Abstract

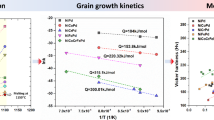

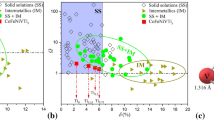

Grain growth is an unavoidable phenomenon occurring during processing of multicomponent high-entropy alloys (HEAs) and medium-entropy alloys (MEAs), which significantly affects the properties and performance of these compositionally complex alloys during service. Accordingly, the present overview article is dedicated to summarize the state of the art of the grain coarsening behavior and its kinetics for HEAs and propose opportunities and scope for future research, with special attention to the Cantor-based compositions. Firstly, the primary recrystallization and grain growth of equiatomic and non-equiatomic CrMnFeCoNi alloys with face-centered cubic (FCC) crystal structure in the single-phase regime and with the presence of intermetallics such as the Cr-rich sigma (σ) phase is considered, which was accompanied by the powerful utilization of the solute drag effect, Zener pinning, and grain boundary segregation engineering via introducing carbon, nitrogen, boron, titanium, and niobium. Subsequently, the quaternary and ternary alloys based on Cr, Mn, Fe, Ni, and Co are taken into account. In these systems, the novel concept of grain boundary high-entropy effect (via the addition of molybdenum, niobium, and zirconium), the formation of pinning insoluble oxide and thermally stable carbide particles during mechanical alloying, the simultaneous solute drag and Zener pinning effects via Mo and C addition, and the formation of Cu-rich phase and the strong segregation effect of Cu atoms to grain boundaries in the FeCoNiCu HEA are critically discussed. Afterward, the thermal stability of AlxFeCoCrNi(Mn) HEAs is treated, where the formation of the Ni–Al-rich B2 phase and the corresponding Zener pinning effect, the influence of aluminum addition on the temperature range for the stability of the σ phase, and cluster drag mechanism of Al atoms are explained. What is more, the grain growth of refractory HEAs with body-centered cubic (BCC) crystal structure is also summarized, where the high grain growth activation energy is attributed to the presence of elements with very low self-diffusivity such as tantalum and niobium. Moreover, the possible effects of short-range ordering on the mobility of grain boundaries are discussed. Finally, the prospects for future research work are presented, including the development of precipitation-temperature-time (PTT) diagrams, systematic investigation of cold rolling and annealing for prior grain refinement, studying abnormal grain growth (secondary recrystallization), and assessment of grain growth behavior of HEAs manufactured by advanced methods such as additive manufacturing (3D printing).

Similar content being viewed by others

Data availability

The authors stated that the processed data required to reproduce these findings were available in this manuscript.

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater. 6(5), 299–303 (2004)

B. Cantor, I.T.H. Chang, P. Knight, A.J.B. Vincent, Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 375, 213–218 (2004)

W. Li, D. Xie, D. Li, Y. Zhang, Y. Gao, P.K. Liaw, Mechanical behavior of high-entropy alloys. Prog. Mater Sci. 118, 100777 (2021)

Z. Li, S. Zhao, R.O. Ritchie, M.A. Meyers, Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog. Mater Sci. 102, 296–345 (2019)

D.B. Miracle, O.N. Senkov, A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448–511 (2017)

S. Praveen, H.S. Kim, High-entropy alloys: potential candidates for high-temperature applications–an overview. Adv. Eng. Mater. 20(1), 1700645 (2018)

E.P. George, D. Raabe, R.O. Ritchie, High-entropy alloys. Nat. Rev. Mater. 4(8), 515–534 (2019)

R. Motallebi, Z. Savaedi, H. Mirzadeh, Superplasticity of high-entropy alloys: a review. Arch. Civil Mech. Eng. 22(1), 20 (2022)

Z. Savaedi, R. Motallebi, H. Mirzadeh, A review of hot deformation behavior and constitutive models to predict flow stress of high-entropy alloys. J. Alloys Compd. 903, 163964 (2022)

K. Ming, L. Li, Z. Li, X. Bi, J. Wang, Grain boundary decohesion by nanoclustering Ni and Cr separately in CrMnFeCoNi high-entropy alloys. Sci. Adv. 5(12), 0639 (2019)

Y. Zhang, M. Liu, J. Sun, G. Li, R. Zheng, W. Xiao, C. Ma, Excellent thermal stability and mechanical properties of bulk nanostructured FeCoNiCu high entropy alloy. Mater. Sci. Eng. A 835, 142670 (2022)

L.S. Mantha, B.E. MacDonald, X. Mu, A. Mazilkin, J. Ivanisenko, H. Hahn, E.J. Lavernia, S. Katnagallu, C. Kübel, Grain boundary segregation induced precipitation in a non equiatomic nanocrystalline CoCuFeMnNi compositionally complex alloy. Acta Mater. 220, 117281 (2021)

H. Ma, Y. Shao, C.H. Shek, CoCuFeNi high entropy alloy reinforced by in-situ W particles. Mater. Sci. Eng. A 797, 140218 (2020)

M. Harivandi, M. Malekan, S.A. Seyyed Ebrahimi, Soft magnetic high entropy FeCoNiCuMn alloy with excellent ductility and high electrical resistance. Met. Mater. Int. 28, 556–564 (2022)

Z. Han, W. Ren, J. Yang, A. Tian, Y. Du, G. Liu, R. Wei, G. Zhang, Y. Chen, The corrosion behavior of ultra-fine grained CoNiFeCrMn high-entropy alloys. J. Alloys Compd. 816, 152583 (2020)

D. Gaertner, J. Kottke, G. Wilde, S.V. Divinski, Y. Chumlyakov, Tracer diffusion in single crystalline CoCrFeNi and CoCrFeMnNi high entropy alloys. J. Mater. Res. 33(19), 3184–3191 (2018)

S.V. Divinski, A.V. Pokoev, N. Esakkiraja, A. Paul, A mystery of" sluggish diffusion" in high-entropy alloys: the truth or a myth? Diffus. Found. 17, 69–104 (2018)

A. Mehta, Y. Sohn, Investigation of sluggish diffusion in FCC Al0.25CoCrFeNi high-entropy alloy. Mater. Res. Lett. 9(5), 239–246 (2021)

J. Zhang, C. Gadelmeier, S. Sen, R. Wang, X. Zhang, Y. Zhong, U. Glatzel, B. Grabowski, G. Wilde, S.V. Divinski, Zr diffusion in BCC refractory high entropy alloys: a case of ‘non-sluggish’ diffusion behavior. Acta Mater. 233, 117970 (2022)

C. Zhang, M.C. Gao, J.W. Yeh, P.K. Liaw, Y. Zhang, High-Entropy Alloys: Fundamentals and Applications (Springer, Cham, 2016), pp.72–92

K.Y. Tsai, M.H. Tsai, J.W. Yeh, Sluggish diffusion in co–cr–fe–mn–ni high-entropy alloys. Acta Mater. 61(13), 4887–4897 (2013)

M. Vaidya, S. Trubel, B.S. Murty, G. Wilde, S.V. Divinski, Ni tracer diffusion in CoCrFeNi and CoCrFeMnNi high entropy alloys. J. Alloys Compd. 688, 994–1001 (2016)

M. Vaidya, K.G. Pradeep, B.S. Murty, G. Wilde, S.V. Divinski, Bulk tracer diffusion in CoCrFeNi and CoCrFeMnNi high entropy alloys. Acta Mater. 146, 211–224 (2018)

J. Dąbrowa, M. Zajusz, W. Kucza, G. Cieślak, K. Berent, T. Czeppe, T. Kulik, M. Danielewski, Demystifying the sluggish diffusion effect in high entropy alloys. J. Alloys Compd. 783, 193–207 (2019)

M. Vaidya, K.G. Pradeep, B.S. Murty, G. Wilde, S.V. Divinski, Radioactive isotopes reveal a non sluggish kinetics of grain boundary diffusion in high entropy alloys. Sci. Rep. 7, 12293 (2017)

