Abstract

Surface tension plays a core role in dominating various surface and interface phenomena. For liquid metals with high melting temperature, a profound understanding of the behaviors of surface tension is crucial in industrial processes such as casting, welding, and solidification, etc. Recently, the room temperature liquid metal (RTLM) mainly composed of gallium-based alloys has caused widespread concerns due to its increasingly realized unique virtues. The surface properties of such materials are rather vital in nearly all applications involved from chip cooling, thermal energy harvesting, hydrogen generation, shape changeable soft machines, printed electronics to 3D fabrication, etc. owing to its pretty large surface tension of approximately 700 mN/m. In order to promote the research of surface tension of RTLM, this paper is dedicated to present an overview on the roles and mechanisms of surface tension of liquid metal and summarize the latest progresses on the understanding of the basic knowledge, theories, influencing factors and experimental measurement methods clarified so far. As a practical technique to regulate the surface tension of RTLM, the fundamental principles and applications of electrowetting are also interpreted. Moreover, the unique phenomena of RTLM surface tension issues such as surface tension driven selfactuation, modified wettability on various substrates and the functions of oxides are discussed to give an insight into the acting mechanism of surface tension. Furthermore, future directions worthy of pursuing are pointed out.

Similar content being viewed by others

References

Brackbill J U, Kothe D B, Zemach C. A continuum method for modeling surface tension. Journal of Computational Physics, 1992, 100(2): 335–354

Ko E Y, Choi J, Park J Y, Sohn I. Simulation of low carbon steel solidification and mold flux crystallization in continuous casting using a multi-mold simulator. Metals and Materials International, 2014, 20(1): 141–151

Shin M, Oh J S, Lee J, Jung S, Lee J. Dissolution rate of solid iron into liquid Fe-C alloy. Metals and Materials International, 2014, 20 (6): 1139–1143

Aqra F, Ayyad A. Surface tension of liquid alkali, alkaline, and main group metals: theoretical treatment and relationship investigations. Metallurgical and Materials Transactions A, Physical Metallurgy and Materials Science, 2011, 42(9): 2680–2684

Amin M R, Gosh R C, Bhuiyan G M. Surface tension of liquid transition and noble metals. Journal of Non-Crystalline Solids, 2013, 380: 42–47

Zhao J, Li J R, Liu S, Han M. A method to measure surface tension of liquid superalloy at room temperature. Hot Working Technology, 2009, 38(23): 57–60

Seo S M, Paik Y H, Kim D S, Lee W P. Interfacial tension and contact angle variations of SUS304 melt in contact with solid oxides and CaO-SiO2-Al2O3 (CaF2) slags at 1470°C. Metals and Materials International, 1996, 2(2): 65–69

Vitos L, Ruban A V, Skriver H L, Kollár J. The surface energy of metals. Surface Science, 1998, 411(1-2): 186–202

Kim S K, Wang W, Kang Y B. Modeling surface tension of multicomponent liquid steel using modified quasichemical model and constrained Gibbs energy minimization. Metals and Materials International, 2015, 21(4): 765–774

Gough R C, Morishita A M, Dang J H, Moorefield M R, Shiroma W A, Ohta A T. Rapid electrocapillary deformation of liquid metal with reversible shape retention. Micro & Nano Systems Letters, 2015, 3(1): 1–9

Yaws C L. Handbook of Vapor Pressure: Volume 4: Inorganic Componds and Elements. Huston: Gulf Professional Publishing, 1995

Blair F M, Whitworth J M, Mccabe J F. The physical properties of a gallium alloy restorative material. Dental Materials Official Publication of the Academy of Dental Materials, 1995, 11(4): 277–280

Zhang Q, Zheng Y, Liu J. Direct writing of electronics based on alloy and metal (DREAM) ink: a newly emerging area and its impact on energy, environment and health sciences. Frontiers in Energy, 2012, 6(4): 311–340

Yang X H, Tan S C, Liu J. Thermal management of Li-ion battery with liquid metal. Energy Conversion and Management, 2016, 117: 577–585

Ge H S, Liu J. Keeping smartphones cool with gallium phase change material. Journal of Heat Transfer, 2013, 135(5): 054503

Ge H S, Li H Y, Mei S F, Liu J. Low melting point liquid metal as a new class of phase change material: an emerging frontier in energy area. Renewable & Sustainable Energy Reviews, 2013, 21: 331–346

Deng Y G, Liu J. Design of practical liquid metal cooling device for heat dissipation of high performance CPUs. Journal of Electronic Packaging, 2010, 132(3): 031009

Ma K Q, Liu J. Nano liquid-metal fluid as ultimate coolant. Physics Letters A, 2007, 361(3): 252–256

Vetrovec J, Litt A S, Copeland D A, Junghans J, Durkee R. Liquid metal heat sink for high-power laser diodes. In: International Society for Optics and Photonics, California, USA: SPIE LASE, 2013: 86050

Jackel J L, Hackwood S, Veselka J J, Beni G. Electrowetting switch for multimode optical fibers. Applied Optics, 1983, 22(11): 1765–1770

Sen P, Kim C J. Microscale liquid-metal switches—a review. IEEE Transactions on Industrial Electronics, 2009, 56(4): 1314–1330

Tsai J T H, Ho C M,Wang F C, Liang C T. Ultrahigh contrast light valve driven by electrocapillarity of liquid gallium. Applied Physics Letters, 2009, 95(25): 251110

Ponce Wong R D, Posner J D, Santos V J. Flexible microfluidic normal force sensor skin for tactile feedback. Sensors and Actuators A, Physical, 2012, 179: 62–69

Majidi C, Kramer R, Wood R J. A non-differential elastomer curvature sensor for softer-than-skin electronics. Smart Materials and Structures, 2011, 20(10): 105017

Park Y L, Majidi C, Kramer R, Bérard P, Wood R J. Hyperelastic pressure sensing with a liquid-embedded elastomer. Journal of Micromechanics and Microengineering, 2010, 20(12): 125029

Fassler A, Majidi C. Soft-matter capacitors and inductors for hyperelastic strain sensing and stretchable electronics. Smart Materials and Structures, 2013, 22(5): 055023

Cheng S, Wu Z. A microfluidic, reversibly stretchable, large-area wireless strain sensor. Advanced Functional Materials, 2011, 21 (12): 2282–2290

So J H, Thelen J, Qusba A, Hayes G J, Lazzi J, Dickey M D. Reversibly deformable and mechanically tunable fluidic antennas. Advanced Functional Materials, 2009, 19(22): 3632–3637

Cheng S, Rydberg A, Hjort K, Wu Z. Liquid metal stretchable unbalanced loop antenna. Applied Physics Letters, 2009, 94(14): 144103

Kubo M, Li X, Kim C, Hashimoto M, Wiley B J, Ham D, Whitesides G M. Stretchable microfluidic radiofrequency antennas. Advanced Materials, 2010, 22(25): 2749–2752

