Abstract

24CrNiMoY alloy steel samples were fabricated by selective laser melting (SLM), and a phase transformation model was established to study the alloy steel microstructural evolution. Meanwhile, microhardness and tensile properties of 24CrNiMoY alloy steel prepared by different laser energy densities (Ev) were investigated. Results indicate that the microstructural evolution of 24CrNiMoY alloy steel is consistent with the phase transformation model. The main microstructure changed from martensite to bainite with the increase in thermal cycle numbers. In addition, a suitable Ev plays an important role in refining the bainite structure and improving the alloy steel properties. When the Ev decreases from 210 to 140 J/mm3, the bainite lath width reduces from 1.7 to 0.6 μm. Simultaneously, the relative density, tensile strength and microhardness of the fabricated samples increase first and decrease later. 24CrNiMoY alloy steel sample prepared by 160 J/mm3 has fine mechanical properties: The tensile strength is 850 MPa and microhardness is 360 HV0.2.

Similar content being viewed by others

References

N. Shamsaei, A. Yadollahi, L. Bian, and S.M. Thompson, An Overview of Direct Laser Deposition for Additive Manufacturing; Part I: Transport Phenomena, Modeling And Diagnostics, Addit. Manuf., 2015, 8, pp 6–62

Y.H. Wang, X.Z. Chen, and S.V. Konovalov, Additive Manufacturing Based on Welding Arc: A Low-Cost Method, J. Surf. Int., 2017, 11(6), pp 1317–1328

C.Y. Yap, C.K. Chua, Z.L. Dong, Z.H. Liu, D.Q. Zhang, and L.E. Loh, Review of Selective Laser Melting: Materials and Applications, Appl. Phys. Rev., 2015, 2(4), p 18–187

R. Acharya, J.A. Sharon, and A. Staroselsky, A Prediction of Microstructure in Laser Powder Bed Fusion Process, Acta Mater., 2017, 124, pp 360–371

T. Persenot, A. Burr, G. Martin, J.Y. Buffiere, R. Dendievel, and E. Maire, Effect of Build Orientation on the Fatigue Properties of As-built Electron Beam Melted Ti-6Al-4V alloy, Int. J. Fatigue, 2019, 118, pp 65–76

H.Y. Yue, Y.Y. Chen, X.P. Wang, and F.T. Kong, Effect of Beam Current on Microstructure, Phase, Grain Characteristic and Mechanical Properties of Ti-47Al-2Cr-2Nb Alloy Fabricated by Selective Electron Beam Melting, J. Alloy. Compd., 2018, 750, pp 617–625

E. Murr, S.M. Gaytan, D.A. Ramirez, E. Martinez, J. Hernandez, and K.N. Amato, Metal Fabrication by Additive Manufacturing using Laser and Electron Beam Melting Technologies, J. Mater. Sci. Technol., 2012, 28(1), pp 1–14

W. Xu, E.W. Lui, A. Pateras, M. Qia, and M. Brandt, In situ Tailoring Microstructure in Additively Manufactured Ti-6Al-4V for Superior Mechanical Performance, Acta Mater., 2017, 125, pp 390–400

H.K. Rafi, N.V. Karthik, H. Gong, T.L. Starr, and B.E. Stucker, MicroStructures and Mechanical Properties of Ti6Al4 V Parts Fabricated by Selective Laser Melting and Electron Beam Melting, J. Mater. Eng. Perform., 2013, 22(12), pp 3872–3883

J.J. Yang, H.C. Yu, H.H. Yang, F.Z. Li, Z.M. Wang, and X.Y. Zeng, Prediction of Microstructure in Selective Laser Melted Ti-6Al-4 V Alloy by Cellular Automaton, J. Alloys Compd., 2018, 748(5), pp 281–290

L. Zheng, Y. Liu, S. Sun, and H. Zhang, Selective Laser Melting of Al-8.5Fe-1.3 V-1.7Si Alloy: Investigation on the Resultant Microstructure and Hardness, Chin. J. Aeronaut., 2015, 28(2), p 564–569

E. Yasa and J.P. Kruth, Microstructural Investigation of Selective Laser Melting 316L Stainless Steel Parts Exposed to Laser Re-melting, Procedia Eng., 2011, 19, pp 389–395

