Abstract

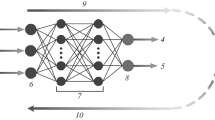

This paper presents a comprehensive approach developed to design an effective prediction model for hardness profile in laser surface transformation hardening process. Based on finite element method and Artificial neural networks, the proposed approach is built progressively by (i) examining the laser hardening parameters and conditions known to have an influence on the hardened surface attributes through a structured experimental investigation, (ii) investigating the laser hardening parameters effects on the hardness profile through extensive 3D modeling and simulation efforts and (ii) integrating the hardening process parameters via neural network model for hardness profile prediction. The experimental validation conducted on AISI4340 steel using a commercial 3 kW Nd:Yag laser, confirm the feasibility and efficiency of the proposed approach leading to an accurate and reliable hardness profile prediction model. With a maximum relative error of about 10 % under various practical conditions, the predictive model can be considered as effective especially in the case of a relatively complex system such as laser surface transformation hardening process.

Similar content being viewed by others

References

S. Soundarapandian and R. Kovacevic, Hardness prediction in multi-pass direct diode laser heat treatment by on-line surface temperature monitoring, Journal of Materials Processing Technology, 212 (11) (2012) 2261–2271.

R. Patwa and Y. C. Shin, Predictive modeling of laser hardening of AISI5150H steels, International Journal of Machine Tools and Manufacture, 47 (2) (2007) 307–320.

J. C. Rozzi et al., Transient thermal response of a rotating cylindrical silicon nitride workpiece subjected to a translating laser heat source, part I: comparison of surface temperature measurements with theoretical results, Journal of Heat transfer, 120 (4) (1998) 899–906.

J. C. Rozzi et al., Transient, three-dimensional heat transfer model for the laser assisted machining of silicon nitride: I. Comparison of predictions with measured surface temperature histories, International Journal of Heat and Mass Transfer, 43 (8) (2000) 1409–1424.

S. Skvarenina and Y. C. Shin, Predictive modeling and experimental results for laser hardening of AISI 1536 steel with complex geometric features by a high power diode laser, Surface and Coatings Technology, 201 (6) (2006) 2256–2269.

L. Orazi et al., Laser surface hardening of large cylindrical components utilizing ring spot geometry, CIRP Annals -Manufacturing Technology, 63 (1) (2014) 233–236.

N. Barka and A. El Ouafi, Effects of laser hardening process parameters on case depth of 4340 steel cylindrical specimen -A statistical analysis, Journal of Surface Engineered Materials and Advanced Technology, 5 (3) (2015) 124.

M. Ilyes, A. El Ouafi and N. Barka, Prediction of 4340 steel hardness profile heat-treated by laser using artificial neural networks and multi regression approaches, International Journal of Engineering and Innovative Technology, 4 (6) (2014) 14–22.

M. F. Ashby and K. E. Easterling, The transformation hardening of steel surfaces by laser beams -I. Hypo-eutectoid steels, Acta Metallurgica, 32 (11) (1984) 1935–1948.

P. Maynier, J. Dollet and P. Bastien, Prediction of microstructure via empirical formulae based on CCT diagrams, Hardenability Concepts With Applications to Steel, Metallurgical Society of AIME (1978) 163–178.

P. Maynier, B. Jungmann and J. Dollet, Creusot-Loire system for the prediction of the mechanical properties of low alloy steel products, Hardenability concepts with Applications to Steel, Metallurgical Society of AIME (1978) 518–545.

R. L. Mason, R. F. Gunst and J. L. Hess, Statistical design and analysis of experiments: with applications to engineering and science, John Wiley & Sons (2003).

B. Acherjee et al., Prediction of weld strength and seam width for laser transmission welding of thermoplastic using response surface methodology, Optics & Laser Technology, 41 (8) (2009) 956–967.

S. K. Dhara, A. S. Kuar and S. Mitra, An artificial neural network approach on parametric optimization of laser micromachining of die-steel, International Journal of Advanced Manufacturing Technology, 39 (1) (2008) 39–46.

G. Buffa, L. Fratini and F. Micari, Mechanical and microstructural properties prediction by artificial neural networks in FSW processes of dual phase titanium alloys, Journal of Manufacturing Processes, 14 (3) (2012) 289–296.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Sang-Hee Yoon

Mahdi Hadhri is a researcher student in the Department of Mathematics, Computer Science and Engineering at the University of Quebec at Rimouski. His research fields include manufacturing materials, manufacturing processes improvement, and quality management for industrial applications.

Abderrazak El Ouafi is a Professor in the Department of Mathematics, Computer Science and Engineering at the University of Quebec at Rimouski. He is also Director of Production and Automation Research Laboratory. His research interests are mainly oriented in precision engineering, manufacturing system design and control, improvement of manufacturing processes performance and intelligent control related to sensor fusion, neural networks and fuzzy control.

Noureddine Barka is an Assistant Professor in the Department of Mathematics, Computer Science and Engineering at the University of Quebec at Rimouski. His research fields include manufacturing materials, CAD/CAM, manufacturing processes improvement, and quality control for industrial applications.

Rights and permissions

About this article

Cite this article

Hadhri, M., El Ouafi, A. & Barka, N. Prediction of the hardness profile of an AISI 4340 steel cylinder heat-treated by laser - 3D and artificial neural networks modelling and experimental validation. J Mech Sci Technol 31, 615–623 (2017). https://doi.org/10.1007/s12206-017-0114-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-017-0114-4