Abstract

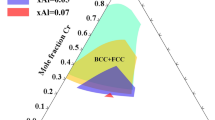

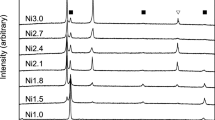

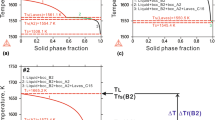

AlxCoCrFeNi high-entropy alloys have received significant attention recently because of their promising mechanical and corrosion-resistance properties. These alloys tend to form a mixture of fcc and bcc phases, where the latter has an important role in material hardening. In many cases, the bcc phase is a mixture of disordered bcc (A2), which is an Fe- and Cr-rich phase, and ordered bcc (primitive cubic, B2), which is an Al- , Ni- , and Co-rich phase. Although phase diagrams above x = 2 are somewhat consistent, they unfortunately contain no valuable data about the mole fraction and phase composition. Moreover, Alx > 2CoCrFeNi alloys suffer from a lack of systematic experimental investigation into the kinetics of the phase transformation. To clarify these points, the present study investigates the phase relations and precipitation kinetics of A2 from the B2 matrix in Al2.75CoCrFeNi. The results show that the compositions of the A2 and B2 phases are temperature-dependent and that, with increasing temperature in the B2 phase, the Al content decreases while the Cr content increases, which correlates with thermodynamic calculations. In addition, the equilibrium composition and phase content lead to a reduced lattice distortion parameter compared with that of the nominal alloy. Concerning the kinetics of phase transformation, the results suggest that, to precipitate in the solid state, the A2 phase within the B2 matrix must overcome the internal stresses that are due to the different lattice parameters of the two phases. Furthermore, the diffusion activation energy is estimated and its implications are discussed from the perspective of sluggish diffusion in multicomponent systems. Finally, the coefficients of thermal expansion of Al2.75CoCrFeNi alloy and of Al–Ni–Co- and Cr–Fe-rich alloys (both alloys containing Al, Co, Cr, Fe, Ni) were measured and are discussed in relation to phase transformation.

Similar content being viewed by others

References

Chen YY, Duval T, Hung UD, Yeh JW, Shih HC (2005) Microstructure and electrochemical properties of high entropy alloys—a comparison with type-304 stainless steel. Corros Sci 47(9):2257–2279

Tsai CW, Tsai MH, Yeh JW, Yang CC (2010) Effect of temperature on mechanical properties of Al0.5CoCrCuFeNi wrought alloy. J Alloys Compd 490(1–2):160–165

Tong CJ, Chen MR, Chen SK, Yeh JW, Shun TT, Lin SJ, Chang SY (2005) Mechanical performance of the AlxCoCrCuFeNi high-entropy alloy system with multiprincipal elements. Metall Mat Trans A 36(5):1263–1271

Lu YP, Dong Y, Guo S, Jiang L, Kang HJ, Wang TM, Wen B, Wang ZJ, Jie JC, Cao ZQ, Ruan HH, Li TJ (2014) A promising new class of high-temperature alloys: eutectic high-entropy alloys. Sci Rep 4:1–5

Munitz A, Salhov S, Hayun S, Frage N (2016) Heat treatment impacts the micro-structure and mechanical properties of AlCoCrFeNi high entropy alloy. J Alloys Compd 683:221–230

Wang WR, Wang WL, Wang SC, Tsai YC, Lai CH, Yeh JW (2012) Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 26:44–51

Kao YF, Chen TJ, Chen SK, Yeh JW (2009) Microstructure and mechanical property of as-cast, -homogenized, and -deformed AlxCoCrFeNi (0≤x≤2) high entropy alloys. J Alloy Compd 488(1):57–64

Zhang C, Zhang F, Chen S, Cao W (2012) Computational dynamics aided high-entropy alloy design. JOM 64 7:839–845

Zhang C, Gao MC (2016) CALPHAD modeling of high-entropy alloys. In: Gao MC, Yeh JW, Liaw PK, Zhang Y (eds) High-entropy alloys fundamentals and applications. Springer, Switzerland, p 422

Tsai KY, Tsai MH, Yeh JW (2013) Sluggish diffusion in Co–Cr–Fe–Mn–Ni high-entropy alloys. Acta Mater 61(13):4887–4897

