Abstract

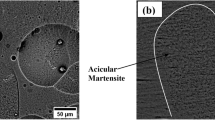

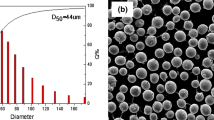

In this study, 24CrNiMo samples with low porosity and high strength were prepared by selecting laser melting technology (SLM). The defect distribution, microstructure evolution, and tensile fracture surface were analyzed by scanning electron microscope and electron backscatter diffraction (EBSD). The experimental results showed that with increase in the energy density, the types of defects would change, and the number of defects showed a trend of first decreasing and then increasing. The microstructure of the samples mainly consisted of martensite with a small amount of lower bainite and residual austenite. EBSD analysis showed that no crystallographic texture was found in the samples. However, the grain orientation would change original direction to form a texture parallel to the load direction during the tensile process. The average grain size increased from 0.346 to 0.381 μm with the increase in energy density. The best sample was prepared under the parameters of 76.56 J/mm3, with the highest microhardness (458.96 HV0.2), ultimate tensile strength (1378.53 MPa), and strength–plasticity product (18.23 GPa%). The relationship among defects distribution, microstructure, and mechanical properties was established, which provided a corresponding theoretical basis for SLM to prepare low-alloy steel.

Similar content being viewed by others

References

D. Zeng, L. Lu, Y. Gong, N. Zhang and Y. Gong, Optimization of Strength and Toughness of Railway Wheel Steel by Alloy Design, Mater. Des., 2016, 92, p 998–1006.

X. Cui, S. Zhang, C. Wang, C.H. Zhang, J. Chen and J.B. Zhang, Effects of Stress-Relief Heat Treatment on the Microstructure and Fatigue Property of a Laser Additive Manufactured 12CrNi2 Low Alloy Steel, Mater. Sci. Eng. A, 2020, 791, p 139738.

C. Wang, S. Zhang, C.H. Zhang, C.L. Wu, J.B. Zhang and A.O. Abdullah, Phase Evolution Mechanism and Wear Resistance of In Situ Synthesized V8C7 Particles Reinforced Fe-Based Coating, Opt. Laser Technol., 2018, 105, p 58–65.

J.H.K. Tan, S.L. Sing and W.Y. Yeong, Microstructure Modelling for Metallic Additive Manufacturing: A Review, Virtual Phys. Prototyp., 2020, 15, p 87–105.

P. Fischer, V. Romano, H.P. Weber, N.P. Karapatis, E. Boillat and R. Glardon, Sintering of Commercially Pure Titanium Powder with a Nd: YAG Laser Source, Acta Mater., 2003, 51, p 1651–1662.

Y.R. Han, C.H. Zhang, X. Cui, S. Zhang, J.B. Zhang and Y. Liu, The Formability and Microstructure Evolution of 24CrNiMo Alloy Steel Fabricated by Selective Laser Melting, Vacuum, 2020, 175, p 109297.

B.Y. Zhang, Z.Z. Zhang, S.H. Zhou, Q.P. Liu and P. Zhang, A Parametric Local Remelting Approach to Improve Mechanical Properties of Selective Laser Melted 24CrNiMo Steel, Mater. Des., 2021, 282, p 128656.

P.F. Jiang, C.H. Zhang, S. Zhang, J.B. Zhang, J. Chen and H.T. Chen, Additive Manufacturing of Novel Ferritic Stainless Steel by Selective Laser Melting: Role of Laser Scanning Speed on the Formability, Microstructure and Properties, Opt. Laser Technol., 2021, 140, p 107055.

C. Emmelmann, P. Sander, J. Kranz and E. Wycisk, Laser Additive Manufacturing and Bionics: Redefining Lightweight Design, Phys. Procedia, 2011, 12, p 364–368.

P. Bajaj, A. Hariharan, A. Kini, P. Kürnsteiner, D. Raabe and E.A. Jägle, Steels in Additive Manufacturing: A Review of Their Microstructure and Properties, Mater. Sci. Eng. A, 2020, 772, p 138633.

C.L. Wu, S. Zhang, C.H. Zhang, H. Zhang and S.Y. Dong, Phase Evolution and Properties in Laser Surface Alloying of FeCoCrAlCuNix High-Entropy Alloy on Copper Substrate, Surf. Coat. Technol., 2017, 315, p 368–376.

B. AlMangour, D. Grzesiak, T. Borkar and J.M. Yang, Scanning Strategies for Texture and Anisotropy Tailoring During Selective Laser Melting of TiC/316L Stainless Steel Nanocomposites, Mater. Des., 2018, 138, p 119–128.

