Abstract

A comprehensive understanding of the failure mechanisms of plasma-sprayed thermal barrier coatings (TBCs) under temperature cycling is a prerequisite for developing the next advanced gas turbine with prolonged thermal cyclic lifetime. In this study, a finite element model including the dynamic growth of thermally grown oxide (TGO) is proposed to explore the combined effect of creep and TGO growth on the cracking driving force in TBCs. A different group of material configurations is designed to satisfy the objective. An adapted interface element based on the virtual crack closure technique is proposed to obtain the strain energy release rate, namely cracking driving force, and crack growth is assessed using a mixed-mode criterion. The results reveal that the cracking predicted by the simulation is in line with the experiment results. Two possible mechanisms of crack coalescence are proposed. The increase in TGO lateral growth strain will induce premature coating spallation. The bond coat and TGO creep only have a slight impact on the ceramic cracking if a comparatively low TGO growth stress is included. Hence, coating optimization suggested in this study may provide additional options for the development of TBCs with extended thermal cyclic lifetime.

Similar content being viewed by others

References

V. Kumar and K. Balasubramanian, Progress Update on Failure Mechanisms of Advanced Thermal Barrier Coatings: A Review, Prog. Org. Coat., 2016, 90, p 54-82

K.P. Jonnalagadda, R. Eriksson, X.H. Li, and R.L. Peng, Thermal Barrier Coatings: Life Model Development and Validation, Surf. Coat. Technol., 2019, 362, p 293-301

K. Knipe, A. Manero Ii, S.F. Siddiqui, C. Meid, J. Wischek, J. Okasinski, J. Almer, A.M. Karlsson, M. Bartsch, and S. Raghavan, Strain Response of Thermal Barrier Coatings Captured under Extreme Engine Environments through Synchrotron X-ray Diffraction, Nat. Commun., 2014, 5, p 4559

Z.Y. Wei, H.N. Cai, and C.J. Li, Comprehensive Dynamic Failure Mechanism of Thermal Barrier Coatings Based on a Novel Crack Propagation and TGO Growth Coupling Model, Ceram. Int., 2018, 44(18), p 22556-22566

Q.M. Yu, H.L. Zhou, and L.B. Wang, Influences of Interface Morphology and Thermally Grown Oxide Thickness on Residual Stress Distribution in Thermal Barrier Coating System, Ceram. Int., 2016, 42(7), p 8338-8350

W. Zhu, M. Cai, L. Yang, J.W. Guo, Y.C. Zhou, and C. Lu, The Effect of Morphology of Thermally Grown Oxide on the Stress Field in a Turbine Blade with Thermal Barrier Coatings, Surf. Coat. Technol., 2015, 276, p 160-167

C. Che, G.Q. Wu, H.Y. Qi, Z. Huang, and X.G. Yang, Uneven Growth of Thermally Grown Oxide and Stress Distribution in Plasma-Sprayed Thermal Barrier Coatings, Surf. Coat. Technol., 2009, 203(20-21), p 3088-3091

M. Karabaş, E. Bal, and Y. Taptık, Thermal Cycling Behavior of La2Zr2O7 Thermal Barrier Coatings by Plasma Spraying of an Amorphous and Crystalline Precursors, Mater. Res. Express, 2018, 6(1), p 015514

C.J. Li, Y. Li, G.J. Yang, and C.X. Li, Evolution of Lamellar Interface Cracks During Isothermal Cyclic Test of Plasma-Sprayed 8YSZ Coating with a Columnar-Structured YSZ Interlayer, J. Therm. Spray Technol., 2013, 22(8), p 1374-1382

V. Kumar and B. Kandasubramanian, Processing and Design Methodologies for Advanced and Novel Thermal Barrier Coatings for Engineering Applications, Particuology, 2016, 27, p 1-28

C.J. Li, Y. Li, G.J. Yang, and C.X. Li, A Novel Plasma-Sprayed Durable Thermal Barrier Coating with a Well-Bonded YSZ Interlayer Between Porous YSZ and Bond Coat, J. Therm. Spray Technol., 2012, 21(3-4), p 383-390

