Abstract

The deformation mechanisms of a rolled high-purity α-titanium plate under monotonic loading along the rolling direction (RD), transverse direction (TD), and normal direction (ND) are investigated by the Elastic Visco-Plastic Self-Consistent (EVPSC) model, which incorporates a Twinning and De-Twinning (TDT) scheme to describe twinning behavior during straining. In the EVPSC-TDT model, plastic deformation is assumed to be accommodated by prismatic, basal and pyramidal \(\left\langle {{\text{c}} + {\text{a}}} \right\rangle\) slip modes as well as the \(\left\{ {10\bar{1}2} \right\}\) extension and \(\left\{ {11\bar{2}2} \right\}\) contraction twin modes. Numerical results based on the EVPSC-TDT model are in good agreement with the corresponding experimental data. The tension–compression asymmetry, anisotropic initial yielding and strain hardening behavior are interpreted in terms of the predicted relative activities of various deformation modes, twin volume fractions and texture evolutions. It is demonstrated that twinning plays an important role in tension–compression asymmetry and plastic anisotropy, which is closely related to the loading direction with respect to crystal orientations in the initial texture. In addition, it can be concluded that the TDT scheme permits better performance in describing twinning-associated deformation behavior for the rolled high-purity α-titanium plate than the Predominant Twin Reorientation (PTR) model even when detwinning is not involved.

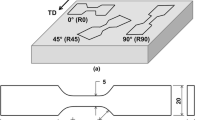

Graphical abstract

taken from Knezevic et al. [24]

Similar content being viewed by others

References

R. Thomas, Geothermics 32, 679 (2003)

F.H. Froes, H. Friedrich, J. Kiese, D. Bergoint, JOM 56, 40 (2004)

H. Conrad, Prog. Mater. Sci. 26, 123 (1981)

S. Nemat-Nasser, W.G. Guo, J.Y. Cheng, Acta Mater. 47, 3705 (1999)

L. Wang, R.I. Barabash, Y. Yang, T.R. Bieler, M.A. Crimp, P. Eisenlohr, W. Liu, G.E. Ice, Metall. Mater. Trans. A 42, 626 (2011)

J.L.W. Warwick, N.G. Jones, K.M. Rahman, D. Dye, Acta Mater. 60, 6720 (2012)

M. Battaini, E.V. Pereloma, C.H.J. Davies, Metall. Mater. Trans. A 38, 276 (2007)

M.E. Nixon, O. Cazacu, R.A. Lebensohn, Int. J. Plast. 26, 516 (2010)

E. Yu, I. Kim, D.H. Shin, J. Kim, Mater. Trans. 49, 38 (2008)

W. Tirry, S. Bouvier, N. Benmhenni, W. Hammami, A.M. Habraken, F. Coghe, D. Schryvers, L. Rabet, Mater. Charact. 72, 24 (2012)

A. Roth, M.A. Lebyodkin, T.A. Lebedkina, J.-S. Lecomte, T. Richeton, K.E.K. Amouzou, Mater. Sci. Eng. A 596, 236 (2014)

N. Yi, T. Hama, A. Kobuki, H. Fujimoto, H. Takuda, Mater. Sci. Eng. A 655, 70 (2016)

J. Won, C. Park, S. Hong, C. Lee, J. Alloys Compd. 651, 245 (2015)

A.A. Salem, S.R. Kalidindi, R.D. Doherty, Acta Mater. 51, 4225 (2003)

T. Hama, H. Nagao, A. Kobuki, H. Fujimoto, H. Takuda, Mater. Sci. Eng. A 620, 390 (2015)

M. Wroński, M. Arul Kumar, R.J. McCabe, K. Wierzbanowski, C.N. Tomé, Int. J. Plast. 148, 103129 (2022)

M.S. Lee, M.K. Ji, Y.T. Hyun, E.Y. Kim, T.S. Jun, Mater. Charact. 172, 110834 (2021)

B. Revil-Baudard, O. Cazacu, E. Massoni, Int. J. Solids Struct. 228, 111121 (2021)

Z.N. Lei, P.F. Gao, X.X. Wang, M. Zhan, H.W. Li, J. Mater. Sci. Technol. 86, 77 (2021)

T. Hama, A. Kobuki, H. Takuda, Int. J. Plast. 91, 77 (2017)

S. Sinha, A. Ghosh, N.P. Gurao, Philos. Mag. 96, 1485 (2016)

N.P. Gurao, R. Kapoor, S. Suwas, Acta Mater. 59, 3431 (2011)

K.E.K. Amouzou, T. Richeton, A. Roth, M.A. Lebyodkin, T.A. Lebedkina, Int. J. Plast. 80, 222 (2016)

