Abstract

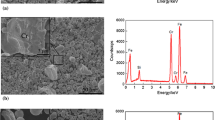

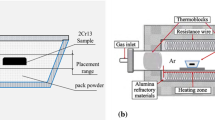

This study comes within the context of wear-resistant coatings and remanufacturing of shaft parts. It used FeMnCrNi and FeMnCrNi-Cr3C2 coatings deposited on the surface of Q235 steel by high-velocity arc spraying. The microstructure and mechanical properties of the coatings were studied and analyzed by scanning electron microscopy, energy dispersive spectrometry, x-ray diffraction (XRD), microhardness testing and an electronic universal testing machine. The FeMnCrNi coating consisted of α-(Fe, Cr) and Fe3O4 phases, while the FeMnCrNi-Cr3C2 coating consisted of γ-(Fe, Ni), α-(Fe, Cr), Fe3O4 phases and a Cr3C2 hard phase. The tensile bond strengths of the FeMnCrNi and FeMnCrNi-Cr3C2 coatings were 31 ± 4 MPa and 27 ± 1 MPa, respectively. The microhardness of the FeMnCrNi-Cr3C2 coating was 694 ± 82 HV0.1, 3.1 times higher than that of Q235 steel and 1.8 times that of the FeMnCrNi coating. The wear behavior of the coatings and substrate under different loads was studied by a material surface performance comprehensive tester. The results indicated that their wear rates increased with increasing load. Compared to the FeMnCrNi coating and Q235 steel, the FeMnCrNi-Cr3C2 coating had the lowest wear rate under different loads. The main wear mechanism of the FeMnCrNi-Cr3C2 coating was surface fatigue and abrasive wear.

Similar content being viewed by others

References

H.L. Tian, S.C. Wei, X.B. Liang, B.S. Xu, C.L. Wang, M.Q. Guo and Z.H. Tang, Bending Fatigue Life and Remanufacturing Benefit Evaluation of High Velocity Arc Spraying Remanufacturing Crankshaft, Rare. Metal. Mat. Eng., 2018, 47(2), p 538-545.

Z. Liu and L. Zhang, A Review of Failure Modes, Condition Monitoring and Fault Diagnosis Methods for LargeScale Wind Turbine Bearings, Measurement, 2020, 149, p 107002.

A.Q. Liu, K. Xiao, C.F. Dong and X.G. Li, Corrosion Behaviour of Zn-Al Pseudo-Alloy Coating on Carbon Steel in Chloride Environments, A. M. R., 2012, 567, p 45-48.

Z.P. Feng, X.N. Yu, D. Zhang and M. Liang, Generalized Adaptive Mode Decomposition for Nonstationary Signal Analysis of Rotating Machinery: Principle and Applications, Mech. Syst. Signal. Pr., 2020, 136, p 106530.

D. Souvik, M. Goutam and B. Sandip, Failure Analysis of Axle Shaft of a Fork Lift, Case. Stud. Therm. Eng., 2015, 3, p 46-51.

C. Moolwan and S. Netpu, Failure Analysis of a Two High Gearbox Shaft, Pro. Social. Behavioral. Sci., 2013, 88, p 154-163.

A. Fulvio and T.P. Laura, Accounting for the Environmental Benefits of Remanufactured Products: Method and Application, J. Clean. Prod., 2018, 198, p 1545-1558.

K.P. Jelena, S. Erik and P. Bonnie, Remanufacturing Challenges and Possible Lean Improvements, J. Clean. Prod., 2018, 172, p 3225-3236.

P.L. Fauchais, J.V.R. Heberlein and M.I. Boulos, Thermal spray fundamentals, Springer Verlag, Berlin, 2014, p 17-72

D. Amir and A. Fardad, Investigation on Relationship Between Microstructural Characteristics and Mechanical Properties of Wire-Arc-Sprayed Zn-Al Coating, J. Therm. Spray. Technol., 2020, 29(1), p 297-307.

A.M. Vilardell, N. Cinca, N. Garcia-Giralt, S. Dosta, I.G. Cano, X. Nogues and J.M. Guilemany, In-Vitro Comparison of Hydroxyapatite Coatings Obtained by Cold Spray and Conventional Thermal Spray Technologies, Mat. Sci. Eng-C., 2020, 107, p 1-8.

P. Das, S. Paul and P.P. Bandyopadhyay, Tribological Behaviour of HVOF Sprayed Diamond Reinforced Bronze Coatings, Diam. Relat. Mater., 2019, 93, p 16-25.