B. Gwalani, R. Salloom, T. Alam, S.G. Valentin, X. Zhou, G. Thompson, S.G. Srinivasan, R. Banerjee, Composition-dependent apparent activation-energy and sluggish grain-growth in high entropy alloys. Mater. Res. Lett. 7(7), 267–274 (2019)

E.P. George, W.A. Curtin, C.C. Tasan, High entropy alloys: a focused review of mechanical properties and deformation mechanisms. Acta Mater. 188, 435–474 (2020)

M. Vaidya, A. Anupam, J.V. Bharadwaj, C. Srivastava, B.S. Murty, Grain growth kinetics in CoCrFeNi and CoCrFeMnNi high entropy alloys processed by spark plasma sintering. J. Alloys Compd. 791, 1114–1121 (2019)

B. Cantor, Multicomponent high-entropy Cantor alloys. Prog. Mater Sci. 120, 100754 (2021)

Z. Zeng, M. Xiang, D. Zhang, J. Shi, W. Wang, X. Tang, W. Tang, Y. Wang, X. Ma, Z. Chen, W. Ma, Mechanical properties of Cantor alloys driven by additional elements: a review. J. Market. Res. 15, 1920–1934 (2021)

Y.J. Li, A. Kostka, A. Savan, A. Ludwig, Correlative chemical and structural investigations of accelerated phase evolution in a nanocrystalline high entropy alloy. Scr. Mater. 183, 122–126 (2020)

B. Schuh, F. Mendez-Martin, B. Völker, E.P. George, H. Clemens, R. Pippan, A. Hohenwarter, Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater. 96, 258–268 (2015)

H. Shahmir, T. Mousavi, J. He, Z. Lu, M. Kawasaki, T.G. Langdon, Microstructure and properties of a CoCrFeNiMn high-entropy alloy processed by equal-channel angular pressing. Mater. Sci. Eng. A 705, 411–419 (2017)

T.H. Chou, J.C. Huang, C.H. Yang, S.K. Lin, T.G. Nieh, Consideration of kinetics on intermetallics formation in solid-solution high entropy alloys. Acta Mater. 195, 71–80 (2020)

M.S. Mehranpour, H. Shahmir, M. Nili-ahmadabadi, CoCrFeNiMn high entropy alloy microstructure and mechanical properties after severe cold shape rolling and annealing. Mater. Sci. Eng. A 793, 139884 (2020)

F. Otto, A. Dlouhý, K.G. Pradeep, M. Kuběnová, D. Raabe, G. Eggeler, E.P. George, Decomposition of the single-phase high-entropy alloy CrMnFeCoNi after prolonged anneals at intermediate temperatures. Acta Mater. 112, 40–52 (2016)

G. Laplanche, S. Berglund, C. Reinhart, A. Kostka, F. Fox, E.P. George, Phase stability and kinetics of σ-phase precipitation in CrMnFeCoNi high-entropy alloys. Acta Mater. 161, 338–351 (2018)

Y.J. Li, A. Savan, A. Kostka, H.S. Stein, A. Ludwig, Accelerated atomic-scale exploration of phase evolution in compositionally complex materials. Mater. Horiz. 5(1), 86–92 (2018)

G. Liu, D.H. Lu, X.W. Liu, F.C. Liu, Q. Yang, H. Du, Q. Hu, Z.T. Fan, Solute segregation effect on grain boundary migration and Hall-Petch relationship in CrMnFeCoNi high-entropy alloy. Mater. Sci. Technol. 35(4), 500–508 (2019)

S.J. Sun, Y.Z. Tian, H.R. Lin, X.G. Dong, Y.H. Wang, Z.J. Zhang, Z.F. Zhang, Enhanced strength and ductility of bulk CoCrFeMnNi high entropy alloy having fully recrystallized ultrafine-grained structure. Mater. Des. 133, 122–127 (2017)

J. Hu, X. Wang, J. Zhang, J. Luo, Z. Zhang, Z. Shen, A general mechanism of grain growth—I Theory. J. Materiomics 7(5), 1007–1013 (2021)

M. Roostaei, M. Shirdel, M.H. Parsa, R. Mahmudi, H. Mirzadeh, Microstructural evolution and grain growth kinetics of GZ31 magnesium alloy. Mater. Charact. 118, 584–592 (2016)

B. Pourbahari, H. Mirzadeh, M. Emamy, Elucidating the effect of intermetallic compounds on the behavior of Mg–Gd–Al–Zn magnesium alloys at elevated temperatures. J. Mater. Res. 32(22), 4186–4195 (2017)

W.H. Liu, Y. Wu, J.Y. He, T.G. Nieh, Z.P. Lu, Grain growth and the Hall-Petch relationship in a high-entropy FeCrNiCoMn alloy. Scr. Mater. 68(7), 526–529 (2013)

F. Otto, N.L. Hanold, E.P. George, Microstructural evolution after thermomechanical processing in an equiatomic, single-phase CoCrFeMnNi high-entropy alloy with special focus on twin boundaries. Intermetallics 54, 39–48 (2014)

L. Li, R.D. Kamachali, Z. Li, Z. Zhang, Grain boundary energy effect on grain boundary segregation in an equiatomic high-entropy alloy. Phys. Rev. Mater. 4(5), 053603 (2020)

L. Li, Z. Li, A.K. da Silva, Z. Peng, H. Zhao, B. Gault, D. Raabe, Segregation-driven grain boundary spinodal decomposition as a pathway for phase nucleation in a high-entropy alloy. Acta Mater. 178, 1–9 (2019)

G.A. Salishchev, M.A. Tikhonovsky, D.G. Shaysultanov, N.D. Stepanov, A.V. Kuznetsov, I.V. Kolodiy, A.S. Tortika, O.N. Senkov, Effect of Mn and V on structure and mechanical properties of high-entropy alloys based on CoCrFeNi system. J. Alloys Compd. 591, 11–21 (2014)

M. Laurent-Brocq, A. Akhatova, L. Perrière, S. Chebini, X. Sauvage, E. Leroy, Y. Champion, Insights into the phase diagram of the CrMnFeCoNi high entropy alloy. Acta Mater. 88, 355–365 (2015)

C. Haase, F. Tang, M.B. Wilms, A. Weisheit, B. Hallstedt, Combining thermodynamic modeling and 3D printing of elemental powder blends for high-throughput investigation of high-entropy alloys–towards rapid alloy screening and design. Mater. Sci. Eng. A 688, 180–189 (2017)

J. Gu, S. Ni, Y. Liu, M. Song, Regulating the strength and ductility of a cold rolled FeCrCoMnNi high-entropy alloy via annealing treatment. Mater. Sci. Eng. A 755, 289–294 (2019)

G.D. Sathiaraj, C.W. Tsai, J.W. Yeh, M. Jahazi, P.P. Bhattacharjee, The effect of heating rate on microstructure and texture formation during annealing of heavily cold-rolled equiatomic CoCrFeMnNi high entropy alloy. J. Alloys Compd. 688, 752–761 (2016)

Z. Nasiri, S. Ghaemifar, M. Naghizadeh, H. Mirzadeh, Thermal mechanisms of grain refinement in steels: a review. Met. Mater. Int. 27(7), 2078–2094 (2021)

M. Tavakoli, H. Mirzadeh, M. Zamani, Static recrystallization kinetics of ferrite in cold-deformed medium carbon steel. Mater. Res. Express 6(12), 1265g9 (2020)

J. Gu, M. Song, Annealing-induced abnormal hardening in a cold rolled CrMnFeCoNi high entropy alloy. Scr. Mater. 162, 345–349 (2019)

R. Besson, Ordering and phase separation in multi-principal-element metallic alloys: contribution from mean-field atomic-scale modelling and simulation. J. Alloys Compd. 898, 162842 (2022)

