Abstract

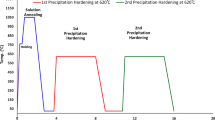

In the present study, the diffusion bonding of 17-4 precipitation hardening stainless steel to Ti alloy with and without nickel alloy as intermediate material was carried out in the temperature range of 1073 K to 1223 K (800 °C to 950 °C) in steps of 298 K (25 °C) for 60 minutes in vacuum. The effects of bonding temperature on interfaces microstructures of bonded joint were analyzed by light optical and scanning electron microscopy. In the case of directly bonded stainless steel and titanium alloy, the layerwise α-Fe + χ, χ, FeTi + λ, FeTi + β-Ti phase, and phase mixture were observed at the bond interface. However, when nickel alloy was used as an interlayer, the interfaces indicate that Ni3Ti, NiTi, and NiTi2 are formed at the nickel alloy-titanium alloy interface and the PHSS-nickel alloy interface is free from intermetallics up to 1148 K (875 °C) and above this temperature, intermetallics were formed. The irregular-shaped particles of Fe5Cr35Ni40Ti15 have been observed within the Ni3Ti intermetallic layer. The joint tensile and shear strength were measured; a maximum tensile strength of ~477 MPa and shear strength of ~356.9 MPa along with ~4.2 pct elongation were obtained for the direct bonded joint when processed at 1173 K (900 °C). However, when nickel base alloy was used as an interlayer in the same materials at the bonding temperature of 1148 K (875 °C), the bond tensile and shear strengths increase to ~523.6 and ~389.6 MPa, respectively, along with 6.2 pct elongation.

Similar content being viewed by others

References

R.K. Shiue, S.K. Wu, C.H. Chan and C.S. Huang: Mater. Trans. 2006, Vol. 37A, pp. 2207–17.

R. K. Shiue, S. K. Wu and J. Y. Shiue: Mater Sci Eng A. 2008, 488, pp. 186-94.

ASM (1990) ASM Metals Handbook, 10th edn. ASM international, Metals Park, OH

O. Torun, A. Karabulut, B. Baksan and I. Çelikyürek: Mater and Des. 2008, Vol. 29, pp. 2043–6.

G. Can and M. Kocak: Int. Mater. Rev. 1998, Vol. 43, pp. 1-44.

A. Fuji, K. Ameyama and T. H. North: J. Mater. Sci. 1996, Vol. 31 pp. 819-827.

S. Kundu, S. Chatterjee, D. Olson, and B. Mishra: Mater. Trans A. 2008, Vol. 39, pp. 2106-14.

A. Changing and J. Zhangpeng: J Less Common Mater. 1990, Vol. 162, pp. 315-22.

X.J. Yuan, G. M. Sheng, B. Qin, W. Z. Huang and B. Zhou: Mater Charact. 2008, Vol. 59, pp. 930–6.

S. Kundu and S. Chatterjee: Mater Sci EngA. 2008, Vol. 480, pp. 316–22.

B. Aleman, I. Gutiérrez and J. J. Urcola: Scripta Mater. 1997, Vol. 36, pp. 509–15.

M. Eroglu, TI Khan, N. Orhan (2002) Mater Sci Technol. 18:68-72.

B. Kurt, N. Orhan and M. Kaya: Mater Sci Technol. 2009, Vol. 25, pp. 556-60.

M. Ferrante, E. V. Pigoretti: J Mater Sci. 2002, Vol. 37, pp. 2825–33.

C. C. Liu, C. L. Ou and R. K. Shiue: J Mater Sci. 2002, Vol. 37, pp.2225–35.

N. Orhan, T. I. Khan and M. Eroglu: Scripta Mater. 2001, Vol. 45, pp. 441-6.

G.M. Sheng, J. W. Huang, B. Qin. B. Zhou and S. Y. Qiu: J Mater Sci. 2005, Vol. 40, pp. 6385-90.

B. Kurt, N. Orhan, E. Evin and A. Çalik: Mater Let. 2007, Vol. 61, pp. 1747–50.

B. Qin, G. M. Sheng, J. W. Huang, B. Zhou, S. Y. Qiu and C. Li: Mater Charact. 2006, Vol. 56, pp. 32–38.

A.S. Ramos, M.T. Vieira, J. Morgiel, J. Grzonka, S. Simões and M.F. Vieira: J of Alloys and Comp. 2009, Vol. 484, pp. 335–40.

S. Kundu, S. Chatterjee, D. Olson and B. Mishra: Mater Trans A. 2007, Vol. 38, pp. 2053-60.

P. He, J. Zhang, R. Zhou and X. Li: Mater Charact. 1999, Vol. 43, pp. 287-92.

P. He, J. H. Zhang and X. Q. Li: Mater Sci Technol. 2001, Vol. 17, pp. 1158-62.

ASTM (1997) Annual Book of ASTM Standards, vol 03. ASTM, Philadelphia, pp. 87-89.

P. Villars, A. Prince, H. Okamoto (1995) Handbook of Ternary Phase Alloys, vol 7. ASM International, Materials Park, OH.

V. Raghavan: J. Phase Equil and diff. 2010, Vol. 31, pp. 186-189.

T. B. Massalski (1996) Binary Alloy Phase Diagrams, 2nd edn. ASM International, Materials Park, OH, p. 1783

B. Aleman, I. Guitterrez, J. J. Urcola: Mater Sci Tech. 1993, Vol. 9, pp. 633-641.

S. Hinotani and Y. Ohmori: Trans Japan Inst Mater. 1988, Vol. 29, pp. 116-24.

N. Orhan, M. Aksoy and M. Eroglu: Mater Sci Eng A. 1999, Vol. 271, pp. 458-68.

G.E. Dieter (1998) Mechanical Metallurgy SI Metric, McGraw-Hill Book Company, London.

J. H. Li and R.Y. Lin: Mater. Sci. Eng., 2004, Vol. A381, pp. 39-50.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 25, 2011.

Rights and permissions

About this article

Cite this article

Kundu, S., Anand, G. & Chatterjee, S. Diffusion Bonding of 17-4 Precipitation Hardening Stainless Steel to Ti Alloy With and Without Ni Alloy Interlayer: Interface Microstructure and Mechanical Properties. Metall Mater Trans A 44, 2196–2211 (2013). https://doi.org/10.1007/s11661-012-1553-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1553-2