Y.Z. Xing, C.J. Li, C.X. Li, and G.J. Yang, Influence of Through-Lamella Grain Growth on Ionic Conductivity of Plasma-Sprayed Yttria-Stabilized Zirconia as an Electrolyte in Solid Oxide Fuel Cells, J. Power Sources, 2008, 176(1), p 31-38

G.R. Li, B.W. Lv, G.J. Yang, W.X. Zhang, C.X. Li, and C.J. Li, Relationship Between Lamellar Structure and Elastic Modulus of Thermally Sprayed Thermal Barrier Coatings with Intra-splat Cracks, J. Therm. Spray Technol., 2015, 24(8), p 1355-1367

W.W. Zhang, G.R. Li, Q. Zhang, G.J. Yang, G.W. Zhang, and H.M. Mu, Self-Enhancing Thermal Insulation Performance of Bimodal-Structured Thermal Barrier Coating, J. Therm. Spray Technol., 2018, 27(7), p 1064-1075

C.J. Li and A. Ohmori, Relationships between the Microstructure and Properties of Thermally Sprayed Deposits, J. Therm. Spray Technol., 2003, 12(1), p 6

Z. Lu, S.W. Myoung, H.S. Kim, M.S. Kim, J.H. Lee, Y.G. Jung, J.C. Jang, and U. Paik, Microstructure Evolution and Interface Stability of Thermal Barrier Coatings with Vertical Type Cracks in Cyclic Thermal Exposure, J. Therm. Spray Technol., 2013, 22(5), p 671-679

G.R. Li, L.S. Wang, and G.J. Yang, A Novel Composite-Layered Coating Enabling Self-Enhancing Thermal Barrier Performance, Scr. Mater., 2019, 163, p 142-147

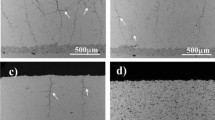

H. Dong, G.J. Yang, C.X. Li, X.T. Luo, C.J. Li, and K. Faber, Effect of TGO Thickness on Thermal Cyclic Lifetime and Failure Mode of Plasma-Sprayed TBCs, J. Am. Ceram. Soc., 2014, 97(4), p 1226-1232

H. Dong, G.J. Yang, H.N. Cai, C.X. Li, and C.J. Li, Propagation Feature of Cracks in Plasma-Sprayed YSZ Coatings under Gradient Thermal Cycling, Ceram. Int., 2015, 41(3), p 3481-3489

C.J. Li, H. Dong, H. Ding, G.J. Yang, and C.X. Li, The Correlation of the TBC Lifetimes in Burner Cycling Test with Thermal Gradient and Furnace Isothermal Cycling Test by TGO Effects, J. Therm. Spray Technol., 2017, 26(3), p 378-387

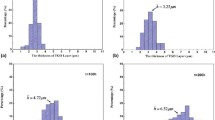

Q. Zhang, Study on Oxidation Behavior of Cold-Sprayed MCrALY Superalloy Bond Coating for Thermal Barrier Coatings, Xi’an jiaotong University, Xi’an, 2009, p 36-37

M. Elhoriny, M. Wenzelburger, A. Killinger, and R. Gadow, Finite Element Simulation of Residual Stress Development in Thermally Sprayed Coatings, J. Therm. Spray Technol., 2017, 26(4), p 735-744

M. Bäker and P. Seiler, A Guide to Finite Element Simulations of Thermal Barrier Coatings, J. Therm. Spray Technol., 2017, 26(6), p 1146-1160

M. Ranjbar-far, J. Absi, G. Mariaux, and D.S. Smith, Crack Propagation Modeling on the Interfaces of Thermal Barrier Coating System with Different Thickness of the Oxide Layer and Different Interface Morphologies, Mater. Des., 2011, 32(10), p 4961-4969