Beke DL, Erdelyi G (2016) On the diffusion in high-entropy alloys. Mater Lett 164:111–113

Vaidya M, Trubel S, Murty BS, Wilde G, Divinski SV (2016) Ni tracer diffusion in CoCrFeNi and CoCrFeMnNi high entropy alloys. J Alloys Compd 688:994–1001

Hallstedt B (2017) private communication

Andersson JO, Helander T, Hoglund L, Shi PF, Sundman B (2002) Thermo-Calc and DICTRA, Computational tools for materials science. Calphad 26(2):273–312

Linden Y, Pinkas M, Munitz A, Meshi L (2017) Long-period antiphase domains and short-range order in a B2 matrix of the AlCoCrFeNi high-entropy alloy. Scr Mater 139:49–52

Lv Y, Hu R, Yao Z, Chen J, Xu D, Liu Y, Fan X (2017) Cooling rate effect on microstructure and mechanical properties of AlxCoCrFeNi high entropy alloys. Mater Des 132:392–399

Zhang Y, Zhou YJ, Lin JP, Chen GL, Liaw PK (2008) Solid-solution phase formation rules for multi-component alloys. Adv Eng Mater 10(6):534–538

Qiao JW, Ma SG, Huang EW, Chuang CP, Liaw PK, Zhang Y (2011) Microstructural characteristics and mechanical behaviors of AlCoCrFeNi high-entropy alloys at ambient and cryogenic temperatures. Mater Sci Forum 688:419–425

Wells AF (1984) Structural inorganic chemistry, 5th edn. Clarendon Press, Oxford

Lifshitz IM, Slyozov VV (1961) The kinetics of precipitation from supersaturated solid solutions. J Phys Chem Solids 19(1–2):35–50

Nadutov VM, Mazanko VF, Makarenko SY (2017) Tracer diffusion of cobalt in high-entropy alloys. AlxFeNiCoCuCrMetallofiz Noveishie Tekhnol 39(3):337–348

Chang SY, Li CE, Huang YC, Hsu HF, Yeh JW, Lin SJ (2014) Structural and thermodynamic factors of suppressed interdiffusion kinetics in multi-component high-entropy materials. Sci Rep 4(1):1–8

Hancock GF, McDonnell BR (1971) Diffusion in the intermetallic compound NiAl. Phys Stat Sol (a) 4(1):143–150

Li C, Li JC, Zhao M, Jiang Q (2010) Effect of aluminum contents on microstructure and properties of AlxCoCrFeNi alloys. J Alloys Compd 504:S515–S518

Tang Z, Senkov ON, Parish CM, Zhang C, Zhang F, Santodonato LJ, Wang G, Zhao G, Yang F, Liawa PK (2015) Tensile ductility of an AlCoCrFeNi multi-phase high-entropy alloy through hot isostatic pressing (HIP) and homogenization. Mater Sci Eng A 647:229–240

Nair RB, Arora HS, Mandal P, Grewal HS (2018) Complex concentrated coatings: effect of processing route on microstructural and mechanical properties. Mater Lett 230:100–104

Yang T, Xia S, Liu S, Wang C, Liu S, Fang Y, Zhang Y, Xue J, Yan S, Wang Y (2016) Precipitation behavior of AlxCoCrFeNi high entropy alloys under ion irradiation. Sci Rep 6:1–8

Chou HP, Chang YS, Chen SK, Yeh JW (2009) Microstructure, thermophysical and electrical properties in AlxCoCrFeNi (0 ≤ x ≤2) high-entropy alloys. Mater Sci Eng B 163(3):184–189

Acknowledgement

The authors would like to thank Dr. Bengt Hallstedt for permission to use his new thermodynamic database for HEAs. Gratitude also goes to Mr. Eyal Attal and Mr. Omri Azulai from the Physics Department at NRC-Negev, Israel, for their valuable technical assistance.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aizenshtein, M., Strumza, E., Brosh, E. et al. Precipitation kinetics, microstructure, and equilibrium state of A2 and B2 phases in multicomponent Al2.75CoCrFeNi alloy. J Mater Sci 55, 7016–7028 (2020). https://doi.org/10.1007/s10853-020-04487-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04487-9