Abstract

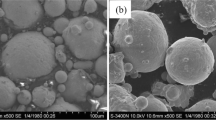

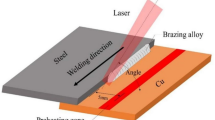

Joining of dissimilar titanium (Ti) alloy to stainless steel is a very significant challenge during conventional fusion welding. In this study, cold metal transfer (CMT) technique is developed for lap joining of Ti alloy to stainless steel with CuSi3 filler wire. The microstructure evolution, mechanical properties and fracture mechanism of Ti alloy/stainless steel joints are investigated. When low heat input is applied, many fine spherical particles are distributed in the fusion zone, which are indicated as iron-rich phase in the Cu matrix. With an increase in the heat input, the particles become irregular and coarser in the fusion zone, inferring as Fe-Si-Ti ternary phase and Fe2Ti phase. Since the fractions of the melted Ti alloy and stainless steel increase, the reaction of Ti with Fe and Si becomes more intense and Fe-Si-Ti ternary phase and Fe2Ti phase thus appear in the fusion zone. The shear strength of the lap joints decreases with an increase in the heat input. There are two fracture modes in the lap joints, suggesting different fracture mechanisms. The fracture path of the joints is along the Ti-Cu interface under low heat input. The brittle Ti-Cu intermetallics are observed on the fracture surface, indicating that the shear strength and fracture feature of the joints are associated with the compound layer. The fracture failure of the lap joints occurs in the fusion zone under large heat input. The Fe-Si-Ti ternary phase and Fe2Ti phase have detrimental effects on the joint strength, resulting in a brittle fracture in the fusion zone.

Similar content being viewed by others

References

B. Kurt, N. Orhan, E. Evin, and A. Çalik, Diffusion Bonding Between Ti-6A-4V Alloy and Ferritic Stainless Steel, Mater. Lett., 2007, 61, p 1747–1750

M. Ghosh and S. Chatterjee, Effect of Interface Microstructure on the Bond Strength of the Diffusion Welded Joints Between Titanium and Stainless Steel, Mater. Charact., 2005, 54, p 327–337

S. Zakipour, A. Halvaee, A.A. Amadeh, M. Samavatian, and A. Khodabandeh, An Investigation on Microstructure Evolution and Mechanical Properties during Transient Liquid Phase Bonding of Stainless Steel 316L to Ti-6Al-4V, J. Alloys Compd., 2015, 626, p 269–276

S. Kundu, G. Anand, and S. Chatterjee, Diffusion Bonding of 17-4 Precipitation Hardening Stainless Steel to Ti Alloy with and without Ni alloy Interlayer: Interface Microstructure and Mechanical Properties, Metall. Mater. Trans. A, 2013, 44, p 2196–2211

C.H. Muralimohan, M. Ashfaq, R. Ashiri, V. Muthupandi, and K. Sivaprasad, Analysis and Characterization of the Role of Ni Interlayer in the Friction Welding of Titanium and 304 Austenitic Stainless Steel, Metall. Mater. Trans. A, 2016, 47, p 347–359

E. Norouzi, M. Atapour, and M. Shamanian, Effect of Bonding Time on the Joint Properties of Transient Liquid Phase Bonding Between Ti-6Al-4V and AISI, 304, J. Alloys Compd., 2017, 701, p 335–341

J.S. Liao, N. Yamamoto, H. Liu, and K. Nakata, Microstructure at Friction Stir Lap Joint Interface of Pure Titanium and Steel, Mater. Lett., 2010, 64, p 2317–2320

S.A.A.A. Mousavi and P.F. Sartangi, Experimental Investigation of Explosive Welding of cp-Titanium/AISI, 304 Stainless Steel, Mater. Des., 2009, 30, p 459–468

Y. Zhang, D.Q. Sun, X.Y. Gu, and H.M. Li, Strength Improvement and Interface Characteristic of Direct Laser Welded Ti Alloy/Stainless Steel Joint, Mater. Lett., 2018, 231, p 31–34

M. Gao, S.W. Mei, Z.M. Wang, X.Y. Li, and X.Y. Zeng, Characterisation of Laser Welded Dissimilar Ti/Steel Joint Using Mg Interlayer, Sci. Technol. Weld. Join., 2012, 17, p 269–276

