Abstract

Metal additive manufacturing (AM), also known as 3D printing, is a disruptive manufacturing technology in which complex engineering parts are produced in a layer-by-layer manner, using a high-energy heating source and powder, wire or sheet as feeding material. The current paper aims to review the achievements in AM of steels in its ability to obtain superior properties that cannot be achieved through conventional manufacturing routes, thanks to the unique microstructural evolution in AM. The challenges that AM encounters are also reviewed, and suggestions for overcoming these challenges are provided if applicable. We focus on laser powder bed fusion and directed energy deposition as these two methods are currently the most common AM methods to process steels. The main foci are on austenitic stainless steels and maraging/precipitation-hardened (PH) steels, the two so far most widely used classes of steels in AM, before summarising the state-of-the-art of AM of other classes of steels. Our comprehensive review highlights that a wide range of steels can be processed by AM. The unique microstructural features including hierarchical (sub)grains and fine precipitates induced by AM result in enhancements of strength, wear resistance and corrosion resistance of AM steels when compared to their conventional counterparts. Achieving an acceptable ductility and fatigue performance remains a challenge in AM steels. AM also acts as an intrinsic heat treatment, triggering ‘in situ’ phase transformations including tempering and other precipitation phenomena in different grades of steels such as PH steels and tool steels. A thorough discussion of the performance of AM steels as a function of these unique microstructural features is presented in this review.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Overview of additive manufacturing of alloys and steels

Additive manufacturing (AM), commonly known as 3D printing, has recently gained huge interest in both academia and industry, with its market value expected to reach $21 billion by the end of 2020 [1]. AM refers to a family of layer-upon-layer building technologies capable of producing geometrically intricate parts in a single step [2]. The idea of using a high-energy beam, such as a laser beam, to manufacture objects of any given geometry using powder material was first patented by Pierre Ciraud in 1973 [3]. The invention of laser powder bed fusion (LPBF) dates back to 1996, when a research project at the Fraunhofer Institute for Laser Technology (Frounhofer ILT) yielded the corresponding first patent DE 19649865 [4]. Since the invention of the first AM machine in Austin, TX almost 34 years ago [5], there has been great progress in both the development of various processing techniques and understanding the processing–microstructure–property relationships in AM. Once the underlying microstructural evolution during AM is understood in more detail, manufacturers will be enabled to systematically optimise the AM processing parameters towards superior properties of engineering parts.

AM has been successfully implemented to different metallic systems over time, including Ti alloys, Ni-based superalloys, Al alloys, and steels [6]. Various groups of metals and alloys can now be processed via AM, with steels currently accounting for about 1/3 of all publications in the metals AM literature. However, this is still only a too small share given that almost 80% (weight per cent) of all the metallic parts for engineering purposes are made of steel. Steels are still mainly processed through conventional routes including casting, forming, and machining [7]. Although the sustainability of AM is discussed controversially in the literature [8, 9], reductions in greenhouse gas emissions could potentially be achieved by producing complex-shaped steel parts through AM, which avoids significant emissions from conventional energy-inefficient production routes [10]. Further, AM unlocks unprecedented design freedom (e.g. complex geometries or hollow structures that are difficult to make through conventional manufacturing), translating into high-performance parts with reduced weight. Considering that steel is a 100% recyclable metal, AM can therefore play a key role in the circular economy by producing high added-value products from recycled powders and enabling reuse of AM by-products in new products [11].

Although AM has recently undergone significant development, it still has not been widely adopted by many industry sectors. If we consider the cost of a final product as a function of material cost, tooling cost, equipment cost, and overhead cost, further work and progress is needed for AM to outperform traditional manufacturing in terms of material cost, equipment cost and overhead cost, as described in detail in [12]. Another critical issue is the fact that despite AM’s physical metallurgy commonalities to phenomena observed during casting, welding, powder metallurgy and thermo-mechanical processing, many of the established textbook theories for traditional manufacturing might fail in AM [13]. A full understanding of microstructure and property evolution during AM to achieve reproducibility and to improve the technology to the point of gaining industry acceptance is, therefore, the current scope for AM researchers. AM of steel looks to be still in its middle stages of maturity and adoption, where new grades of steel more suitable for AM and with better performances are expected to be designed in the future. An overview of how current AM steels compete with conventionally processed steels in terms of performance would, therefore, provide invaluable insight for the ongoing research in AM of steels.

Aim and structure of this review

Overall, an extensive effort has been made on investigating the mechanical and corrosion properties of AM metals and alloys. There have been a number of papers reviewing the processing–microstructure–properties in AM including mechanical properties [14,15,16] and corrosion behaviour [17, 18] of additively manufactured metals. The two most comprehensive currently available reviews on AM of steels are by Fayazfar et al. [14] and Bajaj et al. [19]. Fayazfar et al. [14] comprehensively summarised the processing of steels through different powder-based AM technologies. These authors went through the basics of powder bed, powder-fed and binder jetting AM processes for steels and discussed the solidification microstructure of AM steels. Bajaj et al. [19] reviewed the evolution of steel microstructures during AM. These authors gave an overview over the different series of steels in use in AM processes and reviewed the microstructure– properties relationship in these steels. However, neither of these valuable reviews focused on how and where AM could enable manufacturing of steel parts with superior properties compared to conventional subtractive manufacturing. This is the focus of the current review.

Appreciating the unique microstructural characteristics of AM steels compared to the conventionally processed steels and despite considerable progress made in understanding these microstructural features, there is a lack of overview on how these will potentially result in advanced properties. The current review intends to fill this gap by providing a comprehensive summary of the unique properties of AM steels currently reported in the literature. We mainly concentrate on mechanical, corrosion and wear properties of steels where relevant data are available. Occasionally, other properties such as magnetic properties and hydrogen embrittlement are discussed if they are important properties of the corresponding steel grade. However, we do not include AM steel composites such as AM oxide dispersion strengthened (ODS) [20,21,22] and WC dispersed maraging steels [23, 24]. We also do not discuss the details of different AM processes (for a detail overview on this please see [14]), and we intend to discuss the microstructural evolution during AM only briefly, if necessary, in order to explain differences in properties.

After a few necessary notes on typical AM microstructures, we will start with the two most popular steels in the AM context, i.e. austenitic stainless steels (with the vast body of literature on 316L) and maraging/precipitate hardening (PH) steels. Then we will continue to discuss a variety of other types of steels that have been processed by AM so far. These include duplex stainless steels, ferritic–martensitic steels, carbon-bearing tool steels and transformation-/twinning-induced plasticity (TRIP/TWIP) steels.

A few notes on typical AM microstructures

With the ability to build material through successive adding of layers with thicknesses of a few tens of microns on top of each other, AM is capable of producing site-specific microstructures with tailored mechanical [25, 26] and corrosion properties [27] that are difficult/impossible to achieve through traditional manufacturing. In this regard, understanding the microstructural evolution during AM is essential. The thermal history to which a metal is exposed during AM is very different from that of conventional manufacturing. AM microstructures are formed through rapid solidification rates (dT/dt: 103–108 K/s)Footnote 1 [28], high thermal gradients (dT/dx: 103–107 K/m), and significant thermal gyrations caused by the melting and deposition of several subsequent layers [29,30,31]. All of these processing parameters affect the evolution of key microstructural features including the solidification morphology, segregation, cells, grain structure (size and shape), crystallographic texture, microstructure stability, secondary phases, defects and inclusions. In AM microstructures, solidification cells are subgrains, very similar in orientation, delineated by segregation of alloying elements and dislocation accumulation at their boundaries [19]. Grains are defined by their distinct orientation separated by high angle grain boundaries.

AM microstructures exhibit a variety of grain morphologies. An example of this difference is presented in Fig. 1 for 316L stainless steel. In this regard, fine equiaxed grains at the melt pool boundaries are observed from the transverse direction (plane perpendicular to the building direction), where grains are columnar inside the individual melt pools (Fig. 1a). In contrast to the transverse plane, large columnar grains along the building direction are commonly reported for AM, as shown in Fig. 1b. This columnar grain morphology has been attributed to supercooling conditions inherent to AM that may change the solidification mode from planar to columnar and/or an epitaxial growth [32]. The cooling rate and extent of re-melting of the previous layer during LPBF are the main determining factors in controlling the grain size. For instance, very large, columnar grains with high aspect ratio for LPBF 316L stainless steel are formed as a result of epitaxial growth when using a high laser power (Fig. 1c) [33]. In general, if not epitaxially grown, grains in LPBF steels have been reported to be fine, a distinct feature compared to their conventional counterparts [15], which is a result of the rapid solidification during LPBF. The as-built texture depends mostly on the melt pool size, direction of the local heat flow and competitive grain growth occurring during manufacturing [34]. One can control the texture in AM through imposing a change in the scanning strategy, for example rotations between different layers and/or the so-called point heat source strategy in which the melted area is patterned in ‘points’, leaving some space between individual points [35].

