Abstract

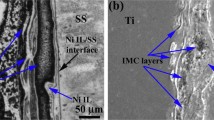

Joining of commercially pure Ti to 304 stainless steel by fusion welding processes possesses problems due to the formation of brittle intermetallic compounds in the weld metal, which degrade the mechanical properties of the joints. Solid-state welding processes are contemplated to overcome these problems. However, intermetallic compounds are likely to form even in Ti-SS joints produced with solid-state welding processes such as friction welding process. Therefore, interlayers are employed to prevent the direct contact between two base metals and thereby mainly to suppress the formation of brittle Ti-Fe intermetallic compounds. In the present study, friction-welded joints between commercially pure titanium and 304 stainless steel were obtained using a thin nickel interlayer. Then, the joints were characterized by optical microscopy, scanning electron microscopy, energy dispersive spectrometry, and X-ray diffractometry. The mechanical properties of the joints were evaluated by microhardness survey and tensile tests. Although the results showed that the tensile strength of the joints is even lower than titanium base metal, it is higher than that of the joints which were produced without nickel interlayer. The highest hardness value was observed at the interface between titanium and nickel interlayers indicating the formation of Ni-Ti intermetallic compounds. Formation these compounds was validated by XRD patterns. Moreover, in tensile tests, fracture of the joints occurred along this interface which is related to its brittle nature.

Similar content being viewed by others

References

S. Chen, J. Huang, K. Ma, X. Zhao, and A. Vivek: Metall. Mater. Trans., 2014, vol. 45A, pp. 3064-3073.

S. Kundu, D. Roy, S. Chatterjee, D. Olson and B. Mishra: Mater. Des., 2012, vol. 37, 560-568.

S. Kundu, S. Sam and S. Chatterjee: Mater. Des., 2011, vol. 32, pp. 2997-3003.

Z. Sun and R. Karppi: J. Mater. Process. Technol., 1996, vol. 59, pp. 257-267.

S. Chen, M. Zhang, J. Huang, C. Cui, H. Zhang and X. Zhao: Mater. Des., 2014, vol. 53, pp. 504-511.

S. Sam, S. Kundu and S. Chatterjee: Mater. Des., 2012, vol. 47, pp. 237-244.

M.J. Torkamany, F. MalekGhaini and R. Poursalehi: Mater. Des., 2014, vol. 53, pp. 915-920.

K. Szymlek: Adv. Mater. Sci., 2008, vol. 8, pp. 186-194.

H. Xia, S. Wang and H. Ben: Mater. Des., 2014, vol. 56, pp. 1014-1019.

S.A.A. Akbari Mousavi and P. Farhadi Sartangi: Mater. Des., 2009, vol. 30, pp. 459-468.

H.C. Dey, M. Ashfaq, A.K. Bhaduri and K. PrasadRao: J. Mater. Process. Technol., 2009, vol. 209, pp. 5862-5870.

T. Vigraman, D. Ravindran and R. Narayanasamy: Mater. Des., 2012, vol. 36, pp. 714-727.

K.N. Campo, L.C. Campanelli, L. Bergmann, J.F. dosSantos and C. Bolfarini: Mater. Des., 2014, vol. 56, pp. 139-145.

M. Fazel-Najafabadi, S.F. Kashani-Bozorg and A. Zarei-Hanzaki: Mater. Des., 2011, vol. 32, pp. 1824-1832.

M. Kimura, T. Iijima, M. Kusaka, K. Kaizu and A. Fuji: Mater. Des. 2014, vol. 55, pp. 152-164.

S. Kundu, M. Ghosh, A. Laik, K. Bhanumurthy, G.B. Kale and S. Chatterjee: Mater. Sci. Eng. A, 2005, vol. 407, pp. 154-160.

J.S. Ha and S.I. Hong: Mater. Des., 2013, vol. 51, pp. 293-299.

S. Kundu, M. Ghosh and S. Chatterjee: ISIJ. Int., 2004, vol. 44, pp. 1882-1887.

H.M. Li, D.Q. Sun, X.L. Cai, P. Dong and W.Q. Wang: Mater. Des., 2012, vol. 39, pp. 285-293.