B. AlMangour, D. Grzesiak and J.M. Yang, Scanning Strategies for Texture and Anisotropy Tailoring During Selective Laser Melting of TiC/316L Stainless Steel Nanocomposites, J. Alloys Compd., 2017, 728, p 424–435.

F. Bartolomeu, M. Buciumeanu, E. Pinto, N. Alves, O. Carvalho, F.S. Silva and G. Miranda, 316L stainless Steel Mechanical and Tribological Behavior-A Comparison Between Selective Laser Melting, Hot Pressing and Conventional Casting, Addit. Manuf., 2017, 16, p 81–89.

E. Liverani, S. Toschi, L. Ceschini and A. Fortunato, Effect of Selective Laser Melting (SLM) Process Parameters on Microstructure and Mechanical Properties of 316L Austenitic Stainless Steel, J. Mater. Process. Technol., 2017, 249, p 255–263.

C. Yan, L. Hao, A. Hussein, P. Young and D. Raymont, Advanced Lightweight 316L Stainless Steel Cellular Lattice Structures Fabricated Via Selective Laser Melting. Mater. Des., 2014, 55, p 533–541.

Z.H. Hu, H.H. Zhu, H. Zhang and X.Y. Zeng, Experimental Investigation On Selective Laser Melting of 17–4PH Stainless Steel, Opt. Laser Technol., 2017, 87, p 17–25.

A. Riemer, S. Leuders, M. Thöne, H.A. Richard, T. Tröster and T. Niendorf, On the Fatigue Crack Growth Behavior in 316L Stainless Steel Manufactured by Selective Laser Melting, Eng. Fract. Mech., 2014, 120, p 15–25.

M. Zheng, L. Wei, J. Chen, Q. Zhang, G.H. Zhang, X. Lin and W.D. Huang, On the Role of Energy Input in the Surface Morphology and Microstructure During Selective Laser Melting of Inconel 718 Alloy, J. Mater. Res. Technol., 2021, 11, p 392–403.

X. Tang, S. Zhang, C.H. Zhang, J. Chen, J.B. Zhang and Y. Liu, Optimization of Laser Energy Density and Scanning Strategy on the Forming Quality of 24CrNiMo Low Alloy Steel Manufactured by SLM, Mater. Charact., 2020, 170, p 110718.

X. Zhao, S.Y. Dong, S.X. Yan, X.T. Liu, Y.X. Liu, D. Xia, Y.H. Lv, P. He, B.S. Xu and H.S. Han, The Effect of Different Scanning Strategies on Microstructural Evolution to 24CrNiMo Alloy Steel During Direct Laser Deposition, Mater. Sci. Eng. A, 2020, 771, p 138557.

L. Cao, S.Y. Chen, M.W. Wei, Q. Guo, J. Liang, C.S. Liu and M. Wang, Effect of Laser Energy Density on Defects Behavior of Direct Laser Depositing 24CrNiMo Alloy Steel, Opt. Laser Technol., 2019, 111, p 541–553.

X. Cui, S. Zhang, C.H. Zhang, J. Chen, J.B. Zhang and S.Y. Dong, Additive Manufacturing of 24CrNiMo Low Alloy Steel By Selective Laser Melting: Influence of Volumetric Energy Density on Densification, Microstructure and Hardness, Mater. Sci. Eng. A, 2021, 809, p 140957.

Q. Wang, Z.H. Zhang, X. Tong, S.Y. Dong, Z.Q. Cui, X. Wang and L.Q. Ren, Effects of Process Parameters on the Microstructure and Mechanical Properties of 24CrNiMo Steel Fabricated by Selective Laser Melting, Opt. Laser Technol., 2020, 128, p 106262.

C.L. Qiu, C. Panwisawas, M. Ward, H.C. Basoalto, J.W. Brooks and M.M. Attallah, On The role of Melt Flow into the Surface Structure and Porosity Development During Selective Laser Melting, Acta Mater., 2015, 96, p 72–79.

C. Tang, J.L. Tan and C.H. Wong, A Numerical Investigation on the Physical Mechanisms of Single Track Defects in Selective Laser Melting, Int. J. Heat Mass Transf., 2018, 126, p 957–968.

W.E. King, H.D. Barth, V.M. Castillo, G.F. Gallegos, J.W. Gibbs, D.E. Hahn, C. Kamath and A.M. Rubenchik, Observation of Keyhole-Mode Laser Melting in Laser Powder-Bed Fusion Additive Manufacturing, J. Mater. Proc. Technol., 2014, 214, p 2915–2925.

K. Saeidi, X. Gao, Y. Zhong and Z.J. Shen, Hardened Austenite Steel with Columnar Sub-grain Structure Formed by Laser Melting, Mater. Sci. Eng. A, 2015, 625, p 221–229.