Hayes G J, So J H, Qusba A, Dickey M D, Lazzi G. Flexible liquid metal alloy (EGaIn) microstrip patch antenna. IEEE Transactions on Antennas and Propagation, 2012, 60(5): 2151–2156

Tang S Y, Khoshmanesh K, Sivan V, Petersen P, O’mullane A P, Abbott D, Mitchell A, Kalantarzadeh K. Liquid metal enabled pump. Proceedings of the National Academy of Sciences of the United States of America, 2014, 111(9): 3304–3309

Tang S Y, Sivan V, Petersen P, Zhang W, Morrison P D, Kalantar-Zadeh K, Mitchell A, Khoshmanesh K. Liquid metal actuator for inducing chaotic advection. Advanced Functional Materials, 2014, 24(37): 5851–5858

Zhang J, Sheng L, Jin C, Liu J. Liquid metal as connecting or functional recovery channel for the transected sciatic Nerve. Eprint arXiv:1404.5931, 2014

Jin C, Zhang J, Li X, Yang X K, Yang X Y, Li J J, Liu J. Injectable 3-D fabrication of medical electronics at the target biological tissues. Scientific Reports, 2013, 3: 3442

Wang Q, Yu Y, Pan K Q, Liu J. Liquid metal angiography for mega contrast X-ray visualization of vascular network in reconstructing in-vitro organ anatomy. IEEE Transactions on Biomedical Engineering, 2014, 61(7): 2161–2166

Lu Y, Hu Q Y, Lin Y L, Pacardo D, Wang C, Sun W J, Ligler F S, Dickey M D, Gu Z. Transformable liquid-metal nanomedicine. Nature Communications, 2015, 6: 10066

Zhang J, Guo R, Liu J. Self-propelled liquid metal motors steered by a magnetic or electrical field for drug delivery. Journal of Materials Chemistry B, Materials for Biology and Medicine, 2016, 4(32): 5349–5357

Jeong S H, Hagman A, Hjort K, Jobs M, Sundqvist J,Wu Z. Liquid alloy printing of microfluidic stretchable electronics. Lab on a Chip, 2012, 12(22): 4657–4664

Tabatabai A, Fassler A, Usiak C, Majidi C. Liquid-phase gallium–indium alloy electronics with microcontact printing. Langmuir, 2013, 29(20): 6194–6200

Gozen B A, Tabatabai A, Ozdoganlar O B, Majidi C. High-density soft-matter electronics with micron-scale line width. Advanced Materials, 2014, 26(30): 5211–5216

Wang L, Liu J. Liquid phase 3D printing for quickly manufacturing conductive metal objects with low melting point alloy ink. Science China. Technological Sciences, 2014, 57(9): 1721–1728

Wang L, Liu J. Compatible hybrid 3D printing of metal and nonmetal inks for direct manufacture of end functional devices. Science China, Technological Sciences, 2014, 57(11): 2089–2095

Zhang J, Yao Y Y, Sheng L, Liu J. Self-fueled biomimetic liquid metal mollusk. Advanced Materials, 2015, 27(16): 2648–2655

Tan S C, Yuan B, Liu J. Electrical method to control the running direction and speed of self-powered tiny liquid metal motors. Proceedings–Royal Society. Mathematical, Physical and Engineering Sciences, 2015, 471(2183): 20150297

Tan S C, Gui H, Yuan B, Liu J. Magnetic trap effect to restrict motion of self-powered tiny liquid metal motors. Applied Physics Letters, 2015, 107(7): 071904

Tang X, Tang S Y, Sivan V, Zhang W, Mitchell A, Kalantarzadeh K, Khoshmanesh K. Photochemically induced motion of liquid metal marbles. Applied Physics Letters, 2013, 103(17): 174104

Zavabeti A, Daeneke T, Chrimes A F, O’Mullane A P, Ou J Z, Mitchell A, Khoshmanesh K, Kalantar-zadeh K. Ionic imbalance induced self-propulsion of liquid metals. Nature Communications, 2016, 7: 12402

Mei S F, Gao Y X, Li H Y, Deng Z S, Liu J. Thermally induced porous structures in printed gallium coating to make transparent conductive film. Applied Physics Letters, 2013, 102(4): 041905

Doudrick K, Liu S, Mutunga EM, Klein K L, Damle V, Varanasi K K, Rykaczewski K. Different shades of oxide: from nanoscale wetting mechanisms to contact printing of gallium-based liquid metals. Langmuir, 2014, 30(23): 6867–6877

Regan M J, Tostmann H, Pershan P S, Magnussen O M, Dimasi E, Ocko B M, Deutsch M. X-ray study of the oxidation of liquidgallium surfaces. Physical Review B: Condensed Matter and Materials Physics, 1997, 55(16): 10786–10790

Regan M J, Pershan P S, Magnussen O M, Ocko B M, Deutsch M, Berman L E. X-ray reflectivity studies of liquid metal and alloy surfaces. Physical Review B: Condensed Matter, 1997, 55(23): 15874–15884

Cademartiri L, Thuo M M, Nijhuis C A, Reus W F, Tricard S, Barber J R, Sodhi R N S, Brodersen P, Kim C, Chiechi R C, Whitesides G M. Electrical resistance of AgTS–S(CH2)n–1CH3//Ga2O3/EGaIn tunneling junctions. Journal of Physical Chemistry C, 2012, 116(20): 10848–10860

Ilyas N, Butcher D P, Durstock M F, Tabor C E. Ion exchange membranes as an interfacial medium to facilitate gallium liquid metal alloy mobility. Advanced Materials Interfaces, 2016, 3(9): 1500665

Tang J, Zhou Y, Liu J, Wang J, Zhu W. Liquid metal actuated ejector vacuum system. Applied Physics Letters, 2015, 106(3): 031901

Baldwin M J, Lynch T, Chousal L, Seraydarian R P, Doerner R P, Luckhardt S C. An injector device for producing clean-surface liquid metal samples of Li, Ga and Sn–Li in vacuum. Fusion Engineering and Design, 2004, 70(2): 107–113

Liu T, Sen P, Kim C J. Characterization of nontoxic liquid-metal alloy Galinstan for applications in microdevices. Journal of Microelectromechanical Systems, 2012, 21(2): 443–450

Zhang Q, Gao Y X, Liu J. Atomized spraying of liquid metal droplets on desired substrate surfaces as a generalized way for ubiquitous printed electronics. Applied Physics A, 2014, 116: 1091–1097

Gao Y X, Liu J. Gallium-based thermal interface material with high complianceand wettability. Applied Physics A, Materials Science & Processing, 2012, 107(3): 701–708

Esinenco D, Codreanu I, Rebigan R. Design of inkjet printing head, based on electrowetting effect, for printable electronics applications. In: International Semiconductor Conference, Sinaia, Romania: IEEE, 2006, 2: 443–446

Semenchenko V K. Surface Phenomena in Metals and Alloys. Oxford: Pergamon Press, 1962