M. Ranjbar-Far, J. Absi, and G. Mariaux, Finite Element Modeling of the Different Failure Mechanisms of a Plasma Sprayed Thermal Barrier Coatings System, J. Therm. Spray Technol., 2012, 21(6), p 1234-1244

B. Lv, H. Xie, R. Xu, X. Fan, W. Zhang, and T.J. Wang, Effects of Sintering and Mixed Oxide Growth on the Interface Cracking of Air-Plasma-Sprayed Thermal Barrier Coating System At High Temperature, Appl. Surf. Sci., 2016, 360, p 461-469

R. Xu, X.L. Fan, W.X. Zhang, and T.J. Wang, Interfacial Fracture Mechanism Associated with Mixed Oxides Growth in Thermal Barrier Coating System, Surf. Coat. Technol., 2014, 253, p 139-147

S.T. Kyaw, I.A. Jones, and T.H. Hyde, Simulation of Failure of Air Plasma Sprayed Thermal Barrier Coating Due to Interfacial and Bulk Cracks Using Surface-Based Cohesive Interaction and Extended Finite Element Method, J. Strain Anal. Eng., 2016, 51(2), p 132-143

X.L. Fan, W.X. Zhang, T.J. Wang, and Q. Sun, The Effect of Thermally Grown Oxide on Multiple Surface Cracking in Air Plasma Sprayed Thermal Barrier Coating System, Surf. Coat. Technol., 2012, 208, p 7-13

W.X. Zhang, X.L. Fan, and T.J. Wang, The Surface Cracking Behavior in Air Plasma Sprayed Thermal Barrier Coating System Incorporating Interface Roughness Effect, Appl. Surf. Sci., 2011, 258(2), p 811-817

X. Fan, W. Jiang, J. Li, T. Suo, T.J. Wang, and R. Xu, Numerical Study on Interfacial Delamination of Thermal Barrier Coatings with Multiple Separations, Surf. Coat. Technol., 2014, 244, p 117-122

X. Fan, R. Xu, and T.J. Wang, Interfacial Delamination of Double-Ceramic-Layer Thermal Barrier Coating System, Ceram. Int., 2014, 40(9), p 13793-13802

W. Zhu, Z.B. Zhang, L. Yang, Y.C. Zhou, and Y.G. Wei, Spallation of Thermal Barrier Coatings with Real Thermally Grown Oxide Morphology Under Thermal Stress, Mater. Des., 2018, 146, p 180-193

L. Cen, W.Y. Qin, and Q.M. Yu, Analysis of Interface Delamination in Thermal Barrier Coating System with Axisymmetric Structure Based on Corresponding Normal and Tangential Stresses, Surf. Coat. Technol., 2019, 358, p 785-795

T.S. Hille, T.J. Nijdam, A.S.J. Suiker, S. Turteltaub, and W.G. Sloof, Damage Growth Triggered by Interface Irregularities in Thermal Barrier Coatings, Acta Mater., 2009, 57(9), p 2624-2630

R. Soulignac, V. Maurel, L. Rémy, and A. Köster, Cohesive Zone Modelling of Thermal Barrier Coatings Interfacial Properties Based on Three-Dimensional Observations and Mechanical Testing, Surf. Coat. Technol., 2013, 237, p 95-104

W. Zhu, L. Yang, J.W. Guo, Y.C. Zhou, and C. Lu, Determination of Interfacial Adhesion Energies of Thermal Barrier Coatings by Compression Test Combined with a Cohesive Zone Finite Element Model, Int. J. Plast, 2015, 64, p 76-87

X.L. Fan, R. Xu, W.X. Zhang, and T.J. Wang, Effect of Periodic Surface Cracks on the Interfacial Fracture of Thermal Barrier Coating System, Appl. Surf. Sci., 2012, 258(24), p 9816-9823

Q.M. Yu and Q. He, Effect of Material Properties on Residual Stress Distribution in Thermal Barrier Coatings, Ceram. Int., 2018, 44(3), p 3371-3380