T. Wang, Y.Y. Zhu, S.Q. Zhang, H.B. Tang and H.M. Wang, Grain Morphology Evolution Behavior of Titanium Alloy Components During Laser Melting Deposition Additive Manufacturing, J. Alloys Compd., 2015, 632, p 505–513.

X.M. Zhao, J. Chen, X. Lin and W.D. Huang, Study on Microstructure and Mechanical Properties of Laser Rapid Forming Inconel 718, Mater. Sci. Eng. A, 2008, 478, p 119–124.

X. Cui, S. Zhang, C. Wang, C.H. Zhang, J. Chen and J.B. Zhang, Microstructure and Fatigue Behavior of a Laser Additive Manufactured 12CrNi2 Low Alloy Steel, Mater. Sci. Eng. A, 2019, 772, p 138685.

O. Lopez-Botello, U. Martinez-Hernandez, J. Ramírez, C. Pinna and K. Mumtaz, Two-Dimensional Simulation of Grain Structure Growth within Selective Laser Melted AA-2024, Mater. Des., 2017, 113, p 369–376.

Y. Zhou, S.Y. Chen, X.T. Chen, J. Liang, C.S. Liu and M. Wang, The Effect of Laser Scanning Speed on Microstructural Evolution During Direct Laser Deposition 12CrNi2 Alloy Steel, Opt. Laser Technol., 2020, 125, p 106041.

G.P. Dinda, A.K. Dasgupta and J. Mazumder, Texture Control During Laser Deposition of Nickel-Based Superalloy, Scr. Mater., 2012, 67, p 503–506.

H.L. Wei, J.W. Elmer and T. DebRoy, Origin of Grain Orientation During Solidification of an Aluminum Alloy, Acta Mater., 2016, 115, p 123–131.

A.M. Ravi, J. Sietsma and M.J. Santofimia, Bainite Formation Kinetics in Steels and the Dynamic Nature of the Autocatalytic Nucleation Process, Scr. Mater., 2017, 140, p 82–86.

A.M. Ravi, J. Sietsma and M.J. Santofimia, Exploring Bainite Formation Kinetics Distinguishing Grain-Boundary and Autocatalytic Nucleation in High and Low-Si Steels, Acta Mater., 2016, 105, p 155–164.

A. Zinoviev, O. Zinovieva, V. Ploshikhin, V. Romanova and R. Balokhonov, Evolution of Grain Structure During Laser Additive Manufacturing. Simulation by a Cellular Automata Method, Mater. Des., 2016, 106, p 321–329.

X. Zhou, K.L. Li, D.D. Zhang, X.H. Liu, J. Ma, W. Liu and Z.J. Shen, Textures Formed in a CoCrMo Alloy by Selective Laser Melting, J. Alloys Compd., 2015, 631, p 153–164.

V.A. Popovich, E.V. Borisov, A.A. Popovich, V.S. Sufiiarov, D.V. Masaylo and L. Alzina, Functionally Graded Inconel 718 Processed by Additive Manufacturing: Crystallographic Texture, Anisotropy of Microstructure and Mechanical Properties, Mater. Des., 2017, 114, p 441–449.

Y. Zhou, X. Zeng, Z. Yang and H.B. Wu, Effect of Crystallographic Textures on Thermal Anisotropy of Selective Laser Melted Cu-2.4Ni-0.7Si Alloy, J. Alloys Compd., 2018, 743, p 258–261.

A. Majeed, Y.F. Zhang, J.X. Lv, T. Peng, Z. Atta and A. Ahmed, Investigation of T4 and T6 Heat Treatment Influences on Relatively Density and Porosity of AlSi10Mg Alloy Components Manufactured by SLM, Comput. Ind. Eng., 2020, 139, p 106194.

B. AlMangour, D. Grzesiak, J. Cheng and Y. Ertas, Thermal Behavior of the Molten Pool, Microstructural Evolution, and Tribological Performance During Selective Laser Melting of TiC/316L Stainless Steel Nanocomposites: Experimental and Simulation Methods, J. Mater. Process. Tech., 2018, 257, p 288–301.

A. Augustin, P. Huilgol, K.R. Udupa and K.U. Bhat, Effect of Current Density During Electrodeposition on Microstructure and Hardness of Textured Cu Coating in the Application of Antimicrobial Al Touch Surface, J. Mech. Behav. Biomed., 2016, 63, p 352–360.

F.M. Gao, Theoretical Model of Hardness Anisotropy in Brittle Materials, J. Appl. Phys., 2012, 112, p 023506.

X.L. Kang, S.Y. Dong, H.B. Wang, S.X. Yan, X.T. Liu and B.S. Xu, Inhomogeneous Microstructure and its Evolution of Laser Melting Deposited 24CrNiMo Steel: From Single-Track to Bulk Sample, Mater. Sci. Eng. A, 2020, 772, p 138795.