Chacon E, Flores F, Navascues G. A theory for liquid metal surface tension. Journal of Physics F: Metal Physics, 1984, 14(7): 1587–1601

Safran S A. Statistical Thermodynamics of Surfaces, Interfaces, and Membranes. Vol. 90. New York: Perseus Books, 1994

Mersmann A. Calculation of interfacial tensions. Journal of Crystal Growth, 1990, 102(4): 841–847

Jain T S, De Pablo J J. Calculation of interfacial tension from density of states. Journal of Chemical Physics, 2003, 118(9): 4226–4229

Digilov R M. Semi-empirical model for prediction of crystal–melt interfacial tension. Surface Science, 2004, 555(1–3): 68–74

Nino-Amezquita O G, Enders S, Jaeger P T, Eggers R. Measurement and prediction of interfacial tension of binary mixtures. Industrial & Engineering Chemistry Research, 2010, 49(2): 592–601

Gloor G J, Jackson G, Blas F, Del Rio E M, De Miguel E. Prediction of the vapor-liquid interfacial tension of nonassociating and associating fluids with the SAFT-VR density functional theory. Journal of Physical Chemistry C, 2007, 111(43): 15513–15522

Barrett J C. Some estimates of the surface tension of curved surfaces using density functional theory. Journal of Chemical Physics, 2006, 124(14): 144705

Fu D, Lu J F, Liu J C, Li Y G. Prediction of interfacial tension for binary liquid-liquid systems based on density functional theory. Journal of Chemical Industry and Engineering, 2002, 53(9): 892–898

Telo Da Gama M, Evans R, Sluckin T. The structure and surface tension of the liquid-vapour interface of a model of a molten salt. Molecular Physics, 1980, 41(6): 1355–1372

Weeks J D. Structure and thermodynamics of the liquid–vapor interface. Journal of Chemical Physics, 1977, 67(7): 3106–3121

Johnson M, Nordholm S. Generalized van der Waals theory. VI. Application to adsorption. Journal of Chemical Physics, 1981, 75 (4): 1953–1957

Ho P S, Kwok T. Electromigration in metals. Reports on Progress in Physics, 1989, 52(3): 301–348

Pai S T, Marton J P. Electromigration in metals. Canadian Journal of Physics, 1977, 55(2): 103–115

Beni G, Hackwood S, Jackel J L. Continuous electrowetting effect. Applied Physics Letters, 1982, 40(10): 912–914

Gongadze E, Van R U, Iglic A. Generalized stern models of the electric double layer considering the spatial variation of permittvity and finite size of ions in saturation regime. Cellular & Molecular Biology Letters, 2011, 16(4): 576–594

Grahame D C. Electrode processes and the electrical double layer. Annual Review of Physical Chemistry, 1955, 6(1): 337–358

Daywitt W C. The electron-vacuum coupling force in the Dirac electron theory and its relation to the zitterbewegung. Progress in Physics, 2013, 3: 25–28

Enderby J, March N. Electron theory of metals and liquid state theory. Advances in Physics, 1967, 16(64): 691–702

Scatchard G. The Gibbs adsorption isotherm 1. Journal of physical chemistry, 1962, 66(4): 618–620

Lippmann G. Relationship between the electric and capillary phenomena. Gauthier-Villars, 1875 (in French)

Quinn A, Sedev R, Ralston J. Contact angle saturation in electrowetting. Journal of Physical Chemistry B, 2005, 109(13): 6268–6275

Nogi K, Ogino K, McLean A, Miller W A. The temperature coefficient of the surface tension of pure liquid metals. Metallurgical Transactions B, Process Metallurgy, 1986, 17(1): 163–170

Keene B J. Review of data for the surface tension of pure metals. International Materials Reviews, 1993, 38(4): 157–192

Wikipedia. Surface tension. https://en.wikipedia.org/wiki/Surface_tension. 2016-11-13

Lu H M, Jiang Q. Surface tension and its temperature coefficient for liquid metals. Journal of Physical Chemistry B, 2005, 109(32): 15463–15468

Dayal B. Surface tension and melting point. Nature, 1952, 169 (4311): 1010

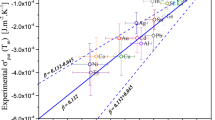

Xiao G. An empirical formula between the surface tensions and the melting points for metals. Jiangxi Science, 1987, 5(4): 31–35 (in Chinese)

Ceotto D. Empirical equation for predicting the surface tension of some liquid metals at their melting point. Russian Journal of Physical Chemistry, 2014, 88(7): 1269–1272

Aqra F, Ayyad A. Surface energies of metals in both liquid and solid states. Applied Surface Science, 2011, 257(15): 6372–6379

Arafune K, Sugiura M, Hirata A. Investigation of thermal Marangoni convection in low-and high-Prandtl-number fluids. Journal of Chemical Engineering of Japan, 1999, 32(1): 104–109

Eustathopoulos N, Drevet B, Ricci E. Temperature coefficient of surface tension for pure liquid metals. Journal of Crystal Growth, 1998, 191(1–2): 268–274

Kobatake H, Brillo J, Schmitz J, Pichon P Y. Surface tension of binary Al–Si liquid alloys. Journal of Materials Science, 2015, 50 (9): 3351–3360

Scheller P R. Surface effects and flow conditions in small volume melts with varying sulphur content. Steel Research, 2001, 72(3): 76–80

Yu J J, Ruan D F, Li Y R, Chen J C. Experimental study on thermocapillary convection of binary mixture in a shallow annular pool with radial temperature gradient. Experimental Thermal and Fluid Science, 2015, 61: 79–86

Zhang Q Z, Peng L, Wang F, Liu J. Thermocapillary convection with bidirectional temperature gradients in a shallow annular pool of silicon melt: effects of ambient temperature and pool rotation. International Journal of Heat and Mass Transfer, 2016, 101: 354–364

Wikipedia. Marangoni effect. https://en.wikipedia.org/wiki/Marangoni_effect. 2016-10-16

Alchagirov B B, Mozgovoi A G. The surface tension of molten gallium at high temperatures. High Temperature, 2005, 43(5): 791–792

Alchagirov B B, Dadashev R K, Dyshekova F F, Elimkhanov D Z. Temperature dependence of the surface tension of indium. Russian Journal of Physical Chemistry A, 2013, 87(6): 890–894

Alchagirov A B, Alchagirov B B, Khokonov K B. A device for the study of the surface tension of liquid metal solutions with an increased elasticity of intrinsic vapors. Instruments and Experimental Techniques, 2003, 46(3): 413–415

Ozawa S, Takahashi S, Suzuki S, Sugawara H, Fukuyama H. Relationship of surface tension, oxygen partial pressure, and temperature for molten iron. Japanese Journal of Applied Physics, 2011, 50(11S): 11R05

Ozawa S, Takahashi S, Watanabe N, Fukuyama H. Influence of oxygen adsorption on surface tension of molten nickel measured under reducing gas atmosphere. International Journal of Thermophysics, 2014, 35(9–10): 1705–1711

