Abstract

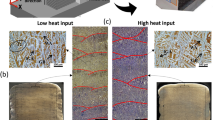

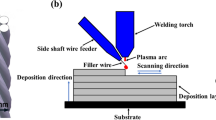

The aim of this study is to investigate the impact of different metal deposition modes—spray (S), pulse (P), and pulse-switchback (PS)—on the metallurgical and mechanical properties of SS308L structures in wire arc additive manufacturing (WAAM). Three thin-walled structures were deposited using optimal process variables and inter-layer time delay. Through metallographic examination, it was found that the P-mode had the highest homogeneity (88.94%) in terms of grain size and phase fraction, followed by the S-mode (86.03%) and the PS-mode (74.68%). Based on micro-hardness data, the P-mode had the highest average hardness value (272.51 HV along BD and 276.99 HV along TD). However, the PS-mode (83.46%) had a more homogeneous hardness distribution compared to the S-mode (83.11%) and P-mode (78.59%). In tensile tests, the P-mode showed higher tensile strength (823 MPa) and more homogeneous (98.68%) properties than the PS-mode and S-mode. However, the P-mode exhibited the highest variability (21.14%) in terms of elongation, followed by PS-mode (20.82%) and S-mode (16.30%). It was also found that the P-mode induced the maximum stress-induced phase transformation from γ-phase to α'-phase, followed by PS-mode and S-mode. This study provides valuable insights for determining the optimal deposition mode for SS308L structural components in the WAAM process.

Similar content being viewed by others

Availability of Data and Material

There is no need for a separate archive since the manuscript contains all the details needed to reproduce the work.

References

L.P. Raut and R.V. Taiwade, Wire Arc Additive Manufacturing: A Comprehensive Review and Research Directions, J. Mater. Eng. Perform., 2021, 30, p 4768–4791.

Md. Javaid and A. Haleem, Using Additive Manufacturing Applications for Design and Development of Food and Agricultural Equipments, Int. J. Mat. Product. Tech., 2019, 58, p 225–238.

C. Buchanan and L. Gardner, Metal 3D Printing in Construction: A Review of Methods, Research, Applications, Opportunities and Challenges, Eng. Struct., 2019, 180, p 332–348.

M. Abbaszadeh, J.R. Hönnige, F. Martina, L. Neto, N. Kashaev, P. Colegrove, S. Williams, and B. Klusemann, Numerical Investigation of the Effect of Rolling on the Localized Stress and Strain Induction for Wire + Arc Additive Manufactured Structures, J. Mater. Eng. Perform., 2019, 28(8), p 4931–4942.

A. Busachi, J. Erkoyuncu, P. Colegrove, F. Martina, C. Watts, and R. Drake, A review of Additive Manufacturing technology and Cost Estimation Techniques for the Defence Sector, CIRP J. Manuf. Sci. Tech., 2017, 19, p 117–128.

S. Zhou, J. Zhang, J. Wang, G. Yang, K. Wu, and L. Qin, Effect of Oxygen Levels in Tent Shielding Atmosphere on Microstructural and Mechanical Properties of Ti-6Al-4V Fabricated by Wire Arc Additive Manufacturing, J. Mater. Eng. Perform., 2022 https://doi.org/10.1007/s11665-022-06684-w

M. Rafieazad, A.V. Nemani, M. Ghaffari, and A. Nasiri, On Microstructure and Mechanical Properties of a Low-Carbon Low-Alloy Steel Block Fabricated by Wire Arc Additive Manufacturing, J. Mater. Eng. Perform., 2021, 30, p 4937–4945.

A. Karpagaraj, S. Baskaran, T. Arunnellaiappan, and N.R. Kumar, A Review on the Suitability of Wire Arc Additive Manufacturing (WAAM) for Stainless Steel 316, In AIP Confer Proc, 2020, 2247, 050001.

L. Wang, J. Xuea, and Q. Wang, Correlation Between Arc Mode, Microstructure, and Mechanical Properties During Wire Arc Additive Manufacturing of 316L Stainless Steel, Mat. Sci. & Eng. A., 2019, 751, p 183–190.

S.H. Lee, CMT-Based Wire Arc Additive Manufacturing Using 316L Stainless Steel: Effect of Heat Accumulation on the Multi-Layer Deposits, Metals., 2020, 10, p 278.