X.Q. Li, H.M. Zhai, W.S. Li, S. Cui, W.C. Ning and X.L. Qiu, Dry Sliding Wear Behaviors of Fe-Based Amorphous Metallic Coating Synthesized by d-Gun Spray, J. Non-Cryst. Solids., 2020, 537, p 120018.

D.D. Liang, J. Ma, Y.F. Cai, X.D. Liu, S.D. Xie, X.S. Wei, G. Xu and J. Shen, Characterization and Elevated Temperature Tribological Performance of AC-HVAF-Sprayed Fe-Based Amorphous Coating, Surf. Coat. Technol., 2020, 387, p 125535.

G.Y. Koga, R. Schulz, S. Savoie, A.R.C. Nascimento, Y. Drolet, C. Bolfarini, C.S. Kiminami and W.J. Botta, Microstructure and Wear Behavior of Fe-Based Amorphous HVOF Coatings Produced from Commercial Precursors, Surf. Coat. Technol., 2017, 309, p 938-944.

H.J. Cao, S.F. Tong, H.F. Chen and L.S. Shu, Analysis of Remanufacturing Process and Residual Stress of Axis Parts Based on Thermal Spraying, China. Mech. Eng., 2014, 25(24), p 3368-3372. ((in Chinese))

M.R. Dorfman and A. Sharma, Challenges and Strategies for Growth of Thermal Spray Markets: The Six-Pillar Plan, J. Therm. Spray. Technol., 2013, 22(5), p 559-563.

A. Vardelle, C. Moreau, J. Akedo et al., The 2016 Thermal Spray Roadmap, J. Therm. Spray. Technol., 2016, 25(8), p 1376-1440.

J.B. Cheng, X.B. Liang, Z.H. Wang and B.S. Xu, Microstructure and Mechanical Properties of FeBSiNb Metallic Glass Coatings by Twin Wire Arc Spraying, J. Therm. Spray. Technol., 2013, 22(4), p 471-477.

J.B. Cheng, Z.H. Wang and B.S. Xu, Wear and Corrosion Behaviors of FeCrBSiNbW Amorphous/Nanocrystalline Coating Prepared by Arc Spraying Process, J. Therm. Spray. Technol., 2012, 21, p 1025-1031.

R. Li, Z. Zhou, D.Y. He, Y.M. Wang, X. Wu and X.Y. Song, Microstructure and High Temperature Corrosion Behavior of Wire-Arc Sprayed FeCrSiB Coating, J. Therm. Spray. Technol., 2015, 24(5), p 857-864.

K.M. Wang, D. Du, G. Liu, B.H. Chang, J. Ju and S.T. Sun, Microstructure and Property of Laser Clad Fe-Based Composite layer Containing Nb and B4C Powders, J. Alloy. Compd., 2019, 802, p 373-384.

Q. Ma, Y. Li, J. Wang and K. Liu, Investigation on Cored-Eutectic Structure in Ni60/ WC Composite Coatings Fabricated by Wide-Band Laser Cladding, J. Alloy. Compd., 2015, 645, p 151-157.

S. Sun, H. Fu, S. Chen, X. Ping, K. Wang, X. Guo, J. Lin and Y. Lei, A Numerical Experimental Investigation of Heat Distribution, Stress Field and Crack Susceptibility in Ni60A Coatings, Opt. Laser Technol., 2019, 117, p 175-185.

Y. Zhao, T.B. Yu, C. Guan, J.Y. Sun and X.F. Tan, Microstructure and Friction Coefficient of Ceramic (TiC, TiN and B4C) Reinforced Ni-Based Coating by Laser Cladding, Ceram. Int., 2019, 45, p 20824-20836.

H.L. Tian, C.L. Wang, M.Q. Guo, Z.H. Tang, S.C. Wei and B.S. Xu, Frictional Wear Performance Under Oil-Lubricated Conditions and Wear Resistance Mechanism of High-Velocity Arc-Sprayed FeNiCrAl Coating, Surf. Coat. Technol., 2018, 353, p 237-246.

P. Ding, X.J. Liu, J.J. Liu, J.B. Li, H.Q. Li, H.Y. Zhao, J.Y. Duan and Y.Z. Jiao, Study on the Properties of FeCrNi/CBN Composite Coating with High Velocity Arc Spraying, Arab. J. Chem., 2018, 11(6), p 935-941.

Z.X. Li, J.J. Fang, Y.W. Shi and C.T. Chun, Microstructures and Properties of Fe-TiB2/Al2O3 Composite Ceramic Coatings Prepared by High Velocity Arc Spraying, T. Nonferr. Metal. Soc., 2005, 11, p 154-159.