Aqra F, Ayyad A. Surface tension of pure liquid bismuth and its temperature dependence: theoretical calculations. Materials Letters, 2011, 65(4): 760–762

Aqra F, Ayyad A. Theoretical temperature-dependence surface tension of pure liquid gold. Materials Letters, 2011, 65(14): 2124–2126

Dubberstein T, Heller H P. Surface tension and density of liquid gold, silver, and tin. High Temperatures–High Pressures, 2015, 44 (5): 393–406

Yakimovich K A, Mozgovoi A G. Experimental investigation of the density and surface tension of molten lithium at temperatures up to 1300 K. High Temperature, 2000, 38(4): 657–659

Fima P, Nowak R, Sobczak N. Effect of metal purity and testing procedure on surface tension measurements of liquid tin. Journal of Materials Science, 2010, 45(8): 2009–2014

Ricci E, Arato E, Passerone A, Costa P. Oxygen tensioactivity on liquid-metal drops. Advances in Colloid and Interface Science, 2005, 117(1–3): 15–32

Fima P. Surface tension and density of liquid Sn–Ag alloys. Applied Surface Science, 2011, 257(8): 3265–3268

Fima P. Surface tension and density of liquid Sn–Cu alloys. Applied Surface Science, 2010, 257(2): 468–471

Aqra F, Ayyad A, Takrori F. Model calculation of the surface tension of liquid Ga–Bi alloy. Applied Surface Science, 2011, 257 (8): 3577–3580

Ricci E, Nanni L, Vizza M, Passerone A. Dynamic surface tension measurements of liquid metals in the presence of oxygen. In: International conference on high temperature capillarity HTC, Krakow, Poland: Foundry Research Institute,1997: 188–193

Ozawa S, Morohoshi K, Hibiya T, Fukuyama H. Influence of oxygen partial pressure on surface tension of molten silver. Journal of Applied Physics, 2010, 107(1): 014910

Heiple C R. Mechanism for minor element effect on GTA fusion zone geometry. Welding Journal, 1982, 61(4): 97–102

Alchagirov B B, Dadashev R K, Dyshekova F F, Elimkhanov D Z. The surface tension of indium: methods and results of investigations. High Temperature, 2014, 52(6): 920–938

Yuan Z F, Mukai K, Takagi K, Ohtaka M, Huang W L, Liu Q S. Surface tension and its temperature coefficient of molten tin determined with the sessile drop method at different oxygen partial pressures. Journal of Colloid and Interface Science, 2002, 254(2): 338–345

Fiori L, Ricci E, Arato E. Dynamic surface tension measurements on molten metal-oxygen systems: model validation on molten tin. Acta Materialia, 2003, 51(10): 2873–2890

Giuranno D, Ricci E, Arato E, Costa P. Dynamic surface tension measurements of an aluminium–oxygen system. Acta Materialia, 2006, 54(10): 2625–2630

Ricci E, Lanata T, Giuranno D, Arato E. The effective oxidation pressure of indium-oxygen system. Journal of Materials Science, 2008, 43(9): 2971–2977

Ricci E, Ratto M, Arato E, Costa P, Passerone A. A theoretical approach for the interpretation of liquid metal surface tension measurements in the presence of oxygen. Transactions of the Iron & Steel Institute of Japan, 2000, 40 (Suppl): S139–S143

Ghetta V, Fouletier J, Chatain D. Oxygen adsorption isotherms at the surfaces of liquid Cu and Au-Cu alloys and their interfaces with Al2O3 detected by wetting experiments. Acta Materialia, 1996, 44 (5): 1927–1936

Yuan Z, Fan J, Li J, Ke J, Mukai K. Surface tension of molten bismuth at different oxygen partial pressure with the sessile drop method. Scandinavian Journal of Metallurgy, 2004, 33(6): 338–346

Abbasi M, Lee J, Shin M, Kim Y, Kang Y. Effect of oxygen adsorption on surface tension of liquid copper: experiments and thermodynamic models. Applied Surface Science, 2014, 313: 116–122

Kasama A, Mclean A, Miller W A, Morita Z, Ward M J. Surface tension of liquid iron and iron-oxygen alloys. Canadian Metallurgical Quarterly, 1983, 22(1): 9–17

Morohoshi K, Uchikoshi M, Isshiki M, Fukuyama H. Surface tension of liquid iron as functions of oxygen activity and temperature. ISIJ International, 2011, 51(10): 1580–1586

SanSoucieM P, Rogers J R, Kumar V, Rodriguez J, Xiao X, Matson D M. Effects of environmental oxygen content and dissolved oxygen on the surface tension and viscosity of liquid nickel. International Journal of Thermophysics, 2016, 37: 76

Fiori L, Ricci E, Arato E, Costa P. Dynamic surface tension measurements on a molten metal-oxygen system: the behaviour of the temperature coefficient of the surface tension of molten tin. Journal of Materials Science, 2005, 40(9): 2155–2159

Ricci E, Passerone A, Joud J C. Thermodynamic study of adsorption in liquid metal-oxygen systems. Surface Science, 1988, 206(3): 533–553

Shebzukhova M A, Shebzukhov Z A, Shebzukhov A A. The Tolman parameter, self-absorption, and surface tension on flat and curved surfaces of liquid metals. Bulletin of the Russian Academy of Sciences. Physics, 2010, 74(5): 697–704

Tolman R C. The effect of droplet size on surface tension. Journal of Chemical Physics, 1949, 17(3): 333–337

Lu H M, Jiang Q. Size dependent surface energy and surface tension. In: IEEE Conference on Emerging Technologies-Nanoelectronics, Singapore: IEEE, 2006: 21–24

Shebzukhova M A, Shebzukhov A A. Surface energy and surface tension of liquid metal nanodrops. EPJ Web of Conferences. EDP Sciences, 2011, 15: 01027

Vinš V, Fransen M, Hykl J, Hrubý J. Surface tension of supercooled water determined by using a counterpressure capillary rise method. Journal of Physical Chemistry B, 2015, 119(17): 5567–5575

Ghatee M H, Ghazipour H. Highly accurate liquid–liquid interfacial tension measurement by a convenient capillary apparatus. Fluid Phase Equilibria, 2014, 377: 76–81

Luo R, Zhang D, Zeng Z, Lytton R L. Effect of surface tension on the measurement of surface energy components of asphalt binders using the Wilhelmy plate method. Construction & Building Materials, 2015, 98: 900–909

Soucková M, Klomfar J, Pátek J. Surface tension of 1-alkyl-3-methylimidazolium based ionic liquids with trifluoromethanesulfonate and tetrafluoroborate anion. Fluid Phase Equilibria, 2011, 303(2): 184–190

Klomfar J, Soucková M, Pátek J. Surface tension measurements with validated accuracy for four 1-alkyl-3-methylimidazolium based ionic liquids. Journal of Chemical Thermodynamics, 2010, 42(3): 323–329