M.V. Klimova, D.G. Shaysultanov, S.V. Zherebtsov, N.D. Stepanov, Effect of second phase particles on mechanical properties and grain growth in a CoCrFeMnNi high entropy alloy. Mater. Sci. Eng. A 748, 228–235 (2019)

F. Najafkhani, S. Kheiri, B. Pourbahari, H. Mirzadeh, Recent advances in the kinetics of normal/abnormal grain growth: a review. Arch. Civil Mech. Eng. 21(1), 29 (2021)

F. Humphreys, J. Rohrer, A. Rollett, Recrystallization and related annealing phenomena, 3rd edn. (Elsevier, Oxford, 2017)

N.D. Stepanov, D.G. Shaysultanov, M.S. Ozerov, S.V. Zherebtsov, G.A. Salishchev, Second phase formation in the CoCrFeNiMn high entropy alloy after recrystallization annealing. Mater. Lett. 185, 1–4 (2016)

M.S. Mehranpour, H. Shahmir, M. Nili-ahmadabadi, Precipitation kinetics in heavily deformed CoCrFeNiMn high entropy alloy. Mater. Lett. 288, 129359 (2021)

J. Wang, S. Wu, S. Fu, S. Liu, M. Yan, Q. Lai, S. Lan, H. Hahn, T. Feng, Ultrahigh hardness with exceptional thermal stability of a nanocrystalline CoCrFeNiMn high-entropy alloy prepared by inert gas condensation. Scr. Mater. 187, 335–339 (2020)

D. Utt, A. Stukowski, K. Albe, Grain boundary structure and mobility in high-entropy alloys: A comparative molecular dynamics study on a Σ11 symmetrical tilt grain boundary in face-centered cubic CuNiCoFe. Acta Mater. 186, 11–19 (2020)

L.R. Owen, E.J. Pickering, H.Y. Playford, H.J. Stone, M.G. Tucker, N.G. Jones, An assessment of the lattice strain in the CrMnFeCoNi high-entropy alloy. Acta Mater. 122, 11–18 (2017)

Y.H. Jo, W.M. Choi, D.G. Kim, A. Zargaran, K. Lee, H. Sung, S.S. Sohn, H.S. Kim, B.J. Lee, S. Lee, Utilization of brittle σ phase for strengthening and strain hardening in ductile VCrFeNi high-entropy alloy. Mater. Sci. Eng. A 743, 665–674 (2019)

X.W. Liu, L. Liu, G. Liu, X.X. Wu, D.H. Lu, J.Q. Yao, W.M. Jiang, Z.T. Fan, W.B. Zhang, The role of carbon in grain refinement of cast CrFeCoNi high-entropy alloys. Metall. Mater. Trans. A 49(6), 2151–2160 (2018)

L. Guo, X. Ou, S. Ni, Y. Liu, M. Song, Effects of carbon on the microstructures and mechanical properties of FeCoCrNiMn high entropy alloys. Mater. Sci. Eng. A 746, 356–362 (2019)

J.Y. Ko, S.I. Hong, Microstructural evolution and mechanical performance of carbon-containing CoCrFeMnNi-C high entropy alloys. J. Alloys Compd. 743, 115–125 (2018)

M.V. Klimova, D.G. Shaysultanov, R.S. Chernichenko, V.N. Sanin, N.D. Stepanov, S.V. Zherebtsov, A.N. Belyakov, Recrystallized microstructures and mechanical properties of a C-containing CoCrFeNiMn-type high-entropy alloy. Mater. Sci. Eng. A 740, 201–210 (2019)

M. Klimova, D. Shaysultanov, A. Semenyuk, S. Zherebtsov, N. Stepanov, Effect of carbon on recrystallised microstructures and properties of CoCrFeMnNi-type high-entropy alloys. J. Alloys Compd. 851, 156839 (2021)

M. Glienke, M. Vaidya, K. Gururaj, L. Daum, B. Tas, L. Rogal, K.G. Pradeep, S.V. Divinski, G. Wilde, Grain boundary diffusion in CoCrFeMnNi high entropy alloy: kinetic hints towards a phase decomposition. Acta Mater. 195, 304–316 (2020)

U. Lee, B. Straumal, N. Park, Dynamic precipitation of σ-phase and element partitioning in equiatomic CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A 804, 140739 (2021)

J. Zhang, G.M. Muralikrishna, A. Asabre, Y. Kalchev, J. Müller, B. Butz, S. Hilke, H. Rösner, G. Laplanche, S.V. Divinski, G. Wilde, Tracer diffusion in the σ phase of the CoCrFeMnNi system. Acta Mater. 203, 116498 (2021)

Y. Xie, D. Zhou, Y. Luo, T. Xia, W. Zeng, C. Li, J. Wang, J. Liang, D. Zhang, Fabrication of CoCrFeNiMn high entropy alloy matrix composites by thermomechanical consolidation of a mechanically milled powder. Mater. Charact. 148, 307–316 (2019)

S.H. Joo, H. Kato, M.J. Jang, J. Moon, E.B. Kim, S.J. Hong, H.S. Kim, Structure and properties of ultrafine-grained CoCrFeMnNi high-entropy alloys produced by mechanical alloying and spark plasma sintering. J. Alloys Compd. 698, 591–604 (2017)

J.M. Park, J. Choe, J.G. Kim, J.W. Bae, J. Moon, S. Yang, K.T. Kim, J.H. Yu, H.S. Kim, Superior tensile properties of 1% C-CoCrFeMnNi high-entropy alloy additively manufactured by selective laser melting. Mater. Res. Lett. 8(1), 1–7 (2020)

R. Zhou, Y. Liu, C. Zhou, S. Li, W. Wu, M. Song, B. Liu, X. Liang, P.K. Liaw, Microstructures and mechanical properties of C-containing FeCoCrNi high-entropy alloy fabricated by selective laser melting. Intermetallics 94, 165–171 (2018)

R. Zhou, Y. Liu, B. Liu, J. Li, Q. Fang, Precipitation behavior of selective laser melted FeCoCrNiC0. 05 high entropy alloy. Intermetallics 106, 20–25 (2019)

J.G. Kim, J.M. Park, J.B. Seol, J. Choe, J.H. Yu, S. Yang, H.S. Kim, Nano-scale solute heterogeneities in the ultrastrong selectively laser melted carbon-doped CoCrFeMnNi alloy. Mater. Sci. Eng. A 773, 138726 (2020)

N. Choi, V. Kulitckii, J. Kottke, B. Tas, J. Choe, J.H. Yu, S. Yang, J.H. Park, J.S. Lee, G. Wilde, S.V. Divinski, Analyzing the ‘non-equilibrium state’ of grain boundaries in additively manufactured high-entropy CoCrFeMnNi alloy using tracer diffusion measurements. J. Alloys Compd. 844, 155757 (2020)

D.E. Jodi, J. Park, B. Straumal, N. Park, Investigation on the precipitate formation and behavior in nitrogen-containing equiatomic CoCrFeMnNi high-entropy alloy. Mater. Lett. 258, 126806 (2020)

F. Xiong, R. Fu, Y. Li, B. Xu, X. Qi, Influences of nitrogen alloying on microstructural evolution and tensile properties of CoCrFeMnNi high-entropy alloy treated by cold-rolling and subsequent annealing. Mater. Sci. Eng. A 787, 139472 (2020)

A. Semenyuk, M. Klimova, D. Shaysultanov, G. Salishchev, S. Zherebtsov, N. Stepanov, Effect of nitrogen on microstructure and mechanical properties of the CoCrFeMnNi high-entropy alloy after cold rolling and subsequent annealing. J. Alloys Compd. 888, 161452 (2021)

