Abstract

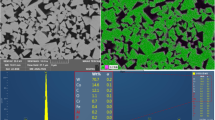

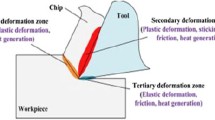

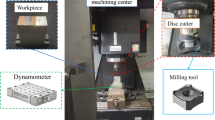

This present study aimed at the wear behaviors of uncoated carbide tools and its effect on machinability in dry milling of magnesium alloy at high cutting speeds. Through the experimental observations, the dominant wear mechanisms for the carbide tool were determined, namely adhesion, abrasion, and diffusion wear. Compared to lower speed, the experimental results indicated that the higher speed could bring much better surface quality in the steady wear stage; however, the duration of this stage was shorter than the lower. Within each steady wear, surface roughness declined gradually with the increasing cutting edge radius. Meanwhile, a mass of workpiece material piled up the stagnant zone below the cutting edge on the flank face, causing the flank built-up edge formation. Besides that, the built-up edge accumulated to a certain size that is beneficial to improve the machined surface quality. In addition, the chip morphologies depended on the severity of the tool wear. The cutting tool during the early period of cutting operation predominantly produced inerratic flake chips. However, with the development of built-up edge, there was a great quantity of threadlike chips formed, as well as the plentiful needlelike chips.

Similar content being viewed by others

References

Kulekci MK (2008) Magnesium and its alloys applications in automotive industry. Int J Adv Manuf Technol 39(9–10):851–865. doi:10.1007/s00170-007-1279-2

Polmear IJ (1994) Magnesium alloys and applications. Mater Sci Technol 10(1):1–16. doi:10.1179/026708394790163401

Mordike BL, Ebert T (2001) Magnesium: properties-applications-potential. Mater Sci Eng A 302(1):37–45

Schwerin R, Joksch S (2007) Experiences with the machining of magnesium. In: Proc. 7th Int. Conf. Magnes Alloy. Their Appl. pp 922–925

Denkena B, Becker JC, Podolsky C, Kuhlmann A (2005) Safe machining of magnesium parts by cutting and burnishing operations. In: Magnes. Proc. 6th Int. Conf. Magnes. Alloy. Their Appl. Verlag GmbH Co.KGaA. pp 895–901

Fang FZ, Lee LC, Liu XD (2005) Mean flank temperature measurement in high speed dry cutting of magnesium alloy. J Mater Process Technol 167(1):119–123. doi:10.1016/j.jmatprotec.2004.10.002

Hou JZ, Zhou W, Zhao N (2010) Effect of cutting parameters on ignition of AM50A Mg alloy during face milling. Mater Manuf Process 25(10):1048–1051. doi:10.1080/10426910903496870

Hou JZ, Zhao N, Zhu SL (2011) Influence of cutting speed on flank temperature during face milling of magnesium alloy. Mater Manuf Process 26(8):1059–1063. doi:10.1080/10426914.2010.536927

Liu M, Shih DS, Parish C, Atrens A (2012) The ignition temperature of Mg alloys WE43, AZ31 and AZ91. Corros Sci 54:139–142. doi:10.1016/j.corsci.2011.09.004

Carou D, Rubio EM, Davim J (2014) Analysis of ignition risk in intermittent turning of UNS M11917 magnesium alloy at low cutting speeds based on the chip morphology. Proc Inst Mech Eng B J Eng Manuf :1–7. doi: 10.1177/0954405414527961

Guo YB, Salahshoor M (2010) Process mechanics and surface integrity by high-speed dry milling of biodegradable magnesium–calcium implant alloys. CIRP Ann Manuf Technol 59(1):151–154. doi:10.1016/j.cirp.2010.03.051

Villeta M, de Agustina B, de Pipaón JMS, Rubio EM (2012) Efficient optimisation of machining processes based on technical specifications for surface roughness: application to magnesium pieces in the aerospace industry. Int J Adv Manuf Technol 60(9–12):1237–1246. doi:10.1007/s00170-011-3685-8

Shi KN, Zhang DH, Ren JX (2015) Optimization of process parameters for surface roughness and microhardness in dry milling of magnesium alloy using Taguchi with grey relational analysis. Int J Adv Manuf Technol 81(1–4):645–651. doi:10.1007/s00170-015-7218-8