Typical grain structure of a LPBF 316L austenitic stainless steel acquired by electron back-scattered diffraction (EBSD) analysis. a An inverse pole figure (IPF) map of a LPBF 316L austenitic stainless steel processed with a 150 W laser power along the building direction, x–z plane. b IPF map of the same specimen shown in (a) but from the transverse (perpendicular to the building) direction, x–y plane. c IPF map of another LPBF 316L austenitic stainless steel processed with a 1000 W laser power along the building direction, indicating more elongated, columnar grains compared to those in the specimen processed with lower laser power in (a). IPF map of a conventionally processed 316L austenitic stainless steel is also presented in (d) for comparison purposes. a, b and d have the same scale bars. a, b, d are adapted from Ref. [36] and c from Ref. [33], with permission

AM has made great progress over the past years in terms of producing high-density parts; however, defect formation remains a challenge [37]. Porosities, delamination and balling are known as the most common types of defects introduced during AM of metals. Two types of pores have been reported in the literature: (1) spherical or gas-induced pores and (2) non-spherical or process-induced pores. The former ones are believed to be due to the trapped gasses among the powder particles, which are released during melting and then locked-in during solidification. Another origin of spherical pores arises from gases being trapped inside the powder feedstock during the preparing process of the powder materials. This entrapped gas is then transferred into the part and leads to formation of gas-induced porosity [38]. On the other hand, non-spherical pores, also known as irregular-shaped, lack-of-fusion (LOF) or process-induced pores are generally formed when the applied laser energy density is not sufficient to completely melt the powder bed. This leads to formation of un-melted powder particles trapped inside of these pores. Furthermore, high laser energy densities have also been observed to induce irregular-shaped pores during a process known as keyhole formation [39].

Delamination, which is defined as the separation of adjacent layers within an AM part, is mainly due to the incomplete melting of adjacent layers [40]. As opposed to LOF that is a microscopic internal defect and can be eliminated through post-processing processes, delamination is a macroscopic crack-like defect which cannot be repaired by post-processing [41]. Thus, careful adjusting of process parameters is necessary in order to avoid delamination. The balling phenomenon is another severe processing defect in AM parts [42]. Balling occurs when the melt pool loses its continuity owing to the Plateau–Rayleigh instability and then segregates into individual spherical islands [43, 44]. This can be mainly attributed to the high viscosity of the liquid, which in turn leads to significant suppression of liquid flow and insufficient wetting of the powder surface by the liquid. Powder particles then tend to agglomerate due to surface tension, and consequently the balling phenomenon occurs. Increasing the laser power or decreasing the scanning speed can help to reduce balling phenomena during AM [31].

Microstructures far from the equilibrium conditions are produced in AM parts due to the rapid solidification rates [31]. For instance, a very fine cellular microstructure with cell sizes of 1 µm or less is usually obtained in AM austenitic stainless steels, as shown in Fig. 2a, b. Some elements like Cr and Mo have been reported to segregate at cell walls, as shown in the transmission electron microscopy (TEM) and energy-dispersive spectroscopy (EDS) maps in Fig. 2c. Inclusions are believed to play a prominent role in a range of properties of AM steels [45]. For example, oxide inclusions have been commonly reported in AM austenitic stainless steels and are shown to be spherical in shape with dimensions between a few tens of nanometres and a few microns and mainly enriched in O, Mn and Si (Fig. 2c) [46,47,48]. This is in contrast to the larger (> 1 µm) and irregular-shaped oxide inclusions in conventional austenitic stainless steels [49].

Non-equilibrium microstructure in LPBF 316L stainless steel. a, b Bright-field TEM images of the solidification cells within the grains at low and high magnification. c EDS analysis showing the segregation of alloying elements like Mo and Cr at cell walls. Spherical dark regions in (c) are nano-inclusions that are enriched with Mn, Si and O. Images are adapted from Ref. [43] with permission

Austenitic stainless steels

Austenitic stainless steels are one of the most widely used group of industrial alloys owing to their excellent corrosion resistance, biocompatibility and ductility, which make them suitable candidates for applications in various industries such as biomedical, aerospace, defence, oil & gas, petrochemical and more. These steels are the most widely used class of steels in AM. Here, AM has been shown to provide some promising properties while many challenges remain. There are a large number of papers on AM of austenitic stainless steels in the literature. Going through all of them individually would make this section too lengthy. Therefore, we will review the trends with their advances and challenges in terms of mechanical and corrosion properties. It should be noted here that most of the literature on AM of austenitic stainless steels focuses on the grade of 316L, the most common material of choice for many industrial applications. However, other kinds of austenitic stainless steels like the 304L grade will also be reviewed here if any achievements or challenges in different properties have been reported. The most important difference between 316L and 304L is in their chemical compositions, where almost 2 wt% Mo is added to 316L to improve its corrosion resistance.

Mechanical properties

Given their unique microstructures, AM austenitic stainless steels show interesting behaviour in tensile testing different from the conventionally produced parts. For instance, LPBF has shown to produce 316L stainless steel that is stronger than its wrought/cast counterpart (ultimate tensile strength (UTS) of 640–700 MPa for LPBF compared to 450–555 MPa for conventional; yield strength (YS) of 450–590 MPa for LPBF compared to 160–365 MPa for conventional) while still remaining ductile (elongation of 36-59% for LPBF compared to 30-43% for conventional) [50, 51]. An example of such superior tensile properties for LPBF 316L stainless steel compared to its conventional counterpart is presented in Fig. 3a. This is mainly attributed to the presence of numerous nano-inclusions that hinder dislocation movements, and a large density of low angle grain boundaries. The exceptional combination of strength and ductility in 316L austenitic stainless steel is a great achievement for AM considering the limitation of conventional manufacturing in overcoming the strength–ductility dilemma [50, 51].

Representative unique mechanical properties of AM austenitic stainless steel. a Tensile engineering stress–strain curve for LPBF 316L austenitic stainless steel, indicating the capability of AM in producing stainless steel with simultaneously enhanced strength and ductility. The minimum requirements for tensile properties for 316L stainless steel are indicated by dashed yellow lines. b Comparison of strain-life fatigue behaviour of LPBF 304L austenitic stainless steel with wrought 304L stainless steel. c Wear behaviour of LPBF 316L austenitic stainless steel displayed as coefficient of friction (COF) versus sliding distance compared to (d) conventional 316 L stainless steel, showing a comparable wear resistance for LPBF 316L austenitic stainless steel at temperatures up to 400 °C. a is adapted from Ref. [51], b from Ref. [53] and c, d from Ref. [54], with permission

There are reports on LPBF 316L austenitic stainless steel showing a good fatigue performance, comparable to its conventionally processed counterpart [52]. LPBF 304 austenitic stainless steel also exhibits a comparable fatigue resistance in high-cycle regimes and an even slightly higher fatigue resistance in low-cycle-fatigue regimes [53], as presented in strain-life fatigue curves in Fig. 3b. AM 316L stainless steel has been shown to have a better wear resistance than its conventional counterpart at room temperature under dry sliding conditions and to even maintain this trend at high temperatures up to 400 °C [54], as depicted in the coefficient of friction versus sliding distance curves in Fig. 3c, d. This is attributed to the role of the cellular sub-grains within the microstructure of the AM 316L austenitic stainless steel in resisting against subsurface deformation through hindering dislocation movement. A similar conclusion has been made for better tribological behaviour of LPBF 316L austenitic stainless steel under wet wear test in a simulated body solution [28].

Corrosion properties

It is generally accepted that the corrosion properties of stainless steels are dependent on their microstructure and chemical composition. Phases such as δ-ferrite, metallic/non-metallic inclusions and precipitates in the steel can all affect its corrosion resistance. The effects of microstructural features of AM stainless steel, which are in turn dependent upon the AM processing conditions, on their corrosion characteristics will be discussed in the following.

