Abstract

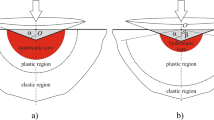

Indentation hardness tests are widely used in engineering to test the hardness of a material, which can be performed on a macroscopic scale or microscopic scale. In the present work, copper specimens with different thicknesses were indented with a mechanically-instrumented Rockwell tester. The effects of spacing between indents, indent distance to the edge of the sample, and specimen thickness on the hardness measurement were systematically quantified. Non-linear finite-element modeling was performed, assuming elastic-plastic material response with strain hardening. The two-dimensional numerical modeling of stand-alone and multiple indentations helped to shed more light on the deformation field under indentation, especially the size of the plastic zones and any interaction between them. In addition to the geometric effects, the influence of strain hardening of the test material was also investigated using the finite element analysis. The combined experimental and numerical results provided a range of indent spacings and thicknesses, which yield small to no effect on hardness values. The simulations also quantified the size and shape of the plastic zone under an indent. Lastly, the modeling results showed a competition between the effect of intrinsic material hardening and indent spacing on the value of the measured hardness.

Similar content being viewed by others

References

D. Tabor, The Hardness of Metals, Clarendon Press, Oxford (1951).

W. D. Callister and D. G. Rethwisch, Materials Science and Engineering: An Introduction, 8th Ed., Wiley, New York (2009).

D. Stone, W. LaFontaine, P. Alexopoulos, T. Wu and C. Li, An investigation of hardness and adhesion of sputter-deposited aluminum on silicon by utilizing a continuous indentation test, Journal of Materials Research, 3(1) (1988) 141–147.

C. B. Ponton and R. D. Rawlings, Vickers indentation fracture toughness test part 1 review of literature and formulation of standardised indentation toughness equations, Materials Science and Technology, 5(9) (1989) 865–872.

K. Hutchins, T. Buchheit, R. Tandon and T. Khraishi, Determination of interfacial fracture energy for pop-in delaminations in a glass-epoxy system using the indentation method, Journal of Theoretical and Applied Multiscale Mechanics, 3(2) (2018) 116–126.

A. Delalleau, G. Josse, J. M. Lagarde, H. Zahouani and J. M. Bergheau, Characterization of the mechanical properties of skin by inverse analysis combined with the indentation test, Journal of Biomechanics, 39(9) (2006) 1603–1610.

N. Ogasawara, N. Chiba and X. Chen, Measuring the plastic properties of bulk materials by single indentation test, Scripta Materialia, 54(1) (2006) 65–70.

G. D. Quinn and R. C. Bradit, On the Vickers indentation fracture toughness test, Journal of the American Ceramic Society, 90(3) (2007) 673–680.

M. Sakamoto, G. Li, T. Hara and E. Y. S. Chao, A new method for theoretical analysis of static indentation test, Journal of Biomechanics, 29(5) (1996) 679–685.

P. L. Larsson, A. E. Giannakopoulos, E. Söderlund, D. J. Rowcliffe and R. Vestergaard, Analysis of Berkovich indentation, International Journal of Solids and Structures, 33(2) (1996) 221–248.

B. D. Kozola and Y.-L. Shen, A mechanistic analysis of the correlation between overall strength and indentation hardness in discontinuously reinforced aluminum, Journal of Materials Science, 38 (2003) 901–907.

A. Biabangard-Oskouyi, E. Atashpaz-Gargari, N. Soltani and C. Lucas, Application of imperialist competitive algorithm for materials property characterization from sharp indentation test, International Journal of Engineering Simulation, 10(1) (2009) 11–12.

G. Tang, Y.-L. Shen, D. R. P. Singh and N. Chawla, Indentation behavior of metal-ceramic multilayers at the nanoscale: numerical analysis and experimental verification, Acta Materialia, 58(6) (2010) 2033–2044.

Y.-L. Shen, C. B. Blada, J. J. Williams and N. Chawla, Cyclic indentation behavior of metal-ceramic nanolayered composites, Material Science and Engineering A, 557 (2012) 119–125.

M. S. Park and Y. S. Suh, Hardness estimation for pile-up materials by strain gradient plasticity incorporating the geometrically necessary dislocation density, J. Mech. Sci. Technol., 27 (2013) 525–531.

M. Hadhri, A. El Ouafi and N. Barka, Prediction of the hardness profile of an AISI 4340 steel cylinder heat-treated by laser — 3D and artificial neural networks modelling and experimental validation, J. Mech. Sci. Technol., 31 (2017) 615–623.

