Abstract

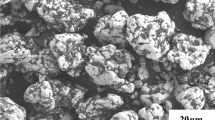

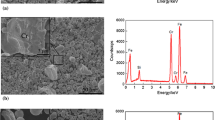

Fe-Cr3C2 hard coatings with varying Cr3C2 content were produced on 35CrMo steel substrates by laser cladding. The experimental results showed that the coatings were uniform, continuous, and free of cracks. High adhesions between all produced coatings and their corresponding substrates were obtained due to the metallurgical interfaces between them. The microstructures of the coatings were mainly composed of austenitic dendrites and M7C3. The microhardness gradually increased from the bottom to the top of the coating, and increased with elevation of Cr3C2 content. The Fe-Cr3C2 coatings improved the sliding wear resistance of the 35CrMo steel substrates obviously, and the dominant wear mechanism was spalling fatigue, with plowed grooves on the worn surfaces.

Similar content being viewed by others

References

J. Nurminen, J. Nakki, and P. Vuoristo, Microstructure and Properties of Hard and Wear Resistant MMC Coatings Deposited by Laser Cladding, Int. J. Refract. Met. Hard Mater., 2009, 27, p 472–478

L. St-Georges, Development and Characterization of Composite Ni-Cr + WC Laser Cladding, Wear, 2007, 263, p 562–566

X. You, C. Zhang, X. Song, M. Huang, and J. Ma, Microstructure Evolution of WC/Steel Composite by Laser Surface Re-Melting, Appl. Surf. Sci., 2007, 253, p 4409–4414

Y. Wang, M.Y. Li, and B. Han, Influence of Secondary Carbides Precipitation and Transformation on the Secondary Hardening of Laser Melted High Chromium Steel, J. Mater. Sci., 2010, 45, p 3442–3447

R. Colaco, E. Gordo, E.M. Ruiz-Navas, M. Otasevic, and R. Vilar, A Comparative Study of the Wear Behaviour of Sintered and Laser Surface Melted AISI, M42 High Speed Steel Diluted with Iron, Wear, 2006, 260, p 949–956

C. Chen, X. Xu, Q. Cao, M. Zhang, Q. Chang, S. Zhang, Laser Surface Cladding of Plastic-Molded Steel 718H by CoCrMo Alloy, J. Mater. Eng. Perform., 2011. DOI:10.1007/s11665-011-9993-1

Y. Altunpak, H. Akbulut, and F. Üstel, The Effect of Plasma Spraying on the Microstructure and Aging Kinetics of the Al-Si Matrix Alloy and Al-Si/SiC Composites, J. Mater. Eng. Perform., 2010, 19(1), p 116–122

A. Nusair Khan and J. Lu, Manipulation of Air Plasma Spraying Parameters for the Production of Ceramic Coatings, J. Mater. Process. Technol., 2009, 209, p 2508–2514

X. Mei, S. Hao, T. Ma, Y. Wang, and Z. Liu, Microstructure and Wear Resistance of High-Speed Steel Treated with Intense Pulsed Ion Beam, Nucl. Instrum. Methods Phys. Res. B, 2005, 239, p 152–158

Li. Xiao, D. Yan, J. He, L. Zhu, Y. Dong, J. Zhang, and X. Li, Nanostructured TiN Coating Prepared by Reactive Plasma Spraying in Atmosphere, Appl. Surf. Sci., 2007, 253, p 7535–7539

H. Zhan, Y. Wang, C. Li, T. Han, B. Han, and W. Zhao, Computational and Experimental Study of a Melt-Hardened Zone on a Roller Modified by Wide-Band Laser Treatment, Opt. Laser Technol., 2009, 41, p 251–257

C. Cui, Z. Guo, H. Wang, and J. Hu, In Situ TiC Particles Reinforced Grey Cast Iron Composite Fabricated by Laser Cladding of Ni-Ti-C System, J. Mater. Process. Technol., 2007, 183, p 380–385

L. Gao, X. Bian, Y. Tian, and C. Fu, Effect of Co on Microstructure and Interfacial Properties of Fe-Based Laser Cladding, J. Iron Steel Res. Int., 2009, 16, p 84–88

D. Zhang and X. Zhang, Laser Cladding of Stainless Steel with Ni- Cr3C2 and Ni-WC for Improving Erosive-Corrosive Wear Performance, Surf. Coat. Technol., 2005, 190, p 212–217

P. Henrikki, Relationship Between Processing Parameters, Alloy Atom Diffusion Distance and Surface Hardness in Laser Hardening of Tool Steel, J. Mater. Process. Technol., 2007, 189, p 435–440

J.H. Ouyang, X. Li, and T.C. Lei, Electron Microscopy Structure Study of Laser-Clad TiC-Ni Particle-Reinforced Coating, J. Mater. Eng. Perform., 2000, 9(2), p 234–246

M. Chao, W. Wang, E. Liang, and D. Ouyang, Microstructure and Wear Resistance of TaC Reinforced Ni-Based Coating by Laser Cladding, Surf. Coat. Technol., 2008, 202, p 1918–1922

Acknowledgments

The authors would like to acknowledge the supports from the National Natural Science Foundation of China (Project No. 51179202), the Natural Science Foundation of Shandong Province (Project No. ZR2009FM030), and the Fundamental Research Funds for the Central Universities (Project No. 13CX02073A).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, B., Li, M. & Wang, Y. Microstructure and Wear Resistance of Laser Clad Fe-Cr3C2 Composite Coating on 35CrMo Steel. J. of Materi Eng and Perform 22, 3749–3754 (2013). https://doi.org/10.1007/s11665-013-0708-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0708-7