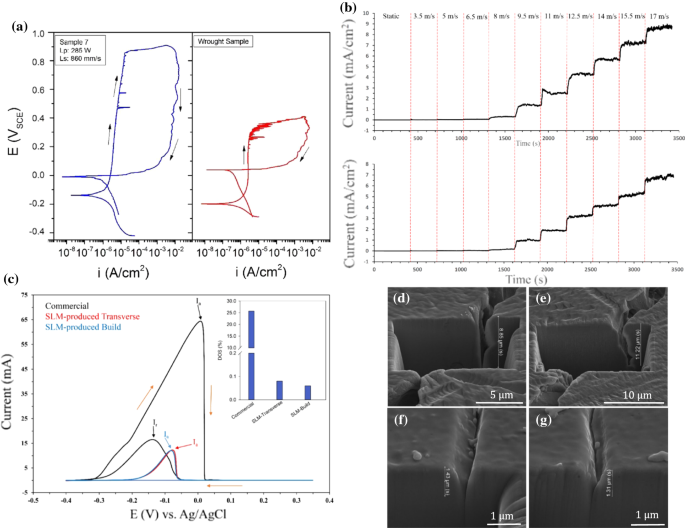

Sulphide inclusions, particularly manganese sulphide (MnS), are detrimental to pitting corrosion resistance of all grades of stainless steels [55,56,57]. Elimination of such harmful MnS inclusions is not practical in conventional subtractive manufacturing, since S is generally added to stainless steel as an alloying element with the aim of improving machinability [58]. Changing the chemical composition of MnS inclusions, e.g. by replacing Mn in the sulphide by Cr, has been shown to be a useful method in enhancing the pitting corrosion resistance though not in severe corrosive environments like ferric chloride solutions [59]. Reducing the size of MnS inclusions through rapid solidification [60] or laser surface re-melting [61] has also been found to improve the pitting corrosion resistance. In this respect, AM has been shown to be capable of producing austenitic stainless steels with excellent pitting corrosion resistance [62, 63], as presented in Fig. 4a. This is mainly attributed to the rapid solidification inherent to AM that limits the formation of MnS inclusions [64, 65].

Representative unique corrosion characteristics of AM austenitic stainless steel. a Potentiodynamic polarisation curves recorded in 0.1 M NaCl solution, indicating an exceptionally higher pitting corrosion resistance for LPBF (= selective laser melting, SLM) 316L austenitic stainless steel compared to a wrought sample. b Potentiostatic polarisation curves recorded using a jet impingement setup in a 0.6 M NaCl solution containing 2.5 wt% sand particles, showing a lower erosion-corrosion resistance for LPBF 316L austenitic stainless steel compared to its conventional counterpart. c Double-loop electrochemical potentiokinetic reactivation (DL-EPR) test recorded in 0.5 M H2SO4 + 0.01 M KSCN, along with the degree of sensitisation values (inset), showing a substantially higher IGC resistance for LPBF 316L austenitic stainless steel at both transverse and building planes relative to the conventional 316L austenitic stainless steel. For sensitisation purpose, the specimens were heat-treated at 700 °C for 60 h followed by water quenching. d–g Post-DL-EPR images of the corroded grain boundaries acquired by focused ion beam SEM from d, e conventional and f, g LPBF 316L austenitic stainless steel specimens, indicating an extensive intergranular corrosion for conventional 316L austenitic stainless steel, while much shallower corrosion along grain boundaries is detected for LPBF 316L austenitic stainless steel. a is adapted from Ref. [62], b from Ref. [63], c, g from Ref. [36], with permission

Given the excellent pitting corrosion resistance and high hardness and wear resistance, as discussed previously, AM austenitic stainless steel is expected to exhibit an enhanced erosion-corrosion resistance compared to its conventional counterpart. However, Laleh et al. [63] report an unexpected lower erosion-corrosion resistance for LPBF 316L austenitic stainless steel (Fig. 4b), which is due to the weaker repassivation ability in LPBF 316L austenitic stainless steel compared to its conventionally processed counterpart. This is in good agreement with other studies [62, 66, 67]. The mechanism behind this behaviour is still unclear; however, the presence of internal porosities and the inhomogeneous microstructure of AM steel are supposed to be the major factors. In this regard, a recent study by Kong et al. [68] shows a similar repassivation potential for LPBF 316L austenitic stainless steel to its conventional counterpart by eliminating the porosity content (< 0.03 vol%).

Intergranular corrosion (IGC) of stainless steel is a localised form of corrosion that proceeds along the grain boundaries and usually happens during exposure to high temperatures (between 500 and 800 °C) or welding [69, 70]. Formation of secondary precipitates like Cr-rich carbides, σ and χ phases along the grain boundaries leaves the adjacent areas more susceptible to corrosion during subsequent exposure to corrosive environments. IGC of AM stainless steel is still under dispute. Some studies report an accelerated interfacial corrosion in LPBF 316L [71, 72] while some others show an opposite behaviour [36]. The enhanced IGC resistance of the LPBF 316L austenitic stainless steel (Fig. 4c–g) is attributed to the presence of a large volume of low angle grain boundaries and twin boundaries [36], which are believed to be not susceptible to IGC. The existing disagreement in the IGC behaviour of AM stainless steels could be related to the sensitisation conditions (heat treatment temperature, cooling conditions) and/or IGC test method.

It has been shown that LPBF 316L austenitic stainless steel has a superior hydrogen damage resistance compared to its conventional counterpart [73], indicating that LPBF 316L austenitic stainless steel could be an option for using in hydrogen fuel cells. This behaviour is mainly attributed to the lower degree of austenite to martensite transformation and, thus, lower volume fraction of martensite in LPBF 316L austenitic stainless steel upon exposure to 4 h hydrogen charging, as the martensite phase has a poorer corrosion resistance than austenite in these steels. A similar conclusion has been made by Baek et al. [74] who report a higher resistance to hydrogen embrittlement under high-pressure H atmosphere for AM 304L austenitic stainless steel compared to its conventional counterpart, which is mainly discussed based on the stability of the austenite phase that does not transform to martensite phase under load stress. These results indicate an ability of the AM austenitic stainless steel to resist again phase transformation during H charging; however, the mechanism behind this phenomenon is still not clear in the literature and needs to be clarified in future work.

Challenges

Despite the above-mentioned promising properties offered by AM, there are still many important challenges inherent to AM of austenitic stainless steels that hinder their widespread industrial application. The most important challenges that AM currently encounters in austenitic stainless steels manufacturing will be reviewed in the following. They include residual stresses, anisotropy, formation of pores and post-processing via heat treatments.

The sharp thermal gradients associated with AM generate large residual stresses that cause part distortion [75, 76]. This will subsequently affect mechanical properties, decrease the stress corrosion cracking resistance [77,78,79] or even deteriorate final geometry [80] of the parts. Preheating the build substrate or feedstock material is the most common way to decrease temperature gradients and, thus, reduce residual stresses [81]. Controlling the scanning strategy is another approach to reduce residual stresses [82,83,84]. Other than these ‘in situ’ methods for controlling residual stresses, heat treatment post-processing has also been reported to be beneficial in terms of releasing residual stresses [85].

Anisotropy in AM is a critical issue and can be categorised into two types: first, anisotropy that arises from building a part in different directions and second, anisotropy that arises from property measurements along different axes. It has been well understood that the building direction (the acute angle between the long axis of the fabricating part and the horizontal plane) can cause anisotropy in the microstructure and mechanical properties of AM austenitic stainless steel parts [86,87,88]. The columnar grain structure and strong crystallographic texture along the building direction have been known as major contributing factors to anisotropy in the mechanical properties of AM austenitic stainless steel parts [89]. For instance, it has been shown that the UTS in horizontally built specimens (loading direction parallel to the layers in the microstructure) is almost 20% higher compared to that of the vertically built specimens [88]. This behaviour is related to the preferential formation of defects between the successive layers during AM fabrication, which thereafter results in a decreased strength when the loading direction is perpendicular to the layers. Anisotropy has not been reported as a critical issue in corrosion properties of AM austenitic stainless steel as long as high-density specimens are produced. The focus in the literature is on the response of the different planes (i.e. transverse and building planes) against various kinds of corrosion, and most of the studies report similar corrosion characteristics in terms of pitting [27, 67, 90] and intergranular [36] corrosion resistances at all planes. It has also been shown that the building direction does not have a significant influence on the tribological performance of the LPBF 316L austenitic stainless steel under dry sliding wear test [91].

