Abstract

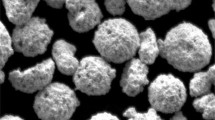

This study aims to compare the wear resistance of nickel aluminide coatings deposited using plasma transferred arc (PTA) and high-velocity oxygen fuel (HVOF) processes. Wear resistance was measured in rubber wheel abrasion tests. In both deposition processes, the same raw material (nickel aluminide powder) was atomized and deposited on a 316L steel plate substrate. After deposition, specimens were subjected to thermal cycling, aiming solubilization and precipitation. Coatings deposited using PTA developed different microstructures as a result of the incorporation of substrate elements. However, despite the presence of these microstructures, they performed better than coatings processed using HVOF before the heat treatment. After thermal cycling, the superficial hardness after the wear tests for both processes was similar, resulting in similar mass losses.

Similar content being viewed by others

References

K. Simunovic, T. Saric, and G. Simunovic, Different Approaches to the Investigation and Testing of the Ni-Based Self-Fluxing Alloy Coatings-A Review. Part 1: General Facts, Wear and Corrosion Investigations, Tribol Trans., 2014, 57, p 955-979

H.-J. Kim, S. Grossi, and Y.-G. Kweon, Wear Performance of Metamorphic Alloy Coatings, Wear, 1999, 232, p 51-60

H.-J. Kim, S. Grossi, and Y.-G. Kweon, Characterization of Fe-Cr-B Based Coatings Produced by HVOF and PTA Processes, Metals Mater., 1999, 5, p 63-72

H. Hill, M. Kunze, C. Heet, A. Petsch, S. Weber, R. Reiter, P. Giese, W. Theisen, B. Wielage, and V. Wesling, Correlation of Processing Route and Heat Treatment with the Abrasive Wear Resistance of a Plastic Mold Steel, Materialwissenschaft und Werkstofftechnik, 2012, 43, p 711-718

K.W.D. Hart, D.H. Harper, and M.J. Gill, Case Studies in Wear Resistance Using HVOF, PTAW and Spray Fusion Surfacing, 1st International Thermal Spray Conference, Materials Park, OH, ASM International, Montreal, Canada, 2000, p 1117-1125.

P. Kulu, R. Tarbe, A. Žikin, H. Sarjas, and A. Surženkov, Abrasive Wear Resistance of Recycled Hardmetal Reinforced Thick Coating, Key Eng. Mater., 2013, 527, p 185-190

W.S. Da Silva, R.M. Souza, J.D.B. De Mello, and H. Goldenstein, Room Temperature Mechanical Properties and Tribology of NICRALC and Stellite Casting Alloys, Wear, 2011, 271, p 1819-1827

M. Benegra, M. Magnani, H. Goldenstein, O. Maranho, and G. Pintaude, Abrasion and Corrosion Resistance of New Ni-Based Coating Deposited by HVOF Thermal Spray Process, Surf. Eng., 2010, 26, p 463-468

M. Benegra, G. Pintaude, G.O. Ribas, and A.S.C.M. D’Oliveira, Microstructural Stability of Nickel Aluminide Coatings Processed by PTA with Different Contents of Aluminum, Acta Microsc., 2014, 23, p 70-77

O. Maranho, D. Rodrigues, M. Boccalini, Jr., and A. Sinatora, Mass Loss and Wear Mechanisms of HVOF-Sprayed Multi-component White Cast Iron Coatings, Wear, 2012, 274, p 162-167

C.H. Lee and K.O. Min, Effects of Heat Treatment on the Microstructure and Properties of HVOF-Sprayed Ni-Cr-W-Mo-B Alloy Coatings, Surf. Coat Technol., 2000, 132(1), p 49-57

L. Gil, M.A. Prato, and M.H. Staia, Effect of Post-Heat Treatment on the Corrosion Resistance of NiWCrBSi HVOF Coatings in Chloride Solution, J. Thermal Spray Technol., 2002, 11(1), p 95-99

A.E. Yaedu and A.S.C.M. D’Oliveira, Cobalt Based Alloy PTA Hardfacing on Different Substrate Steels, Mater. Sci. Technol., 2005, 21(4), p 459-466

V.B. Almeida, E.H. Takano, I. Mazzaro, and A.S.C.M. D’Oliveira, Evaluation of Ni-Al Coatings Processed by Plasma Transferred Arc, Surf. Eng., 2011, 27, p 266-271

W.S. da Silva, P. Ferrandini, R. Caram, and H. Goldenstein, Proceedings of the 17th Brazilian Cong. on ‘Materials science and engineering’, Foz do Iguaçu, Brazil, October 2006, Instituto de Pesquisas Energéticas e Nucleares (IPEN), Paper 310-033.

Standard test method for measuring abrasion using the dry sand/rubber wheel apparatus’, G65-04, ASTM, Philadelphia, PA, USA.

ABNT, Standard NBR 7214, “Regular sand for cement test (in Portuguese)”, ABNT, Rio de Janeiro, Brazil, p 7.

L. Ajdelsztajn, J.A. Picas, G.E. Kim, F.L. Bastian, J. Schoenung, and V. Provenzano, Oxidation Behavior of HVOF Sprayed Nanocrystalline NiCrAlY Powder, Mater. Sci. Eng. A, 2002, 338(1), p 33-43

S.C. Deevi and V.K. Sikka, Nickel and Iron Aluminides: An Overview on Properties, Processing, and Applications, Intermetallics, 1996, 4, p 315-351

G. Pintaude, D.K. Tanaka, and A. Sinatora, The Effects of Abrasive Particle Size on the Sliding Friction Coefficient of Steel Using a Spiral Pin-on-Disk Apparatus, Wear, 2003, 255(1), p 55-59

Acknowledgment

The authors would like to thank CNPq for funding this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Benegra, M., Santana, A.L.B., Maranho, O. et al. Effect of Heat Treatment on Wear Resistance of Nickel Aluminide Coatings Deposited by HVOF and PTA. J Therm Spray Tech 24, 1111–1116 (2015). https://doi.org/10.1007/s11666-015-0266-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0266-7