Abstract

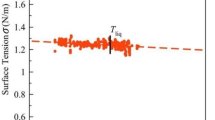

Within the Integrated Project IMPRESS, funded by the EU, a concerted action was taken to determine the thermophysical properties of a γ-TiAl-based alloys, suitable for casting of large turbine blades for aero-engines and stationary gas turbines. The challenge was to develop a castable alloy, free of grain refiners and susceptible to heat treatment. Owing to the high reactivity of this class of alloys, many difficulties were encountered to process the liquid phase in a crucible. This prevented also the measurements of specific heat, viscosity and electrical conductivity in the liquid phase. However, surface tension and density could be measured using container-less techniques. For the surface tension determination, both the oscillating droplet method by the electromagnetic levitation as well as a combined method using two methodologies in one test (i.e. the pendant drop and sessile drop) by an advanced experimental complex that has been designed for investigations of high temperature capillarity phenomena were applied. All the quantities have been obtained as a function of temperature, in some cases also in the undercooled liquid. In this article, we report a comparative discussion on the results obtained for the surface tension of Ti–Al–Nb and Ti–Al–Ta alloys, together with the corresponding theoretical values calculated by thermodynamic models.

Similar content being viewed by others

References

Lapin J, Pelechova T, Domankova M, Daloz D, Nazmy M (2007) Metall Mater 45:121

Jarvis DJ, Voss D (2005) Mater Sci Eng A 413–414:583

Kuang JP, Harding RA, Campbell J (2001) Int J Cast Met Res 13:277

Johnson DR, Masuda Y, Inui H, Yamaguchi M (1997) Acta Mater 45:2523

Egry I, Brooks R, Holland-Moritz D, Novakovic R, Matsushita T, Ricci E, Seetharaman S, Wunderlich R, Jarvis D (2007) Int J Thermophys 28:1026

Choudhury NS, Graham HC, Hinze JW (1976) In: Foroulis ZA, Pettit FS (eds) Properties of high temperature alloys. The Electrochemical Society, Princeton, p 668

Lang C, Schütze M (1997) Mater Corros 48:13

Herlach DM, Cochrane RF, Egry I, Fecht HJ, Greer AL (1993) Int Mater Rev 38:273

Fabrichnaya O, Seifert HJ, Ludwig T, Aldinger F, Navrotsky A (2001) Scand J Metall 30:17

Barzilai S, Aizenshtein M, Froumin N, Frage N (2006) J Mater Sci 41:5108. doi:10.1007/s10853-006-0435-7

Cummings DL, Blackburn DA (1991) J Fluid Mech 224:395

Naidich YuV (1981) In: Cadenhead DA, Danielli JF (eds) Progress in surface and membrane science, vol 14. Academic Press, New York

Sobczak N, Nowak R, Radziwill W, Budzioch J, Glenz A (2008) Mater Sci Eng A 495:43

Garandet JP, Vinet B, Gros P (1994) J Colloid Interface Sci 165:351

Butler JAV (1932) Proc R Soc A135:348

Singh RN (1987) Can J Phys 65:309

Singh RN, Sommer F (1997) Rep Prog Phys 60:57

Speiser R, Poirier DR, Yeum K (1987) Scripta Metall 21:687

Tanaka T, Hack K, Hara S (1999) MRS Bull April 1999:45

Egry I, Brillo J, Matsushita T (2005) Mater Sci Eng A 413–414:460

Novakovic R, Ricci E, Giuranno D, Passerone A (2005) Surf Sci 576(1–3):175

Saunders N (1998) In: Ansara I, Dinsdale AT, Rand MH (eds) COST 507—Thermochemical database for light metal alloys, vol 2. European Communities, Luxembourg, p 89

Witusiewicz VT, Bondar AA, Hecht U, Rex S, Velikanova TYa (2008) J Alloys Compd 465:64

Iida T, Guthrie RIL (1993) The physical properties of liquid metals. Clarendon Press, Oxford

Lang G, Laty P, Joud JC, Desré P (1977) Z Metallkd 68(2):113

Ishikawa T, Paradis PF, Itami T, Yoda S (2003) J Chem Phys 118(17):7912

Vinet B, Magnusson L, Fredriksson H, Desré PJ (2002) J Colloid Interface Sci 255:363

Acknowledgements

This study has been partially supported by the European Union (6th E.C. Framework Programme) in the framework of the IP IMPRESS (Contract NMP3-CT-2004-500635) financed research project. Financial support from the Foundry Research Institute has also been acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nowak, R., Lanata, T., Sobczak, N. et al. Surface tension of γ-TiAl-based alloys. J Mater Sci 45, 1993–2001 (2010). https://doi.org/10.1007/s10853-009-4061-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-4061-z