K. Slámečka, P. Skalka, J. Pokluda, and L. Čelko, Finite Element Simulation of Stresses in a Plasma-Sprayed Thermal Barrier Coating with an Irregular Top-coat/Bond-coat Interface, Surf. Coat. Technol., 2016, 304, p 574-583

P. Skalka, K. Slámečka, J. Pokluda, and L. Čelko, Finite Element Simulation of Stresses in a Plasma-Sprayed Thermal Barrier Coating with a Crack at the TGO/Bond-Coat Interface, Surf. Coat. Technol., 2018, 337, p 321-334

Y. Chai, C. Lin, and Y. Li, Effects of Creep-Plastic Behavior on Stress Development in TBCs During Cooling, Ceram. Int., 2017, 43(15), p 11627-11634

J. Rösler, M. Bäker, and K. Aufzug, A Parametric Study of the Stress State of Thermal Barrier Coatings Part I: Creep relaxation, Acta Mater., 2004, 52(16), p 4809-4817

M. Bäker, Influence of Material Models on the Stress State in Thermal Barrier Coating Simulations, Surf. Coat. Technol., 2014, 240, p 301-310

B. Li, X. Fan, K. Zhou, and T.J. Wang, Effect of Oxide Growth on the Stress Development in Double-Ceramic-Layer Thermal Barrier Coatings, Ceram. Int., 2017, 43(17), p 14763-14774

Q. Shen, L. Yang, Y.C. Zhou, Y.G. Wei, and W. Zhu, Effects of Growth Stress in Finite-Deformation Thermally Grown Oxide on Failure Mechanism of Thermal Barrier Coatings, Mech. Mater., 2017, 114, p 228-242

L. Wang, Y.X. Zhao, X.H. Zhong, S.Y. Tao, W. Zhang, and Y. Wang, Influence of “Island-Like” Oxides in the Bond-Coat on the Stress and Failure Patterns of the Thermal-Barrier Coatings Fabricated by Atmospheric Plasma Spraying During Long-Term High Temperature Oxidation, J. Therm. Spray Technol., 2013, 23(3), p 431-446

E.P. Busso, Z.Q. Qian, M.P. Taylor, and H.E. Evans, The Influence of Bondcoat and Topcoat Mechanical Properties on Stress Development in Thermal Barrier Coating Systems, Acta Mater., 2009, 57(8), p 2349-2361

G.R. Li and L.S. Wang, Durable TBCs with Self-Enhanced Thermal Insulation Based on Co-design on Macro- and Microstructure, Appl. Surf. Sci., 2019, 483, p 472-480

G.R. Li and G.J. Yang, Understanding of Degradation-Resistant Behavior of Nanostructured Thermal Barrier Coatings with Bimodal Structure, J. Mater. Sci. Technol., 2019, 35(3), p 231-238

H. Meng, J. Huang, and S. Chen, The Influence of Interface Morphology on the Stress Distribution in Double-Ceramic-Layer Thermal Barrier Coatings, Ceram. Int., 2015, 41(3), p 4312-4325

P. Skalka, K. Slámečka, J. Pokluda, and L. Čelko, Stability of Plasma-Sprayed Thermal Barrier Coatings: The Role of the Waviness of the Bond Coat and the Thickness of the Thermally Grown Oxide Layer, Surf. Coat. Technol., 2015, 274, p 26-36

C. Lin, Q. Sun, Y. Chai, H. Chen, and Y. Li, Stress Evolution in Top Coat of Thermal Barrier Coatings by Considering Strength Difference Property in Tension and Compression, Surf. Coat. Technol., 2017, 329, p 86-96

J. Jiang, Z. Zou, W. Wang, X. Zhao, Y. Liu, and Z. Cao, Effect of Internal Oxidation on the Interfacial Morphology and Residual Stress in Air Plasma Sprayed Thermal Barrier Coatings, Surf. Coat. Technol., 2018, 334, p 215-226

M. Białas, Finite Element Analysis of Stress Distribution in Thermal Barrier Coatings, Surf. Coat. Technol., 2008, 202(24), p 6002-6010