M. E. Cordova and Y.-L. Shen, Indentation vs. uniaxial power-law creep: a numerical assessment, Journal of Materials Science, 50 (2015) 1394–1400.

N. J. Martinez and Y.-L. Shen, Analysis of indentation-derived power-law creep response, Journal of Materials Engineering and Performance, 25 (2016) 1109–1116.

R. D. Jamison and Y.-L. Shen, Indentation and overall compression behavior of multilayered thin-film composites: effect of undulating layer geometry, Journal of Composite Materials, 50(4) (2016) 507–521.

R. D. Jamison and Y.-L. Shen, Delamination analysis of metal-ceramic multilayer coatings subject to nanoindentation, Surface and Coatings Technology, 303A (2016) 3–11.

S. Bigelow and Y.-L. Shen, Parametric computational analysis of indentation-induced shear band formation in metal-ceramic multilayer coatings, Surface and Coatings Technology, 350 (2018) 779–787.

G. Tang, M. Galluzzi, B. Zhang, Y.-L. Shen and F. Stadler, Biomechanical heterogeneity of living cells: comparison between atomic force microscopy and finite element simulation, Langmuir, 35 (2019) 7578–7587.

Y.-L. Shen, On the viscoelastic drift behavior during nanoindentation, Frontiers in Materials, 9 (2022) 900088.

EMCO-TEST, General Tips. Minimum Distance between Test Points and to the Specimen Edge, EMCO-TEST Prüfmaschinen GmbH, https://www.emcotest.com/en/the-world-of-hardness-testing/hardness-know-how/applications-tips/general-tips/minimum-distance-between-test-points-and-to-the-specimen-edge/.

P. S. Phani and W. C. Oliver, A critical assessment of the effect of the indentation spacing on the measurement of hardness and modulus using instrumented indention testing, Journal of Materials and Design, 164 (2009) 107563.

T. Khraishi and M. S. Al-Haik, Experiments in Materials Science and Engineering, Cognella, Solana Beach (2011).

J. W. Harris and H. Stocker, Handbook of Mathematics and Computational Science, Springer, New York (1998).

McMaster-Carr, Multipurpose 110 Copper Bars with Rounded Edges, McMaster-Carr Supply Company (2022) https://www.mcmaster.com/copper/multipurpose-110-copper-bars-with-round-ed-edges-9/.

EMCO-TEST, Rockwell Method, Minimum Specimen Thickness, EMCO-TEST Prüfmaschinen GmbH (2022) https://www.emcotest.com/en/the-world-of-hardness-testing/hardness-know-how/applications-tips/general-tips/rockwell-method-minimum-specimen-thickness/.

J. L. Bucaille, S. Stauss, E. Felder and J. Michler, Determination of plastic properties of metals by insutrmented indentation using different sharp indenters, Journal of Acta Materialia, 51(6) (2003) 1663–1678.

A. B. Siddique, H. Lim and T. A. Khraishi, The effect of multi-poles on the elasto-plastic properties of a crystal: theory and three-dimensional dislocation dynamics modeling, Journal of Engineering Materials and Technology, 144(1) (2022) 011016.

Acknowledgments

The authors would like to thank the University of New Mexico’s (UNM) Mechanical Engineering Department for supporting this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Luo Li is a Ph.D. student in the Mechanical Engineering Department at the University of New Mexico. His research interests include materials science with emphasis on mechanical properties and characterization, mechanics of materials, composite materials, and advanced manufacturing.

Tariq Khraishi is currently a Professor of Mechanical Engineering at the University of New Mexico, U.S.A. He received his Ph.D. in Engineering from Washington State University. His research work is in the general areas of mechanics and materials science. In particular he has performed modelling, theoretical and/or experimental research in biomechanics, dislocation dynamics, eigenstrain theory/modelling, fracture mechanics, nano structures, irradiation damage, void growth/interaction in superplasticity, and stresses in thin films.

Yu-Lin Shen is currently a Professor and Chair of the Department of Mechanical Engineering at University of New Mexico, U.S.A. He received his Ph.D. in Engineering from Brown University. His research areas include mechanical behavior of materials and solid mechanics, with particular interests in applying modeling techniques to address micro-mechanical problems related to thin films, microelectronic devices and packages, and composite materials.

Rights and permissions

About this article

Cite this article

Li, L., Khraishi, T. & Shen, YL. Investigation of the effect of indentation spacing, edge distance and specimen thickness on the measurement of hardness. J Mech Sci Technol 37, 687–696 (2023). https://doi.org/10.1007/s12206-023-0112-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-023-0112-7