Different types of pores have been reported in AM austenitic stainless steels [41, 67,68,69,70,71,72,73]. LOF pores are shown to be more detrimental to wear properties [66, 92, 93], fatigue resistance [94, 95] and corrosion resistance [96,97,98] than spherical gas pores, since they act as the crack initiation site during tensile testing and pit formation site upon immersion in a corrosive environment. Examples of pit development at the sites of LOF pores in AM austenitic stainless steels when subjected to corrosive environments are presented in Fig. 5, indicated by potentiodynamic polarisation tests and three-dimensional computed tomography analysis. They show that the pitting corrosion resistance will decrease in the presence of LOF pores because of their susceptibility to act as the pit formation sites. Spherical gas pores have also been classified as open and covered pores based on their geometry at the top external surface. Open spherical gas pores are found to be less susceptible to stable pit formation compared to the semi-covered ones, which is attributed to the differences in the ions diffusion rates upon exposure to corrosive environments [99].

The role of LOF pores in pitting corrosion of AM austenitic stainless steels. a Potentiodynamic polarisation curves obtained using a micro-electrochemical cell in 0.6 M NaCl solution for LPBF 304L stainless steels, showing that the testing areas containing LOF pores have lower pitting corrosion resistance than the areas with no pores. b–f Three-dimensional computed tomography imaging of an LPBF 316L austenitic stainless steel specimen before and after one-week immersion into 6 wt% ferric chloride solution, indicating the development of corrosion within a LOF pore. b General overview of the target LOF pore. The external surface is indicated by the dashed white line. The entry points into the LOF structure are also indicated by the labels E1 and E2. c, d LOF pore before and after corrosion, respectively; only entry point E1 can be seen from this perspective. c Shows two major LOF structures in off-white and cyan. d Shows that after corrosion these structures are connected via the LOF pores indicating propagation of corrosion within the structure. e, f Shows the LOF structure within the powder bed plane before and after corrosion, respectively. The spacing between two linear features is around 40 µm which is slightly larger than the powder bed thickness of 30 µm. Entry points E1 and E2 are also shown. f After corrosion, all these independent features have the same colour indicating that they are joined. The white ellipse indicates where the corrosion has propagated from the off-white LOF structure to the cyan LOF structure. a is adapted from Ref. [97] and b–f from Ref. [96], with permission

Interaction between the heat source and feedstock material during AM leads to a large number of rapid heating and cooling cycles, which might result in a microstructure far from the equilibrium conditions. In this regard, post-processing treatments including stress relief heat treatment and hot isostatic pressing (HIP) have been commonly used to eliminate these issues. Current standards for the heat treatment of austenitic stainless steels have all been developed for the cast and wrought materials and not optimised for AM parts. Examining the effect of such heat treatments on the properties of the AM parts and optimising heat treatment routes for AM products is therefore essential.

As an example, in terms of corrosion properties, solution annealing heat treatment at a temperature range between 1010 and 1120 °C has generally been used for conventional austenitic stainless steel to increase corrosion resistance through dissolving carbides into the solid solution of the γ matrix [100, 101]. A summary of dependence of pitting potential for LPBF 316L austenitic stainless steel on the post-processing heat treatment is presented in Table 1. This table summarises a wide range of post-processing heat treatments (temperature, holding time and cooling conditions) used in the literature. In most of cases, heat treatment above 1000 °C leads to a decrease in the pitting corrosion resistance, suggesting that the commonly used solution annealing heat treatment for conventional austenitic stainless steels may not be applicable for AM 316L austenitic stainless steel.

It has been shown that heat treatments at temperatures above 1000 °C drastically decrease the pitting corrosion resistance [64, 68, 102], indicating that such heat treatments are not practical for AM austenitic stainless steel in applications where high resistance to pitting corrosion is required. There is still no agreement on the mechanism behind the drastic decline in pitting corrosion resistance after subjecting to temperatures above 1000 °C, although some authors believe that formation of detrimental MnS inclusions is responsible for this phenomenon [64] while others propose that release of compressive residual stresses leads to such behaviour [102]. Apparently, a heat treatment at high temperatures leads to the partial/complete transformation of some existing inclusions to inclusions with different chemical compositions, and even the formation of some new inclusions that were not present in the as-built condition [48, 64]. The mechanism behind the inclusion transformation under such high-temperature heat treatments remains unclear.

Maraging and precipitate hardening stainless steels

Introduction

A number of steels have been developed which can undergo age hardening through the precipitation of phases other than carbides. Two such classes of alloys that have been extensively analysed for their suitability for production through AM are precipitation hardening (PH) stainless steels and maraging (i.e. martensitic and aging) steels. Although PH stainless steels may also have matrix phases that are austenitic or semi-austenitic [105], the only PH stainless steels discussed in this section are classified as martensitic, as these are the most widely researched in the field of AM. Both alloy classes exhibit similar precipitate strengthening behaviour. They have a low C content, in order to suppress carbide precipitation [7], which is particularly detrimental to corrosion resistance in stainless steels [105]. Martensitic PH stainless steels have moderate Ni content (4–11 wt%) [105] whilst maraging steels have higher Ni content (17–25 wt%) [7]. After quenching from the austenite phase field, the room temperature microstructure of these alloys is mainly martensitic but may contain some retained austenite depending on the composition of the steel in question and the temperature to which it is quenched [7]. The high strength of these precipitation hardening steel classes has led to their use as tools. Furthermore, the high strength-to-weight ratio and decent toughness of maraging steels are particularly desirable for applications in the aerospace (from landing gear components to aircraft fittings), automotive and defence [106, 107].

The most commonly used PH stainless steel in AM research so far has been 17–4 PH stainless steel due to its good printability and diverse range of applications, owing to its combination of high strength and corrosion resistance. In conventional processing, after being cast, 17-4 PH parts are subjected to a solution annealing heat treatment. This is typically at 1040 °C for 1 h, although longer solution annealing times are required for thicker samples [108]. After solution annealing and quenching to room temperature, the martensitic microstructure is supersaturated in Cu. From this condition, referred to as condition A, the part undergoes a thermal aging treatment to induce precipitation of Cu-rich precipitates on the nanoscale. The most commonly applied aging treatment to 17–4 PH is at 482 °C for 1 h, as this has been shown to generate the highest strength in such parts [108]. This is referred to as the H900 condition. In this condition, the UTS of parts is typically around 1380 MPa [109].

15–5 PH stainless steel is a similar alloy to 17–4 PH. Although much less commonly used, this alloy has also been assessed for applicability for AM in a number of studies. Whilst it is still a martensitic precipitate hardening stainless steel, changes to the alloy composition allow it to have a greater wrought toughness than 17–4 PH due to the diminished levels of δ-ferrite within the microstructure [110]. The kinetics of Cu precipitation are very similar to 17–4 PH, resulting in both alloys reaching peak age hardening after the H900 heat treatment [111].

A maraging steel that has been widely discussed for its applicability for AM is the 18Ni 300 maraging steel. After quenching from the austenite phase field to form a martensitic microstructure, aging at temperatures between 400 and 500 °C causes the precipitation of Ni3(Ti, Mo) and then Fe7Mo6 phases [112,113,114]. After aging at 482 °C for 6 h, the UTS of 18Ni 300 maraging steel parts can exceed 2200 MPa [115]. This high strength has allowed this alloy to be used in a range of military and aerospace applications.

Another important precipitate hardening stainless steel, identified in recent research for its applicability to additive manufacturing, is CX stainless steel. This material was recently developed and commercially produced as a powder by EOS GmbH [116]. CX stainless steel parts produced using LPBF can exhibit superior toughness to LPBF 17–4 PH and 316L steels in the as-built condition, perhaps paving the way for the replacement of these steels with CX in certain applications [117]. Thermal aging treatments performed at 530 °C for 3 h result in the formation of rod-/needle-shaped NiAl-based nanoprecipitates within the martensitic matrix both with and without a preceding solutionising heat treatment [118, 119]. With these heat treatments, LPBF-produced CX stainless steel can be fabricated with UTS of up to 1601 MPa [118]. Due to the relative lack of literature discussing it, CX steel will not be discussed further in the following section.

This section will summarise the literature assessing the influence of the production of PH stainless steels and maraging steels by AM on their properties. Most of this literature has focused on 17–4 PH for PH stainless steels and 18Ni 300 for maraging steels.

Mechanical properties

For simplicity, the American Society for Metals (ASM) standard wrought tensile properties for the alloys discussed in this section are presented in Table 2 for comparison to the properties exhibited by AM produced parts of these steels.