D.Y. He, B.Y. Fu, J.M. Jiang and X.Y. Li, Microstructure and Wear Performance of Arc Sprayed Fe-FeB-WC Coatings, J. Therm. Spray. Technol., 2008, 17(5-6), p 757-761.

C.M. Wang, H.F. Sun, Q. Song and Z. Qu, Properties of Fe-based Cr3C2 Coatings Produced with a High-Velocity Arc-Spraying Process, J. Korean. Phys. Soc., 2009, 54(3), p 1339-1343.

W.P. Xu, B.S. Xu, W. Zhang and Y.X. Wu, High Temperature Behaviors of High Velocity Arc Sprayed Fe-Al/Cr3C2 Composite Coatings, J. Univ SCI. Technol. B., 2005, 12(4), p 340-346.

B.S. Xu, W. Zhang and W.P. Xu, Influence of Oxides on High Velocity Arc Sprayed Fe-Al/Cr3C2 Composite Coatings, J. Cent. South. Univ., 2005, 12(3), p 259-262.

X.B. Liang, Y.X. Chen, J.Y. Bai, Y. Liu and B.S. Xu, An Automatic High Velocity Arc Spraying Technology Applied to Remanufacture Engine Crankshaft, China. Surf. Eng., 2010, 23(2), p 112-116. ((in Chinese))

F. Huang, M. Kang, J.P. Zhu, J.R. Lin, Y. Zhang and J.N. Ndumia, Process Optimization and Wear Performance of High Velocity Arc Spraying FeMnCrNi/Cr3C2 Coating, T. Mater. Heat. Treat., 2021, 42(03), p 151-161. ((in Chinese))

ASTM E2109-01, Standard Test Methods for Determining Area Percentage Porosity in Thermal Sprayed Coatings, 2017. https://doi.org/10.1520/E2109-01R14.

ASTM E92-17, Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials, 2017. https://doi.org/10.1520/E0092-17.

ASTM C633-13, Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings, 2013. https://doi.org/10.1520/C0633-13.

ASTM G133-05, Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear, 2016. https://doi.org/10.1520/G0133-05R16.

ASTM E1920-03, Standard Guide for Metallographic Preparation of Thermal Sprayed Coatings, 2008. https://doi.org/10.1520/E1920-03R08.

F.K. Deng, T. Jiang, K.D. Yang and F.C. Huang, Low friction and wear self-assembly nano tribofilm of amphiphilic functionalized tea saponin in a water/oil phase, J. Clean. Prod., 2020, 270, p 122414.

J.R. Lin, Z.H. Wang, P.H. Lin, J.B. Cheng, X. Zhang and S. Hong, Microstructure and Cavitation Erosion Behavior of FeNiCrBSiNbW Coating Prepared by Twin Wires Arc Spraying Process, Surf. Coat. Technol., 2014, 240, p 432-436.

J.L. Xu, J.Z. Zhou, W.S. Tan, S. Huang, S.T. Wang and W.Y. He, Ultrasonic Vibration on Wear Property of Laser Cladding Fe-Based Coating, Surf. Eng., 2020, 36(12), p 1261-1269.

Q. Wang, X. Rui, Q.J. Wang, Y. Bai, Z.Z. Du, W.J. Niu, W. Wang, K.S. Wang and Y. Gao, Bonding and Wear Behaviors of Supersonic Plasma Sprayed Fe-Based Coatings on Al-Si Alloy Substrate, Surf. Coat. Technol., 2019, 367, p 288-301.

J. Luo, N. Shi, Y.Z. Xing, C. Jiang and Y. Chen, Effect of Arc Power on the Wear and High-Temperature Oxidation Resistances of Plasma-Sprayed Fe-Based Amorphous Coatings, High. Temp. Mat. PR-ISR., 2019, 38, p 639-646.

Z.W. Zhou, X.D. Jiang, P. Huang, X.Y. Chen, D.M. Wei and Z.B. Xu, Microstructure, Wear and Corrosion Resistance of FeAlCrTiC Coatings Prepared by High-Velocity Arc Spraying, Mat. Rep., 2019, 33(16), p 2771-2776. ((in Chinese))

X. Zhang, Z.H. Wang, J.R. Lin and Z.H. Zhou, A Study on High Temperature Oxidation Behavior of High-Velocity Arc Sprayed Fe-Based Coatings, Surf. Coat. Technol., 2015, 283, p 255-261.

C.Z. Zeng, J. Shen, M.Q. Gong and H. Chen, Enhanced Thermal Conductivity in TiC/Diamond or Cr3C2/Diamond Particles Modified Bi-In-Sn Compounds, J. Mater. Sci-Mater., 2021, 32(10), p 13205-13219.