M. Knezevic, R.A. Lebensohn, O. Cazacu, B. Revil-Baudard, G.P. Proust, S.C. Vogel, M.E. Nixon, Mater. Sci. Eng. A 564, 116 (2013)

M. Wronski, M.A. Kumar, L. Capolungo, R.J. Mccabe, K. Wierzbanowski, C.N. Tomé, Mater. Sci. Eng. A 724, 289 (2018)

D. Gloaguen, B. Girault, J. Fajoui, V. Klosek, M.J. Moya, Mater. Sci. Eng. A 662, 395 (2016)

X.P. Wu, S.R. Kalidindi, C. Necker, A.A. Salem, Acta Mater. 55, 423 (2007)

N. Benmhenni, S. Bouvier, R. Brenner, T. Chauveau, B. Bacroix, Int. J. Plast. 80, 222 (2013)

N. Benmhenni, S. Bouvier, R. Brenner, T. Chauveau, B. Bacroix, Mater. Sci. Eng. A 573, 222 (2013)

P. Van Houtte, Acta Metall. 26, 591 (1978)

P.A. Turner, C.N. Tomé, Acta Metall. Mater. 42, 4143 (1994)

A. Molinari, G.R. Canova, S. Ahzi, Acta Metall. 35, 2983 (1987)

R.A. Lebensohn, C.N. Tomé, Acta Metall. Mater. 41, 2611 (1993)

C.N. Tomé, R.A. Lebensohn, U.F. Kocks, Acta Metall. Mater. 39, 2667 (1991)

H. Wang, P.D. Wu, C.N. Tomé, Y. Huang, J. Mech. Phys. Solids 58, 594 (2010)

H. Wang, P.D. Wu, C.N. Tomé, J. Wang, Mater. Sci. Eng. A 55, 93 (2012)

H. Wang, P.D. Wu, J. Wang, C.N. Tomé, Int. J. Plast. 49, 36 (2013)

H. Qiao, S.R. Agnew, P.D. Wu, Int. J. Plast. 65, 61 (2015)

H. Wang, P.D. Wu, J. Wang, Metall. Mater. Trans. A 46, 3079 (2015)

X.Q. Guo, A. Chapuis, P.D. Wu, S.R. Agnew, Int. J. Solids Struct. 64–65, 42 (2015)

H. Wang, P.D. Wu, J. Wang, Comput. Mater. Sci. 96, 214 (2015)

C. Ma, A. Chapuis, X.Q. Guo, L.Y. Zhao, P.D. Wu, Q. Liu, X.B. Mao, Mater. Sci. Eng. A 682, 332 (2017)

H. Qiao, X.Q. Guo, A.L. Oppedal, H.E. Kariri, P.D. Wu, S.R. Agnew, Mater. Sci. Eng. A 687, 17 (2017)

F.H. Wang, H. Qiao, Y.Q. Wang, J. Dong, Y.Y. Jiang, P.D. Wu, Int. J. Plast. 147, 103109 (2021)

Q.C. He, X.D. Zhang, H. Qiao, H. Wang, P.D. Wu, Appl. Phys. A 127, 615 (2021)

C. Ma, X. Duan, X.Q. Guo, H. Qiao, L.Y. Zhang, P.D. Wu, Materials 14, 6069 (2021)

H. Qiao, Y.C. Xin, Z.L. Zong, P.D. Wu, Int. J. Solids Struct. 216, 211 (2021)

C. Ma, H.M. Wang, T. Hama, X.Q. Guo, X.B. Mao, J. Wang, P.D. Wu, Int. J. Plast. 121, 261 (2019)

S.R. Agnew, M.H. Yoo, C.N. Tomé, Acta Mater. 49, 4277 (2001)

M.A. Meyers, K.K. Chawla, Mechanical Behavior of Materials (Prentice Hall, Upper Saddle River, NJ, 1998)

N.W. Landry, M. Knezevic, Materials 8, 6326 (2015)

A.A. Salem, S.R. Kalidindi, S.L. Semiatin, Acta Mater. 53, 3495 (2005)

L.Y. Zhao, X.Q. Guo, A. Chapuis, Y.C. Xin, Q. Liu, P.D. Wu, Metall. Mater. Trans. A 50, 118 (2019)

Acknowledgements

The authors acknowledge the support of the National Natural Science Foundation of China (52101154, 51601218), Natural Science Foundation of Jiangsu Province (BK20200172), China Postdoctoral Science Foundation funded project (2020M671640), Project supported by the Key Laboratory of Lightweight Materials, Nanjing Tech University, and Excellent Scientific and Technological Innovation Team of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, C., Duan, X., Guo, X. et al. Study of Deformation Mechanisms of a High-Purity α-Titanium Plate Under Monotonic Loading with the EVPSC-TDT Model. Met. Mater. Int. 29, 315–326 (2023). https://doi.org/10.1007/s12540-022-01241-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01241-5