Alkindi A S, Alwahaibi Y M, Muggeridge A H. Physical properties (density, excess molar volume, viscosity, surface tension, and refractive index) of ethanol + glycerol. Journal of Chemical & Engineering Data, 2008, 53(12): 2793–2796

Fainerman V B, Miller R, Joos P. The measurement of dynamic surface tension by the maximum bubble pressure method. Colloid & Polymer Science, 1994, 272(6): 731–739

Fainerman V B, Kazakov V N, Lylyk S V, Makievski A V, Miller R. Dynamic surface tension measurements of surfactant solutions using the maximum bubble pressure method — limits of applicability. Colloids and Surfaces A, Physicochemical and Engineering Aspects, 2004, 250(1–3): 97–102

Sangiorgi R, Muolo M L, Chatain D, Eustathopoulos N. Wettability and work of adhesion of nonreactive liquid metals on silica. Journal of the American Ceramic Society, 1988, 71(9): 742–748

Man K F. Surface tension measurements of liquid metals by the quasi-containerless pendant drop method. International Journal of Thermophysics, 2000, 21(3): 793–804

Vinet B, Garandet J P, Cortella L. Surface tension measurements of refractory liquid metals by the pendant drop method under ultrahigh vacuum conditions: extension and comments on Tate’s law. Journal of Applied Physics, 1993, 73(8): 3830–3834

Keene B J, Mills K C, Brooks R F. Surface properties of liquid metals and their effects on weldability. Materials Science and Technology, 1985, 1(7): 559–567

Takiguchi H, Nagasaka Y. Development of near-infrared laserinduced capillary wave method to measure viscosity and surface tension. Transactions of the Japan Society of Mechanical Engineers, 2013, 79(800): 690–700

Osada R, Hoshino T, Okada K, Ohmasa Y, YaoM. Surface tension of room temperature ionic liquids measured by dynamic light scattering. Journal of Chemical Physics, 2009, 130(18): 184705

Korkmaz S D, Korkmaz S. Investigation of surface properties of liquid transition metals: surface tension and surface entropy. Applied Surface Science, 2010, 257(1): 261–265

Bashforth F, Adams J C. An Attempt to Test the Theories of Capillary Action: by Comparing the Theoretical and Measured Forms of Drops of Fluid with an Explanation of the Method of Integration Employed in Constucting the Tables Which Give the Theoretical Forms of Such Drops. Cambridge: Cambridge University Press, 1883

Andreas J, Hauser E, Tucker W. Boundary tension by pendant drops 1. Journal of Physical Chemistry, 1938, 42(8): 1001–1019

Schaefers K, Kuppermann G, Thiedemann U, Qin J, Frohberg M. A new variant for measuring the surface tension of liquid metals and alloys by the oscillating drop method. International Journal of Thermophysics, 1996, 17(5): 1173–1179

Pichon E, Nain D. A Laplace equation approach for shape comparison. Proceedings of SPIE–The International Society for Optics and Photonics, 2006, 6141: 614119

Naidich J V. The wettability of solids by liquid metals. Progress in Surface & Membrane Science, 1981, 14: 353–484

Lee J, Kiyose A, Nakatsuka S, Nakamoto M, Tanaka T. Improvements in surface tension measurements of liquid metals having low capillary constants by the constrained drop method. ISIJ International, 2004, 44(11): 1793–1799

Plevachuk Y, Sklyarchuk V, Gerbeth G, Eckert S, Novakovic R. Surface tension and density of liquid Bi–Pb, Bi–Sn and Bi–Pb–Sn eutectic alloys. Surface Science, 2011, 605(11–12): 1034–1042

Sobczak N, Nowak R, Radziwill W, Budzioch J, Glenz A. Experimental complex for investigations of high temperature capillarity phenomena. Materials Science and Engineering A, 2008, 495(12): 43–49

Liggieri L, Passerone A. An automatic technique for measuring the surface tension of liquid metals. High Temperature Technology, 1989, 7(2): 82–86

Maze C, Burnet G. A non-linear regression method for calculating surface tension and contact angle from the shape of a sessile drop. Surface Science, 1969, 13(2): 451–470

Aune R, Seetharaman S, Battezzati L, Egry I, Schmidt-Hohagen F, Etay J, Fecht H J, Wunderlich R, Passerone A, Ricci E, Novakovic R, Giuranno D. Surface tension measurements of Al-Ni based alloys from ground-based and parabolic flight experiments: results from the ThermoLab project. Microgravity Science and Technology, 2006, 18: 73

Egry I, Brooks R, Hollandmoritz D, Novakovic R, Matsushita T, Ricci E, Seetharaman S, Wunderlich R, Jarvis D. Thermophysical properties of ?-titanium aluminide: the European IMPRESS Project. International Journal of Thermophysics, 2007, 28(3): 1026–1036

Kucharski M, Fima P, Skrzyniarz P, Przebinda-Stefanowa W. Surface tension and density of Cu-Ag, Cu-In and Ag-In alloys. Archives of Metallurgy and Materials, 2006, 51(3): 389–397

Plevachuk Y, Hoyer W, Kaban I, Köhler M, Novakovic R. Experimental study of density, surface tension, and contact angle of Sn-Sb-based alloys for high temperature soldering. Journal of Materials Science, 2010, 45(8): 2051–2056

Lee J, Le T H, Shin M. Density and surface tension of liquid Fe-Mn alloys. Metallurgical and Materials Transactions B, Process Metallurgy and Materials Processing Science, 2011, 42(3): 546–549

Brillo J, Plevachuk Y, Egry I. Surface tension of liquid Al–Cu–Ag ternary alloys. Journal of Materials Science, 2010, 45(19): 5150–5157

Willner J, Siwiec G, Botor J. The surface tension of liquid Cu–Fe–Sb alloys. Applied Surface Science, 2010, 256(9): 2939–2943

Guo Z, Hindler M, Yuan W, Mikula A. The density and surface tension of In–Sn and Cu–In–Sn alloys. Monatshefte für Chemie-Chemical Monthly, 2011, 142(6): 579–584

Guo Z N, Li S, Mikula A, YuanWX. Surface tension of liquid Au-Bi-Sn alloys. Rare Metals, 2012, 31(3): 250–254

Chentsov V P, Shevchenko V G, Mozgovoi A G, Pokrasin M A. Density and surface tension of heavy liquid-metal coolants: Gallium and indium. Inorganic Materials: Applied Research, 2011, 2(5): 468–473

Novakovic R, Ricci E, Giuranno D, Passerone A. Surface and transport properties of Ag–Cu liquid alloys. Surface Science, 2005, 576(1–3): 175–187

Egry I, Hollandmoritz D, Novakovic R, Ricci E, Wunderlich R, Sobczak N. Thermophysical properties of liquid AlTi-based alloys. International Journal of Thermophysics, 2010, 31(4): 949–965

Nowak R, Lanata T, Sobczak N, Ricci E, Giuranno D, Novakovic R, Hollandmoritz D, Egry I. Surface tension of ?-TiAl-based alloys. Journal of Materials Science, 2010, 45(8): 1993–2001

