This paper presents the results from investigation using constant stress-controlled fatigue tests with in-situ scanning electron microscopy (SEM), electron backscattering diffraction (EBSD) and fatigue fractography analysis. Microscopic images arrested by in-situ SEM showed that the second hard bainite phase distributed in the soft ferrite matrix had a significant effect on preventing the cracks opening compared with pearlite, and that the cracks in ferrite-bainite steel were “locked” in the second hard bainite phase while the crack propagation path in ferrite-pearlite steel was more tortuous. Moreover, the fatigue fracture surface analysis and the coincidence site lattice (CSL) obtained by EBSD indicated that low-Σ CSL grain boundaries in ferrite-bainite steel distributed more uniformly, which has a more significant effect on the resistance of crack propagation. It was revealed that ferrite-bainite dual-phase microstructures could inhibit the fatigue crack propagation more effectively than ferrite-pearlite microstructures.

Similar content being viewed by others

References

Li Y X, Lin Z Q, Jiang A Q, et al. Use of high strength steel sheet for lightweight and crashworthy car body. Mater Des, 2003, 24(3): 177–182

Nie W J, Wang X M, Wu S J, et al. Stress-strain behavior of multi-phase high performance structural steel. Sci China Tech Sci, 2012, 55(7): 1791–1796

Sun X J, Li Z D, Yong Q L, et al. Third generation high strength low alloy steels with improved toughness. Sci China Tech Sci, 2012, 55(7): 1797–1805

Shimizu T, Aoyagi N. TS780MPa grade hot rolled sheet steels with high fatigue strength. Kawasaki Steel Giho, 1999, 31(3): 185–189

Akay S K, Yazici M, Bayram A, et al. Fatigue life behaviour of the dual-phase low carbon steel sheets. J Mater Process Technol, 2009, 209(7): 3358–3365

Okayasu M, Sato K, Mizuno M, et al. Fatigue properties of ultra-fine grained dual phase ferrite/martensite low carbon steel. Int J Fatigue, 2008, 30(8): 1358–1365

Sankaran S, Subramanya S V, Padmanabhan K A, et al. High cycle fatigue behaviour of a multiphase microalloyed medium carbon steel: A comparison between ferrite-pearlite and tempered martensite microstructures. Mater Sci Eng A, 2003, 362(1–2): 249–256

Mutoh Y, Korda A A, Miyashita Y, et al. Stress shielding and fatigue crack growth resistance in ferritic-pearlitic steel. Mater Sci Eng A, 2007, 468–470(0): 114–119

Zhang W, Liu Y. Investigation of incremental fatigue crack growth mechanisms using in situ SEM testing. Int J Fatigue, 2012, 42: 14–23

Hu Z G, Zhu P, Meng J. Fatigue properties of transformation-induced plasticity and dual-phase steels for auto-body lightweight: Experiment, modeling and application. Mater Des, 2010, 31(6): 2884–2890

Sankaran S, Subramanya S V, Padmanabhan K A. Low cycle fatigue behavior of a multiphase microalloyed medium carbon steel: Comparison between ferrite/pearlite and quenched and tempered microstructures. Mater Sci Eng A, 2003, 345(1–2): 328–335

Chakraborti P C, Mitra M K. Microstructural response on the room temperature low cycle fatigue behaviour of two high strength duplex ferrite-martensite steels and a normalised ferrite-pearlite steel. Int J Fatigue, 2006, 28(3): 194–202

Sun S J, Pugh M. Properties of thermomechanically processed dual-phase steels containing fibrous martensite. Mater Sci Eng A, 2002, 335(1–2): 298–308

Hu Z Z, Ma M L, Liu Y Q, et al. The effect of austenite on low cycle fatigue in three-phase steel. Int J Fatigue, 1997, 19(8–9): 641–646

Oliver S, Jones T B, Fourlaris G. Dual phase versus TRIP strip steels: Microstructural changes as a consequence of quasi-static and dynamic tensile testing. Mater Charact, 2007, 58(4): 390–400

LePera F S. Improved etching technique for the determination of percent martensite in high-strength dual-phase steels. Metallography, 1979, 12(3): 263–268

Schijve J. Fatigue of Structures and Materials. New York: Springer, 2008

Kocańda S. Fatigue Failure of Metals. Alphen aan den Rijn: Sijthoff & Noordhoff International Publishers, 1978

Zhai T, Wilkinson A J, Martin J W. A crystallographic mechanism for fatigue crack propagation through grain boundaries. Acta Mater, 2000, 48(20): 4917–4927

Wolf D, Yip S. Materials interfaces: Atomic-level structure and properties. 1st ed. New York: Chapman & Hall, London, 1992

Guo N, Liu Q, Xin Y, et al. The application of back-scattered electron imaging for characterization of pearlitic steels. Sci China Tech Sci, 2011, 54(9): 2368–2372

Yu H. Influences of microstructure and texture on crack propagation path of X70 acicular ferrite pipeline steel. J Univ Sci Technol Beijing, Miner Metal Mater, 2008, 15(6): 683–687

Chen S, Yu H. Investigation on martensitic steel using a quenching-partitioning-tempering process via electron backscatter diffraction analysis. Sci China Tech Sci, 2012, 55: 646–651

Schaef W, Marx M. A numerical description of short fatigue cracks interacting with grain boundaries. Acta Mater, 2012, 60(5): 2425–2436

Kobayashi S, Hirata M, Tsurekawa S, et al. Grain boundary engineering for control of fatigue crack propagation in austenitic stainless steel. Procedia Eng, 2011, 10: 112–117

Palumbo G, Aust K T, Lehockey E M, et al. On a more restrictive geometric criterion for “special” csl grain boundaries. Scripta Mater, 1998, 38(11): 1685–1690

Cheung C, Erb U, Palumbo G. Application of grain boundary engineering concepts to alleviate intergranular cracking in Alloys 600 and 690. Mater Sci Eng A, 1994, 185(1–2): 39–43

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guan, M., Yu, H. In-situ investigation on the fatigue crack propagation behavior in ferrite-pearlite and dual-phase ferrite-bainite low carbon steels. Sci. China Technol. Sci. 56, 71–79 (2013). https://doi.org/10.1007/s11431-012-5047-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-012-5047-7