Abstract

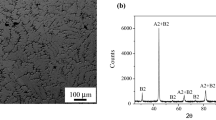

In the context of the recent developments in the field of high entropy alloys (HEAs), CrFeNi based alloys with the addition of Al have gained significant attention due to their interesting combination of mechanical properties and corrosion resistance, enabling an even wider range of applications for HEAs. A key feature of this system is the co-existence of multiple phases such as body centered cubic (BCC) and face centered cubic (FCC) phase, which significantly enhances the mechanical performance of the alloy. However, despite the ongoing research efforts, an in-depth study of the effect of Al on the phase transformation kinetics in this system is not yet available, which undermines the design of effective heat treatments, curbing the optimization of microstructures and properties. In this work, the influence of 5 at.%Al addition on the interdiffusion behavior and phase transformation kinetics from FCC to BCC phase at 700 °C is studied by experiments and state-of-the-art phase field simulations. The kinetics of BCC precipitation are observed experimentally through the sequential characterization of samples heat treated up to 11 days. 2D phase field (PF) simulations of the growth and coarsening of BCC-precipitates in a dual-phase BCC/FCC system are performed on the same alloy system. Experimental observations reveal that the growth of BCC is greatly enhanced by the addition of Al to the ternary CrFeNi system. This result is consistent with findings from the phase field simulation. PF results show that the gradients of the diffusion potentials and interdiffusion mobilities are increased in the case of Al addition, which explains the significant increase of the phase transformation rate from FCC to BCC. Finally, the cross terms in multi-component diffusion equations are found to significantly affect the evolution of the phases. These findings demonstrate the need of multicomponent models to fully understand the complex interdiffusion behavior in high and medium entropy alloys to foster the design of these materials.

Similar content being viewed by others

References

E.P. George, D. Raabe, and R.O. Ritchie, High-Entropy Alloys, Nat. Rev. Mater., 2019, 4(8), p 515–534.

D.B. Miracle, and O.N. Senkov, A Critical Review of High Entropy Alloys and Related Concepts, Acta Mater., 2017, 122, p 448–511.

O.N. Senkov, D.B. Miracle, K.J. Chaput, and J.P. Couzinie, Development and Exploration of Refractory High Entropy Alloys—A Review, J. Mater. Res., 2018, 33(19), p 3092–3128.

E.J. Pickering, and N.G. Jones, High-Entropy Alloys: A Critical Assessment of Their Founding Principles and Future Prospects, Int. Mater. Rev., 2016, 61(3), p 183–202.

G. Laplanche, A. Kostka, O.M. Horst, G. Eggeler, and E.P. George, Microstructure Evolution and Critical Stress for Twinning in the CrMnFeCoNi High-Entropy Alloy, Acta Mater., 2016, 118, p 152–163.

G. Singh, H. Chan, A. Baskin, E. Gelman, N. Repnin, P. Král, and R. Klajn, Self-Assembly of Magnetite Nanocubes into Helical Superstructures, N. Y. Sci. J., 2014, 345(6201), p 1149–1153.

J. Miao, C.E. Slone, T.M. Smith, C. Niu, H. Bei, M. Ghazisaeidi, G.M. Pharr, and M.J. Mills, The Evolution of the Deformation Substructure in a Ni-Co-Cr Equiatomic Solid Solution Alloy, Acta Mater., 2017, 132, p 35–48.

G. Laplanche, A. Kostka, C. Reinhart, J. Hunfeld, G. Eggeler, and E.P. George, Reasons for the Superior Mechanical Properties of Medium-Entropy CrCoNi Compared to High-Entropy CrMnFeCoNi, Acta Mater., 2017, 128, p 292–303.

B. Gludovatz, A. Hohenwarter, K.V.S. Thurston, H. Bei, Z. Wu, E.P. George, and R.O. Ritchie, Exceptional Damage-Tolerance of a Medium-Entropy Alloy CrCoNi at Cryogenic Temperatures, Nat. Commun., 2016, 7, p 10602.

D. Choudhuri, M. Komarasamy, V. Ageh, and R.S. Mishra, Investigation of Plastic Deformation Modes in Al0.1CoCrFeNi High Entropy Alloy, Mater. Chem. Phys., 2018, 217, p 308–314.

