Abstract

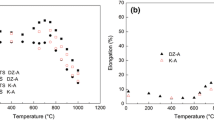

Adopting effective strategies to control the solidification structure of Ni-based superalloys is a very interesting subject for metallurgists. Despite the achievement of developing and applying the continuous unidirectional solidification process in simple alloys, the utilization of this process for K418 alloys has been ignored. The microstructure and mechanical properties of a K418 alloy ingot produced by the continuous unidirectional solidification process were investigated. We found that the γ dendrites were typically cross-shaped in the transverse section. The orientation of surviving grains along the casting direction was <001> during competitive growth. The secondary dendrite arm spacing was 32.3 ± 2.5 μm at a cooling rate of 1.75 ± 0.35 °C/s from the surface to the center of the K418 alloy ingot. Due to the higher cooling rate than that of the conventional casting process, a more uniform microstructure and finer γ′ precipitation were obtained in the ingot. Thus, compared with the conventional casting, the tensile strength and the elongation are increased by 8.4 and 21.3%, respectively, at 25 °C. The tensile strength and elongation increased by 15.2 and 49.3%, respectively, at 800 °C. In addition, the fracture surfaces exhibited numerous typical dimples and dendritic fracture characteristics.

Similar content being viewed by others

References

J.R. Davis, Metallurgy, Processing and Properties of Superalloys, Heat-Resistant Materials-ASM Specialty Handbook, ASM International, Material Park (OH), 1997, p 221–254

H. Wang, Y.B. Zhong, Q. Li, Y.P. Fang, W.L. Ren, Z.S. Lei, and Z.M. Ren, Effect of Current Frequency on Droplet Evolution during Magnetic-Field-Controlled Eletroslag Remelting Process Via Visualization Method, Metall. Mater. Trans. B, 2017, 48, p 655–663

D.M. Shevchenko and R.M. Ward, Liquid Metal Pool Behavior during the Vacuum Arc Remelting of Inconel 718, Mater. Trans. B, 2009, 40, p 263–270

Z.Y. Chen, S.F. Yang, J.L. Qu, J.S. Li, A.P. Dong, Y. Gu, Effect of Different Melting Technologies on the Purity of Superalloy GH4738, Mater., 2018, 11, p 1838–1848

W.Z. Jin, J. Li, T.J. Li, and G.M. Yin, Linear Electromagnetic Stirring and Microstructures of K417 Superalloy Master Alloy Ingot, Chin. J. Vac. Sci. Technol., 2008, 28, p 579–583

F. Zupanič, T. Bončina, A. Križman, and F.D. Tichelaar, Structure of Continuously Cast Ni-Based Superalloy Inconel 713C, J. Alloys Compd., 2001, 329, p 290–297

F. Zupanič, T. Bončina, A. Križman, and F.D. Tichelaar, Microstructural Evolution on Continuous Casting of Nickel Based Superalloy Inconel 713C, Mater. Sci. Technol., 2002, 18, p 811–819

D. Hendley, N. Gravill, and C.R. Thomas, Continuously Cast Superalloy Barstock, Foundry Trade J., 2000, 9, p 24

F. Wang, L.T. Zhang, A.Y. Deng, X.J. Xu, and E.G. Wang, Continuous Casting of Incoloy800H Superalloy Billet under an Alternating Electromagnetic Field, Met., 2016, 6, p 2–13

H.L. Luo, D. Feng, S.P. Li, X. Cao, and J.T. Wang, Microstructure and Property of High Cleanliness K418 Superalloy by Vacuum Horizontal Continuous Casting, J. Iron Steel Res., 2016, 28, p 33–37

A. Ohno, Continuous Casting of Single Crystal Ingots by the OCC Process, JOM, 1986, 38, p 14–16

J.X. Xie, J. Mei, X.H. Liu, X.F. Liu, A Kind of Process and Equipment for Fabricating Cupronickel Pipes with Heating-cooling Combined Mold Casting, Chinese Patent., 2012, Appl. ZL201010501407.4

M. Okayasu, S. Takasu, and S. Yoshie, Microstructure and Material Properties of an Al-Cu Alloy Provided by the Ohno Continuous Casting Technique, J. Mater. Process. Technol., 2010, 210, p 1529–1535