I. Tomashchuk, P. Sallamand, N. Belyavina, and M. Pilloz, Evolution of Microstructures and Mechanical Properties during Dissimilar Electron Beam Welding of Titanium Alloy to Stainless Steel via Copper Interlayer, Mater. Sci. Eng. A, 2013, 585, p 114–122

X.H. Hao, H.G. Dong, S. Li, X.X. Xu, and P. Li, Lap Joining of TC4 Titanium Alloy to 304 Stainless Steel with Fillet Weld by GTAW Using Copper-Based Filler Wire, J. Mater. Process. Technol., 2018, 257, p 88–100

P. Wang, S.S. Hu, J.Q. Shen, and Y. Liang, Characterization the Contribution and Limitation of the Characteristic Processing Parameters in Cold Metal Transfer Deposition of an Al Alloy, J. Mater. Process. Technol., 2017, 245, p 122–133

O.T. Ola and F.E. Doern, A Study of Cold Metal Transfer Clads in Nickel-Base INCONEL 718 Superalloy, Mater. Des., 2014, 57, p 51–59

H.T. Zhang, J.C. Feng, P. He, B.B. Zhang, J.M. Chen, and L. Wang, The Arc Characteristics and Metal Transfer Behaviour of Cold Metal Transfer and Its Use in Joining Aluminium to Zinc-Coated Steel, Mater. Sci. Eng. A, 2009, 499, p 111–113

S. Babu, S.K. Panigrahi, G.D.J. Ram, P.V. Venkitakrishnan, and R.S. Kumar, Cold Metal Transfer Welding of Aluminium Alloy AA 2219 to Austenitic Stainless Steel AISI, 321, J. Mater. Process. Technol., 2019, 266, p 155–164

G. Pardal, S. Ganguly, S. Williams, and J. Vaja, Dissimilar Metal Joining of Stainless Steel and Titanium Using Copper as Transition Metal, Int. J Adv. Manuf. Technol., 2016, 86, p 1139–1150

J. Kar, S.K. Roy, and G.G. Roy, Effect of Beam Oscillation on Electron Beam Welding of Copper with AISI-304 Stainless Steel, J. Mater. Process. Technol., 2016, 233, p 174–185

V. Shokri, A. Sadeghi, and M.H. Sadeghi, Effect of Friction Stir Welding Parameters on Microstructure and Mechanical Properties of DSS-Cu Joints, Mater. Sci. Eng. A, 2017, 693, p 111–120

J.G. Lee, G.H. Kim, M.K. Lee, and C.K. Rhee, Intermetallic Formation in a Ti-Cu Dissimilar Joint Brazed Using a Zr-Based Amorphous Alloy Filler, Intermetallics, 2010, 18, p 529–535

K. Aydin, Y. Kaya, and N. Kahraman, Experimental Study of Diffusion Welding/Bonding of Titanium to Copper, Mater. Des., 2012, 37, p 356–368

D. Wang, S.Y. Yang, J.P. Zheng, H.F. Hu, X.J. Liu, and C.P. Wang, Experimental Investigation of Phase Equilibria in the Fe-Si-Ti Ternary System, J. Phase Equilib. Diffus., 2017, 38, p 865–873

F. Weitzer, J.C. Schuster, M. Naka, F. Stein, and M. Palm, On the Reaction Scheme and Liquidus Surface in the Ternary System Fe-Si-Ti, Intermetallics, 2008, 16, p 273–282

M. Gao, C. Chen, L. Wang, Z. Wang, and X.Y. Zeng, Laser-Arc Hybrid Welding of Dissimilar Titanium Alloy and Stainless Steel Using Copper Wire, Metall. Mater. Trans. A, 2015, 47, p 2007–2020

I. Tomashchuk, P. Andrzejewski, H. Andrzejewski, and D. Grevey, The Formation of Intermetallics in Dissimilar Ti6Al4V/copper/AISI, 316L Electron Beam and Nd: yAG Laser Joints, Intermetallics, 2011, 19, p 1466–1473

Acknowledgments

The authors gratefully acknowledge the National Natural Science Foundation of China (Grant No. 51605216) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, G., Xu, S., Lu, X. et al. Microstructural Evolution and Mechanical Properties of Ti Alloy/Stainless Steel Lap Joints during Cold Metal Transfer Technique with CuSi3 Filler Wire. J. of Materi Eng and Perform 29, 5291–5306 (2020). https://doi.org/10.1007/s11665-020-05053-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05053-9