15–5 PH stainless steel

AM is able to generate improvements upon the mechanical properties of conventionally processed 15–5 PH stainless steel. Comparing LPBF and conventionally manufactured 15–5 PH, distinct differences of the martensitic microstructure are observed, with the AM material showing shorter and narrower martensitic laths [121]. AM material has been shown to have ∼ 34% greater UTS of 830 MPa at 593 °C but over 50% lower ductility, at 9% elongation to failure, than the wrought material [121, 122]. In another study on 15-5 PH samples produced by LPBF after an age hardening heat treatment, it has been shown that, compared to the ASM wrought properties of 15–5 PH (listed in Table 2), horizontally built samples show a ∼ 10% increase in YS with vertically built samples showing a ∼ 6% decrease in YS. Regardless of build orientation, the UTS increases by a similar margin compared to wrought values (∼ 11% for horizontal builds, ∼ 12% for vertical builds). These samples have been shown to fail predominantly by cleavage fracture [122, 123]. The fracture toughness from a Charpy impact test for LPBF 15-5 PH stainless steel has been measured to be 10.85 ± 1.20 J/cm2, well within the standards for wrought samples (9.4–18.6 J/cm2) [123, 121]. It has also been found that the microhardness of LPBF 15–5 PH stainless steel is greater than that of the wrought material, with the hardness in transverse direction of the AM samples being 500 HV 0.5 [121]. This is 56% greater than the wrought material.

Cyclic loading is inherent in many desired applications for PH stainless steels. Therefore, a component’s fatigue performance is one of the most important concerns in the AM of these steels. Fatigue tests have shown 15–5 PH samples fabricated by LPBF to have a 20% reduced fatigue endurance limit as compared to wrought samples [122, 124]. This is attributed to the poor surface finish resultant from the LPBF process [125]. Significant improvement in fatigue life can be achieved by surface machining of the AM samples to remove surface defects [125, 126], but not to the point of improving upon wrought properties. This supports the observation that surface defects are the most detrimental to the fatigue performance of AM 15–5 PH stainless steel [110]. However, an optimisation of process parameters combined with surface machining has produced 15–5 PH samples with fatigue performances well comparable to those of wrought components [110].

The high-temperature creep performance of additively manufactured PH stainless steels has not been extensively studied. An improvement in creep life of ∼ 17% in LPBF 15–5 PH samples compared to wrought samples at 530 °C has been shown [121]. The reason for this difference is not yet fully understood.

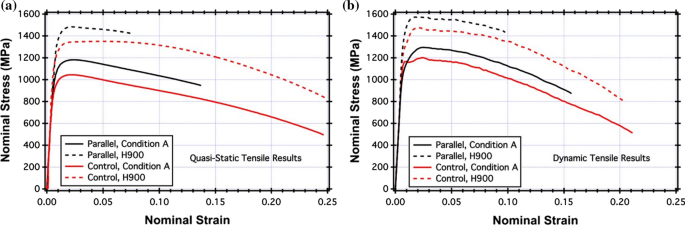

17–4 PH stainless steel

A reduced ductility as compared to wrought parts is an issue for AM 17–4 PH stainless steel. In both condition A and the H900 condition, the strength of AM produced 17–4 PH samples has been found to be superior to conventionally produced samples but the elongation to failure is inferior [127]. This result persists in both low strain rate (quasi-static) and high strain rate (dynamic) tensile testing, which can be seen in the strain curves in Fig. 6 [127]. Many studies into AM 17–4 PH stainless steel parts have also shown increased strength [128,129,130,131,132] and reduced ductility [129, 130, 133,134,135] as compared to wrought parts. Increased strength is cited to be due to the refined microstructure of AM parts [127] and reduced ductility is generally attributed to porosity resultant from the AM process [129, 136].

Stress vs strain curves for LPBF (with loading direction parallel to the X–Y plane, normal to the building direction), shown in black, and conventionally produced, shown in red, 17–4 PH stainless steel. a Low strain rate, quasi-static tensile test results. b High strain rate dynamic tensile test results. Adapted from Ref. [127] with permission

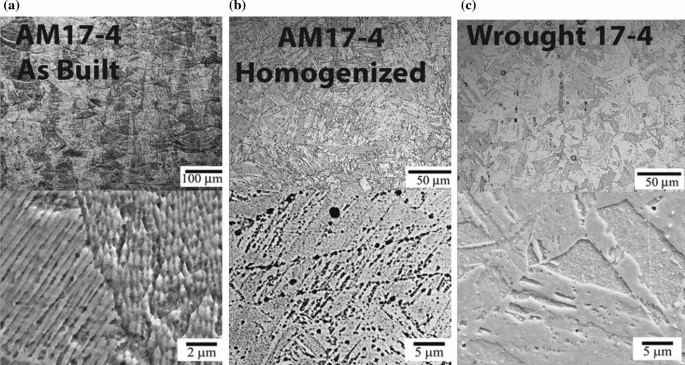

A study by Lass et al. [134] analyses the tensile properties of a number of LPBF-fabricated 17–4 PH samples with differing post-processing heat treatments and compares the results to data for wrought samples in condition A (YS = 824 MPa, UTS = 1121 MPa, Elongation to failure = 10%). An alternative post-build solution annealing treatment developed by these researchers results in a YS > 90% of wrought samples. For comparison, the AM samples in the as-built and condition A states show YS of ∼ 55% that of wrought samples. Samples treated with this new processing route also show a greater UTS and a diminished ductility as compared to wrought samples. The general effect of post-build heat treatments on the microstructure is illustrated in Fig. 7, showing several different morphologies obtained in 17–4 PH stainless steel. The melt pool boundaries and cellular solidification structure are clearly visible in the as-built microstructure (Fig. 7a), but after homogenising and solution annealing (i.e. being treated to condition A), this solidification structure is removed. The resultant microstructure (Fig. 7b) is comparable to the wrought microstructure (Fig. 7c). Other studies have also shown these distinct microstructural changes in AM 17–4 with heat treatment [137, 138], with these changes generating increases in strength for AM 17–4 parts [127, 139].

Optical micrographs of 17-4 PH stainless steel microstructures. (a) As-built by LPBF. (b) After a post-build homogenisation treatment. (c) Wrought. These micrographs were taken parallel to the building direction and the rolling direction for the LPBF and wrought samples, respectively. Adapted from Ref. [141] with permission

The characteristics of the powder feedstock used to produce additively manufactured parts also have an impact on the mechanical performance [140]. It has been found that by changing the 17–4 PH powder and/or adjusting the laser energy density, tensile properties comparable to or greater than wrought samples can be produced [140]. Pasebani et al. [131] show a significant effect of producing 17–4 PH parts by LPBF from gas-atomised or water-atomised powder to conventional part production and different post-production heat treatments on the mechanical properties. Using a suitable energy density during part production, LPBF parts produced from the gas-atomised powders, solution annealed at 1051 °C for 45 min and aged at 482 °C for 1 h, show the greatest strength; comparable YS (consistently within 5%) and superior UTS (up to 4.4%) than the ASM reported data for wrought samples (from [120] in Table 2). Solution annealing at 1315 °C for 1 h before aging results in significantly improved YS and UTS for parts produced from water atomised powder. This is attributed to refinement in the martensitic lath structure. The properties of the parts produced from water atomised powder, although still inferior (∼ 15% reduced YS and ∼ 4% reduced UTS) are comparable to the wrought properties. This is significant due to the relatively low cost of production of water atomised powder compared to gas atomised powder [131].

The presence of austenite within the microstructure has been observed to greatly affect the mechanical properties of 17–4 PH due to the transformation of austenite to martensite during mechanical testing [142,143,144]. AM samples of 17–4 PH with a greater austenite content exhibit greater ductility and capacities for work hardening in the same way as TRIP-assisted steels [139, 145]. 17–4 PH parts with the greatest levels of austenite in the microstructure are generally in the AM or directly aged (i.e. aged without a solution annealing treatment after fabrication) conditions [127, 143]. The results of Lebrun et al. [142] show that such samples give comparable ductility to wrought standards [108]. For instance, the as-built specimen in this study has a 36% volume fraction of retained austenite and a 16.2% elongation to failure, the expected ASM wrought elongation to failure being 15% (Table 2). Austenite retention during LPBF in 17-4 PH has also shown increased ductility in compression as well as tension [146]. Figure 8a shows the AM microstructure of LPBF produced 17–4 PH, whilst Fig. 8b shows the distribution of phases within microstructure, showing an increased presence of austenite along melt pool boundaries.