W.M. Tucho, V.H. Lysne, H. Austbø, A. Sjolyst-Kverneland, and V. Hansen, Investigation of Effects of Process Parameters on Microstructure and Hardness of SLM Manufactured ss316L, J. Alloys Compd., 2018, 740, pp 910–925

J.J. Yan, D.L. Zheng, H.X. Li, X. Jia, J.F. Sun, Y.L. Li, M. Qian, and M. Yan, Selective Laser Melting of H13: Microstructure and Residual Stress, J. Mater. Sci., 2017, 52(20), pp 12476–12485

Z. Hu, H. Zhu, H. Zhang, and H. Zeng, Experimental Investigation on Selective Laser Melting of 17-4PH Stainless Steel, Opt. Laser Technol., 2015, 87, pp 17–25

J. Sander, J. Hufenbach, M. Bleckmann, L. Giebeler, H. Wendrock, S. Oswald, T. Gemming, J. Eckert, and U. Kühn, Selective Laser Melting of Ultra-High-Strength TRIP Steel: Processing, Microstructure, and Properties, J. Mater. Sci., 2017, 52(9), p 4944–4956

T. Vilaro, C. Colin, J.D. Bartout, L. Nazé, and M. Sennour, Microstructural and Mechanical Approaches of the Selective Laser Melting Process Applied to a Nickel-base Superalloy, Mater. Sci. Eng. A, 2012, 534(1), pp 446–451

G.L. Yin, S.Y. Chen, Y.Y. Liu, J. Liang, C.S. Liu, and Z. Kuang, Effect of Nano-Y2O3 on Microstructure and Crack Formation in Laser Direct-deposited In situ Particle-Reinforced Fe-based Coatings, J. Mater. Eng. Perform., 2018, 27, pp 1–14

B. Ai, X. Cheng, T. Kürner, Z. Zhong, K. Guan, and R. He, Challenges toward Wireless Communications for High-Speed Railway, IEEE. T. Intell. Transp., 2014, 15(5), pp 2143–2158

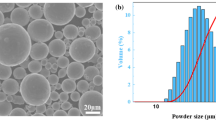

C.F. Shi, S.Y. Chen, Q. Xia, and Z. Li, Preparation and Printability of 24CrNiMo Alloy Steel Powder for Selective Laser Melting Fabrcating Brake Disc, Powder Metall., 2017, 61(1), pp 1–8

M. Yin, L. Bertolini, and J. Duan, The Effects of the High-Speed Railway on Urban Development: International Experience and Potential Implications for China, Program Plann., 2015, 98, pp 1–52

Z. Chen, Z.Y. Wei, P. Wei, S.G. Chen, B.H. Lu, J. Du, J.F. Li, and S.Z. Zhang, Experimental Research on Selective Laser Melting AlSi10 Mg Alloys: Process, Densification and Performance, J. Mater. Eng. Perform., 2017, 26(12), pp 1–9

I. Tolosa, F. Garciandía, F. Zubiri, F. Zapirain, and A. Esnaola, Study of Mechanical Properties of AISI, 316 Stainless Steel Processed by “Selective Laser Melting”, Following Different Manufacturing Strategies, Int. J. Adv. Manuf. Technol., 2010, 51(5–8), pp 639–647

B.A. Mangour, D. Grzesiak, T. Borkar, and M.Y. Jenn, Densification Behavior, Microstructural Evolution, and Mechanical Properties of TiC/316L Stainless Steel Nanocomposites Fabricated by Selective Laser Melting, Mater. Des., 2018, 138(5), p 119–128

R.D. Li, Y.S. Shi, Z.G. Wang, L. Wang, J.H. Liu, and W. Jiang, Densification Behavior of Gas and Water Atomized 316L Stainless Steel Powder During Selective Laser Melting, Appl. Surf. Sci., 2010, 256(13), pp 4350–4356

Y. Guo, Z. Li, C. Yao, K. Zhang, F. Lu, and K. Feng, Microstructure Evolution of Fe-based Nanostructured Bainite Coating by Laser Cladding, Mater. Des., 2014, 63(21), pp 100–108

J. Liu, J. Li, X. Cheng, and H. Wang, Microstructural Evolution of AerMet100 Steel Coating on 300 M Steel Fabricated by Laser Cladding Technique, Metall. Mater. Trans. A, 2018, 49(2), p 595–603