Ricci E, Giuranno D, Sobczak N. Further development of testing procedures for high temperature surface tension measurements. Journal of Materials Engineering and Performance, 2013, 22(11): 3381–3388

Amore S, Giuranno D, Novakovic R, Ricci E, Nowak R, Sobczak N. Thermodynamic and surface properties of liquid Ge-Si alloys. Calphad-computer Coupling of Phase Diagrams & Thermochemistry, 2014, 44(1): 95–101

Okress E C, Wroughton D M, Comenetz G, Brace P H, Kelly J C R. Electromagnetic levitation of solid and molten metals. Journal of Applied Physics, 1952, 23(5): 545–552

Fraser M E, Lu W K, Hamielec A E, Murarka R. Surface tension measurements on pure liquid iron and nickel by an oscillating drop technique. Metallurgical and Materials Transactions B, Process Metallurgy and Materials Processing Science, 1971, 2(3): 817–823

Murarka R, Lu W K, Hamielec A E. Surface tension of pure liquid and supercooled iron. Metallurgical and Materials Transactions B, Process Metallurgy and Materials Processing Science, 1971, 2(10): 2949–2950

Murarka R N, Lu W K, Hamielec A E. Effect of dissolved oxygen on the surface tension of liquid iron. Canadian Metallurgical Quarterly, 1975, 14(2): 111–115

Egry I, Ricci E, Novakovic R, Ozawa S. Surface tension of liquid metals and alloys–recent developments. Advances in Colloid and Interface Science, 2010, 159(2): 198–212

Brillo J, Lohöfer G, Schmidt-Hohagen F, Schneider S, Egry I. Thermophysical property measurements of liquid metals by electromagnetic levitation. International Journal of Materials & Product Technology, 2006, 26(3/4): 247–273

Egry I, Lohoefer G, Jacobs G. Surface tension of liquid metals: results from measurements on ground and in space. Physical Review Letters, 1995, 75(22): 4043–4046

Cummings D L, Blackburn D A. Oscillations of magnetically levitated aspherical droplets. Journal of Fluid Mechanics, 1991, 224: 395–416

Brillo J, Egry I, Matsushita T. Density and surface tension of liquid ternary Ni-Cu-Fe alloys. International Journal of Thermophysics, 2006, 97(1): 28–34

Brillo J, Egry I. Surface tension of nickel, copper, iron and their binary alloys. Journal of Materials Science, 2005, 40(9): 2213–2216

Egry I, Brillo J. Surface tension and density of liquid metallic alloys measured by electromagnetic levitation. Journal of Chemical & Engineering Data, 2009, 54(9): 2347–2352

Schmitz J, Brillo J, Egry I. Surface tension of liquid Cu and anisotropy of its wetting of sapphire. Journal of Materials Science, 2010, 45(8): 2144–2149

Brillo J, Kolland G. Surface tension of liquid Al-Au binary alloys. Journal of Materials Science, 2016, 51(10): 4888–4901

Brillo J, Egry I, Westphal J. Density and thermal expansion of liquid binary Al-Ag and Al-Cu alloys. International Journal of Materials Research, 2008, 99(2): 162–167

Brillo J, Lauletta G, Vaianella L, Arato E, Giuranno D, Novakovic R, Ricci E. Surface tension of liquid Ag–Cu binary alloys. Transactions of the Iron & Steel Institute of Japan, 2014, 54(9): 2115–2119

Wunderlich R K, Fecht H J. Surface tension and viscosity of NiAl catalytic precursor alloys from microgravity experiments. International Journal of Materials Research, 2011, 102(9): 1164–1173

Amore S, Brillo J, Egry I, Novakovic R. Surface tension of liquid Cu-Ti binary alloys measured by electromagnetic levitation and thermodynamic modelling. Applied Surface Science, 2011, 257 (17): 7739–7745

Zhou K, Wang H P, Chang J, Wei B. Surface tension measurement of metastable liquid Ti–Al–Nb alloys. Applied Physics A, Materials Science & Processing, 2011, 105(1): 211–214

Chang J, Wang H P, Zhou K, Wei B. Surface tension measurement of undercooled liquid Ni-based multicomponent alloys. Philosophical Magazine Letters, 2012, 92(9): 428–435

Egry I, Lohöfer G, Neuhaus P, Sauerland S. Surface tension measurements of liquid metals using levitation, microgravity, and image processing. International Journal of Thermophysics, 1992, 13(1): 65–74

Egry I. Surface tension measurements of liquid metals by the oscillating drop technique. Journal of Materials Science, 1991, 26 (11): 2997–3003

Egry I, Lohoefer G, Schwartz E, Szekely J, Neuhaus P. Surface tension measurements on liquid metals in microgravity. Metallurgical and Materials Transactions B, Process Metallurgy and Materials Processing Science, 1998, 29(5): 1031–1035

Ohnishi M, Nagasaka Y. Measurement of surface tension and viscosity of molten lithium niobate by the surface laser-light scattering method. High Temperatures—High Pressures, 2000, 32 (1): 103–108

Levich V G. Physicochemical Hydrodynamics. New Jersey: Prentice Hall, 1962

Nagasaka Y, Kobayashi Y. Effect of atmosphere on the surface tension and viscosity of molten LiNbO3 measured using the surface laser-light scattering method. Journal of Crystal Growth, 2007, 307(1): 51–58

Wang F K, Yue H Y, Fan X W, Liu Z G. Surface tension and viscosity measurement with surface laser light scattering method. Thermal Science, 2013, 17(5): 1467–1471

Ayyad A, Aqra F. Theoretical consideration of the anomalous temperature dependence of the surface tension of pure liquid gallium. Theoretical Chemistry Accounts, 2010, 127(5): 443–448

Ayyad A, Mechdiev I, Freyland W. Light scattering study of surface freezing and surface viscoelasticity in a eutectic liquid Ga–Bi alloy. Chemical Physics Letters, 2002, 359(3–4): 326–330

Minami Y. Surface tension measurement of liquid metal with inelastic light-scattering spectroscopy of a thermally excited capillary wave. Applied Physics B, Lasers and Optics, 2014, 117 (3): 969–972

Osada R, Hoshino T, Okada K, Ohmasa Y, YaoM. Surface tension of room temperature ionic liquids measured by dynamic light scattering. Journal of Chemical Physics, 2009, 130(18): 184705

Kirby B J. Micro-and Nanoscale Fluid Mechanics: Transport in Microfluidic Devices. Cambridge: Cambridge University Press, 2010

Chang H C, Yeo L Y. Electrokinetically Driven Microfluidics and Nanofluidics. Cambridge: Cambridge University Press, 2010

Hong J S, Ko S H, Kang K H, Kang I S. A numerical investigation on AC electrowetting of a droplet. Microfluidics and Nanofluidics, 2008, 5(2): 263–271