S.H. Shim, J. Moon, H. Pouraliakbar, B.J. Lee, S.I. Hong, H.S. Kim, Toward excellent tensile properties of nitrogen-doped CoCrFeMnNi high-entropy alloy at room and cryogenic temperatures. J. Alloys Compd. 897, 163217 (2022)

F. Xiong, R.D. Fu, Y.J. Li, D.L. Sang, Effects of nitrogen alloying and friction stir processing on the microstructures and mechanical properties of CoCrFeMnNi high-entropy alloys. J. Alloys Compd. 822, 153512 (2020)

I. Moravcik, J. Cizek, L.D.A. Gouvea, J. Cupera, I. Guban, I. Dlouhy, Nitrogen interstitial alloying of CoCrFeMnNi high entropy alloy through reactive powder milling. Entropy 21(4), 363 (2019)

D. Zhao, Q. Yang, D. Wang, M. Yan, P. Wang, M. Jiang, C. Liu, D. Diao, C. Lao, Z. Chen, Z. Liu, Ordered nitrogen complexes overcoming strength–ductility trade-off in an additively manufactured high-entropy alloy. Virtual and Physical Prototyping 15(sup1), 532–542 (2020)

M. Song, R. Zhou, J. Gu, Z. Wang, S. Ni, Y. Liu, Nitrogen induced heterogeneous structures overcome strength-ductility trade-off in an additively manufactured high-entropy alloy. Appl. Mater. Today 18, 100498 (2020)

S. Thapliyal, P. Agrawal, P. Agrawal, S.S. Nene, R.S. Mishra, B.A. McWilliams, K.C. Cho, Segregation engineering of grain boundaries of a metastable Fe-Mn-Co-Cr-Si high entropy alloy with laser-powder bed fusion additive manufacturing. Acta Mater. 219, 117271 (2021)

W.H. Liu, Z.P. Lu, J.Y. He, J.H. Luan, Z.J. Wang, B. Liu, Y. Liu, M.W. Chen, C.T. Liu, Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases. Acta Mater. 116, 332–342 (2016)

Y. Shi, Y.D. Wang, S. Li, R. Li, Y. Wang, Mechanical behavior in boron-microalloyed CoCrNi medium-entropy alloy studied by in situ high-energy X-ray diffraction. Mater. Sci. Eng. A 788, 139600 (2020)

J.B. Seol, J.W. Bae, Z. Li, J.C. Han, J.G. Kim, D. Raabe, H.S. Kim, Boron doped ultrastrong and ductile high-entropy alloys. Acta Mater. 151, 366–376 (2018)

D.W. Kim, J. Yoo, S.S. Sohn, S. Lee, Austenite reversion through subzero transformation and tempering of a boron-doped strong and ductile medium-Mn lightweight steel. Mater. Sci. Eng. A 802, 140619 (2021)

D. Raabe, M. Herbig, S. Sandlöbes, Y. Li, D. Tytko, M. Kuzmina, D. Ponge, P.P. Choi, Grain boundary segregation engineering in metallic alloys: a pathway to the design of interfaces. Curr. Opin. Solid State Mater. Sci. 18(4), 253–261 (2014)

J.B. Seol, J.W. Bae, J.G. Kim, H. Sung, Z. Li, H.H. Lee, S.H. Shim, J.H. Jang, W.S. Ko, S.I. Hong, H.S. Kim, Short-range order strengthening in boron-doped high-entropy alloys for cryogenic applications. Acta Mater. 194, 366–377 (2020)

T. Osanai, N. Sekido, M. Yonemura, K. Maruyama, M. Takeuchi, K. Yoshimi, Evolution of boron segregation during tempering in B doped 9% Cr ferritic steel. Mater. Charact. 177, 111192 (2021)

G. Miyamoto, A. Goto, N. Takayama, T. Furuhara, Three-dimensional atom probe analysis of boron segregation at austenite grain boundary in a low carbon steel-effects of boundary misorientation and quenching temperature. Scr. Mater. 154, 168–171 (2018)

H. Shahmir, M. Nili-Ahmadabadi, A. Shafiee, T.G. Langdon, Effect of a minor titanium addition on the superplastic properties of a CoCrFeNiMn high-entropy alloy processed by high-pressure torsion. Mater. Sci. Eng. A 718, 468–476 (2018)

H. Shahmir, M. Nili-Ahmadabadi, A. Shafie, T.G. Langdon, Hardening and thermal stability of a nanocrystalline CoCrFeNiMnTi0 1 high-entropy alloy processed by high-pressure torsion. IOP Conf. Ser. 194, 012017 (2017)

Y. Xie, Y. Luo, T. Xia, W. Zeng, J. Wang, J. Liang, D. Zhou, D. Zhang, Grain growth and strengthening mechanisms of ultrafine-grained CoCrFeNiMn high entropy alloy matrix nanocomposites fabricated by powder metallurgy. J. Alloys Compd. 819, 152937 (2020)

A. Fu, W. Guo, B. Liu, Y. Cao, L. Xu, Q. Fang, H. Yang, Y. Liu, A particle reinforced NbTaTiV refractory high entropy alloy based composite with attractive mechanical properties. J. Alloys Compd. 815, 152466 (2020)

Y. Xie, Z. Zhang, Y. Luo, J. Wang, J. Liang, D. Zhang, Plastic deformation behavior of ultrafine grained CoCrFeNiMn high entropy alloy with nanoparticles. Intermetallics 142, 107459 (2022)

N. Gao, D.H. Lu, Y.Y. Zhao, X.W. Liu, G.H. Liu, Y. Wu, G. Liu, Z.T. Fan, Z.P. Lu, E.P. George, Strengthening of a CrMnFeCoNi high-entropy alloy by carbide precipitation. J. Alloys Compd. 792, 1028–1035 (2019)

M. Li, Y. Guo, W. Li, Y. Zhang, Y. Chang, Property enhancement of CoCrNi medium-entropy alloy by introducing nano-scale features. Mater. Sci. Eng. A 817, 141368 (2021)

Y. Guo, M. Li, P. Li, C. Chen, Q. Zhan, Y. Chang, Y. Zhang, Microstructure and mechanical properties of oxide dispersion strengthened FeCoNi concentrated solid solution alloys. J. Alloys Compd. 820, 153104 (2020)

P. Asghari-Rad, N.T.C. Nguyen, Y. Kim, A. Zargaran, P. Sathiyamoorthi, H.S. Kim, TiC-reinforced CoCrFeMnNi composite processed by cold-consolidation and subsequent annealing. Mater. Lett. 303, 130503 (2021)

K.A. Christofidou, T.P. McAuliffe, P.M. Mignanelli, H.J. Stone, N.G. Jones, On the prediction and the formation of the sigma phase in CrMnCoFeNix high entropy alloys. J. Alloys Compd. 770, 285–293 (2019)

K. Cho, Y. Fujioka, T. Nagase, H.Y. Yasuda, Grain refinement of non-equiatomic Cr-rich CoCrFeMnNi high-entropy alloys through combination of cold rolling and precipitation of σ phase. Mater. Sci. Eng., A 735, 191–200 (2018)

C. Wagner, A. Ferrari, J. Schreuer, J.P. Couzinié, Y. Ikeda, F. Körmann, G. Eggeler, E.P. George, G. Laplanche, Effects of Cr/Ni ratio on physical properties of Cr-Mn-Fe-Co-Ni high-entropy alloys. Acta Mater. 227, 117693 (2022)

Y.C. Huang, C.H. Su, S.K. Wu, C. Lin, A study on the Hall-Petch relationship and grain growth kinetics in FCC-structured high/medium entropy alloys. Entropy 21(3), 297 (2019)

Z. Wu, H. Bei, F. Otto, G.M. Pharr, E.P. George, Recovery, recrystallization, grain growth and phase stability of a family of FCC-structured multi-component equiatomic solid solution alloys. Intermetallics 46, 131–140 (2014)

