Abstract

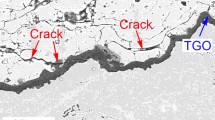

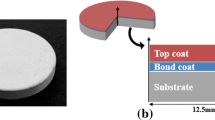

Thermal barrier coating is a high-temperature protective technology widely used in industrial gas turbines. However, the failure of coating peeling because of the generation of thermally grown oxide (TGO) at the interface during service hinders its further application. In this study, Raman spectroscopy and wedge indentation are used to determine the TGO residual stress and the interface energy release rate, respectively. The effect of TGO on the interfacial fracture toughness during the growth process was discussed. Raman spectroscopy test results show that the residual stress of TGO is about 0.5 GPa. Wedge indentation test results illustrate that high-temperature heat treatment could accelerate the interface degradation of thermal barrier coatings. Stress analysis and test research demonstrate that the microcracks induced by compressive stress of TGO will propagate with increasing heating time, ending with failure of barrier coatings.

Similar content being viewed by others

References

N.P. Padture: Thermal barrier coatings for gas-turbine engine applications. Science280, 296 (2002).

S. Tailor, R.M. Mohanty, and A.V. Doub: Development of a new TBC system for more efficient gas turbine engine application. Mater. Today3, 725–2734 (2016).

R. Rajendran: Gas turbine coatings—An overview. Eng. Fail. Anal.26, 355 (2012).

T. Sadowski and P. Golewski: Multidisciplinary analysis of the operational temperature increase of turbine blades in combustion engines by application of the ceramic thermal barrier coatings (TBC). Comput. Mater. Sci.50, 1326 (2011).

N.P. Padture: Advanced structural ceramics in aerospace propulsion. Nat. Mater.15, 804 (2016).

M.S. Sahith, G. Ga, and R.S. Kumara: Development and analysis of thermal barrier coatings on gas turbine blades—A review. Mater. Today5, 2746 (2018).

J. Aktaa, K. Sfar, and D. Munz: Assessment of TBC systems failure mechanisms using a fracture mechanics approach. Acta Mater.53, 4399–4413 (2005).

E. Tzimas, H. Müllejans, S.D. Peteves, and J. Bressers: Failure of thermal barrier coating systems under cyclic thermomechanical loading. Acta Mater.48, 4699 (2000).

A.G. Evans, D.R. Clarke, and C.G. Levi: The influence of oxides on the performance of advanced gas turbines. J. Eur. Ceram. Soc.28, 1405–1419 (2008).

G.X. Lu, L.J. Hao, and F.X. Ye: Thermal analysis and failure behavior of 8YSZ thermal barrier coatings under thermal cycling tests. Appl. Mech. Mater.441, 91 (2013).

P. Fauchais, M. Vardelle, and S. Goutier: Latest researches advances of plasma spraying: From splat to coating formation. J. Therm. Spray Technol.25, 1 (2017).

K. Kokini, A. Banerjee, and A.T. Thomas: Thermal fracture of interfaces in precracked thermal barrier coatings. Mater. Sci. Eng., A323, 70 (2002).

G. Thurn, G.A. Schneider, H.A. Bahr, and F. Aldinger: Toughness anisotropy and damage behavior of plasma sprayed ZrO2 thermal barrier coatings. Surf. Coat. Tech.123, 147 (2000).

J. Tong, K.Y. Wong, and C. Lupton: Determination of interfacial fracture toughness of bone–cement interface using sandwich Brazilian disks. Eng. Fract. Mech.74, 1904–1916 (2007).

J. Elambasseril and R.N. Ibrahim: Determination of interfacial fracture toughness of coatings using circumferentially notched cylindrical substrate. Mater. Sci. Eng., A529, 406 (2011).

S.Y. Liu, J.M. Wheeler, P. R. Howie, and X.T. Zeng: Measuring the fracture resistance of hard coatings. Appl. Phys. Lett.102, 1–4 (2013).

G. Sernicola, T. Giovannini, P. Patel, and J.R. Kermode: In situstable crack growth at the micron scale. Nat. Mater.8, 1–9 (2017).

D.R. Clarke, C.G. Levi: Materials design for the next generation thermal barrier coatings. Annu. Rev. Mater. Res. 33, 383–417 (2003).

H. Guo, Y. Cui Y, H. Peng, and S.K. Gong: Improved cyclic oxidation resistance of electron beam physical vapor deposited nano-oxide dispersed β-NiAl coatings for Hf-containing superalloy. Corros. Sci.52, 1440 (2010).

