Abstract

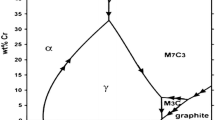

A series of Fe-Cr-C hardfacing alloys is deposited by gas tungsten arc welding and subjected to abrasive wear testing. Pure Fe with various amounts of CrC (Cr:C=4:1) powders are mixed as the fillers and used to deposit hardfacing alloys on low carbon steel. Depending on the various CrC additions to the alloy fillers, the claddings mainly contain hypoeutectic, near eutectic, or hypereutectic microstructures of austenite γ-Fe phase and (Cr,Fe)7C3 carbides on hardfacing alloys, respectively. When 30% CrC is added to the filler, the finest microstructure is achieved, which corresponds to the γ-Fe+(Cr,Fe)7C3 eutectic structure. With the addition of 35% and 40% CrC to the fillers, the results show that the cladding consists of the massive primary (Cr,Fe)7C3 as the reinforcing phase and interdendritic γ-Fe+(Cr,Fe)7C3 eutectics as the matrix. The (Cr,Fe)7C3 carbide-reinforced claddings have high hardness and excellent wear resistance under abrasive wear test conditions. Concerning the abrasive wear feature observable on the worn surface, the formation and fraction of massive primary (Cr,Fe)7C3 carbides predominates the wear resistance of hardfacing alloys. Abrasive particles result in continuous plastic grooves when the cladding has primary γ-Fe phase in a hypoeutectic structure.

Similar content being viewed by others

References

S. Ozel, B. Kurt, I. Somunkiran, and N. Orhan, Surf. Coat. Technol. 202, 3633 (2008).

C. Fan, M. C. Chen, C. M. Chang, and W. Wu, Surf. Coat. Technol. 201, 908 (2006).

S. Buytoz and M. Ulutan, Surf. Coat. Technol. 200, 3698 (2006).

K. Y. Chiu, F. T. Cheng, and H. C. Man, Mater. Sci. Eng. A 392, 348 (2005).

Y. C. Lin and Y. H. Cho, Surf. Coat. Technol. 203, 1694 (2009).

C. M. Chang, C. C. Hsieh, C. M. Lin, J. H. Chen, C.M. Fan, and W. Wu, Mater. Chem. Phys. 123, 241 (2010).

C. M. Chang, C. M. Lin, C. C. Hsieh, J. H. Chen, and W. Wu, J. Alloy. Compd. 487, 83 (2009).

M. H. Korkut, O. Yilmaz, and S. Buytoz, Surf. Coat. Technol. 157, 5 (2002).

J. Khedkar, A. S. Khanna, and K. M. Gupt, Wear. 205, 220 (1997).

Metals Handbook, Welding, Brazing and Soldering, 9th ed., pp.771–803, ASM, Metals Park, OH (1983).

A. B. Jacuinde, R. Correa, I. Mejia, J. G. Quezada, and W. M. Rainforth, Wear. 263, 808 (2007).

T. A. Adler and O. N. Dogan, Wear. 229, 174 (1999).

H. Berns and A. Fischer, Metallography. 20, 401 (1987).

O. N. Dogan, J. A. Hawk, and G. Laird, Metallur. Mater. Trans. A 28, 1315 (1997).

A. N. J. Stevenson, and I. M. Hutchings, Wear. 186, 150 (1995).

L. Lu, H. Soda, and A. McLean, Mater. Sci. Eng. A 347, 214 (2003).

C. M. Chang, C. M. Lin, C. C. Hsieh, J. H. Chen, C. M. Fan, and W. Wu, Mater. Chem. Phy. 117, 257 (2009).

S. Frangini, A. Masci, and A. D. Bartolomeo, Surf. Coat. Technol. 149, 279 (2002).

P. Q. La, Q. J. Xue, W. M. Liu, and S. R. Yang, Wear. 240, 1 (2000).

C. M. Lin, C. M. Chang, J. H. Chen, and W. Wu, J. Alloy. Compd. 498, 30 (2010).

C. M. Chang, L. H. Chen, C. M. Lin, J. H. Chen, C. M. Fan, and W. Wu, Surf. Coat. Technol. 205, 245 (2010).

ASTM G65-85, Annual Book of ASTM Standards, vol. 03.02, ASTM (1990).

L. E. Svensson, B. Gretoft, B. Ulander, and H. K. D. H. Bhadeshia, J. Mater. Sci. 21, 1015 (1986).

S. Atamert and H. K. D. H. Bhadeshia, Mater. Sci. Eng. A 130, 101 (1990).

R. Richardson, Wear. 10, 291 (1967).

R. Richardson, Wear. 14, 290 (1969).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, JH., Hsieh, CC., Hua, PS. et al. Microstructure and abrasive wear properties of Fe-Cr-C hardfacing alloy cladding manufactured by Gas Tungsten Arc Welding (GTAW). Met. Mater. Int. 19, 93–98 (2013). https://doi.org/10.1007/s12540-013-1015-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-013-1015-4