P. Thirathipviwat, G. Song, J. Jayaraj, J. Bednarcik, H. Wendrock, T. Gemming, J. Freudenberger, K. Nielsch, J. Han, A comparison study of dislocation density, recrystallization and grain growth among nickel, FeNiCo ternary alloy and FeNiCoCrMn high entropy alloy. J. Alloys Compd. 790, 266–273 (2019)

D. Xu, M. Wang, T. Li, X. Wei, Y. Lu, A critical review of the mechanical properties of CoCrNi-based medium-entropy alloys. Microstructures 2(1), 2022001 (2022)

K.A. Christofidou, E.J. Pickering, P. Orsatti, P.M. Mignanelli, T.J.A. Slater, H.J. Stone, N.G. Jones, On the influence of Mn on the phase stability of the CrMnxFeCoNi high entropy alloys. Intermetallics 92, 84–92 (2018)

G. Bracq, M. Laurent-Brocq, L. Perrière, R. Pirès, J.M. Joubert, I. Guillot, The fcc solid solution stability in the Co-Cr-Fe-Mn-Ni multi-component system. Acta Mater. 128, 327–336 (2017)

N.D. Stepanov, D.G. Shaysultanov, M.A. Tikhonovsky, G.A. Salishchev, Tensile properties of the Cr–Fe–Ni–Mn non-equiatomic multicomponent alloys with different Cr contents. Mater. Des. 87, 60–65 (2015)

M. Tian, C. Wu, Y. Liu, H. Peng, J. Wang, X. Su, Phase stability and microhardness of CoCrFeMnxNi2-x high entropy alloys. J. Alloys Compd. 811, 152025 (2019)

S. Praveen, J. Basu, S. Kashyap, K.G. Pradeep, R.S. Kottada, Thermal stability and grain boundary strengthening in ultrafine-grained CoCrFeNi high entropy alloy composite. Mater. Des. 134, 426–433 (2017)

S. Praveen, J. Basu, S. Kashyap, R.S. Kottada, Exceptional resistance to grain growth in nanocrystalline CoCrFeNi high entropy alloy at high homologous temperatures. J. Alloys Compd. 662, 361–367 (2016)

M. Tekin, G. Polat, Y.E. Kalay, H. Kotan, Grain size stabilization of oxide dispersion strengthened CoCrFeNi-Y2O3 high entropy alloys synthesized by mechanical alloying. J. Alloys Compd. 887, 161363 (2021)

B. Gwalani, R.M. Pohan, O.A. Waseem, T. Alam, S.H. Hong, H.J. Ryu, R. Banerjee, Strengthening of Al0. 3CoCrFeMnNi-based ODS high entropy alloys with incremental changes in the concentration of Y2O3. Scr. Mater. 162, 477–481 (2019)

B. Jia, X. Liu, H. Wang, Y. Wu, Z. Lu, Microstructure and mechanical properties of FeCoNiCr high-entropy alloy strengthened by nano-Y2O3 dispersion. Sci. China Technol. Sci. 61(2), 179–183 (2018)

Y.K. Kim, J.E. Ahn, Y. Song, H. Choi, S. Yang, K.A. Lee, Selective laser melted CrMnFeCoNi+ 3 wt% Y2O3 high-entropy alloy matrix nanocomposite: fabrication, microstructure and nanoindentation properties. Intermetallics 138, 107319 (2021)

N. Zhou, T. Hu, J. Huang, J. Luo, Stabilization of nanocrystalline alloys at high temperatures via utilizing high-entropy grain boundary complexions. Scr. Mater. 124, 160–163 (2016)

N. Zhou, T. Hu, J. Luo, Grain boundary complexions in multicomponent alloys: challenges and opportunities. Curr. Opin. Solid State Mater. Sci. 20(5), 268–277 (2016)

P. Lejček, S. Hofmann, M. Všianská, M. Šob, Entropy matters in grain boundary segregation. Acta Mater. 206, 116597 (2021)

X. Liang, Q. Wu, H. Li, R. Wang, L. Kang, B. Liu, L. Wang, Static recrystallization and texture evolution of cold-rolled powder metallurgy CoCrFeNiN0.07 high-entropy alloy. J. Alloys Compd. 862, 158602 (2021)

M.H. Mohammad-Ebrahimi, A. Zarei-Hanzaki, H.R. Abedi, S.M. Vakili, C.K. Soundararajan, Decelerated grain growth kinetic and effectiveness of Hall-Petch relationship in a cold-rolled non-equiatomic high entropy alloy. J. Alloys Compd. 874, 159849 (2021)

M. Soleimani, A. Kalhor, H. Mirzadeh, Transformation-induced plasticity (TRIP) in advanced steels: a review. Mater. Sci. Eng. A 795, 140023 (2020)

M.J. Sohrabi, M. Naghizadeh, H. Mirzadeh, Deformation-induced martensite in austenitic stainless steels: a review. Arch. Civil Mech. Eng. 20(4), 1–24 (2020)

J.M. Park, P. Asghari-Rad, A. Zargaran, J.W. Bae, J. Moon, H. Kwon, J. Choe, S. Yang, J.H. Yu, H.S. Kim, Nano-scale heterogeneity-driven metastability engineering in ferrous medium-entropy alloy induced by additive manufacturing. Acta Mater. 221, 117426 (2021)

K. Zhang, X. Zhang, E. Zhang, R. Wei, L. Wang, J. Chen, S. Yuan, Z. Han, C. Chen, F. Li, Strengthening of ferrous medium entropy alloys by promoting phase transformation. Intermetallics 136, 107265 (2021)

P. Sathiyamoorthi, P. Asghari-Rad, J.W. Bae, H.S. Kim, Fine tuning of tensile properties in CrCoNi medium entropy alloy through cold rolling and annealing. Intermetallics 113, 106578 (2019)

G.D. Sathiaraj, W. Skrotzki, A. Pukenas, R. Schaarschuch, R.J. Immanuel, S.K. Panigrahi, J.A. Chelvane, S.S. Kumar, Effect of annealing on the microstructure and texture of cold rolled CrCoNi medium-entropy alloy. Intermetallics 101, 87–98 (2018)

G.W. Hu, L.C. Zeng, H. Du, X.W. Liu, Y. Wu, P. Gong, Z.T. Fan, Q. Hu, E.P. George, Tailoring grain growth and solid solution strengthening of single-phase CrCoNi medium-entropy alloys by solute selection. J. Mater. Sci. Technol. 54, 196–205 (2020)

R. Chang, W. Fang, X. Bai, C. Xia, X. Zhang, H. Yu, B. Liu, F. Yin, Effects of tungsten additions on the microstructure and mechanical properties of CoCrNi medium entropy alloys. J. Alloys Compd. 790, 732–743 (2019)

G.W. Hu, L.C. Zeng, H. Du, Q. Wang, Z.T. Fan, X.W. Liu, Combined effects of solute drag and Zener pinning on grain growth of a NiCoCr medium-entropy alloy. Intermetallics 136, 107271 (2021)

E.A. Brandes, G.B. Brook (eds.), Smithells metals reference book (Elsevier, Burlington, 2013)

N. Li, J. Gu, B. Gan, Q. Qiao, S. Ni, M. Song, Effects of Mo-doping on the microstructure and mechanical properties of CoCrNi medium entropy alloy. J. Mater. Res. 35(20), 2726–2736 (2020)

J.W. Cahn, The impurity-drag effect in grain boundary motion. Acta Metall. 10(9), 789–798 (1962)

M. Naghizadeh, H. Mirzadeh, Elucidating the effect of alloying elements on the behavior of austenitic stainless steels at elevated temperatures. Metall. Mater. Trans. A 47(12), 5698–5703 (2016)

H.M. Tawancy, On the tensile strength of medium entropy Fe30Ni30Cr20Co17Mo2W1 alloy with high microstructural stability. Mater. Sci. Eng. A 781, 139239 (2020)

