Abstract

New expanding spherical cavity model (ECM) for conical indentation is proposed. For polymeric materials description, the model incorporates isotropic non-monotonic strain hardening. For capturing the indentation size effect (ISE), the model incorporates the strain gradient dependence in yield strength based on lower-order strain gradient plasticity assumptions. Specifically, the forward gradient of the equivalent (accumulated) plastic strain is utilized as a non-local part of the yield strength. To predict the indentation depth-dependent hardness based on the proposed model, it is sufficient to numerically integrate one nonlinear ODE of the first order, and then calculate the definite integral. For the local perfect plasticity model, the hardness is obtained as an analytical expression that differs from known ECMs. The hardness estimate obtained numerically using the proposed model is compared with the experimental ISE data for polycarbonate (PC) and polymethyl methacrylate (PMMA). For the local perfect plasticity model, the formula obtained in the study is compared with the experimental data on the hardness of preliminary work-hardened materials. In both cases, the model shows good agreement with the experimental data. Fitting the experimental data on ISE, we found that intrinsic length scale of PMMA should be near 3 microns and near 9 microns for PC.

Similar content being viewed by others

Notes

Most of the data are given for metallic materials; however, the leftmost experimental points correspond to polymeric materials. For them, it is not clear what is meant by the state of full-hardening, which is indicated in [46] (see, for example, stress–strain curve for PMMA on Fig. 8). In [34] it is indicated that the pre-strain of the samples was in limits 1.1 and 1.5.

In contrast to viscoplastic models, in which the plastic strain rate vanishes at the elastic–plastic boundary and increases rapidly with deepening into the plastic region up to values comparable to those predicted by rate-independent plasticity.

References

Aifantis, E.C.: On the microstructural origin of certain inelastic models. J. Eng. Mater. T ASME 106(4), 326–330 (1984). https://doi.org/10.1115/1.3225725

Aifantis, E.C.: The physics of plastic deformation. Int. J. Plast. 3(3), 211–247 (1987). https://doi.org/10.1016/0749-6419(87)90021-0

Aifantis, E.C.: Update on a class of gradient theories. Mech. Mater. 35(3–6), 259–280 (2003). https://doi.org/10.1016/S0167-6636(02)00278-8

Alisafaei, F., Han, C.-S.: Indentation depth dependent mechanical behavior in polymers. Adv. Cond. Matter Phys. 2015, 391579 (2015). https://doi.org/10.1155/2015/391579

Ames, N.M., Srivastava, V., Chester, S.A., Anand, L.: A thermo-mechanically coupled theory for large deformations of amorphous polymers. Part II: Applications. Int. J. Plast. 25(8), 1495–1539 (2009). https://doi.org/10.1016/j.ijplas.2008.11.005

Anand, L.: On H. Hencky’s approximate strain-energy function for moderate deformations. J. Appl. Mech. 46(1), 78–82 (1979). https://doi.org/10.1115/1.3424532

Atkins, A.G., Tabor, D.: Plastic indentation in metals with cones. J. Mech. Phys. Solids 13(3), 149–164 (1965). https://doi.org/10.1016/0022-5096(65)90018-9

Balta Calleja, F.J., Flores, A., Michler, G.H.: Microindentation studies at the near surface of glassy polymers: Influence of molecular weight. J. Appl. Polym. Sci. 93, 1951–1956 (2004). https://doi.org/10.1002/app.20665

Bhattacharya, A.K., Nix, W.D.: Finite element analysis of cone indentation. Int. J. Solids Struct. 27(8), 1047–1058 (1991). https://doi.org/10.1016/0020-7683(91)90100-T

Bilby, B.A., Lardner, L.R.T., Stroh, A.N.: Continuous distributions of dislocations and the theory of plasticity. In: Actes du IXe congres international de mecanique appliquee (Bruxelles, 1956), V. 8, pp. 35–44 (1957)

Bishop, R.F., Hill, R., Mott, N.F.: The theory of indentation and hardness tests. Proc. Phys. Soc. 57(321), 147–159 (1945). https://doi.org/10.1088/0959-5309/57/3/301