EBSD maps for 17–4 PH stainless steel manufactured by LPBF. a Image quality map and b Phase Map. Approximate locations of melt pool boundaries are shown by dashed black lines. The apparent difference in melt pool shape between layers is due to a 90° rotation in the scanning strategy. Image courtesy of Maxwell Moyle and Sophie Primig (UNSW Sydney)

A comparison of the microstructure and mechanical properties of 17–4 PH when produced by LPBF as well as by conventional methods shows significant variation between the tensile properties achieved in all cases [136]. However, none of the results from LPBF produced samples in this comparison are able to produce YS or UTS comparable to those of the wrought samples in the H900 condition. The variation in mechanical properties is attributed to the fact that LPBF samples show a greater level of retained austenite as well as porosity within the microstructure [136]. It is important to note that the presence of austenite in precipitate hardening steels affects their hardenability as solute atoms may be more soluble in austenite than in either ferrite or martensite, which inhibits their ability to form precipitates upon aging [142]. Absence of precipitation in austenitic regions of the microstructure has been observed both in 17–4 PH [142] and 18Ni 300 maraging steels [147]. Atom probe analysis of 18Ni 300 maraging steel given in Fig. 9 shows this effect. Figure 9a, b shows martensitic areas of microstructures, each after some form of thermal aging. Intermetallic precipitates form as shown by the enclosed iso-concentration surfaces. Contrastingly, the atom probe dataset shown in Fig. 9c exhibits an interface between an austenitic and a martensitic area of the microstructure in an AM produced sample. The total absence of precipitation in the austenite as compared to the martensite is apparent.

Atom probe tomography conducted on 18Ni 300 maraging steel. a DED (= LMD) produced material versus b conventionally produced material. (c) Another data set from DED-produced material showing the difference in precipitation behaviour between austenite and martensite. Adapted from Ref. [147] with permission

The atmosphere in which AM is carried out has also been shown to affect the properties of AM 17–4 PH stainless steel. A study into the effect of building atmosphere on mechanical properties of 17–4 PH stainless steel when produced by directed energy deposition (DED), an AM technique where the metal powder is fed directly into the melt pool without the need to form a powder bed, has been conducted by Wang et al. [148]. Two chamber atmospheres have been considered in this study, Ar and air. Whilst the UTS of all the samples produced by AM are lower than that of conventionally produced samples [108], an increase in strength is noted for the samples processed in air, namely the UTS of air processed samples after heat treatment reaches 1145 MPa. This represents a 7% increase in the Ar processed sample in the same condition. Further analysis of the microstructure led the authors to conclude that this is due to dispersion strengthening effect of amorphous oxides and solution strengthening of N resultant from processing in air. Furthermore, it has been shown that [149] printing in an N2 atmosphere, producing an austenitic microstructure, leads to 17–4 PH parts with comparable UTS and ductility to wrought parts due to significant strain hardening during plastic deformation in tensile testing [149].

The scatter graph in Fig. 10 shows a number of different combinations of UTS and ductility for additively manufactured 17–4 PH stainless steel reported. This figure also shows the properties for conventionally manufactured 17–4 PH samples to which the AM properties are compared in the literature. It should be noted when viewing this figure that the parameters of the AM process, surface treatments and post-build aging treatments vary between each study and between samples in the same study. From this figure, it can be seen that there is both a wide range of properties that have been achieved in the AM of this alloy and a wide range of reported wrought properties. It can also be seen that without optimisation of the AM process as well as post-build treatments, the resulting material can have very poor strength and/or ductility. However, this plot does highlight that with the optimisation, comparable or even enhanced properties compared to wrought values are possible. The combination of excellent UTS and ductility achieved by Facchini et al. [145] is partly due to the high levels of austenite within the microstructure of the material produced, which undergoes a strain induced transformation to martensite during tensile testing. Rafi et al. [139] also attribute the large ductility of their as-built sample to this effect. It is to be noted that the results by Dobson et al. [149] are presented in engineering stress.

Scatter plot showing ranges of ultimate tensile stress and elongation to failure reported in literature for 17–4 PH stainless steel samples made by additive manufacturing, along with the properties of wrought samples to which they were compared [108, 109, 129,130,131, 134,135,136, 139, 142, 143, 145, 148, 149, 152,153,154,155,156,157]

Figures 11 and 12 show scatter plots composed of data from literature showing the UTS and elongation until failure, respectively, against the measured austenite volume fraction of additively manufactured 17–4 PH stainless steel. Figure 11 shows no strong dependence of UTS on the austenite volume fraction, with a UTS range of around 700 MPa displayed across the austenite content range. Considering the datapoints taken from individual sources, both positive (Hsu, 2019 [143]) and negative (Lass, 2019 [134]) correlations between UTS and austenite volume fraction can be seen. This demonstrates that the UTS is dependent on factors other than the austenite content. The large variation in UTS is caused, in part, by the difference in printing parameters as well as the differing post-build thermal treatments. This results in differing levels of Cu precipitation within the microstructure. Examining individual datasets in Fig. 12, it can be seen that many show clear correlations between elongation to failure and austenite volume fraction, which is in agreement with observations of the presence of austenite increasing the ductility due to the TRIP effect [139, 145].

Comparable microhardness to wrought samples (∼ 450 HV 0.5) can be achieved during the LPBF of 17–4 PH with appropriate process parameters optimisation and heat treatment [129] as well as chamber gas [150]. 17–4 PH samples produced by atomic diffusion AM have also been investigated [151]. In the as-printed state and following any heat treatment investigated, atomic diffusion additively manufactured samples have shown inferior hardness to cast samples.

The wear performance of LPBF 17–4 PH stainless steel parts relative to wrought parts has been shown to be dependent on the dominant wear mechanism. When tested dry, conventionally manufactured specimens show a greater wear rate than LPBF produced samples. This is a result of the finer microstructure and greater hardness of LPBF samples. However, in the lubricated condition, LPBF samples show a higher wear rate. This has been attributed to the fact that lubrication changes the dominant wear mechanisms from adhesion to surface fatigue and abrasion [144, 154].

As is also the case for monotonic mechanical properties, the most widely investigated precipitation hardening steel for its resistance for failure under cyclic loading after production by AM has been 17–4 PH. A study by Carneiro et al. [135] compares the fatigue behaviour of LPBF 17–4 PH to conventionally manufactured samples. The conventionally manufactured samples have a fatigue endurance limit (greatest stress amplitude of cyclic loading at which the sample will never fail) of 640 MPa whilst for the AM samples only show fatigue limits of 300 MPa. This reduction in fatigue strength is attributed to defects and poor surface finish [109, 158]. LPBF 17–4 PH samples exhibit a lower fatigue strength than wrought samples even after solution quenching as AM samples have a lower resistance to crack initiation due to the presence of defects [158]. However, LPBF samples interestingly show a lower rate of crack growth than conventionally produced samples. This is attributed to the effect of crack deflection and crack branching observed in AM and not wrought samples [158].

Some studies into the fatigue behaviour of AM 17–4 PH stainless steel have analysed the effect of subsequent heat treatments on the fatigue performances of these samples [132]. It has been determined that after solution annealing and aging, 17–4 LPBF parts still show lower fatigue strengths than wrought samples following the same thermal treatment [132]. Yadollahi et al. [87] also report that the fatigue strength of their LPBF 17–4 PH samples is far lower than wrought material which is attributed to the defects resultant from the LPBF process. The authors report that solution heat treating and aging the samples to the H900 condition results in improved fatigue resistance in ‘low-cycle’ fatigue but worsens the ‘high cycle’ fatigue lives. This is thought to be due to the hardening caused by the heat treatment resulting in an increased sensitivity to impurities. This sensitivity is less pronounced in the low-cycle regime. This effect is not seen in wrought samples [87, 159]. A similar effect is also observed in the analysis of the LPBF 15–5 PH alloy [126].

18Ni 300 maraging steel

Changing the processing parameters towards achieving highest density has been an important means to achieve optimum properties in this grade of steel. A study by Casalino et al. [160] shows that optimisation of the density of the resultant parts from the LPBF processing of 18Ni 300 maraging steel can result in advanced strength. The parts which have the maximum density (ρ = 99.7%) show a UTS of 1192 MPa and an elongation to failure of 8%, an improvement upon the typical solution annealed UTS of 18Ni 300 maraging steel in the solution annealed condition and within the range of ductility (Table 2).