R. Chang, W. Fang, J. Yan, H. Yu, X. Bai, J. Li, S. Wang, S. Zheng, F. Yin, Microstructure and mechanical properties of CoCrNi-Mo medium entropy alloys: experiments and first-principle calculations. J. Mater. Sci. Technol. 62, 25–33 (2021)

J. He, S.K. Makineni, W. Lu, Y. Shang, Z. Lu, Z. Li, B. Gault, On the formation of hierarchical microstructure in a Mo-doped NiCoCr medium-entropy alloy with enhanced strength-ductility synergy. Scr. Mater. 175, 1–6 (2020)

C. Zhang, B. Liu, Y. Liu, Q. Fang, W. Guo, H. Yang, Effects of annealing on microstructure and mechanical properties of metastable powder metallurgy CoCrFeNiMo0.2 high entropy alloy. Entropy 21(5), 448 (2019)

J.W. Bae, J.M. Park, J. Moon, W.M. Choi, B.J. Lee, H.S. Kim, Effect of μ-precipitates on the microstructure and mechanical properties of non-equiatomic CoCrFeNiMo medium-entropy alloys. J. Alloys Compd. 781, 75–83 (2019)

D.E. Jodi, J. Park, N. Park, Precipitate behavior in nitrogen-containing CoCrNi medium-entropy alloys. Mater. Charact. 157, 109888 (2019)

P.C. Zhao, B. Guan, Y.G. Tong, R.Z. Wang, X. Li, X.C. Zhang, S.T. Tu, A quasi-in-situ EBSD study of the thermal stability and grain growth mechanisms of CoCrNi medium entropy alloy with gradient-nanograined structure. J. Mater. Sci. Technol. 109, 54–63 (2022)

B. Zhang, J. Chen, P. Wang, B. Sun, Y. Cao, Enhanced strength-ductility of CoCrFeMnNi high-entropy alloy with inverse gradient-grained structure prepared by laser surface heat-treatment technique. J. Mater. Sci. Technol. 111, 111–119 (2022)

H.T. Jeong, W.J. Kim, Grain size and temperature effect on the tensile behavior and deformation mechanisms of non-equiatomic Fe41Mn25Ni24Co8Cr2 high entropy alloy. J. Mater. Sci. Technol. 42, 190–202 (2020)

B. Kang, J. Lee, H.J. Ryu, S.H. Hong, Microstructure, mechanical property and Hall-Petch relationship of a light-weight refractory Al0. 1CrNbVMo high entropy alloy fabricated by powder metallurgical process. J. Alloys Compd. 767, 1012–1021 (2018)

L. Li, J. Lu, X. Liu, T. Dong, X. Zhao, F. Yang, F. Guo, AlxCoCrFeNi high entropy alloys with superior hot corrosion resistance to Na2SO4+ 25% NaCl at 900° C. Corros. Sci. 187, 109479 (2021)

Z.Y. Ding, B.X. Cao, J.H. Luan, Z.B. Jiao, Synergistic effects of Al and Ti on the oxidation behaviour and mechanical properties of L12-strengthened FeCoCrNi high-entropy alloys. Corros. Sci. 184, 109365 (2021)

R. Gawel, Ł Rogal, J. Dąbek, M. Wójcik-Bania, K. Przybylski, High temperature oxidation behaviour of non-equimolar AlCoCrFeNi high entropy alloys. Vacuum 184, 109969 (2021)

Z. Li, L. Fu, J. Peng, H. Zheng, A. Shan, Effect of annealing on microstructure and mechanical properties of an ultrafine-structured Al-containing FeCoCrNiMn high-entropy alloy produced by severe cold rolling. Mater. Sci. Eng. A 786, 139446 (2020)

M.M. Garlapati, M. Vaidya, A. Karati, S. Mishra, R. Bhattacharya, B.S. Murty, Influence of Al content on thermal stability of nanocrystalline AlxCoCrFeNi high entropy alloys at low and intermediate temperatures. Adv. Powder Technol. 31(5), 1985–1993 (2020)

Z. Sun, X. Tan, C. Wang, M. Descoins, D. Mangelinck, S.B. Tor, E.A. Jägle, S. Zaefferer, D. Raabe, Reducing hot tearing by grain boundary segregation engineering in additive manufacturing: example of an AlxCoCrFeNi high-entropy alloy. Acta Mater. 204, 116505 (2021)

D. Hachet, S. Gorsse, S. Godet, Microstructure study of cold rolled Al0 32CoCrFeMnNi high-entropy alloy: interactions between recrystallization and precipitation. Mater. Sci. Eng. A 802, 140452 (2021)

J.M. Park, J. Moon, J.W. Bae, J. Jung, S. Lee, H.S. Kim, Effect of annealing heat treatment on microstructural evolution and tensile behavior of Al0.5CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A 728, 251–258 (2018)

N.D. Stepanov, D.G. Shaysultanov, R.S. Chernichenko, D.M. Ikornikov, V.N. Sanin, S.V. Zherebtsov, Mechanical properties of a new high entropy alloy with a duplex ultra-fine grained structure. Mater. Sci. Eng. A 728, 54–62 (2018)

J.C. Rao, H.Y. Diao, V. Ocelík, D. Vainchtein, C. Zhang, C. Kuo, Z. Tang, W. Guo, J.D. Poplawsky, Y. Zhou, P.K. Liaw, Secondary phases in AlxCoCrFeNi high-entropy alloys: an in-situ TEM heating study and thermodynamic appraisal. Acta Mater. 131, 206–220 (2017)

B. Gwalani, V. Soni, M. Lee, S.A. Mantri, Y. Ren, R. Banerjee, Optimizing the coupled effects of Hall-Petch and precipitation strengthening in a Al0.3CoCrFeNi high entropy alloy. Mater. Des. 121, 254–260 (2017)

T. Guo, J. Li, J. Wang, W.Y. Wang, Y. Liu, X. Luo, H. Kou, E. Beaugnon, Microstructure and properties of bulk Al0.5CoCrFeNi high-entropy alloy by cold rolling and subsequent annealing. Mater. Sci. Eng. A 729, 141–148 (2018)

I.S. Wani, G.D. Sathiaraj, M.Z. Ahmed, S.R. Reddy, P.P. Bhattacharjee, Evolution of microstructure and texture during thermo-mechanical processing of a two phase Al0. 5CoCrFeMnNi high entropy alloy. Mater. Charact. 118, 417–424 (2016)

H.Y. Yasuda, H. Miyamoto, K. Cho, T. Nagase, Formation of ultrafine-grained microstructure in Al0.3CoCrFeNi high entropy alloys with grain boundary precipitates. Mater. Lett. 199, 120–123 (2017)

Z. Zhang, Y.H. Xie, X.Y. Huo, S.L.I. Chan, J.M. Liang, Y.F. Luo, D.K.Q. Mu, J. Ju, J. Sun, J. Wang, Microstructure and mechanical properties of ultrafine grained CoCrFeNi and CoCrFeNiAl0.3 high entropy alloys reinforced with Cr2O3/Al2O3 nanoparticles. Mater. Sci. Eng. A 816, 141313 (2021)

J. Hou, X. Shi, J. Qiao, Y. Zhang, P.K. Liaw, Y. Wu, Ultrafine-grained dual phase Al0.45CoCrFeNi high-entropy alloys. Mater. Design 180, 107910 (2019)

C. Zener, Grains, phases and interfaces: an interpretation of microstructure. Trans. AIME 175, 15–51 (1948)

P. Hellman, M. Hillert, On the effect of second-phase particles on grain growth. Scand. J. Metall. 4, 211–219 (1975)

L. Anand, J. Gurland, The relationship between the size of cementite particles and the subgrain size in quenched-and-tempered steels. Metall. Trans. A 6(4), 928–931 (1975)