J. Mei, X.H. Liu, Y.B. Jiang, S. Chen, and J.X. Xie, Liquid–Solid Interface Control of BFe10-1-1 Cupronickel Alloy Tubes during HCCM Horizontal Continuous Casting and its Effect on the Microstructure and Properties, Int. J. Miner. Metall. Mater., 2013, 20, p 748–758

Z.X. Shi, J.X. Dong, M.C. Zhang, and L. Zheng, Solidification Characteristics and Segregation Behavior of Ni-Based Superalloy K418 for Auto Turbocharge Turbine, J. Alloys Compd., 2013, 571, p 168–177

R.E. Spear and G.R. Gardner, Dendrite Cell Size, AFS Trans., 1963, 71, p 209–215

A.K. Bhambri, T.Z. Kattamis, and J.E. Morral, Cast Microstructure of Inconel 713C and Its Dependence on Solidification Variables, Metall. Trans. B, 1975, 6, p 523–537

S. Kou, Welding Metallurgy, Wiley, New York, 1987, p 129–177

D. Walton and B. Challmers, The Origin of the Preferred Orientation in the Columnar Zone of Ingots, Trans. Metal. Soc. Am. Inst. Min. Met. Eng., 1959, 215, p 447–457

M. Gäumann and W. Kurz, Why is it So Difficult to Produce an Equiaxed Microstructure during Welding, Mathematical Modelling of Weld Phenomena, Vol 4, H. Cerjak, Ed., Institute of Materials, Minerals and Mining, London, 1998, p 125–135

N.M. Souza, M.G. Ardakani, M. Mclean, B.A. Shollock, Directional and Single-Crystal Solidification of Ni-Based Superalloys: Part I. The Role of Curved Isotherms on Grain Selection, Metall. Mater. Trans. A., 2000, 31, p 2877–2886

A.J. Elliott, S. Tin, W.T. King, S.C. Huang, M.F.X. Gigliotti, and T.M. Pollock, Directional Solidification of Large Superalloy Castings with Radiation and Liquid-Metal Cooling: A Comparative Assessment, Metall. Mater. Trans. A, 2004, 35A, p 3221–3231

R. Ricks, A. Porter, and R. Ecob, The Growth of γ′ Precipitates in Nickel-Base Superalloys, Acta Metall., 1983, 31, p 43–53

T. Miyazaki, K. Nakamura, H.Mori, Experimental and Theoretical Investigations on Morphological Changes of γ′ Precipitates in Ni-Al Single Crystals during Uniaxial Stress-Annealing, J. Mater. Sci., 1979, p 1827–1837

A.G. Khachaturyan, S.V. Semenovskaya, and J.W. Morris, Theoretical Analysis of Strain-Induced Shape Changes in Cubic Precipitates during Coarsening, Acta Metall., 1988, 36, p 1563–1572

F. Wang, D. Ma, J. Zhang, L. Liu, J. Hong, S. Bogner, and A. Bührig-Polaczek, Effect of Solidification Parameters on the Microstructure of Superalloy CMSX-6 Formed during the Downward Directional Solidification Process, J. Cryst. Growth, 2014, 389, p 47–54

X.P. Guo, H.Z. Fu, and J.H. Sun, Influence of Solid/Liquid Interfaces on the Microstructure and Stress-Rupture Life of the Single-Crystal Nickel-Base Superalloy NASAIR 100, Metall. Mater. Trans. A, 1997, 28, p 997–1009

Z.K. Chu, J.J. Yu, X.F. Sun, H.R. Guan, and Z.Q. Hu, Tensile Properties and Deformation Behaviors of a Directionally Solidified Ni-Base Superalloy, Mater. Sci. Eng. A, 2010, 527, p 3010–3014

Acknowledgments

This work is financially supported by the Natural Science Foundation of China (Nos. U1560202, 51604171, 51690162), National Science and Technology Major Project “Aeroengine and Gas Turbine” (2017-VII-0008-0102), and the Project of the Ministry of Science and Technology of China (2017YFB0405902).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, F., Wang, J., Yu, J. et al. Microstructure and Mechanical Properties of Ni-based Superalloy K418 Produced by the Continuous Unidirectional Solidification Process. J. of Materi Eng and Perform 28, 6483–6491 (2019). https://doi.org/10.1007/s11665-019-04385-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04385-5