Briscoe, B.J., Fiori, L., Pelillo, E.: Nano-indentation of polymeric surfaces. J. Phys. D Appl. Phys. 31, 2395–2405 (1998). https://doi.org/10.1088/0022-3727/31/19/006

Cheng, L., Guo, T.F.: Void interaction and coalescence in polymeric materials. Int. J. Solids Struct. 44(6), 1787–1808 (2007). https://doi.org/10.1016/j.ijsolstr.2006.08.007

Chong, A.C.M., Lam, D.C.C.: Strain gradient plasticity effect in indentation hardness of polymers. J. Mater. Res. 14(10), 4103–4110 (1999). https://doi.org/10.1557/JMR.1999.0554

Dorogoy, A., Rittel, D., Brill, A.: Experimentation and modeling of inclined ballistic impact in thick polycarbonate plates. Int. J. Impact Eng 38(10), 804–814 (2011). https://doi.org/10.1016/j.ijimpeng.2011.05.001

Dugdale, D.S.: Cone indentation experiments. J. Mech. Phys. Solids 2(4), 265–277 (1954). https://doi.org/10.1016/0022-5096(54)90017-4

Durban, D., Baruch, M.: On the problem of a spherical cavity in an infinite elasto-plastic medium. J. Appl. Mech. 43(4), 633–638 (1976). https://doi.org/10.1115/1.3423946

Durban, D., Fleck, N.A.: Singular plastic fields in steady penetration of a rigid cone. J. Appl. Mech. 59(4), 706–710 (1992). https://doi.org/10.1115/1.2894032

Durban, D., Masri, R.: Dynamic spherical cavity expansion in a pressure sensitive elastoplastic medium. Int. J. Solids Struct. 41(20), 5697–5716 (2004). https://doi.org/10.1016/j.ijsolstr.2004.03.009

Durban, D., Masri, R.: Conical indentation of strain-hardening solids. Eur. J. Mech. A Solid 27(2), 210–221 (2008). https://doi.org/10.1016/j.euromechsol.2007.05.007

Evans, P.D.: The hardness and abrasion of polymers. PhD dissertation. Department of Chemical Engineering and Chemical Technology. Imperial College London (1987)

Felder, E., Ramond-Angelelis, C.: Mechanical analysis of indentation experiments with a conical indenter. Philos. Mag. 86(33–55), 5219–5230 (2006). https://doi.org/10.1080/14786430600589071

Fleck, N.A., Muller, G.M., Ashby, M.F., Hutchinson, J.W.: Strain gradient plasticity: theory and experiment. Acta Metall. Mater. 42(2), 475–487 (1994). https://doi.org/10.1016/0956-7151(94)90502-9

Fleck, N.A., Hutchinson, J.W.: Strain gradient plasticity. Adv. Appl. Mech. 33, 295–361 (1997). https://doi.org/10.1016/S0065-2156(08)70388-0

Flores, A., Balta Calleja, F.J., Attenburrow, G.E., Bassett, D.C.: Microhardness studies of chain-extended PE: III. Correlation with yield stress and elastic modulus. Polymer 41(14), 5431–5435 (2000). https://doi.org/10.1016/S0032-3861(99)00755-7

Gao, X.L.: New expanding cavity model for indentation hardness including strain-hardening and indentation size effects. J. Mater. Res. 21(5), 1317–1326 (2006). https://doi.org/10.1557/jmr.2006.0158

Gao, X.-L.: An expanding cavity model incorporating strain-hardening and indentation size effects. Int. J. Solids Struct. 43(21), 6615–6629 (2006). https://doi.org/10.1016/j.ijsolstr.2006.01.008

Gao, X.-L., Jing, X.N., Subhash, G.: Two new expanding cavity models for indentation deformations of elastic strain-hardening materials. Int. J. Solids Struct. 43(7–8), 2193–2208 (2006). https://doi.org/10.1016/j.ijsolstr.2005.03.062

Green, A.E., Shield, R.T.: Finite elastic deformation of incompressible isotropic bodies. Proc. R. Soc. Lond. A 202, 407–419 (1950). https://doi.org/10.1098/rspa.1950.0109

Han, C.S., Nikolov, S.: Indentation size effects in polymers and related rotation gradients. J. Mater. Res. 22, 1662–1672 (2007). https://doi.org/10.1557/JMR.2007.0197