H. Kim, D. Lee, H. Kim, Y. Kim, M. Jang, D. Kwen, Y. Koo, E. Kim, H. Cho, M.P. Agustianingrum, N. Park, The formation of B2-precipitate and its effect on grain growth behavior in aluminum-containing CoCrNi medium-entropy alloy. Mater. Lett. 303, 130481 (2021)

M. Annasamy, N. Haghdadi, A. Taylor, P. Hodgson, D. Fabijanic, Static recrystallization and grain growth behaviour of Al0. 3CoCrFeNi high entropy alloy. Mater. Sci. Eng. A 754, 282–294 (2019)

S. Dudala, S.C. Krishna, R. Korla, Microstructural evolution and grain-growth kinetics of Al0 2CoCrFeNi high-entropy alloy. Philos. Mag. Lett. 101(11), 444–454 (2021)

C.S. Wu, P.H. Tsai, C.M. Kuo, C.W. Tsai, Effect of atomic size difference on the microstructure and mechanical properties of high-entropy alloys. Entropy 20(12), 967 (2018)

M. Wang, Z.L. Ma, Z.Q. Xu, X.W. Cheng, Designing VxNbMoTa refractory high-entropy alloys with improved properties for high-temperature applications. Scr. Mater. 191, 131–136 (2021)

R.R. Eleti, V. Raju, M. Veerasham, S.R. Reddy, P.P. Bhattacharjee, Influence of strain on the formation of cold-rolling and grain growth textures of an equiatomic HfZrTiTaNb refractory high entropy alloy. Mater. Charact. 136, 286–292 (2018)

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, P.K. Liaw, Refractory high-entropy alloys. Intermetallics 18(9), 1758–1765 (2010)

Z.K. Dehkordi, M. Malekan, M. Nili-Ahmadabadi, Superplastic formability of the developed Zr40Hf10Ti5Al10Cu25Ni10 high entropy bulk metallic glass with enhanced thermal stability. J. Non-Cryst. Solids 576, 121265 (2022)

A. Jalali, M. Malekan, E.S. Park, R. Rashidi, A. Bahmani, G.H. Yoo, Thermal behavior of newly developed Zr33Hf8Ti6Cu32Ni10Co5Al6 high-entropy bulk metallic glass. J. Alloys Compd. 892, 162220 (2022)

A. Jalali, M. Malekan, E.S. Park, R. Rashidi, A. Bahmani, G.H. Yoo, Deformation behavior of Zr33Hf8Ti6Cu32Ni10Co5Al6 high-entropy bulk metallic glass and Cu47Zr47Al6 low-entropy bulk metallic glass at room and high temperatures. Mater. Sci. Eng. A 832, 142499 (2022)

C.C. Juan, M.H. Tsai, C.W. Tsai, W.L. Hsu, C.M. Lin, S.K. Chen, S.J. Lin, J.W. Yeh, Simultaneously increasing the strength and ductility of a refractory high-entropy alloy via grain refining. Mater. Lett. 184, 200–203 (2016)

S. Chen, K.K. Tseng, Y. Tong, W. Li, C.W. Tsai, J.W. Yeh, P.K. Liaw, Grain growth and Hall-Petch relationship in a refractory HfNbTaZrTi high-entropy alloy. J. Alloys Compd. 795, 19–26 (2019)

G. Neumann, C. Tuijn, Self-diffusion and impurity diffusion in pure metals: handbook of experimental data (Elsevier, 2011)

X. Huang, L. Liu, X. Duan, W. Liao, J. Huang, H. Sun, C. Yu, Atomistic simulation of chemical short-range order in HfNbTaZr high entropy alloy based on a newly-developed interatomic potential. Mater. Des. 202, 109560 (2021)

Y.C. Huang, Y.C. Lai, Y.H. Lin, S.K. Wu, A study on the severely cold-rolled and annealed quaternary equiatomic derivatives from quinary HfNbTaTiZr refractory high entropy alloy. J. Alloys Compd. 855, 157404 (2021)

O.N. Senkov, A.L. Pilchak, S.L. Semiatin, Effect of cold deformation and annealing on the microstructure and tensile properties of a HfNbTaTiZr refractory high entropy alloy. Metall. Mater. Trans. A 49(7), 2876–2892 (2018)

L. Xiang, W. Guo, B. Liu, A. Fu, J. Li, Q. Fang, Y. Liu, Microstructure and mechanical properties of TaNbVTiAlx refractory high-entropy alloys. Entropy 22(3), 282 (2020)

B. Guo, R.K. Ray, S. Yoshida, Y. Bai, N. Tsuji, In-situ observations of static recrystallization and texture formation in a cold-rolled CoCrFeMnNi high entropy alloy. Scr. Mater. 215, 114706 (2022)

F. Najafkhani, H. Mirzadeh, M. Zamani, Effect of intercritical annealing conditions on grain growth kinetics of dual phase steel. Met. Mater. Int. 25(4), 1039–1046 (2019)

M. Naghizadeh, H. Mirzadeh, Microstructural evolutions during reversion annealing of cold-rolled AISI 316 austenitic stainless steel. Metall. Mater. Trans. A 49(6), 2248–2256 (2018)

Y. Liu, G. He, Y. Yang, K. Li, H. Gong, B. Gan, C. Huang, Revealing the microstructural evolution and mechanism during the thermomechanical treatment of polycrystalline CrCoNi medium-entropy alloy. J. Alloys Compd. 870, 159518 (2021)

M. Naghizadeh, H. Mirzadeh, Microstructural evolutions during annealing of plastically deformed AISI 304 austenitic stainless steel: martensite reversion, grain refinement, recrystallization, and grain growth. Metall. Mater. Trans. A 47(8), 4210–4216 (2016)

M.J. Sohrabi, H. Mirzadeh, C. Dehghanian, Significance of martensite reversion and austenite stability to the mechanical properties and transformation-induced plasticity effect of austenitic stainless steels. J. Mater. Eng. Perform. 29(5), 3233–3242 (2020)

S. Kheiri, H. Mirzadeh, M. Naghizadeh, Tailoring the microstructure and mechanical properties of AISI 316L austenitic stainless steel via cold rolling and reversion annealing. Mater. Sci. Eng. A 759, 90–96 (2019)

S. Schmidt, G.D. Sathiaraj, S.S. Kumar, B. Sulkowski, S. Suwas, J. Jaschinski, A. Pukenas, B. Gu, W. Skrotzki, Effect of rolling and annealing temperature on the mechanical properties of CrMnFeCoNi high-entropy alloy. Mater. Chem. Phys. 270, 124830 (2021)

Y. Wu, J. Liu, L. Bhatta, C. Kong, H. Yu, Study of texture analysis on asymmetric cryorolled and annealed CoCrNi medium entropy alloy. Curr. Comput.-Aided Drug Des. 10(12), 1154 (2020)

H. Thota, R. Jeyaraam, L.R. Bairi, A.S. Tirunilai, A. Kauffmann, J. Freudenberger, M. Heilmaier, S. Mandal, S.S. Vadlamani, Grain boundary engineering and its implications on corrosion behavior of equiatomic CoCrFeMnNi high entropy alloy. J. Alloys Compd. 888, 161500 (2021)

M. Liu, S. Zhang, F. Li, Y. Luo, Y. Yao, H. Zhang, Z. Wang, L. Wang, Z. Wang, Tailoring the strength and ductility of Al0.25CoCrFeNi high entropy alloy through cryo-rolling and annealing. Mater. Sci. Eng. A 826, 141964 (2021)

J. Wang, H. Li, H. Yang, Y. Zhang, W.Y. Wang, J. Li, Hot deformation and subsequent annealing on the microstructure and hardness of an Al0.3CoCrFeNi high-entropy alloy. Acta Metall. Sin. (English Letters) 34(11), 1527–1536 (2021)