Y. Murakami and M. Endo, Effects of Defects, Inclusions and Inhomogeneities on Fatigue Strength, Int. J. Fatigue, 1994, 16, p 163–182.

X. Wang, C.H. Zhang, X. Cui, S. Zhang, J. Chen and J.B. Zhang, Microstructure and Mechanical Behavior of Additive Manufactured Cr-Ni-V Low Alloy Steel in Different Heat Treatment, Vacuum, 2020, 175, p 109216.

K. Zhang, M.H. Zhang, Z.H. Guo, N.L. Chen and Y.H. Rong, A New Effect of Retained Austenite on Ductility Enhancement in High-Strength Quenching-Partitioning-Tempering Martensitic Steel, Mater. Sci. Eng. A, 2011, 528, p 8486–8491.

Y.C. Wan, S.Y. Xu, C.M. Liu, Y.H. Gao, S.N. Jiang and Z.Y. Chen, Enhanced Strength and Corrosion Resistance of Mg-Gd-Y-Zr Alloy with Ultrafine Grains, Mater. Lett., 2018, 213, p 274–277.

R.D.K. Misra, V.S.A. Challa, P.K.C. Venkatsurya, Y.F. Shen, M.C. Somani and L.P. Karjalainen, Interplay Between Grain Structure, Deformation Mechanisms and Austenite Stability in Phase-Reversion-Induced Nanograined/Ultrafine-Grained Austenitic Ferrous Alloy, Acta Mater., 2015, 84, p 339–348.

R.D.K. Misra, X.L. Wan, V.S.A. Challa, M.C. Somani and L.E. Murr, Relationship of Grain Size and Deformation Mechanism to the Fracture Behavior in High Strength-High Ductility Nanostructured Austenitic Stainless Steel, Mater. Sci. Eng. A, 2015, 626, p 41–50.

X.Z. Ran, D. Liu, J. Li, X. Liu, H.M. Wang, X. Cheng, B. He and H.B. Tang, Effects of Post Homogeneity Heat Treatment Processes on Microstructural Evolution Behavior and Tensile Mechanical Properties of Laser Additive Manufactured Ultrahigh-Strength AerMet100 Steel, Mater. Sci. Eng. A, 2018, 723, p 8–21.

D. Wang, C.H. Hui, Y.Q. Yang and Y.C. Bai, Investigation of Crystal Growth Mechanism During Selective Laser Melting and Mechanical Property Characterization of 316L Stainless Steel Parts, Mater. Des., 2016, 100, p 291–299.

P. Liu, R. Zhang, Y. Yuan, C.Y. Cui, F.G. Liang, X. Liu, Y.F. Gu, Y.Z. Zhou and X.F. Sun, Effects of Nitrogen Content on Microstructures and Tensile Properties of a New Ni–Fe Based Wrought Superalloy, Mater. Sci. Eng. A, 2021, 801, p 140436.

J.B. Yan, Y.F. Gu, F. Sun, Y. Michinari, Z.H. Zhong, Y. Yuan and J.T. Lu, Microstructural Study in a Fe-Ni-Base Superalloy During Creep-Rupture at Intermediate Temperature, Mater. Sci. Eng. A, 2015, 639, p 15–20.

J. Moerman, P.R. Triguero, C. Tasan and P. van Liempt, Evaluation of Geometrically Necessary Dislocations Density (GNDD) Near Phase Boundaries in Dual Phase Steels by Means of EBSD, Mater. Sci. Forum, 2011, 702–703, p 485–488.

A.A. Gazder, V.Q. Vu, A.A. Saleh, P.E. Markovsky, O.M. Ivasishin, C.H.J. Davies and E.V. Pereloma, Recrystallisation in a Cold Drawn Low Cost Beta Titanium Alloy During Rapid Resistance Heating, J. Alloys Compd., 2014, 585, p 245–259.

Acknowledgments

The authors gratefully acknowledge the financial support for this research from National Key Research and Development Program of China (No. 2016YFB1100204), Key Research Project from Science and Shenyang Science and Technology-Funded Project (No. 19-109-1-03).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work. There is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled, “Effect of energy density on the defects, microstructure, and mechanical properties of selective laser melted 24CrNiMo low alloy steel.”

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, F.Z., Zhang, C.H., Cui, X. et al. Effect of Energy Density on the Defects, Microstructure, and Mechanical Properties of Selective-Laser-Melted 24CrNiMo Low-Alloy Steel. J. of Materi Eng and Perform 31, 3520–3534 (2022). https://doi.org/10.1007/s11665-021-06500-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06500-x