R.C. Dykhuizen, Review of Impact and Solidification of Molten Thermal Spray Droplets, J. Therm. Spray. Technol., 1994, 3(4), p 351-361.

L.M. Luo, J. Yu, S.G. Liu and J. Li, Thermal Shock Resistances of FeMnCr/Cr3C2 Coatings Deposited by Arc Spraying, J. Wuhan. Univ. Technol., 2010, 2, p 243-247.

L. Zhou, F. Luo, W.C. Zhou and D.M. Zhu, Influence of FeCrAl Content on Microstructure and Bonding Strength of Plasma-Sprayed FeCrAl/Al2O3 Coatings, J. Therm. Spray. Technol., 2016, 25(3), p 509-517.

Y.C. Yang, Influence of Residual Stress on Bonding Strength of the Plasma-Sprayed Hydroxyapatite Coating After the Vacuum Heat Treatment, Surf. Coat. Technol., 2007, 201, p 7187-7193.

P. Berthod, Influence of Carbides and of the Dendritic Orientation on the Thermal Expansion of Ni-Base, Co-Base and Fe-Base Simple Cast Alloys, Int. J. Mater. Res., 2013, 99(3), p 265-272.

D.J. Greving, J.R. Shadley and E.F. Rybicki, Effects of Coating Thickness and Residual Stresses on the Bond Strength of ASTM C633–79 Thermal Spray Coating Test Specimens, J. Therm. Spray. Technol., 1994, 3(4), p 371-378.

X.C. Zhang, B.S. Xu, H.D. Wang, Y.X. Wu and Y. Jiang, Effects of Compositional Gradient and Thickness of Coating on the Residual Stresses Within the Graded Coating, Mater. Design., 2007, 28(4), p 1192-1197.

P.J. Tang, X.Q. Li, H.M. Zhai and W.S. Li, Properties of Cr3C2-20NiCr Coatings Sprayed on Different Substrates by High Velocity Oxygen Fuel, Mat. Rep., 2020, 34(12), p 12115-12121.

Y. Peng, C. Zhang, H. Zhou and L. Liu, On the Bonding Strength in Thermally Sprayed Fe-Based Amorphous Coatings, Surf. Coat. Technol., 2013, 218, p 17-22.

C. Cui, F.X. Ye and G.R. Song, Laser Surface Remelting of Fe-Based Alloy Coatings Deposited by HVOF, Surf. Coat. Technol., 2012, 206(8-9), p 2388-2395.

H.F. Guo, Z.J. Tian and Y.H. Huang, Laser Surface Remelting of WC-12Co Coating Finite Element Simulations and Experimental Analyses, Mater. Sci. Tech-Lond., 2016, 32(8), p 813-822.

Y.F. Sun, H.G. Fu, S.Y. Chen, X.L. Ping, S.T. Sun, X.Y. Guo and J. Lin, Effects of B4C and Cr3C2 on Microstructure and Properties of Laser Cladding Co-based Alloy Coatings, Surf. Rev. Lett., 2020, 27(12), p 2050021.

J. Cheng, Y.P. Wu, L. Qian, S. Hong and L. Qiao, High Temperature Oxidation Behavior and Mechanism of High-Velocity Arc Sprayed FeCrNiAlBSi/Cr3C2 Coating, Mater. Res. Express., 2019, 6(11), p 116598.

B. Han, M. Li and W. Yong, Microstructure and Wear Resistance of Laser Clad Fe-Cr3C2 Composite Coating on 35CrMo Steel, J. Mater. Eng. Perform., 2013, 22(12), p 3749-3754.

Y.S. Wu, D.C. Zeng, Z.W. Liu, W.Q. Qiu, X.C. Zhong, H.Y. Yu and S.Z. Li, Microstructure and Sliding Wear Behavior of Nanostructured Ni60-TiB2 Composite Coating Sprayed by HVOF Technique, Surf. Coat. Technol., 2011, 206, p 1102-1108.

B. Mao, A. Siddaiah, Y.L. Liao and P.L. Menezes, Laser Surface Texturing and Related Techniques for Enhancing Tribological Performance of Engineering Materials: A Review, J. Manuf. Process., 2020, 53, p 153-173.

J.H. Chen, C.C. Hsieh, P.S. Hua, C.M. Chang, C.M. Lin, P.T.Y. Wu and W.T. Wu, Microstructure and Abrasive Wear Properties of Fe-Cr-C Hardfacing Alloy Cladding Manufactured by Gas Tungsten Arc Welding (GTAW), Met. Mater. Int., 2013, 19(1), p 93-98.