M. Eriksson, M. Lervåg, C. Sørensen, A. Robertstad, B.M. Brønstad, B. Nyhus, R. Aune, X. Ren, and O.M. Akselsen, Additive Manufacture of Superduplex Stainless Steel Using WAAM, MATEC Web of Confer, 2018, 188, p 03014.

A. Caballero, J. Ding, S. Ganguly, and S. Williams, Wire + Arc Additive Manufacture of 17–4 PH Stainless Steel: Effect of Different Processing Conditions on Microstructure, Hardness, and Tensile Strength, J. Mat. Proc. Tech., 2019, 268, p 54–62.

C. Guo, R. Hu, and F. Chen, Microstructure and Performances for 15-5 PH Stainless Steel Fabricated Through the Wire-Arc Additive Manufacturing Technology. Mat. Tech. 2020, p. 1–12.

V.A. Hosseini, M. Högström, K. Hurtig, M. Asuncion, V. Bermejo, L. Stridh, and L. Karlsson, Wire-Arc Additive Manufacturing of a Duplex Stainless Steel: Thermal Cycle Analysis and Microstructure Characterization, Weld World, 2019, 63, p 975–987.

R. Mamedipaka, and S. Thapliyal, Data-Driven Model for Predicting Tensile Properties of Wire Arc Additive Manufactured 316L Steels and Its Validation. Journal of Materials Engineering and Performance, 2023, p1-9.

V.T. Le, M.C. Bui, T.D. Nguyen, V.A. Nguyen, and V.C. Nguyen, On the Connection of the Heat Input to the Forming Quality in Wire-and-Arc Additive Manufacturing of Stainless Steels, Vacuum, 2023, 209, 111807.

V.T. Le and D.S. Mai, Microstructural and Mechanical Characteristics of 308L Stainless Steel Manufactured by Gas Metal Arc Welding-Based Additive Manufacturing. Mater. Lett. 2020, 271.

V. Laghi, M. Palermo, G. Gasparini, V.A. Girelli, and T. Trombetti, Experimental Results for Structural Design of Wire-and-Arc Additive Manufactured Stainless Steel Members, J. Constr. Steel Res., 2019, 11, 105858.

V. Laghi, M. Palermo, G. Gasparini, and T. Trombetti, Computational Design and Manufacturing of a Half-Scaled 3D-Printed Stainless Steel Diagrid Column, Addit. Manuf., 2020, 36, 101505.

M. Bruggi, V. Laghi, and T. Trombetti, Simultaneous Design of the Topology and the Build Orientation of Wire-and-Arc Additively Manufactured Structural Elements, Comp. & Struct., 2020, 242, 106370.

B. Işcan, V. Onar, and A. Uluköy, Investigation of the Mechanical Properties of AISI 304 Austenitic Stainless Steel Joints Produced by TIG and MIG Welding Methods using 308L Filler Wire, Int. J. Innovative. Res. Sci. Eng. Tech., 2017, 6, p 10.

O. Grong, Metallurgical Modelling of Welding. 2nd ed. The institute of materials; 1997.

N. Murugan and V. Gunaraj, Prediction and Control of Weld Bead Geometry and Shape Relationships in Submerged Arc Welding of Pipes, J. Mat. Proc. Tech., 2005, 168, p 478–487.

M. Sen, M. Mukherjee, S.K. Singh, and T.K. Pal, Effect of Double-Pulsed Gas Metal Arc Welding (DP-GMAW) Process Variables on Microstructural Constituents and Hardness of low Carbon Steel Weld Deposits, J. Manuf. Proc., 2018, 31, p 424–439.

A.R. Paul, M. Mukherjee, R. Manivannan, S. Kundu, and A. Chatterjee, Development of Near Homogeneous Properties in Wire Arc Additive Manufacturing Process for Near-Net Shaped Structural Component of Low-Carbon Steel, Proc. Inst. Mech. Eng. C: J. Mech. Eng. Sci., 2021, 236(7), p 3497–3511.

Z. Zhengwu, M. Xiuquan, W. Chunming, M. Gaoyang, and Z. Shuye, The Metallurgical Behaviors and Crystallographic Characteristic on Macro Deformation Mechanism of 316 L laser-MIG Hybrid Welded Joint, Mater. Des., 2020, 194, 108893.