M.W. Wei, S.Y. Chen, L.Y. Xi, J. Liang, and C.S. Liu, Selective Laser Melting of 24CrNiMo Steel for Brake Disc: Fabrication Efficiency, Microstructure Evolution, and Properties, Opt. Laser Technol., 2018, 107, pp 99–109

F.G. Liu, X. Lin, M.H. Song, H.Y. Yang, Y.Y. Zhang, L.L. Wang, and W.D. Huang, Microstructure and Mechanical Properties of Laser Solid Formed 300 m Steel, J. Alloys Compd., 2015, 621, pp 35–41

M. Shaha and S.D. Bakshi, Three-body Abrasive Wear of Carbide-free Bainite, Martensite and Bainite–martensite Structure of Similar Hardness, Wear, 2018, 402–403, p 207–215

W. Xu, M. Brandt, S. Sun, J. Elambasseril, Q. Liu, K. Latham, K. Xia, and M. Qian, Additive Manufacturing of Strong and Ductile Ti-6Al-4V by Selective Laser Melting via In situ Martensite Decomposition, Acta Mater., 2015, 85, pp 74–84

T.L. Fu, R.Q. Wang, Z.D. Wang, G.D. Wang, and M.T. Wang, Construction and Application of Quenching Critical Cooling Rate Model, J. Iron. Steel Res. Int., 2010, 17(3), p 40–45

B. Li, P. Xu, F. Lu, H. Gong, H. Cui, and C. Liu, Microstructure Characterization of Fiber Laser Welds of s690ql High-Strength Steels, Metall. Mater. Trans. B, 2018, 49(1), pp 225–237

M.M. Ma, Comparison of Laser Additive Manufacturing Technology Basics of Two Typical Metal Parts, Ph.D. Thesis, Huazhong University of Science and Technology, 2016

S. Berretta, Y. Wang, R. Davies, and O.R. Ghita, Polymer Viscosity, Particle Coalescence and Mechanical Performance in High-Temperature Laser Sintering, J. Mater. Sci., 2016, 51(10), pp 4778–4794

E.V. Pereloma, F. Al-Harbi, and A.A. Gazder, The Crystallography of Carbide-Free Bainites in Thermo-Mechanically Processed Low Si Transformation-Induced Plasticity Steels, J. Alloys Compd., 2014, 615, pp 96–110

L.Y. Lan, X.W. Kong, and C.L. Qiu, Characterization of Coarse Bainite Transformation in Low Carbon Steel During Simulated Welding Thermal Cycles, Mater. Charact., 2015, 105, pp 95–103

J. Sander, L. Giebeler, U. Kühn, and J. Eckert, Microstructure and Properties of FeCrMoVC Tool Steel Produced by Selective Laser Melting, Mater. Des., 2016, 89, pp 335–341

F.M. Gao, Theoretical Model of Hardness Anisotropy in Brittle Materials, J. Appl. Phys., 2012, 112(2), pp 023506

A. Augustin, P. Huilgol, K.R. Udupa, and K.U. Bhat, Effect of Current Density During Electrodeposition on Microstructure and Hardness of Textured Cu Coating in the Application of Antimicrobial Al Touch Surface, J. Mech. Behav. Biomed., 2016, 63, pp 352–360

S.L. Long, Y.L. Liang, Y. Jiang, Y. Liang, M. Yang, and Y.L. Yi, Effect of Quenching Temperature on Martensite Multi-Level Microstructures and Properties of Strength and Toughness in 20CrNi2Mo Steel, Mat. Sci. Eng. A, 2016, 676, pp38–47

C.Y. Zhang, Q.F. Wang, J.X. Ren, R.X. Li, M.Z. Wang, F.C. Zhang, and K.M. Sun, Effect of Martensitic Morphology on Mechanical Properties of an As-quenched and Tempered 25CrMo48V Steel, Mat. Sci. Eng. A, 2012, 534, pp 339–346

Acknowledgments

This work was financially supported by the National Key R&D Program of China (No.2016YFB1100201), the Green Manufacturing System Integration Project of the Industry and Information Ministry of China (2017), and the Research and development plan for the future emerging industries in Shenyang (No.18-004-2-26).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xi, L., Chen, S., Wei, M. et al. Microstructural Evolution and Properties of 24CrNiMoY Alloy Steel Fabricated by Selective Laser Melting. J. of Materi Eng and Perform 28, 5521–5532 (2019). https://doi.org/10.1007/s11665-019-04280-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04280-z