Z. Wei, Y.P. Wu, W.H. Yang, S. Hong, L. Qiao and J. Cheng, Effects of Loads on High-Temperature Wear Properties of HVOF Sprayed CoCrAlYTa-10%Al2O3 and Cr3C2-NiCr Coatings, Mater. Res. Express., 2019, 6(10), p 106541.

Y.J. Chao, S.G. Liu, Y.B. Dai, M. Su, J. Li and J.P. Sang, Microstructure and Wear Resistance of RE-Containing FeMnCrNiAl/Cr3C2 Composite Coatings Prepared by High Velocity Arc Spraying, T. Mater. Heat. Treat., 2012, 33(3), p 137-141. ((in Chinese))

A. Mahato, H. Yeung, Y. Guo, K. Viswanathan, N.K. Sundaram, A. Udupa, J.B. Mann and S. Chandrasekar, Sinuous Flow and Folding in Metals: Implications for Delamination Wear and Surface Phenomena in Sliding and Cutting, Wear, 2017, 376, p 1534-1541.

G.L. Hou, Y.L. An, X.Q. Zhao, H.D. Zhou and J.M. Chen, Effect of Alumina Dispersion on Oxidation Behavior as Well as Friction and Wear Behavior of HVOF-sprayed CoCrAlYTaCSi coating at Elevated Temperature up to 1000°C, ACTA. Mater., 2015, 95, p 164-175.

G. Bolelli, B. Bonferroni, J. Laurila, L. Lusvarghi and P. Vuoristo, Micromechanical Properties and Sliding Wear Behaviour of HVOF-Sprayed Fe-Based Alloy Coatings, Wear, 2012, 276-277(4), p 29-47.

M.F. Ashby, J. Abulawi and H.S. Kong, Temperature Maps for Frictional Heating in Dry Sliding, Tribol. T., 1991, 34, p 577-587.

W.P. Xu, B.S. Xu, W. Zhang, Z.X. Zhu and Y.X. Wu, Abrasive Wear Behaviors of High Velocity Arc Sprayed Iron Aluminum Composite Coatings, J. Univ SCI. Technol. B., 2005, 05, p 68-72.

X.Q. Liu, M. Xiao, M. Liu, Z.G. Qiu and D.C. Zeng, Preparation and Enhanced Wear Resistance of HVAF-Sprayed Fe-TiB2 Cermet Coating Reinforced by Carbon Nanotubes, Surf. Coat. Technol., 2021, 408, p 126860.

M. Benegra, A.L.B. Santana, O. Maranho and G. Pintaude, Effect of Heat Treatment on Wear Resistance of Nickel Aluminide Coatings Deposited by HVOF and PTA, J. Therm. Spray. Technol., 2015, 24(6), p 1111-1116.

M.A. Zavareh, A.A.D.M. Sarhan, B. BintiAbd Razak and W.J. Basirun, The Tribological and Electrochemical Behavior of HVOF-Sprayed Cr3C2-NiCr Ceramic Coating on Carbon Steel, Ceram. Int., 2015, 41(4), p 5387-5396.

K. Satit, M.S. Vilas and N. Panadda, Wear Resistance of Thermally Sprayed Rotary Tiller Blades, Wear, 2006, 263(1), p 604-608.

A. Souchet, J. Fontaine, J.L. Loubet, Z. Hassan, M. Belin and M.W. Barsoum, The Role of Tribofilm Evolution on Tribological Behaviour of Ti3SiC2 Ceramic, Proc. World Tribol. Congr., 2005, III, p 1.

X.S. Wang, Z.L. Lu, G.T. Lin, L. Jia and J.X. Chen, Effect of Cr2AlC Content on the Properties of a Cu-Cr2AlC Composite, Results Phys., 2016, 1(6), p 789-795.

B. Janette, L. Mariana, G. Anna, D. L’udmila and D. Dagmar, Microstructure, Wear Behavior and Corrosion Resistance of WC-FeCrAl and WC-WB-Co Coatings, Metals, 2018, 8(6), p 399.

Acknowledgment

This work was supported by the National Natural Science Foundation of China (No. 52109091) and the Natural Science Foundation of Jiangsu Province of China (No. BK20210409).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, J., Lin, J., Kang, M. et al. Microstructure and Tribological Properties of Fe-Based Composite Coatings Prepared by High-Velocity Arc Spraying. J Therm Spray Tech 31, 644–657 (2022). https://doi.org/10.1007/s11666-022-01338-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01338-8