D. Choudhuri, S. Shukla, B. Gwalani, R. Banerjee, and R.S. Mishra, Deformation Induced Intermediate Metastable Lattice Structures Facilitate Ordered B2 Nucleation in a FCC-Based High Entropy Alloy, Mater. Res. Lett., 2019, 7(1), p 40–46.

S. Gangireddy, B. Gwalani, K. Liu, R. Banerjee, and R.S. Mishra, Microstructures with Extraordinary Dynamic Work Hardening and Strain Rate Sensitivity in Al0.3CoCrFeNi High Entropy Alloy, Mater. Sci. Eng. A, 2018, 734, p 42–50.

S. Gangireddy, B. Gwalani, V. Soni, R. Banerjee, and R.S. Mishra, Contrasting Mechanical Behavior in Precipitation Hardenable AlXCoCrFeNi High Entropy Alloy Microstructures: Single Phase FCC vs. Dual Phase FCC-BCC, Mater. Sci. Eng. A, 2019, 739, p 158–166.

S. Gangireddy, D. Whitaker, and R.S. Mishra, Significant Contribution to Strength Enhancement from Deformation Twins in Thermomechanically Processed Al0.1CoCrFeNi Microstructures, J. Mater. Eng. Perform., 2019, 28(3), p 1661–1667.

D. Li, and Y. Zhang, The Ultrahigh Charpy Impact Toughness of Forged AlxCoCrFeNi High Entropy Alloys at Room and Cryogenic Temperatures, Intermetallics, 2016, 70, p 24–28.

S.Q. Xia, M.C. Gao, and Y. Zhang, Abnormal Temperature Dependence of Impact Toughness in Al CoCrFeNi System High Entropy Alloys, Mater. Chem. Phys., 2018, 210, p 213–221.

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, and Z.P. Lu, Effects of Al Addition on Structural Evolution and Tensile Properties of the FeCoNiCrMn High-Entropy Alloy System, Acta Mater., 2014, 62, p 105–113.

C. Zhang, F. Zhang, H. Diao, M.C. Gao, Z. Tang, J.D. Poplawsky, and P.K. Liaw, Understanding Phase Stability of Al-Co-Cr-Fe-Ni High Entropy Alloys, Mater. Des., 2016, 109, p 425–433.

H. Yang, J. Li, T. Guo, W.Y. Wang, H. Kou, and J. Wang, Fully Recrystallized Al0.5CoCrFeNi High-Entropy Alloy Strengthened by Nanoscale Precipitates, Met. Mater. Int., 2019, 25(5), p 1145–1150.

Q. Li, T.W. Zhang, J.W. Qiao, S.G. Ma, D. Zhao, P. Lu, and Z.H. Wang, Mechanical Properties and Deformation Behavior of Dual-Phase Al0.6CoCrFeNi High-Entropy Alloys with Heterogeneous Structure at Room and Cryogenic Temperatures, J. Alloys Compd., 2020, 816, p 152663.

Y.Y. Du, Y.P. Lu, T.J. Li, T.M. Wang, and G.L. Zhang, Effect of aluminium Content of AlxCrFe1.5Ni0.5 Multiprincipal Alloys on Microstructure and Alloy Hardness, Mater. Res. Innov., 2011, 15(2), p 107–110.

W.R. Wang, W.L. Wang, and J.W. Yeh, Phases, Microstructure and Mechanical Properties of AlxCoCrFeNi High-Entropy Alloys at Elevated Temperatures, J. Alloy Compd., 2014, 589, p 143–152.

J. Zeng, C. Wu, H. Peng, Y. Liu, J. Wang, and X. Su, Microstructure and microhardness of as-cast and 800 °C annealed Al x Cr 0.2 Fe 0.2 Ni 0.6–x and Al 0.2 Cr 0.2 Fe y Ni 0.6-y alloys, Vacuum, 2018, 152, p 214–221.

T. Yang, S. Xia, S. Liu, C. Wang, S. Liu, Y. Zhang, J. Xue, S. Yan, and Y. Wang, Effects of AL Addition on Microstructure and Mechanical Properties of Al CoCrFeNi High-Entropy Alloy, Mater. Sci. Eng. A, 2015, 648, p 15–22.

W.R. Wang, W.L. Wang, S.C. Wang, Y.C. Tsai, C.H. Lai, and J.W. Yeh, Effects of Al Addition on the Microstructure and Mechanical Property of AlxCoCrFeNi High-Entropy Alloys, Intermetallics, 2012, 26, p 44–51.