As with the 17–4 PH alloy system, post-build heat treatments have been shown to increase the mechanical properties of 18Ni 300 maraging steel. Kempen et al. [161] have produced 18Ni 300 maraging steel by LPBF with a UTS of 2217 MPa following solution and aging heat treatments. This is even superior to the ATI datasheet reported values for the standard wrought UTS of this alloy in the same condition of ∼ 2210 MPa [162]. It has been also found that the best tribological performance and UTS for LPBF 18Ni 300 maraging steel both occur after the same thermal treatment [163]. With the appropriate selection of process parameters and building strategy [164, 165], it is feasible to produce 18Ni 300 maraging steel samples with YS and UTS comparable and even superior to those of the ASM standard wrought properties (shown in Table 2) in both the solution treated and aged conditions [108, 164, 165]. It is generally the case that the ductility of LPBF samples is inferior to those exhibited by wrought samples, but in some cases they can be comparable. As is also the case for the 17–4 PH alloy system, many studies into the AM of 18Ni 300 maraging steel have also shown comparable or increased strength but reduced ductility in comparison to wrought data from literature [106, 112, 161, 166,167,168]. The increase in strength is attributed to aging during the LPBF process due to cyclic reheating of the metal as well as the fine resultant solidification structure [106, 161]. The decrease in ductility is attributed to the presence of defects in AM parts [167].

Figure 13 is a scatter plot showing the combinations of UTS and ductility for additively manufactured 18Ni 300 maraging steel samples from literature. As is the case with Fig. 10, it is important to consider that different process parameters and treatments have been used to produce each data point. It is particularly apparent from this figure, the difference in strength between samples that did or did not undergo an aging heat treatment, with those that did being grouped together on the scatter plot at a much higher UTS. This plot also shows the scale of improvement in mechanical properties that can be achieved by optimising the AM part production process.

In a study on the production of 18Ni 300 maraging steel by LPBF and DED, Jägle et al. [147] compare the build hardness values as a function of build height to conventionally processed material in the solution annealed and quenched conditions (i.e. with little to no precipitation). The LPBF and conventionally produced material give similar hardness values, around 310 HV 10. In the DED-produced material, however, the hardness is distinctly greater, around 360–420 HV 10, except for the topmost layers. Atom probe analysis reveals that this is because early stages of precipitation already occur in the as-built DED sample. This is resultant from the cyclic reheating of already solidified layers of material as new layers are deposited during the DED process, which explains why the hardening effect is not observed in the topmost layers of the builds. This effect must also take place in LPBF, though it is clearly not as significant. This is likely due to the fact that the melt pool is smaller and the scan speed is higher in LPBF than in DED which led to a reduced thermal amplitude of cyclic reheating [147].

All materials tested by Jägle et al. [147] have been then aged to induce precipitate hardening. At the peak aged state, the conventionally produced material is the hardest due to the greater presence of retained austenite in the AM produced samples, which is cited to be due to chemical inhomogeneity from the AM processes [147]. Other studies which have observed large levels of retained austenite in AM produced steel attribute this to the large solidification undercooling [145] and microstructural refinement stabilising austenite [139] during the AM process.

AM produced 18Ni 300 maraging steel has also been analysed for its fatigue properties [171]. LPBF samples show lower fatigue lives than wrought ones [167] with fatigue cracks in these specimens initiating at subsurface lack-of-fusion defects or cluster defects [167, 171, 172]. It has also been found that the number of mechanical cycles until the elastic and plastic strains become equal, known as the transition life, of AM 18Ni 300 maraging steel samples is extremely low as compared to wrought samples [172]. In summary, the main factor limiting the adoption of additively manufactured PH steels in applications which require high levels of fatigue performances is the presence of defects resultant from the AM process which act as favourable sites for crack initiation under cyclic loading, which have been widely observed in the published literature [95, 124, 135, 158, 167, 171].

Corrosion resistance

15–5 PH stainless steel

Due to its high Cr content, 15–5 PH is expected to have high levels of corrosion resistance. In corrosive environments, a passive oxide layer (Cr2O3) forms on the surface of the steel, protecting the bulk from further corrosion. It is, therefore, important to determine the effect of AM on the corrosion resistance of parts made of this alloy. A study by Li et al. [173] report a high volume fraction of austenite in the LPBF samples, especially after aging without a prior solution heat treatment, distributed strongly around the melt pool boundaries. Samples that undergo a solution heat treatment before aging exhibit fully martensitic microstructures, comparable to those of traditionally manufactured 15–5 PH parts. The large austenite content in non-solution-treated samples leads to greater corrosion resistance than solution-treated samples due to the greater surface potential of austenite than martensite.

17–4 PH stainless steel

As a stainless steel, corrosion resistance is an important property in 17–4 PH stainless steel. A study by Schaller et al. [174] shows that the LPBF 17–4 PH steel exhibits a reduced corrosion resistance compared to conventionally produced material. This is attributed to the greater level of porosity in the LPBF samples. In particular, the presence of pores >50 µm in diameter gives rise to active corrosion whilst passive behaviour persists around regions of pores <10 µm [174]. Contrastingly, the study by Stoudt et al. [141] notes that 17–4 PH samples produced by LPBF exhibit on average less negative pitting potentials than wrought samples which shows a greater level of corrosion resistance. This is attributed to two main factors. The first is that the AM process produces a more homogeneous distribution of elements within the microstructure, making the components more resistant to localised attack in corrosive environments. The second is that during the AM process (and subsequent heat treatments if applicable) N is absorbed which results in a more stable passive film.

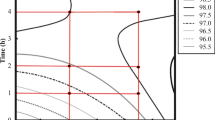

The laser power during production as well as different 17–4 PH feedstock powders can also influence the corrosion resistance of the resulting parts. For instance, LPBF parts can have a lower corrosion current in NaCl (meaning a greater corrosion resistance) than wrought samples (0.9 ± 0.1 µA), with the lowest corrosion current exhibited by an LPBF part being ∼ 0.1 µA [175]. However, parts that, as a result of their fabrication route, have lower than ∼ 97% density show significantly lower corrosion resistances than wrought parts, with further reductions in density leading to even more diminished corrosion resistances [175]. This is cited to be due to the stagnation of the NaCl within surface pores, leading to a breakdown of the passive Cr2O3 layer.

The effect of post-build thermal processing also affects the corrosion behaviour of LPBF 17–4 PH stainless steel [176]. Solution heat treatment has little effect on the general corrosion properties. Pitting potential is found to be higher in the as-built condition, which is attributed to the increased presence of higher angle grain boundaries and greater dislocation densities [175]. In the re-austenised condition, LPBF steel exhibits greater corrosion resistance than wrought samples. This is associated with the greater Mn and S content of the wrought material, as the formation and subsequent dissolution of MnS nanoparticles leads to localised S enrichment on the sample surface leading to destabilisation of the passive film. However, re-austenised LPBF samples have a microstructure comprised of fine martensitic laths resulting in a high grain boundary density. This leads to a reduced resistance to pitting in comparison to the wrought material.

Overall, the corrosion resistance of PH stainless steels is still a matter of debate. Porosity has been found to play a detrimental role in the pitting corrosion resistance. In the case of high-density materials, it has generally been shown that AM PH stainless steels exhibit an improved pitting corrosion resistance compared to their conventional counterparts. However, the extents of this improvement reported in the open literature are inconclusive. There are a number of factors that must be considered when discussing the corrosion resistance, including the amount of retained austenite, size and content of secondary precipitates/inclusions, and grain size/grain boundary area. All of these parameters are highly dependent on the AM processing parameters as well as powder feedstock conditions (argon or nitrogen atomised), which make it difficult to reach a conclusion on what parameter is more important in evaluating the corrosion resistance.

Other steels

Duplex stainless steels

Duplex stainless steels (DSSs) have microstructures of essentially equal fractions of δ-ferrite and austenite. This unlocks a wide range of attractive properties such as high strength, good ductility and excellent corrosion resistance for applications in oil & gas, petrochemical, construction, marine, and desalination [177]. The current challenge with DSSs is their complex microstructural evolution where various further deleterious phases may be precipitated during multistep conventional processing, impacting the properties of these steels. AM can overcome the current challenges inherent to complex multistep traditional processing of DSSs. Most of the work published until now on AM of DSSs is on the microstructure evolution during AM and post-heat treatment of 2205 and 2507 grades. 2205 is the most common grade of duplex stainless steels, containing 22% Cr, 3.2% Mo and 5% Ni (wt%), offering high strength, good weldability and excellent pitting and crevice corrosion resistance. 2507 is a super-duplex stainless steel, containing 25% Cr, 4% Mo and 7% Ni (wt%), that possesses an excellent combination of strength and corrosion resistance. This makes it an ideal candidate for aggressive environments such as warm seawater and acids for examples in offshore oil & gas infrastructures [178]. Two types of the AM methods, i.e. LPBF and DED have mainly been employed for DSSs. The microstructures obtained through these techniques have been reported to be different. LPBF parts show mostly a ferritic microstructure with high strength but poor ductility, necessitating further heat treatments, while DED-produced ones exhibit a considerable fraction of austenite offering higher ductility at the expense of strength. This is mainly due to the significant difference in the cooling rates between these two processing methods.