Haward, R.N., Thackray, G.: The use of a mathematical model to describe isothermal stress-strain curves in glassy thermoplastics. Proc. R. Soc. Lond. A 302(1471), 453–472 (1967). https://doi.org/10.1098/rspa.1968.0029

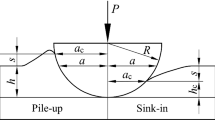

Hernot, X., Bartier, O.: An expanding cavity model incorporating pile-up and sink-in effects. J. Mater. Res. 27(1), 132–140 (2012). https://doi.org/10.1557/jmr.2011.394

Hill, R.: The Mathematical Theory of Plasticity. Clarendon Press, Oxford (1950)

Hirst, W., Howse, M.G.J.W.: The indentation of materials by wedges. Proc. R. Soc. Lond. A 311, 429–444 (1969). https://doi.org/10.1098/rspa.1969.0126

Huang, Y., Qu, S., Hwang, K.C., Li, M., Gao, H.: A conventional theory of mechanism-based strain gradient plasticity. Int. J. Plast. 20(4–5), 753–782 (2004). https://doi.org/10.1016/j.ijplas.2003.08.002

Johnson, K.L.: The correlation of indentation experiments. J. Mech. Phys. Solids 18(2), 115–126 (1970). https://doi.org/10.1016/0022-5096(70)90029-3

Johnson, K.L.: Normal contact of inelastic solids. In: Contact Mechanics, Cambridge University Press, Cambridge, pp. 153–201 (1985). https://doi.org/10.1017/CBO9781139171731.007

Kröner, E.: Allgemeine kontinuumstheorie der versetzungen und eigenspannungen. Arch. Ration. Mech. An. 4(1), 273–334 (1959). https://doi.org/10.1007/BF00281393

Lam, D.C.C., Chong, A.C.M.: Indentation model and strain gradient plasticity law for glassy polymers. J. Mater. Res. 14(9), 3784–3788 (1999). https://doi.org/10.1557/JMR.1999.0512

Lee, E., Liu, D.: Finite-strain elastic-plastic theory with application to plane-wave analysis. J. Appl. Phys. 38(1), 19–27 (1967). https://doi.org/10.1063/1.1708953

Lee, E.H.: Elastic-plastic deformation at finite strains. J. Appl. Mech. 36(1), 1–6 (1969). https://doi.org/10.1115/1.3564580

Levitas, V.I.: Large Deformation of Materials with Complex Rheological Properties at Normal and High Pressure. Nova Science Publishers, New York (1996)

Liu, D., Dunstan, D.J.: Material length scale of strain gradient plasticity: a physical interpretation. Int. J. Plast. 98, 156–174 (2017). https://doi.org/10.1016/j.ijplas.2017.07.007

Lockett, F.J.: Indentation of a rigid/plastic material by a conical indenter. J. Mech. Phys. Solids 11(5), 345–355 (1963). https://doi.org/10.1016/0022-5096(63)90035-8

Ma, Q., Clarke, D.R.: Size dependent hardness of silver single crystals. J. Mater. Res. 10(4), 853–863 (1995). https://doi.org/10.1557/JMR.1995.0853

Marsh, D.M.: Plastic flow in glass. Proc. R. Soc. Lond. A 279, 420–435 (1964). https://doi.org/10.1098/rspa.1964.0114

Mata, M., Casals, O., Alcala, J.: The plastic zone size in indentation experiments: the analogy with the expansion of a spherical cavity. Int. J. Solids Struct. 43(20), 5994–6013 (2006). https://doi.org/10.1016/j.ijsolstr.2005.07.002

Meijer, H.E.H., Govaert, L.E.: Mechanical performance of polymer systems: the relation between structure and properties. Prog. Polym. Sci. 30, 915–938 (2005). https://doi.org/10.1016/j.progpolymsci.2005.06.009

Naghdi, P.M.: Stresses and displacements in an elastic-plastic wedge. J. Appl. Mech. 24(1), 98–104 (1957). https://doi.org/10.1115/1.4011452

Prager, W., Hodge, P.G.: The Theory of Perfectly Plastic Solids. Wiley, New York (1951)

