Abstract

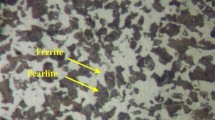

This study presents the experimental and statistical examination of machinability of AZ91 alloy, in terms of cutting forces (Fc, Ff, and Fp), surface roughness (Ra) and cutting temperature (T). In the first step, test samples have been produced using the casting method and the microstructures of these samples have been characterized by SEM and EDS. Secondly, the turning tests have been performed in CNC turning at three different cutting speeds (200, 300, and 400 m/min), three different feed rates (0.1, 0.2, and 0.3 mm/rev), and three different depths of cut (1, 1.5, and 2 mm). Thereafter, the turning simulations have been performed by Deform 3D software. Finally, experiment results were statistically analyzed using Taguchi, Anova, and regression analysis. The outcomes of this study show that the feed rate is the most significant parameter with 69.43, 90.04, 88.53, and 96.22% effect rates on the cutting force components (Fc, Ff, and Fp) and surface roughness (Ra) respectively, while the cutting speed is the most significant parameter with 70.83% effect rates on the cutting temperature. There is an average of 4.5% deviation between the experimental and simulation results of Fc. The results also stated that the microstructure of the samples consisted of α-Mg phase and β-intermetallic (Mg17Al12) phase, and the built-up edge (BUE) formation was the dominant wear mode for all the cutting tools.

Similar content being viewed by others

References

Mordike B L and Ebert T 2001 Magnesium properties applications potential. Mater. Sci. Eng. A. 302: 37–45

Buldum B, Şik A and Özkul I 2012 Investigation of magnesium alloys machinability. Int. J. Elect. Mech. Mechat. Eng. 2(3): 261–268

Shi K, Zhang D and Ren J 2015 Optimization of process parameters for surface roughness and microhardness in dry milling of magnesium alloy using Taguchi with grey relational analysis. Int. J. Adv. Manuf. Technol. 81(1): 645–651

Akyuz B 2014 Effects of Si and Zn on machinability and wear resistance of AZ91 and AS91 magnesium alloys. Mater. Test. 56(9): 703–708

Tönshoff H K and Winkler J 1997 The influence of tool coatings in machining of magnesium. Surf. Coat. Technol. 94: 610–616

Akyuz B 2014 Comparison of the machinability and wear properties of magnesium alloys. Int. J. Adv. Manuf. Technol. 75(9–12): 1735–1742

Öztürk F and Kaçar I 2012 Investigation of magnesium alloys and their applications. NOHU. J. Eng. Sci. 1(2): 12–20

Aghion E, Bronfin B and Eliezer D 2001 The role of the magnesium industry in protecting the environment. J. Mater. Process. Technol. 117(3): 381–385

Staiger M P, Pietak A M, Huadmai J and Dias G 2006 Magnesium and its alloys as orthopedic biomaterials: a review. Biomaterials 27(9): 1728–1734

Gariboldi E 2003 Drilling a magnesium alloy using PVD coated twist drills. J Mater. Process. Technol. 134(3): 287–295

Shi K, Ren J, Zhang D, Zhai Z and Huang X 2017 Tool wear behaviors and its effect on machinability in dry high-speed milling of magnesium alloy. J. Adv. Manuf. Technol. 90(9): 3265–3273

Hou J Z, Zhou W and Zhao N 2010 Effect of cutting parameters on ignition of AM50A Mg alloy during face milling. Mater. Manuf. Process. 25(10): 1048–1051

Şirin Ş, Yıldırım Ç V, Kıvak T and Sarıkaya M 2021 Performance of cryogenically treated carbide inserts under sustainable cryo-lubrication assisted milling of Inconel X750 alloy. Sustain. Mater. Technol 29: e00314

Esfe M H, Bahiraei M and Mir A 2020 Application of conventional and hybrid nanofluids in different machining processes: a critical review. Adv. Colloid Interface Sci. 282: 102199

Hou J, Zhao N and Zhu S 2011 Influence of cutting speed on flank temperature during face milling of magnesium alloy. Mater. Manuf. Process. 26(8): 1059–1063

Aslan D and Budak E 2014 Semi-analytical force model for grinding operations. Procedia CIRP 14: 7–12

Kayir Y 2014 Optimization of the cutting parameters for drilling magnesium alloy AZ91. Mater. Test. 56(1): 47–53

Vasu C, Andhare A B and Dumpala R 2021 Multiobjective optimization of performance characteristics in turning of AZ91 mg alloy using grey relational analysis Mater. Today Proc. 42: 642–649

Shi K, Ren J, Zhang D, Zhai Z and Huang X 2017 Tool wear behaviors and its effect on machinability in dry high-speed milling of magnesium alloy. Int. J. Adv. Manuf. Technol. 90(9): 3265–3273

Dey A, Debnath S and Pandey K M 2017 Optimization of electrical discharge machining process parameters for Al6061/Cenosphere composite using grey-based hybrid approach. T. Nonferr. Met. Soc. 27(5): 998–1010

Akyuz B 2013 Influence of Al content on machinability of AZ series mg alloys. T. Nonferr. Met. Soc. 23(8): 2243–2249

Chowdary S, Dumpala R and Kondaiah V V 2018 Influence of heat treatment on the machinability and corrosion behavior of AZ91 Mg alloy. J. Magn. Alloys. 6(1): 52–58

Çiçek B, Ahlatçı H and Sun Y 2013 Wear behaviours of Pb added Mg–Al–Si composites reinforced with in situ Mg2Si particles. Mater. Des. 50: 929–935