M. Ranjbar-Far, J. Absi, G. Mariaux, and F. Dubois, Simulation of the Effect of Material Properties and Interface Roughness on the Stress Distribution in Thermal Barrier Coatings Using Finite Element Method, Mater. Des., 2010, 31(2), p 772-781

M.Y. He, J.W. Hutchinson, and A.G. Evans, Simulation of Stresses and Delamination in a Plasma-Dprayed Thermal Barrier System upon Thermal Cycling, Mater. Sci. Eng., A, 2003, 345(1), p 172-178

K. Al-Athel, K. Loeffel, H. Liu, and L. Anand, Modeling Decohesion of a Top-Coat From a Thermally-Growing Oxide in a Thermal Barrier Coating, Surf. Coat. Technol., 2013, 222, p 68-78

ABAQUS, Version 6.14 Documentation, Dassault Systemes Simulia Corp. Providence, RI, USA, 2014

J. Aktaa, K. Sfar, and D. Munz, Assessment of TBC Systems Failure Mechanisms Using a Fracture Mechanics Approach, Acta Mater., 2005, 53(16), p 4399-4413

A.M. Karlsson, C.G. Levi, and A.G. Evans, A Model Study of Displacement Instabilities During Cyclic Oxidation, Acta Mater., 2002, 50(6), p 1263-1273

K. Sfar, J. Aktaa, and D. Munz, Numerical Investigation of Residual Stress Fields and Crack Behavior in TBC Systems, Mater. Sci. Eng., A, 2002, 333(1-2), p 351-360

H. Dong, Thermal Cyclic Lifetime and Crack Propagation Behavior of Plasma-Sprayed Thermal Barrier Coatings, Xi’an jiaotong University, Xi’an, 2013, p 47-48

E.F. Rybicki and M.F. Kanninen, A Finite Element Calculation of Stress Intensity Factors by a Modified Crack Closure Integral, Eng. Fract. Mech., 1977, 9(4), p 931-938

D. Xie and S.B. Biggers, Calculation of Transient Strain Energy Release Rates under Impact Loading Based on the Virtual Crack Closure Technique, Int. J. Impact Eng, 2007, 34(6), p 1047-1060

D. Xie and S.B. Biggers, Progressive Crack Growth Analysis Using Interface Element Based on the Virtual Crack Closure Technique, Finite Elem. Anal. Des., 2006, 42(11), p 977-984

P.F. Zhao, C.A. Sun, X.Y. Zhu, F.L. Shang, and C.J. Li, Fracture Toughness Measurements of Plasma-Sprayed Thermal Barrier Coatings Using a Modified Four-point Bending Method, Surf. Coat. Technol., 2010, 204(24), p 4066-4074

A. Rabiei and G.A. Evans, Failure Mechanisms Associated with the Thermally Grown Oxide in Plasma-Sprayed Thermal Barrier Coatings, Acta Mater., 2000, 48(15), p 3963-3976

K.W. Schlichting, N.P. Padture, E.H. Jordan, and M. Gell, Failure Modes in Plasma-Sprayed Thermal Barrier Coatings, Mater. Sci. Eng., A, 2003, 342(1), p 120-130

D. Renusch, H. Echsler, and M. Schütze, Progress in Life Time Modeling of APS-TBC Part I: Residual, Thermal and Growth Stresses Including the Role of Thermal Fatigue, Mater. High Temp., 2004, 21(2), p 65-76

Acknowledgments

The present project is financially supported by the National Science Foundation of China (No. 51671159), the National Basic Research Program of China (No. 2012CB625100), the Fundamental Research Funds for the Central Universities and the National Program for Support of Top-notch Young Professionals.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wei, ZY., Cai, HN., Feng, RX. et al. The Combined Effect of Creep and TGO Growth on the Cracking Driving Force in a Plasma-Sprayed Thermal Barrier System. J Therm Spray Tech 28, 1000–1016 (2019). https://doi.org/10.1007/s11666-019-00873-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-019-00873-1