Richeton, J., Ahzi, S., Vecchio, K.S., Jiang, F.C., Adharapurapu, R.R.: Influence of temperature and strain rate on the mechanical behavior of three amorphous polymers: characterization and modeling of the compressive yield stress. Int. J. Solids Struct. 43(7–8), 2318–2335 (2006). https://doi.org/10.1016/j.ijsolstr.2005.06.040

Sakharova, N.A., Fernandes, J.V., Antunes, J.M., Oliveira, M.C.: Comparison between Berkovich, Vickers and conical indentation tests: a three-dimensional numerical simulation study. Int. J. Solids Struct. 46(5), 1095–1104 (2009). https://doi.org/10.1016/j.ijsolstr.2008.10.032

Santos, T., Srivastava, A., Rodriguez-Martinez, J.A.: The combined effect of size, inertia and porosity on the indentation response of ductile materials. Mech. Mater. 153, 103674 (2021). https://doi.org/10.1016/j.mechmat.2020.103674

Shapiro, G.S.: Elastic-plastic equilibrium of a wedge and discontinuous solutions in the theory of plasticity. J. Appl. Math. Mech. 16(1), 101–106 (1952). (in Russian)

Sevastyanov, G.M.: Adiabatic heating effect in elastic-plastic contraction / expansion of spherical cavity in isotropic incompressible material. Eur. J. Mech. A Solid 87, 104223 (2021). https://doi.org/10.1016/j.euromechsol.2021.104223

Sneddon, I.N.: The relation between load and penetration in the axisymmetric boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 3(1), 47–57 (1965). https://doi.org/10.1016/0020-7225(65)90019-4

Sokolovsky, V.V.: Theory of Plasticity. Vischaya shkola, Moscow (1969). (in Russian)

Stolken, J.S., Evans, A.G.: A microbend test method for measuring the plasticity length scale. Acta Mater. 46(14), 5109–5115 (1998). https://doi.org/10.1016/S1359-6454(98)00153-0

Studman, C.J., Moore, M.A., Jones, S.E.: On the correlation of indentation experiments. J. Phys. D Appl. Phys. 10(6), 949–956 (1977). https://doi.org/10.1088/0022-3727/10/6/019

Tabor, D.: Hardness of Metals. Clarendon Press, Oxford (1951)

Turnbull, A., White, D.: Nanoindentation and microindentation of weathered unplasticised poly-vinyl chloride (UPVC). J. Mater. Sci. 31, 4189–4198 (1996). https://doi.org/10.1007/BF00356438

Tvergaard, V., Needleman, A.: Polymer indentation: Numerical analysis and comparison with a spherical cavity model. J. Mech. Phys. Solids 59(9), 1669–1684 (2011). https://doi.org/10.1016/j.jmps.2011.06.006

Voyiadjis, G.Z., Song, Y.: Strain gradient continuum plasticity theories: theoretical, numerical and experimental investigations. Int J Plasticity 121, 21–75 (2019). https://doi.org/10.1016/j.ijplas.2019.03.002

Weiss A., Durban D.: Cavitation theory applied to polycarbonate ballistic response. In: 28th International Symposium on Ballistics (2014)

Wright, S.C., Huang, Y., Fleck, N.A.: Deep penetration of polycarbonate by a cylindrical punch. Mech. Mater. 13(4), 277–284 (1992). https://doi.org/10.1016/0167-6636(92)90020-E

Wu, P.D., van der Giessen, E.: On improved network models for rubber elasticity and their applications to orientation hardening in glassy polymers. J. Mech. Phys. Solids 41, 427–456 (1993). https://doi.org/10.1016/0022-5096(93)90043-F

Yuan, H., Chen, J.: Analysis of size effects based on a symmetric lower-order gradient plasticity model. Comp. Mater. Sci. 19(1–4), 143–157 (2000). https://doi.org/10.1016/S0927-0256(00)00149-X

Yun, G., Qin, J., Huang, Y., Hwang, K.C.: A study of lower-order strain gradient plasticity theories by the method of characteristics. Eur. J. Mech. A Solid 23(3), 387–394 (2004). https://doi.org/10.1016/j.euromechsol.2004.02.003