Berry S, Kedzierski J, Abedian B. Low voltage electrowetting using thin fluoroploymer films. Journal of Colloid and Interface Science, 2006, 303(2): 517–524

Shamai R, Andelman D, Berge B, Hayes R. Water, electricity, and between … on electrowetting and its applications. Soft Matter, 2008, 4(1): 38–45

Thomas D, AudryMC, Thibaut RM, Kleimann P, Chassagneux F, Maillard M, Brioude A. Charge injection in dielectric films during electrowetting actuation under direct current voltage. Thin Solid Films, 2015, 590: 224–229

Klarman D, Andelman D, Urbakh M. A model of electrowetting, reversed electrowetting, and contact angle saturation. Langmuir, 2011, 27(10): 6031–6041

Monroe CW, Daikhin L, Urbakh M, Kornyshev A. Electrowetting with an interface between two immiscible electrolytic solutions. In: 210th ECS Meeting. Cancun, Mexico: ECS, 2006: 43

Monroe C W, Daikhin L I, Urbakh M, Kornyshev A A. Electrowetting with electrolytes. Physical Review Letters, 2006, 97(13): 136102

Jones T B, Fowler J D, Chang Y S, Kim C J. Frequency-based relationship of electrowetting and dielectrophoretic liquid microactuation. Langmuir, 2003, 19(18): 7646–7651

Kang K H. How electrostatic fields change contact angle in electrowetting. Langmuir, 2002, 18(26): 10318–10322

Mugele F, Baret J C. Electrowetting: from basics to applications. Journal of Physics Condensed Matter, 2005, 17(28): R705–R774

Sedev R. Electrowetting: electrocapillarity, saturation, and dynamics. European Physical Journal. Special Topics, 2011, 197 (1): 307–319

Wang K L, Jones T B. Saturation effects in dynamic electrowetting. Applied Physics Letters, 2005, 86(5): 054104

Shapiro B, Moon H, Garrell R L, Kim C J. Equilibrium behavior of sessile drops under surface tension, applied external fields, and material variations. Journal of Applied Physics, 2003, 93(9): 5794–5811

Yang X H, Tan S C, Yuan B, Liu J. Alternating electric field actuated oscillating behavior of liquid metal and its application. Science China Technological Sciences, 2016, 59(4): 597–603

Tan S C, Zhou Y X,Wang L, Liu J. Electrically driven chip cooling device using hybrid coolants of liquid metal and aqueous solution. Science China Technological Sciences, 2016, 59(2): 301–308

Lee J, Moon H, Fowler J, Schoellhammer T, Kim C J. Electrowetting and electrowetting-on-dielectric for microscale liquid handling. Sensors and Actuators A: Physical, 2002, 95(2–3): 259–268

Yun K S, Cho I J, Bu J U, Kim C J. A surface-tension driven micropump for low-voltage and low-power operations. Journal of Microelectromechanical Systems, 2002, 11(5): 454–461

Lee J, Kim C J C. Liquid micromotor driven by continuous electrowetting. In: Proceedings of 11th Annual International Workshop on Micro Electro Mechanical Systems. Heidelberg, Germany: IEEE, 1998: 538–543

Lee H J, Kim C J. Surface-tension-driven microactuation based on continuous electrowetting. Journal of Microelectromechanical Systems, 2000, 9(2): 171–180

Ni J, Zhong C J, Coldiron S J, Porter M D. Electrochemically actuated mercury pump for fluid flow and delivery. Analytical Chemistry, 2001, 73(1): 103–110

Pollack M G, Fair R B, Shenderov A D. Electrowetting-based actuation of liquid droplets for microfluidic applications. Applied Physics Letters, 2000, 77(11): 1725–1726

Yi U C, Kim C J. Characterization of electrowetting actuation on addressable single-side coplanar electrodes. Journal of Micromechanics and Microengineering, 2006, 16(10): 2053–2059

Accardo A, Mecarini F, Leoncini M, Brandi F, Di Cola E, Burghammer M, Riekel C, Di Fabrizio E. Fast, active droplet interaction: coalescence and reactive mixing controlled by electrowetting on a superhydrophobic surface. Lab on a Chip, 2013, 13(3): 332–335

Krupenkin T, Taylor J A. Reverse electrowetting as a new approach to high-power energy harvesting. Nature Communications, 2011, 2: 448

Moon J K, Jeong J, Lee D, Pak H K. Electrical power generation by mechanically modulating electrical double layers. Nature Communications, 2013, 4: 1487

Thramann J. Generation of electrical energy in a ski or snowboard. US Patent No. 9024462, 2015

Berge B, Peseux J. Variable focal lens controlled by an external voltage: an application of electrowetting. European Physical Journal E, 2000, 3(2): 159–163

Kuiper S, Hendriks B H W. Variable-focus liquid lens for miniature cameras. Applied Physics Letters, 2004, 85(7): 1128–1130

Hayes R A, Feenstra B J. Video-speed electronic paper based on electrowetting. Nature, 2003, 425(6956): 383–385

You H, Steckl A J. Three-color electrowetting display device for electronic paper. Applied Physics Letters, 2010, 97(2): 023514

Feenstra B J, Hayes R A, Van Dijk R, Boom R G H. Electrowetting-based displays: bringing microfluidics alive onscreen. In: 19th IEEE International Conference on Micro Electro Mechanical Systems. Istanbul, Turkey: IEEE, 2006: 48–53

Fair R B, Khlystov A, Tailor T D, Ivanov V, Evans R D, Srinivasan V, Pamula V K, Pollack M G, Griffin P B, Zhou J. Chemical and biological applications of digital-microfluidic devices. IEEE Design & Test of Computers, 2007, 24(1): 10–24

Cho S K, Moon H, Kim C J. Creating, transporting, cutting, and merging liquid droplets by electrowetting-based actuation for digital microfluidic circuits. Journal of Microelectromechanical Systems, 2003, 12(1): 70–80

Yu Y, Wang Q, Yi L, Liu J. Channelless fabrication for large-scale preparation of room temperature liquid metal droplets. Advanced Engineering Materials, 2014, 16(2): 255–262

Sheng L, He Z Z, Yao Y Y, Liu J. Transient state machine enabled from the colliding and coalescence of a swarm of autonomously running liquid metal motors. Small, 2015, 11(39): 5253–5261

Gao W, Pei A, Wang J. Water-driven micromotors. ACS Nano, 2012, 6(9): 8432–8438

Yuan B, Wang L, Yang X H, Ding Y J, Tan S C, Yi L T, He Z Z, Liu J. Liquid metal machine triggered violin-like wire oscillator. 2016, 3(10): 1600212

Monroe C W, Daikhin L I, Urbakh M, Kornyshev A A. Principles of electrowetting with two immiscible electrolytic solutions. Journal of Physics Condensed Matter, 2006, 18(10): 2837–2869

Grahame D C. The electrical double layer and the theory of electrocapillarity. Chemical Reviews, 1947, 41(3): 441–501