Nas E and Altan N 2020 Optimization of the machining parameters in turning of hardened hot work tool steel using cryogenically treated tools. Surf. Rev. Lett. 27(05): 1950177

Sharma A, Singh R C and Singari R M 2020 Optimization of machining parameters during cryogenic turning of AISI D3 steel. Sādhanā 45: 124

Akgün M and Demir H 2021 Optimization of cutting parameters affecting surface roughness in turning of Inconel 625 superalloy by cryogenically treated tungsten carbide inserts. SN Appl. Sci. 3: 277

Kalyon A 2020 Optimization of machining parameters in sinking electrical discharge machine of caldie plastic mold tool steel. Sādhanā. 45: 65

Korkmaz M E and Günay M 2018 Finite element modelling of cutting forces and power consumption in turning of AISI 420 martensitic stainless steel. Arab. J. Sci. Eng. 43(9): 4863–4870

Bagheri B, Abdollahzadeh A, Abbasi M and Kokabi A H 2021 Effect of vibration on machining and mechanical properties of AZ91 alloy during FSP: modeling and experiments. Int. J. Mater. Form. 14(4): 623–640

Zhou X, Zhao C M, Li L and Huang H J 2014 Numerical simulation of dynamic behavior of extruded AZ91D magnesium alloy based on SHPB experiment. Chin. J. Nonferr. Metal. 24(8): 1968–1975

Yaşar N 2019 Thrust force modelling and surface roughness optimization in drilling of AA-7075: FEM and GRA. J. Mech. Sci. Technol. 33(10): 4771–4781

Kerenciler H, Gündüz S, Erden M A, Türkmen M and Karabulut H 2016 Effect of aging on the microstructure and mechanical properties of magnesium alloy AZ31. Met. Sci. Heat Treat. 58(3): 179–184

Fu X Y, Jia R L, Ding Y F, Gong T H, Ma W and Guo F 2022 Effect of hot extrusion on AZ91 alloy corrosion behaviour. Corros. Eng. Sci. Technol. 57(2): 140–146

Gassama B, Ozden G and Oteyaka M O 2022 The effect of deep cryogenic treatment on the wear properties of AZ91 magnesium alloy in dry and in 0.9 wt% NaCl medium. Sādhanā. 47(1): 15

Liang S M, Chena R S, Blandin J J, Suery M and Han E H 2008 Thermal analysis and solidification pathways of Mg–Al–Ca system alloys. Mater. Sci. Eng., A. 480: 365-372

Floriano R, Leiva D R, Melo G C, Ishikawa T T, Huot J, Kaufman M, Figueroa S J A, Mendoza-Zelis L A, Damonte L C and Botta W J 2017 Low temperature rolling of AZ91 alloy for hydrogen storage. Int. J. Hydrogen Energy 42(49): 29394–29405

Ciftci I 2006 Machining of austenitic stainless steels using CVD multi-layer coated cemented carbide tools. Tribol. Int. 39(6): 565–569

Özlü B 2021 Investigation of the effect of cutting parameters on cutting force, surface roughness and chip shape in turning of Sleipner cold work tool steel. J. Fac. Eng. Archit. Gazi Univ. 36(3): 1241–1251

Demir H and Gündüz S 2009 The effects of aging on machinability of 6061 aluminium alloy. Mater. Des. 30: 1480–1483

Demir H, Gündüz S and Erden M A 2018 Influence of the heat treatment on the microstructure and machinability of AISI H13 hot work tool steel. Int. J. Adv. Manuf. Technol. 95(5): 2951–2958

Boothroyd G and Knight W A 2005 Fundamentals of metal machining and machine tools. London: 3rd Ed., CRC Press. p. 50–180

Polmear I J 1994 Magnesium alloys and applications. Mater. Sci. Technol. 10(1): 1–16

Danish M 2020 Chapter 10-high speed machining of magnesium and its alloys. High Speed Machining. Academic, London, p. 263–279

Dinesh S, Senthilkumar V, Asokan P and Arulkirubakaran D 2015 Effect of cryogenic cooling on machinability and surface quality of bio-degradable ZK60 Mg alloy. Mater. Des. 87: 1030–1036

Korkmaz M E, Yaşar N and Günay M 2020 Numerical and experimental investigation of cutting forces in turning of Nimonic 80A superalloy. Eng. Sci. Technol. Int. J. 23(3): 664–673

Thrinadh J, Mohapatra A, Datta S and Masanta M 2020 Machining behavior of Inconel 718 superalloy: Effects of cutting speed and depth of cut. Mater. Today Proc. 26: 200–208

Özel T 2006 The influence of friction models on finite element simulations of machining. Int. J. Mach. Tools Manuf. 46(5): 518–530

Kumar R, Bilga P S and Singh S 2017 Multi objective optimization using different methods of assigning weights to energy consumption responses, surface roughness and material removal rate during rough turning operation. J. Clean. Prod. 164: 45–57

Iç Y T, Yurdakul M, Dengiz B and Şaşmaz T 2023 Investigation of the importance of machine sequence flexibility on a flexible manufacturing system performance. GU J. Sci. 36(2): 735–750

Günay M and Meral T 2020 Modelling and multiresponse optimization for minimizing burr height, thrust force and surface roughness in drilling of ferritic stainless steel. Sādhanā 45: 273

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akgün, M. Measurement and optimization of cutting forces, surface roughness and temperature in turning of AZ91 Mg alloy. Sādhanā 48, 60 (2023). https://doi.org/10.1007/s12046-023-02113-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-023-02113-3