T.T. Shun, and Y.C. Du, Microstructure and Tensile Behaviors of FCC Al0.3CoCrFeNi High Entropy Alloy, J. Alloys Compd., 2009, 479(1–2), p 157–160.

C.M. Lin, and H.L. Tsai, Evolution of Microstructure, Hardness, and Corrosion Properties of High-Entropy Al0.5CoCrFeNi alloy, Intermetallics, 2011, 19(3), p 288–294.

Z. Tang, M.C. Gao, H. Diao, T. Yang, J. Liu, T. Zuo, Y. Zhang, Z. Lu, Y. Cheng, Y. Zhang, K.A. Dahmen, P.K. Liaw, and T. Egami, Aluminum Alloying Effects on Lattice Types, Microstructures, and Mechanical Behavior of High-Entropy Alloys Systems, JOM, 2013, 65(12), p 1848–1858.

C. Zhang, F. Zhang, S. Chen, and W. Cao, Computational Thermodynamics Aided High-Entropy Alloy Design, JOM, 2012, 64(7), p 839–845.

A.H. Tkaczyk, A. Bartl, A. Amato, V. Lapkovskis, and M. Petranikova, Sustainability Evaluation of Essential Critical Raw Materials: Cobalt, Niobium, Tungsten and Rare Earth Elements, J. Phys. D: Appl. Phys., 2018, 51(20), p 203001.

X. Chen, Y. Sui, J. Qi, Y. He, F. Wei, Q. Meng, and Z. Sun, Microstructure of Al 1.3 CrFeNi Eutectic High Entropy Alloy and Oxidation Behavior at 1000 °C, J. Mater. Res., 2017, 32(11), p 2109–2116.

X. Chen, J.Q. Qi, Y.W. Sui, Y.Z. He, F.X. Wei, Q.K. Meng, and Z. Sun, Effects of Aluminum on Microstructure and Compressive Properties of Al-Cr-Fe-Ni Eutectic Multi-component Alloys, Mater. Sci. Eng. A, 2017, 681, p 25–31.

Y. Dong, X. Gao, Y. Lu, T. Wang, and T. Li, A multi-component AlCrFe2Ni2 alloy with excellent mechanical properties, Mater. Lett., 2016, 169, p 62–64.

F. Tian, L. Delczeg, N. Chen, L.K. Varga, J. Shen, and L. Vitos, Structural stability of NiCoFeCrAl x high-entropy alloy from ab initio theory, Phys. Rev. B, 2013, 88(8), p 085128.

E. Eshed, S. Abds El Majid, M. Bamberger, and S. Osovski, TEM and High Resolution TEM Investigation of Phase Formation in High Entropy Alloy AlCrFe2Ni2, Front. Mater., 2020, 7

L.Q. Chen, Phase-Field Models for Microstructure Evolution, Annu. Rev. Mater. Res., 2002, 32(1), p 113–140.

N. Moelans, B. Blanpain, and P. Wollants, An Introduction to Phase-Field Modeling of Microstructure Evolution, Calphad, 2008, 32, p 268–294.

Y. Li, S. Hu, X. Sun, and M. Stan, A Review: Applications of the Phase Field Method in Predicting Microstructure and Property Evolution of Irradiated Nuclear Materials, npj Comput. Mater., 2017, 3(1), p 11.

J. Zhou, J. Odqvist, L. Höglund, M. Thuvander, T. Barkar, and P. Hedström, Initial Clustering—A Key Factor for Phase Separation Kinetics in Fe–Cr-Based Alloys, Scr. Mater., 2014, 75, p 62–65.

G. Mi, L. Xiong, C. Wang, P. Jiang, and G. Zhu, Two-Dimensional Phase-Field Simulations of Competitive Dendritic Growth During Laser Welding, Mater. Des., 2019, 181, p 107980.

B. Nestler and A. A. Wheeler, Phase-Field Modeling of Multi-phase Solidification, Comput. Phys. Commun., 2002, p 230–233

Q. Chen, N. Ma, K. Wu, and Y. Wang, Quantitative Phase Field Modeling of Diffusion-Controlled Precipitate Growth and Dissolution in Ti–Al–V, Scr. Mater., 2004, 50(4), p 471–476.

T. Naseri, D. Larouche, R. Martinez, F. Breton, and D. Massinon, Analytical Modeling of the Mixed-Mode Growth and Dissolution of Precipitates in a Finite System, Metals, 2019, 9(8), p 889.