Kornyshev A A, Kucernak A R, Marinescu M, Monroe C W, Sleightholme A E S, Urbakh M. Ultra-low-voltage electrowetting. Journal of Physical Chemistry C, 2010, 114(35): 14885–14890

Yao Y Y, Liu J. Liquid metal wheeled small vehicle for cargo delivery. Royal Scoiety of Chemistry Advances, 2016, 6: 56482–56488

Yuan B, Tan S C, Zhou Y X, Liu J. Self-powered macroscopic Brownian motion of spontaneously running liquid metal motors. Chinese Science Bulletin, 2015, 60(13): 1203–1210

Fang W Q, He Z Z, Liu J. Electro-hydrodynamic shooting phenomenon of liquid metal stream. Applied Physics Letters, 2014, 105(13): 134104

Tang S Y, Lin Y, Joshipura I D, Khoshmanesh K, Dickey M D. Steering liquid metal flow in microchannels using low voltages. Lab on a Chip, 2015, 15(19): 3905–3911

Tang S Y, Sivan V, Khoshmanesh K, O’mullane A P, Tang X, Gol B, Eshtiaghi N, Lieder F, Petersen P, Mitchell A, Kalantar-zadeh K. Electrochemically induced actuation of liquid metal marbles. Nanoscale, 2013, 5(13): 5949–5957

Chrimes A F, Berean K J, Mitchell A, Rosengarten G, Kalantar-Zadeh K. Controlled electrochemical deformation of liquid-phase gallium. ACS Applied Materials & Interfaces, 2016, 8(6): 3833–3839

Sheng L, Zhang J, Liu J. Diverse transformations of liquid metals between different morphologies. Advanced Materials, 2014, 26 (34): 6036–6042

Wang L, Liu J. Liquid metal folding patterns induced by electric capillary force. Applied Physics Letters, 2016, 108(16): 161602

Mohammed M, Sundaresan R, Dickey M D. Self-running liquid metal drops that delaminate metal films at record velocities. ACS Applied Materials & Interfaces, 2015, 7(41): 23163–23171

Hirsch A, Michaud H O, Gerratt A P, De Mulatier S V, Lacour S P. Intrinsically stretchable biphasic (solid–liquid) thin metal films. Advanced Materials, 2016, 28(22): 4507–4512

Zheng Y, He Z Z, Yang J, Liu J. Personal electronics printing via tapping mode composite liquid metal ink delivery and adhesion mechanism. Scientific Reports, 2014, 4: 4588

Zheng Y, He Z Z, Gao Y X, Liu J. Direct desktop printed-circuitson-paper flexible electronics. Scientific Reports, 2013, 3: 1786

Wang Q, Yu Y, Yang J, Liu J. Fast fabrication of flexible functional circuits based on liquid metal dual-trans printing. Advanced Materials, 2015, 27(44): 7109–7116

Zheng Y, Zhang Q, Liu J. Pervasive liquid metal based direct writing electronics with roller-ball pen. AIP Advances, 2013, 3 (11): 112117

Gao Y X, Li H Y, Liu J. Direct writing of flexible electronics through room temperature liquid metal ink. PLoS One, 2012, 7(9): e45485

Yu Y, Zhang J, Liu J. Biomedical implementation of liquid metal ink as drawable ECG electrode and skin circuit. PLoS One, 2013, 8 (3): e58771

Guo C R, Yu Y, Liu J. Rapidly patterning conductive components on skin substrates as physiological testing devices via liquid metal spraying and pre-designed mask. Journal of Materials Chemistry B, Materials for Biology and Medicine, 2014, 2(35): 5739–5745

Zrnic D, Swatik D. On the resistivity and surface tension of the eutectic alloy of gallium and indium. Journal of the Less Common Metals, 1969, 18(1): 67–68

Dickey M D, Chiechi R C, Larsen R J, Weiss E A, Weitz D A, Whitesides G M. Eutectic gallium-indium (EGaIn): a liquid metal alloy for the formation of stable structures in microchannels at room temperature. Advanced Functional Materials, 2008, 18(7): 1097–1104

Boley J W, White E L, Chiu G T C, Kramer R K. Direct writing of gallium-indium alloy for stretchable electronics. Advanced Functional Materials, 2014, 24(23): 3501–3507

Xu Q, Oudalov N, Guo Q, Jaeger H M, Brown E. Effect of oxidation on the mechanical properties of liquid gallium and eutectic gallium-indium. Physics of Fluids, 2012, 24(6): 063101

Larsen R J, Dickey MD, Whitesides G M,Weitz D A. Viscoelastic properties of oxide-coated liquid metals. Journal of Rheology (New York, N.Y.), 2009, 53(6): 1305–1326

Jin C, Zhang J, Li X K, Yang X Y, Li J J, Liu J. Injectable 3-D fabrication of medical electronics at the target biological tissues. Scientific Reports, 2013, 3: 3442

Zhang J, Sheng L, Liu J. Synthetically chemical-electrical mechanism for controlling large scale reversible deformation of liquid metal objects. Scientific Reports, 2014, 4: 7116

Gough R C, Dang J H, Moorefield M R, Zhang G B, Hihara L H, Shiroma W A, Ohta A T. Self-actuation of liquid metal via redox reaction. ACS Applied Materials & Interfaces, 2016, 8(1): 6–10

Shen W, Edwards R T, Kim C J. Electrostatically actuated metaldroplet microswitches integrated on CMOS chip. Journal of Microelectromechanical Systems, 2006, 15(4): 879–889

Hammock M L, Chortos A, Tee B C K, Tok J B H, Bao Z. 25th anniversary article: the evolution of electronic skin (E-Skin): a brief history, design considerations, and recent progress. Advanced Materials, 2013, 25(42): 5997–6038

Park Y L, Chen B R, Wood R J. Design and fabrication of soft artificial skin using embedded microchannels and liquid conductors. IEEE Sensors Journal, 2012, 12(8): 2711–2718

Kramer R K, Majidi C, Wood R J. Wearable tactile keypad with stretchable artificial skin. In: IEEE International Conference on Robotics & Automation, IEEE, 2011: 1103–1107

Bauer S, Bauer-Gogonea S, Graz I, Kaltenbrunner M, Keplinger C, Schwödiauer R. 25th anniversary article: a soft future: from robots and sensor skin to energy harvesters. Advanced Materials, 2014, 26(1): 149–162

Hu L, Wang L, Ding Y J, Zhan S H, Liu J. Manipulation of liquid metals on a graphite surface. Advanced Materials, 2016, 28(41): 9210–9217

Acknowledgments

This work is partially supported by the Ministry of Education Equipment Development Fund, Dean’s Research Funding and the Frontier Project of the Chinese Academy of Sciences, as well as Beijing Municipal Science (Grant No. Z151100003715002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, X., Xu, S. & Liu, J. Surface tension of liquid metal: role, mechanism and application. Front. Energy 11, 535–567 (2017). https://doi.org/10.1007/s11708-017-0463-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11708-017-0463-9