2507 Alloy

It has been shown by Davidson et al. [179] that LPBF 2507 DSS offers higher hardness (380–440 HV) than that achieved in wrought alloy, particularly demonstrating an improvement in hardness with reducing the laser energy density. This is mainly due to a corresponding decrease in the austenite content. Similar improvements in strength can be achieved in a LPBF 2507 DSS using a bidirectional scanning pattern with a constant 45° angle rotation between subsequent layers [180]. The observed superior YS and UTS of 1214 MPa and 1321 MPa, respectively, might be due to several factors. One is the unique mosaic-type microstructure (Fig. 14) in which grains in each ‘tessera’ have a different crystallographic orientation compared to the grains inside adjacent tesserae. Also, the high concentration of dislocations inside the material restricts further dislocation movement and imposes hardening effect. Moreover, nano-oxide inclusions and chromium nitride precipitates can inhibit free dislocation slip/glide and contribute to a hardening effect. Finally, the solubility of N in the ferrite structure steel leads to solid solution strengthening.

a Optical microscopy images of LPBF 2507 DSS and b EBSD Euler angle map of the same microstructure showing the single-phase ferritic structure with a mosaic-type macrostructure. Adapted from Ref. [180] with permission

A post-heat treatment of LPBF 2507 DSS can impart UTS values (920 MPa) higher than that of as-cast and solution-treated (~ 600–800 MPa) [181]. This is due to precipitation of Mo-/Cr-rich intermetallic phases (mainly σ and χ). LPBF 2507 possesses a metastable ferritic microstructure that partially transforms to austenite during heat treatment. A promising sliding wear resistance of the heat-treated LPBF 2507 parts at 800 °C has been reported mainly due to the high hardness induced by the precipitation of intermetallics and formation of iron oxides acting as a third body lubricant.

Remarkably, magnetic properties of LPBF 2507 DSS are also promising, as reported by Davidson et al. [182], where a saturation magnetism (Ms) value of 110.9 Am2/kg, which is more than twice of that of the wrought specimen (45.1 Am2/kg), can be achieved. The anisotropy in grain structure of LPBF 2507 DSS, however, leads to a directional specific saturation magnetism. Super DSS deposited by LPBF enhances the corrosion of substrate [183]. An enhancement of the pitting corrosion resistance with decreasing the laser scan speed is observed which is related to a reduction in both surface roughness and the size of columnar grains in the deposited layer.

2205 Alloy

The challenge with AM of 2205 has been mostly around achieving desirable volume fraction of austenite and ferrite. For example, a work by Hengsbach et al. [184] demonstrates that an almost fully (99%) ferritic structure is obtained for 2205 DSS through LPBF. Such structures offer a high strength of ~ 940 MPa and an elongation of 12%. This enhanced strength compared to the wrought condition (~ 620 MPa) is attributed to the high density of dislocations and nitrides in the LPBF microstructure. It has been found that a post-heat treatment at 900–1200 °C is needed for austenite to precipitate out of the ferritic matrix, with the highest volume fraction of austenite (34%) achievable at 1000 °C (Fig. 15). Annealing decreases the UTS to the range of 720–770 MPa, but significantly increases the elongation with the highest elongation value obtained at 1000 °C (28%). This implies that an increase in austenite volume fraction through adjusting the post-AM heat treatment time/temperature might be a major means for enhanced ductility.

EBSD maps: a–d IPF maps, e–h phase maps of the LPBF 2205 steel in the as-built and post-AM heat-treated conditions (for 5 min). Adapted from Ref. [184] with permission

Similar observations have been seen in other works too, where for example, Papula et al. [185] show a post-annealing of LPBF 2205 DSS at 1050–1100 °C for 5–60 min is needed to bring its ductility back to the wrought level (i.e. elongation > 40%). The pitting corrosion resistance substantially increases after annealing [185]. This is because annealing reduces the residual stresses within the build and changes the residual stress state of the surface layers from tensile to compressive, causing improvements in both ductility and pitting corrosion resistance.

It has been shown that in contrast to the LPBF, DED duplex stainless steel products show a mixture of austenite and ferrite in the as-built condition, with intragranular austenite particles preferentially nucleating on the inclusions [186]. Austenite content increases with the laser energy density. The volume fraction of austenite also increases with the N level. The higher the N content, the higher the hardness mostly due to the pronounced solid solution hardening effect by N.

Ferritic/martensitic steels

Different grades of low-carbon ferritic and martensitic steels can be processed by AM for applications where wear and corrosion resistance are needed. These include parts such as medical tools, bearings and blades as well as pumps, valves and shafts. It has been shown that AM products can achieve tensile strength, corrosion and magnetic properties equivalent or superior to those of wrought and conventionally processed samples. Poor ductility and toughness as well as anisotropy are, however, the remaining challenges with AM of these steels. One of these steels that has been studied in the context of AM is grade 420, a general-purpose medium C martensitic stainless steel with excellent hardenability and acceptable corrosion resistance. For example, an improvement in both tensile properties and corrosion resistance of 420 stainless steels in both AM and post-heat-treated conditions has been observed with the addition of Nb and Mo [187]. A summary of comparison of Nb/Mo AM 420 steel with the AM 420 steel without Nb/Mo and wrought 420 steel is given in Table 3. The enhancement of the mechanical properties is attributed to the formation of a martensitic microstructure containing nanoscale carbide such as NbC. Such phases are not observed in the AM 420 stainless steel without Nb/Mo.

High strength is achievable also for 420 stainless steel via LPBF (UTS of 1670 MPa, YS of 600 MPa and elongation of 3.5%) [188]. The UTS achieved is much higher than the value reported for the wrought material (800 MPa). The elongation is, however, lower than wrought 420 stainless steel. A post-AM tempering heat treatment at 400 °C for 15 min can yield an extremely high UTS of 1800 MPa and YS of 1400 MPa. Tempering also enhances the elongation to ~ 25% that is about 5 times of elongation in the LPBF condition. The enhanced mechanical properties is attributed to the transformation of retained austenite to martensite during tensile testing. Similarly, there are also observations of higher YS and UTS in LPBF 4140 steel compared to the wrought steel in both building and normal to building directions without compromising ductility and impact toughness [189].

Post-AM heat treatment can significantly affect the mechanical performance of some other grades of martensitic/ferritic steels. For instance, as shown by Sridharan et al. [190] for both HT9 (a 12%Cr–1%Mo martensitic stainless steel widely used in turbines and boilers in fossil-fired power plants and nuclear energy systems) [191] and P91 ferritic-martensitic steel (9%Cr–1%Mo steel mostly used in nuclear fission reactors) [192], a post-heat treatment reduces the YS and UTS but improves the ductility, at room and warm working temperatures (330 and 550 °C). As another example, Liu et al. [193] reports that the impact toughness of an AM 300 M ultra-high strength steel (a modified version of 4340 steel with Si added to enhance hot working) is extremely low (9 J/cm2), while a post-deposition heat treatment can recover the toughness to ~ 25 J/cm2. The extremely low toughness in the as-built condition is attributed to the coarse size of ‘effective microstructure unit’ where coarse epitaxial primary austenite columnar grains result in coarse martensite packets in the as-deposited condition. In another study by Sridharan et al. [194], AM HT9 steel shows superior tensile properties (YS = 1043 MPa, UTS = 1168 MPa and elongation at fracture = 14.2%) compared to its wrought counterpart (YS = 800 MPa, UTS = 950 MPa and elongation at fracture = 10–16%). A post-process heat treatment of the AM samples results in properties in the range of normalised and tempered HT9. This is mainly because a higher austenitising temperature and a lower tempering temperature results in a fine dispersion of the carbide structure and a fine-grained lath martensite, maximising tensile properties.