Shi KN, Zhang DH, Ren JX, Yao CF, Huang XC (2016) Effect of cutting parameters on machinability characteristics in milling of magnesium alloy with carbide tool. Adv Mech Eng 8(1):1–9. doi:10.1177/1687814016628392

Pu Z, Outeiro JC, Batista AC, Dillon OW, Puleo DA, Jawahir IS (2012) Enhanced surface integrity of AZ31B Mg alloy by cryogenic machining towards improved functional performance of machined components. Int J Mach Tools Manuf 56:17–27. doi:10.1016/j.ijmachtools.2011.12.006

Nasr MNA, Outeiro JC (2015) Sensitivity analysis of cryogenic cooling on machining of magnesium alloy AZ31B-O. Procedia CIRP 31:264–269. doi:10.1016/j.procir.2015.03.030

Rubio EM, Villeta M, Carou D, Saá A (2014) Comparative analysis of sustainable cooling systems in intermittent turning of magnesium pieces. Int J Precis Eng Manuf 15(5):929–940. doi:10.1007/s12541-014-0419-5

Dinesh S, Senthilkumar V, Asokan P, Arulkirubakaran D (2015) Effect of cryogenic cooling on machinability and surface quality of bio-degradable ZK60 Mg alloy. Mater Des 87:1030–1036. doi:10.1016/j.matdes.2015.08.099

Gziut O, Kuczmaszewski J (2016) Analysis of chip fragmentation in AZ91HP alloy milling with respect to reducing the risk of chip ignition. Eksploatacja I Niezawodnosc 18(1):73

Twardowski P, Legutko S, Krolczyk GM, Hloch S (2015) Investigation of wear and tool life of coated carbide and cubic boron nitride cutting tools in high speed milling. Adv Mech Eng 7(6):1687814015590216

Tomac N, Tonnessen K, Rasch FO (1991) Formation of flank build-up in cutting magnesium alloys. CIRP Ann Manuf Technol 40(1):79–82

Tönshoff H, Winkler J (1997) The influence of tool coatings in machining of magnesium. Surf Coatings Technol 94-95:610–616. doi:10.1016/S0257-8972(97)00505-7

Wang J, Liu YB, An J, Wang LM (2008) Wear mechanism map of uncoated HSS tools during drilling die-cast magnesium alloy. Wear 265(5):685–691. doi:10.1016/j.wear.2007.12.009

Bhowmick S, Lukitsch MJ, Alpas AT (2010) Dry and minimum quantity lubrication drilling of cast magnesium alloy (AM60). Int J Mach Tools Manuf 50(5):444–457. doi:10.1016/j.ijmachtools.2010.02.001

Tlusty J (1993) High-speed machining. CIRP Ann Technol 42(2):733–738

Sanz C, Fuentes E, Obermair F, Muntada L (2007) Efficient and ecological machining of magnesium hybrid parts. In: Proc. Seventh Int. Conf. Mg Alloy. Their Appl. pp 916–921

Quiza R, Figueira L, Davim JP (2008) Comparing statistical models and artificial neural networks on predicting the tool wear in hard machining D2 AISI steel. Int J Adv Manuf Technol 37(7-8):641-648

Straffelini G (2015) Friction and Wear. Springer International Publishing, Switzerland. doi: 10.1007/978-3-319-05894-8

Bosheh SS, Mativenga PT (2006) White layer formation in hard turning of H13 tool steel at high cutting speeds using CBN tooling. Int J Mach Tools Manuf 46(2):225–233

Zhu DH, Zhang XM, Ding H (2013) Tool wear characteristics in machining of nickel-based superalloys. Int J Mach Tools Manuf 64:60–77. doi:10.1016/j.ijmachtools.2012.08.001

Özel T, Karpat Y, Figueira L, Davim J (2007) Modelling of surface finish and tool flank wear in turning of AISI D2 steel with ceramic wiper inserts. J Mater Process Technol 189(1):192–198

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, K., Ren, J., Zhang, D. et al. Tool wear behaviors and its effect on machinability in dry high-speed milling of magnesium alloy. Int J Adv Manuf Technol 90, 3265–3273 (2017). https://doi.org/10.1007/s00170-016-9645-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9645-6