M. Martena, D. Botto, P. Fino: Modelling of TBC system failure: Stress distribution as a function of TGO thickness and thermal expansion mismatch. Eng. Fail. Anal.13, 409 (2006).

A.S.M. Ang, C.C. Berndt: A review of testing methods for thermal spray coatings. Int. Mater. Rev.59, 179 (2014).

K. Suzuki, K. Tanaka: Spalling stress in oxidized thermal barrier coatings evaluated by X-Ray diffraction method. Mater. Sci. Forum.490, 631 (2005).

Y. Chen, X. Zhao, Y. Dang, and P. Xiao: Characterization and understanding of residual stresses in a NiCoCrAlY bond coat for thermal barrier coating application. Acta Materi.94, 1 (2015).

A. Selçuk, A. Atkinson: The evolution of residual stress in the thermally grown oxide on Pt diffusion bond coats in TBCs. Acta Mater.51, 535 (2003).

B. Heeg, D.R. Clarke: Non-destructive thermal barrier coating (TBC) damage assessment using laser-induced luminescence and infrared radiometry. Surf. Coat. Tech.200, 1298 (2005).

R.J. Christensen, D.M. Lipkin, D.R. Clarke: Nondestructive evaluation of the oxidation stresses through thermal barrier coatings using Cr3+ piezospectroscopy. Appl. Phys. Lett.69, 3754 (1996).

J. Yang, L. Wang, D. Li, and X.H. Zhong: Stress Analysis and Failure Mechanisms of plasma-sprayed thermal barrier coatings. J. Therm. Spray. Techn.26, 1 (2017).

C.R.C. Lima, S. Dosta, J.M. Guilemany, and D.R. Clarke: The application of photoluminescence piezospectroscopy for residual stresses measurement in thermally sprayed TBCs. Surf. Coat. Tech.318, 147 (2016).

X. Wang, A. Atkinson: Piezo-spectroscopic mapping of the thermally grown oxide in thermal barrier coatings. Mater. Sci. Eng. A.465, 49–58 (2007).

G.R. Irwin: Measuring plane-strains near the end of a crack traversing a plate. J. Appl. Mech.24, 361 (1957).

A.J. Smiley, R.B. Pipes: Rate effects on mode I interlaminar fracture toughness in composite materials. J. Compos. Mater.21, 670 (1987).

X. Qiao, Y.M. Wang, W.X. Weng, Q. Li: Influence of pores on mechanical properties of plasma sprayed coatings: Case study of YSZ thermal barrier coatings. Ceram. Int.44, 21564 (2018).

S. Guo, Y. Kagawa: Young’s moduli of zirconia top-coat and thermally grown oxide in a plasmasprayed thermal barrier coating system. Scripta Mater.50, 1401–1406 (2004).

J.W. Hutchinson, M.E. Mear, J.R. Rice: Crack Paralleling an Interface Between Dissimilar Materials. J. Appl. Mech, 54, 828 (1987).

J. He, D.R. Clarke: Determination of the piezospectroscopic coefficients for chromium-doped sapphire. J. Am. Ceram. Soc.78, 1347 (1995).

K. W. Schlichting, N. P. Padture, E. H. Jordan, and M. Gell: Failure modes in plasma-sprayed thermal barrier coatings. Mater. Sci. Eng. A.342, 120 (2003).

D. R. Clarke, W. Pompe: Critical radius for interface separation of a compressively stressed film from a rough surface. Acta Mater.47, 1749 (1999).

S.S. Kim, Y.F. Liu, and Yutaka Kagawa: Evaluation of interfacial mechanical properties under shear loading in EB-PVD TBCs by the pushout method. Acta Mater.55, 3771 (2007).

T. W. Clyne, S.C. Gill: Residual stresses in thermal spray coatings and their effect on interfacial adhesive: A review of recent work. J. Therm. Spray. Techn.5, 401 (1996).

M. Ranjbar-Far, J. Absi, G. Mariaux, and F. Dubois: Simulation of the effect of material properties and interface roughness on the stress distribution in thermal barrier coatings using finite element method. Mater. Design.31, 772 (2010).

D. Liu, M. Seraffon, P.E.J. Flewitt, and N.J. Simms: Effect of substrate curvature on residual stresses and failure modes of an air plasma sprayed thermal barrier coating system. J. Eur. Ceram. Soc.33, 3345 (2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y.M., Weng, W.X., Chi, M.H. et al. Investigation into the evolution of interface fracture toughness of thermal barrier coatings with thermal exposure treatment by wedge indentation. Journal of Materials Research 35, 1715–1725 (2020). https://doi.org/10.1557/jmr.2020.79

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.79