Zhang, P., Li, S.X., Zhang, Z.F.: General relationship between strength and hardness. Mat. Sci. Eng. A Struct. 529, 62–73 (2011). https://doi.org/10.1016/j.msea.2011.08.061

Acknowledgements

This research was funded by the Russian Science Foundation (Project No 22-11-00163).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1

Appendix 1

In [46] (Fig. 5 on p. 425), the abscissa axis displays the complex \(B\ln z = {3 \mathord{\left/ {\vphantom {3 {\left( {3 - \lambda } \right)}}} \right. \kern-0pt} {\left( {3 - \lambda } \right)}}\ln \left[ {{3 \mathord{\left/ {\vphantom {3 {\left( {\lambda + 3\mu - \lambda \mu } \right)}}} \right. \kern-0pt} {\left( {\lambda + 3\mu - \lambda \mu } \right)}}} \right]\) for various materials. Here, \(\lambda = \left( {1 - 2\nu } \right){{\sigma_{y} } \mathord{\left/ {\vphantom {{\sigma_{y} } E}} \right. \kern-0pt} E}\), \(\mu = \left( {1 + \nu } \right){{\sigma_{y} } \mathord{\left/ {\vphantom {{\sigma_{y} } E}} \right. \kern-0pt} E}\). In our study in Fig. 6 (hexagram markers), we use the values \(\lg \left( {{E \mathord{\left/ {\vphantom {E {\sigma_{y} }}} \right. \kern-0pt} {\sigma_{y} }}} \right)\) extracted from the Marsh data (see table below; the first line of the table corresponds to the rightmost hexagram on Fig. 6, further from right to left). Poisson’s ratio values are taken from publicly available sources.

Material | Poisson’s ratio \(\nu\) | \(B\ln z\)(extracted) | \({H \mathord{\left/ {\vphantom {H {\sigma_{y} }}} \right. \kern-0pt} {\sigma_{y} }}\)(extracted) | \(\lg \left( {{E \mathord{\left/ {\vphantom {E {\sigma_{y} }}} \right. \kern-0pt} {\sigma_{y} }}} \right)\)(calculated) | \({H \mathord{\left/ {\vphantom {H {\sigma_{y} }}} \right. \kern-0pt} {\sigma_{y} }}\), calculated by Eq. (2) (Johnson model, incompressible elasticity), with relative error | \({H \mathord{\left/ {\vphantom {H {\sigma_{y} }}} \right. \kern-0pt} {\sigma_{y} }}\), calculated by Eq. (36) (Johnson model, compressible elasticity), with relative error | \({H \mathord{\left/ {\vphantom {H {\sigma_{y} }}} \right. \kern-0pt} {\sigma_{y} }}\), calculated by Eq. (37) (Durban–Masri model, compressible elasticity), with relative error |

|---|---|---|---|---|---|---|---|

Tellurium-lead | 0.42 | 6.2 | 2.95 | 2.86 | 4.31 (+ 46%) | 4.21 (+ 43%) | 4.21 (+ 43%) |

Aluminum | 0.33 | 5.5 | 3.05 | 2.55 | 3.83 (+ 26%) | 3.64 (+ 19%) | 3.64 (+ 19%) |

Copper | 0.36 | 5.1 | 3.00 | 2.38 | 3.57 (+ 19%) | 3.41 (+ 14%) | 3.42 (+ 14%) |

Mild steel | 0.3 | 4.8 | 2.95 | 2.24 | 3.36 (+ 14%) | 3.15 (+ 7%) | 3.16 (+ 7%) |

Steel 1 | 0.28 | 4.5 | 3.10 | 2.11 | 3.16 (+ 2%) | 2.94 (− 5%) | 2.96 (− 5%) |

Steel 2 | 0.28 | 4.3 | 2.95 | 2.02 | 3.02 (+ 2%) | 2.81 (− 5%) | 2.83 (− 4%) |

Steel 3 | 0.28 | 4.1 | 2.75 | 1.93 | 2.88 (+ 5%) | 2.67 (− 3%) | 2.61 (− 5%) |

Steel 4 | 0.28 | 3.9 | 2.60 | 1.84 | 2.74 (+ 5%) | 2.54 (− 2%) | 2.60 (0%) |

Steel 5 | 0.28 | 3.7 | 2.50 | 1.76 | 2.62 (+ 5%) | 2.43 (− 3%) | 2.49 (0%) |

Copper-beryllium | 0.285 | 3.5 | 2.35 | 1.67 | 2.48 (+ 6%) | 2.31 (− 2%) | 2.38 (+ 1%) |