M. Dorta-Almenara and M.C. Capace, Microstructure and Mechanical Properties of GTAW Welded Joints of AA6105 Aluminum Alloy, Revista Facultad de Ingeniería, 2016, 25(43), p 7–19.

V.T. Le, D.S. Mai, T.K. Doan, and H. Paris, Wire and arc Additive Manufacturing of 308L Stainless Steel Components: Optimization of Processing Parameters and Material Properties, Eng. Sci. Technol. Int. J., 2021, 24(4), p 1015–1026.

M. Mukherjee and T.K. Pal, Evaluation of Microstructural and Mechanical Properties of Fe-16Cr-1Ni-9Mn-012 N Austenitic Stainless Steel Welded Joints, Mater. Charact., 2017, 131, p 406–424.

X.S. Yang, S. Sun, X.L. Wu, E. Ma, and T.Y. Zhang, Dissecting the Mechanism of Martensitic Transformation via Atomic-Scale Observations, Sci. Rep., 2014, 4, p 6141.

G.V. Kurdyumov and G. Sachs, About the Mechanism of Steel, Z. Phys., 1930, 64, p 325–343.

Z. Nishiyama, Martensitic Transformation. Mat Sci Tech. 2nd ed. Academic Press; 1978.

G. Sun, M. Zhao, L. Du, and H. Wu, Significant Effects of Grain Size on Mechanical Response Characteristics and Deformation Mechanisms of Metastable Austenitic Stainless Steel, Mater. Charact., 2022, 184, 111674.

J.C. Shyne and W.D. Nix, Dislocations in Martensite Inherited from Austenite, Acta Metal., 1965, 13(7), p 869–870.

C. Pandey, M.M. Mahapatra, P. Kumar, P. Kumar, N. Saini, J.G. Thakare, and S. Kumar, Study on Effect of Double Austenitization Treatment on Fracture Morphology Tensile Tested Nuclear Grade P92 Steel, Eng. Fail. Anal., 2019, 96, p 158–167.

C. Pandey, N. Saini, M.M. Mahapatra, and P. Kumar, Study of the Fracture Surface Morphology of Impact and Tensile Tested Cast and Forged (C&F) Grade 91 Steel At Room Temperature for Different Heat Treatment Regimes, Eng. Fail. Anal., 2017, 71, p 131–147.

A.L.V. da Costae Silva, The Effects of Non-Metallic Inclusions on Properties Relevant to the Performance of Steel in Structural and Mechanical Applications, J. Mater. Res. Technol., 2019, 8(2), p 2408–2422.

W. Yongqiang, S. Hao, L. Na, X. Yanhao, and J. Hemin, Effect of Sigma Phase Precipitation on the pitting Corrosion Mechanism of Duplex Stainless Steels, Int. J. Electrochem. Sci., 2018, 13, p 9868–9887.

T.G. Lach, D.A. Collins, and T.S. Byun, Evolution of the Role of Molybdenum in Duplex Stainless Steels During Thermal Aging: From Enhancing Spinodal Decomposition to Forming Heterogeneous Precipitates, J. Nucl. Mater., 2021, 557, 153268.

Acknowledgment

The authors would like to acknowledge the DST-SERB for the financial support (sanction no. ECR/2018/001250) to carry out the research activities. The authors would also like to acknowledge Director, CSIR-CMERI for providing opportunity, and facilities to carry out the research work.

Author information

Authors and Affiliations

Contributions

ARP, MM, and DS performed the experiments and measurements, MM and MR were involved in planning and supervised the work, ARP and MM processed the experimental data, performed the analysis, drafted the manuscript, and designed the figures. MM and ARP performed the calculations, manufactured the samples, and characterized them with scanning electron microscopy, MKM performed the SEM and EDS analysis. MM aided in interpreting the results and worked on the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known conflicts of interest that could have influenced the research presented in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Paul, A.R., Mukherjee, M., Singh, D. et al. Influence of Deposition Mode on Microstructural and Mechanical Properties of Wire Arc Additive Manufactured 308L Stainless Steel Structures. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08453-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08453-9