S. Kundu, B. Mishra, D.L. Olson and S. Chatterjee: Mater. Des., 2013, vol. 51, pp. 714-722.

Y. Deng, G. Sheng and C. Xu: Mater. Des., 2013, vol. 46, pp. 84-87.

R. SoltaniTashi, S.A.A. AkbariMousavi and M. MazarAtabaki: Mater. Des., 2014, vol. 54, pp. 161-167.

T.B. Massalski: Binary Alloy Phase Diagrams, 2nd ed., ASM International, Materials Park, OH, 1996.

Z. Zhong, T. Hinoki, H.-C. Jung, Y.-H. Park and A. Kohyama: Mater. Des., 2010, vol. 31, pp. 1070-1076.

G.R. Kamat: Weld. J., 1988, vol. 67, pp. 44-46.

S.D. Meshram, T. Mohandas and G. Madhusudhan Reddy: J. Mater. Process. Technol., 2007, vol. 184, pp. 330-337.

D. Ananthapadmanaban, V. SeshagiriRao, N. Abraham and K. PrasadRao: Mater. Des., 2009, vol. 30, pp. 2642-2646.

P. Sathiya, S. Aravindan and A. Noorul Haq: Mater. Des., 2008, vol. 29, pp. 1099-1109.

A.R. Mcandrew, P.A. Colegrove, A.C. Addison, B.C.D. Flipo and M.J. Russell: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 6118-6128.

A. Fuji, K. Ameyama and T.H. North: J. Mater. Sci., 1996, vol. 31, pp. 819-827.

G. Luetjering and J. Albrecht: Ti-2003 Science and Technology, Wiley-VCH Verlag GmbH & Co. KGaA, Germany, 2004, pp. 793-798.

L.S. Lance: Proceedings of the Symposium on Materials for Extreme Environments, GE Global Research, Niskayuna, New York, May 23–24, 2005.

DeZurik: Technical Report, 10.60-2. DeZurik. http://www.spxprocessequipment.com/sites/dezurik/AppDataPDF/10602.pdf, 1997.

J.D. Whittenberger and E. Vesely: Technical Memorandum, NASA, USA, 1990, pp. 1–21.

A. Fuji, T.H. North, K. Ameyama and M. Futamata: Mater. Sci. Technol., 1992, vol. 8, pp. 219-235.

P. Li, J. Li, M. Salman, L. Li, J. Xiong and F. Zhang: Mater. Des., 2014, vol. 56, pp. 649-656.

M. Ghosh and S. Chatterjee: Mater. Sci. Eng. A, 2003, vol. 358, pp. 152-158.

K. Otsuka and X. Ren: Prog. Mater. Sci., 2005, vol. 50, pp. 511-678.

A. Fuji, Y. Horiuchi and K. Yamamoto: Sci. Technol. Weld. Join., 2005, vol. 10, pp. 287-294.

N. Ozdemir: Mater. Lett., 2005, vol. 59, pp. 2504-2509.

K. Topolski, P. Wiecinski, Z. Szulc, A. Galka and H. Garbacz: Mater. Des., 2014, vol. 63, pp. 479-487.

S. Kundu, G. Anand and S. Chatterjee: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 2196-2211.

M. Fazel-Najafabadi, S.F. Kashani-Bozorg and A. Zarei-Hanzaki: Mater. Des., 2010, vol. 31, pp. 4800-4807.

S.A.A. Akbarimousavi and M. Goharikia: Mater. Des., 2011, vol. 32, pp. 3066-3075.

M. Fazel-Najafabadi, S.F. Kashani-Bozorg and A. Zarei-Hanzaki: Mater. Des., 2011, vol. 32, pp. 1824-1832.

Acknowledgments

The authors would like to acknowledge the Grants received from the Directorate of Naval R & D, Naval Research Board, New Delhi (DNRD/05/4003/NRB/126, dated 20.11.2007) for supporting this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 7, 2015.

Rights and permissions

About this article

Cite this article

Muralimohan, C.H., Ashfaq, M., Ashiri, R. et al. Analysis and Characterization of the Role of Ni Interlayer in the Friction Welding of Titanium and 304 Austenitic Stainless Steel. Metall Mater Trans A 47, 347–359 (2016). https://doi.org/10.1007/s11661-015-3210-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-3210-z