S. Vervynckt, K. Verbeken, B. Lopez, J.J. Jonas, Modern HSLA steels and role of non-recrystallisation temperature. Int. Mater. Rev. 57(4), 187–207 (2012)

H. Chen, T. Lu, Y. Wang, Y. Liu, T. Shi, K.G. Prashanth, K. Kosiba, Laser additive manufacturing of nano-TiC particles reinforced CoCrFeMnNi high-entropy alloy matrix composites with high strength and ductility. Mater. Sci. Eng. A 833, 142512 (2021)

Y.L. Wang, L. Zhao, D. Wan, S. Guan, K.C. Chan, Additive manufacturing of TiB2-containing CoCrFeMnNi high-entropy alloy matrix composites with high density and enhanced mechanical properties. Mater. Sci. Eng. A 825, 141871 (2021)

J. Li, S. Xiang, H. Luan, A. Amar, X. Liu, S. Lu, Y. Zeng, G. Le, X. Wang, F. Qu, C. Jiang, Additive manufacturing of high-strength CrMnFeCoNi high-entropy alloys-based composites with WC addition. J. Mater. Sci. Technol. 35(11), 2430–2434 (2019)

Y.Y. Shang, Y. Wu, J.Y. He, X.Y. Zhu, S.F. Liu, H.L. Huang, K. An, Y. Chen, S.H. Jiang, H. Wang, X.J. Liu, Solving the strength-ductility tradeoff in the medium-entropy NiCoCr alloy via interstitial strengthening of carbon. Intermetallics 106, 77–87 (2019)

Y.K. Kim, K.A. Lee, Stabilized sub–grain and nano carbides–driven 1.2 GPa grade ultra–strong CrMnFeCoNi high–entropy alloy additively manufactured by laser powder bed fusion. J. Mater. Sci. Technol. 117, 8–22 (2022)

M. Traversier, P. Mestre-Rinn, N. Peillon, E. Rigal, X. Boulnat, F. Tancret, J. Dhers, A. Fraczkiewicz, Nitrogen-induced hardening in an austenitic CrFeMnNi high-entropy alloy (HEA). Mater. Sci. Eng. A 804, 140725 (2021)

K.S. Chung, P.M. Yiu, T.F. Hung, C.H. Shek, Strengthening and deformation mechanism of a Fe20Co20Cr20Mn20Ni20 high entropy alloy with high nitrogen content. J. Alloys Compd. 871, 159587 (2021)

X.W. Liu, G. Laplanche, A. Kostka, S.G. Fries, J. Pfetzing-Micklich, G. Liu, E.P. George, Columnar to equiaxed transition and grain refinement of cast CrCoNi medium-entropy alloy by microalloying with titanium and carbon. J. Alloys Compd. 775, 1068–1076 (2019)

H. Chang, T.W. Zhang, S.G. Ma, D. Zhao, R.L. Xiong, T. Wang, Z.Q. Li, Z.H. Wang, Novel Si-added CrCoNi medium entropy alloys achieving the breakthrough of strength-ductility trade-off. Mater. Des. 197, 109202 (2021)

O.N. Senkov, G.B. Wilks, J.M. Scott, D.B. Miracle, Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 19(5), 698–706 (2011)

Z. Lei, X. Liu, Y. Wu, H. Wang, S. Jiang, S. Wang, X. Hui, Y. Wu, B. Gault, P. Kontis, D. Raabe, Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature 563(7732), 546–550 (2018)

J.A. Smeltzer, B.C. Hornbuckle, A.K. Giri, K.A. Darling, M.P. Harmer, H.M. Chan, C.J. Marvel, Nitrogen-induced hardening of refractory high entropy alloys containing laminar ordered phases. Acta Mater. 211, 116884 (2021)

Y. Guo, J. He, Z. Li, L. Jia, X. Wu, C. Liu, Strengthening and dynamic recrystallization mediated by Si-alloying in a refractory high entropy alloy. Mater. Sci. Eng. A 832, 142480 (2022)

S.S. Sohn, A. Kwiatkowski da Silva, Y. Ikeda, F. Körmann, W. Lu, W.S. Choi, B. Gault, D. Ponge, J. Neugebauer, D. Raabe, Ultrastrong medium-entropy single-phase alloys designed via severe lattice distortion. Adv. Mater. 31(8), 1807142 (2019)

J.M. Park, D.C. Yang, H.J. Kim, D.G. Kim, S. Lee, H.S. Kim, S.S. Sohn, Ultra-strong and strain-hardenable ultrafine-grained medium-entropy alloy via enhanced grain-boundary strengthening. Mater. Res. Lett. 9(7), 315–321 (2021)

G.D. Sathiaraj, M.Z. Ahmed, P.P. Bhattacharjee, Microstructure and texture of heavily cold-rolled and annealed fcc equiatomic medium to high entropy alloys. J. Alloys Compd. 664, 109–119 (2016)

H. Ma, Y. Shao, C.H. Shek, Microstructure, grain growth behavior and mechanical properties of W-CoCuFeNi tungsten heavy alloys prepared by infiltration. Int. J. Refract Metal Hard Mater. 98, 105572 (2021)

R. Jian, L. Wang, S. Zhou, Y. Zhu, Y.J. Liang, B. Wang, Y. Xue, Achieving fine-grain tungsten heavy alloys by selecting a high entropy alloy matrix with low W grain growth rate. Mater. Lett. 278, 128405 (2020)

C.S. Chen, C.C. Yang, H.Y. Chai, J.W. Yeh, J.L.H. Chau, Novel cermet material of WC/multi-element alloy. Int. J. Refract Metal Hard Mater. 43, 200–204 (2014)

P.F. Zhou, D.H. Xiao, T.C. Yuan, Comparison between ultrafine-grained WC–Co and WC–HEA-cemented carbides. Powder Metall. 60(1), 1–6 (2017)

Y. Shao, Z. Guo, Y. Wang, H. Ma, Fabrication and characterization of NbC-CoCrFeNiMn high-entropy alloy cermets. Int. J. Refract Metal Hard Mater. 94, 105388 (2021)

W. Luo, Y. Liu, J. Shen, Effects of binders on the microstructures and mechanical properties of ultrafine WC-10% AlxCoCrCuFeNi composites by spark plasma sintering. J. Alloys Compd. 791, 540–549 (2019)

S. Zhou, Y.J. Liang, Y. Zhu, B. Wang, L. Wang, Y. Xue, Ultrashort-time liquid phase sintering of high-performance fine-grain tungsten heavy alloys by laser additive manufacturing. J. Mater. Sci. Technol. 90, 30–36 (2021)

P.K. Huang, J.W. Yeh, Inhibition of grain coarsening up to 1000 C in (AlCrNbSiTiV) N superhard coatings. Scr. Mater. 62(2), 105–108 (2010)

J.J. Ruan, N. Ueshima, K. Oikawa, Phase transformations and grain growth behaviors in superalloy 718. J. Alloys Compd. 737, 83–91 (2018)

Acknowledgements

Jien-Wei Yeh acknowledges the financial support by the “High Entropy Materials Center” from The Featured Areas Research Center Program within the framework of the Higher Education Sprout Project by the Ministry of Education and from the Project MOST 111-2634-F-007-008 by Ministry of Science and Technology in Taiwan. Mohammad Reza Zamani and Hamed Mirzadeh would like to greatly thank the members of the Advanced Steels and Thermomechanically Processed Engineering Materials Laboratory for their help and support.

Author information

Authors and Affiliations

Contributions

The manuscript has been prepared by the contribution of all authors

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zamani, M.R., Mirzadeh, H., Malekan, M. et al. Grain Growth in High-Entropy Alloys (HEAs): A Review. High Entropy Alloys & Materials 1, 25–59 (2023). https://doi.org/10.1007/s44210-022-00002-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s44210-022-00002-8