L. Hou, N. Moelans, J. Derakhshandeh, I. de Wolf, and E. Beyne, Study of the Effect of Sn Grain Boundaries on IMC Morphology in Solid State Inter-diffusion Soldering, Sci. Rep., 2019, 9(1), p 14862.

J.L. Li, Z. Li, Q. Wang, C. Dong, and P.K. Liaw, Phase-Field Simulation of Coherent BCC/B2 Microstructures in high Entropy Alloys, Acta Mater., 2020, 197, p 10–19.

A. Malik, J. Odqvist, L. Höglund, S. Hertzman, and J. Ågren, Phase-Field Modeling of Sigma-Phase Precipitation in 25Cr7Ni4Mo Duplex Stainless Steel, Metall. Mater. Trans. A, 2017, 48(10), p 4914–4928.

S. Chatterjee, and N. Moelans, A Grand-Potential Based Phase-Field Approach for Simulating Growth of Intermetallic Phases in Multicomponent Alloy Systems, Acta Mater., 2021, 206, p 116630.

N. Saunders and A.P. Miodownik, CALPHAD (Calculation of Phase Diagrams)-A Comprehensive Guide, Volume 1, Elsevier Science, 1998

S.G. Kim, W.T. Kim, and T. Suzuki, Phase-Field Model for Binary Alloys: KKS, Phys. Rev. E, 1999, 60, p 7186–7196.

S.G. Kim, A Phase-Field Model with Antitrapping Current for Multicomponent Alloys with Arbitrary Thermodynamic Properties, Acta Mater., 2007, 55(13), p 4391–4399.

S.G. Kim, W. Tae Kim, T. Suzuki, and M. Ode, Phase-Field Modeling of Eutectic Solidification, J. Cryst. Growth, 2004, 261(1), p 135–158.

N. Moelans, B. Blanpain, and P. Wollants, Quantitative Analysis of Grain Boundary Properties in a Generalized Phase Field Model for Grain Growth in Anisotropic Systems, Phys. Rev. B, 2008, 78(2), p 24113.

N. Moelans, A Quantitative and Thermodynamically Consistent phase-Field Interpolation Function for Multi-phase Systems, Acta Mater., 2011, 59(3), p 1077–1086.

N. Moelans, http://nele.studentenweb.org/docs/parameters.m; http://nele.studentenweb.org/docs/GammaDependence.txt; [Accessed 27/08/2021].

M.R. Tonks, D. Gaston, P.C. Millett, D. Andrs, and P. Talbot, An Object-Oriented Finite Element Framework for Multiphysics Phase Field Simulations, Comput. Mater. Sci., 2012, 51(1), p 20–29.

A. Mehta, and Y. Sohn, High Entropy and Sluggish Diffusion “Core” Effects in Senary FCC Al-Co-Cr-Fe-Ni-Mn Alloys, ACS Comb. Sci., 2020, 22(12), p 757–767.

G.V. Kurdjumov, and G.Z. Sach, Über den Mechanisms der Stahlhärtnung, Z. Phys., 1930, 64, p 518.

Acknowledgments

The research was partly funded by the Walloon Region under the agreement No. 1610154-EntroTough in the context of the 2016 WallInnov call. The simulation work was supported by the European Research Council (ERC) under the European Union's Horizon 2020 research and innovation program (INTERDIFFUSION, Grant Agreement No. 714754). The computational resources and services used in this work were provided by the VSC (Flemish Supercomputer Center), funded by the Research Foundation - Flanders (FWO) and the Flemish Government - department EWI.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of a special topical focus in the Journal of Phase Equilibria and Diffusion on the Thermodynamics and Kinetics of High-Entropy Alloys. This issue was organized by Dr. Michael Gao, National Energy Technology Laboratory; Dr. Ursula Kattner, NIST; Prof. Raymundo Arroyave, Texas A&M University; and the late Dr. John Morral, The Ohio State University.

Rights and permissions

About this article

Cite this article

Zuo, X., Miotti Bettanini, A., Hilhorst, A. et al. Influence of 5 at.%Al-Additions on the FCC to BCC Phase Transformation in CrFeNi Concentrated Alloys. J. Phase Equilib. Diffus. 42, 794–813 (2021). https://doi.org/10.1007/s11669-021-00924-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-021-00924-7