PMMA 1 | 0.38 | 3.2 | 2.25 | 1.55 | 2.30 (+ 2%) | 2.20 (− 2%) | 2.26 (0%) |

Epoxy resin | 0.35 | 3.1 | 2.10 | 1.50 | 2.22 (+ 6%) | 2.11 (0%) | 2.18 (+ 4%) |

Polystyrene | 0.34 | 3.0 | 2.30 | 1.46 | 2.16 (− 6%) | 2.05 (− 11%) | 2.13 (− 7%) |

PMMA 2 | 0.38 | 2.8 | 1.95 | 1.38 | 2.04 (+ 5%) | 1.96 (0%) | 2.03 (+ 4%) |

Polyacetal resin | 0.44 | 1.3 | 1.15 | 0.73 | 1.04 (− 10%) | 1.11 (− 3%) | 1.05 (− 9%) |

Experimental data [34], Table 1 on p. 432) (the first line of the table corresponds to the rightmost pentagram in Fig. 6 in the presented study, further from right to left). Poisson’s ratio values are taken from publicly available sources.

Material | Poisson’s ratio \(\nu\) | \({E \mathord{\left/ {\vphantom {E {\sigma_{y} }}} \right. \kern-0pt} {\sigma_{y} }}\) | \({H \mathord{\left/ {\vphantom {H {\sigma_{y} }}} \right. \kern-0pt} {\sigma_{y} }}\) | \({H \mathord{\left/ {\vphantom {H {\sigma_{y} }}} \right. \kern-0pt} {\sigma_{y} }}\), calculated by Eq. (2) (Johnson model, incompressible elasticity), with relative error | \({H \mathord{\left/ {\vphantom {H {\sigma_{y} }}} \right. \kern-0pt} {\sigma_{y} }}\), calculated by Eq. (36) (Johnson model, compressible elasticity), with relative error | \({H \mathord{\left/ {\vphantom {H {\sigma_{y} }}} \right. \kern-0pt} {\sigma_{y} }}\), calculated by Eq. (37) (Durban – Masri model, compressible elasticity), with relative error |

|---|---|---|---|---|---|---|

Lead alloy | 0.4 | 828 | 3.16 | 4.40 (+ 39%) | 4.276 (+ 35%) | 4.272 (+ 35%) |

Aluminum | 0.33 | 459 | 3.35 | 4.00 (+ 19%) | 3.813 (+ 14%) | 3.803 (+ 14%) |

Copper | 0.36 | 318 | 3.22 | 3.76 (+ 17%) | 3.6 (+ 12%) | 3.6 (+ 12%) |

Mild steel | 0.3 | 268 | 3.27 | 3.64 (+ 11%) | 3.43 (+ 5%) | 3.43 (+ 5%) |

Beryllium copper | 0.285 | 102.6 | 2.64 | 3.00 (+ 14%) | 2.80 (+ 6%) | 2.83 (+ 7%) |

PTFE | 0.46 | 22.6 | 1.73 | 2.00 (+ 16%) | 1.97 (+ 14%) | 1.99 (+ 15%) |

PCTFE | 0.38 | 15.3 | 1.28 | 1.74 (+ 36%) | 1.70 (+ 33%) | 1.76 (+ 38%) |

Nylon | 0.4 | 13.1 | 1.25 | 1.63 (+ 30%) | 1.62 (+ 30%) | 1.66 (+ 33%) |

Perspex | 0.38 | 11.2 | 1.07 | 1.53 (+ 43%) | 1.53 (+ 43%) | 1.57 (+ 47%) |

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sevastyanov, G.M. New expanding cavity model for conical indentation and its application to determine an intrinsic length scale of polymeric materials. Acta Mech (2024). https://doi.org/10.1007/s00707-024-03921-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00707-024-03921-2