Abstract

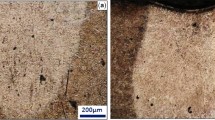

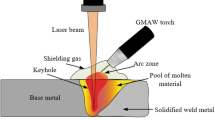

The use of fiber laser welding to join S690QL steels has attracted interest in the field of construction and assembly. Herein, 13-mm-thick S690QL welded joints were obtained without filler materials using the fiber laser. The as-welded microstructures and the impact energies of the joints were characterized and measured using electron microscopy in conjunction with high-resolution transmission electron images, X-ray diffraction, and impact tests. The results indicated that a single-sided welding technique could be used to join S690QL steels up to a thickness of 12 mm (fail to fuse the joint in the root) when the laser power is equal to 12 kW (scan speed 1 m/min). Double-side welding technique allows better weld penetration and better control of heat distribution. Observation of the samples showed that the fusion zone exhibited bainitic and martensitic microstructures with increased amounts of martensites (Ms) compared with the base materials. Also, the grains in the fusion zone increased in coarseness as the heat input was increased. The fusion zone exhibited increased hardness (397 HV0.2) while exhibiting a simultaneous decrease in the impact toughness. The maximum impact energy value of 26 J was obtained from the single-side-welded sample, which is greater than those obtained from the double-side-welded samples (maximum of 18 J). Many more dislocations and plastic deformations were found in the fusion zone than the heat-affected zone in the joint, which hardened the joints and lowered the impact toughness. The microstructures characterized by FTEM–energy-dispersive X-ray spectrometer also exhibited laths of M, as well as stacking faults and dislocations featuring high-density, interfacial structure ledges that occur between the high-angle grain boundaries and the M and bainite.

Similar content being viewed by others

References

X.H. Qiang, F. Bijlaard, and H. Kolstein: Constr. Build Mater, 2012, vol. 30, pp. 73-9.

S.P. Chiew, M.S. Zhao, and C.K. Lee: J. Constr. Steel Res., 2014, vol. 98, pp. 12-9.

R. Nikolić, D. Arsić, V. Lazić, and M. Djordjevic: Mater. Eng., 2013, vol. 20, pp.174-83.

H.C. Yildirim, and G.B. Marquis: Int. J. Fatigue., 2012, vol. 44, pp. 168-76.

P. Paillard, E. Bertrand, M. Allart, A. Benoit, and G. Ruckert: Mater. Charact, 2016, vol. 122, pp. 183-8.

Y.D. Chung, H. Fujii, R. Ueji, and N. Tsuji: Scripta Mater., 2010, vol. 63, pp. 223-6.

H. Fujii, L. Cui, N. Tsuji, M. Maeda, K. Nakata, and K. Nogi: Mater. Sci. Eng. A., 2006, vol. 429, pp. 50-7.

S. Błacha, M.S. Węglowski, S. Dymek, and M. Kopuściański: Arch. Metall. Mater., 2016, vol. 61, pp. 1193-1200.

L. Zhang and T. Kannengiesser: Mater. Sci. Eng. A., 2014, vol. 613, pp. 326-35.

M. Węglowski, S. Błacha, and A. Phillips: Vacuum, 2016, vol. 130, pp. 72-92.

H.S. Shin, K.T. Park, C.H. Lee, K.H. Chang, V.N.V. Do: KSCE J. Civ. Eng., 2015, vol. 19, pp. 1431-37.

H. Koga, H. Goda, S. Terada, K. Hirota, S. Nakayama, and S. Tsubota: Mitsubishi Heavy Indust Tech. Rev., 2010, vol. 47, pp. 59-64.

F. Roland, L. Manzon, P.Kujala, M. Brede, and J. Weitzenböck: J. Ship Prod., 2004, vol. 20, pp. 200-10.

C. Gerritsen and D. Howarth: 11th CF/DRDC Int. Meet. Naval Appl. Mater. Technol., Halifax, Nova Scotia, Canada, 2005, pp. 1–4.

P. Kah: Mater. Sci., 2012, vol. 30, pp. 112-32.

H. Pinto, M. Corpas, J.A. Guio, A.R. Pyzalla, A. Jahn, and J. Standfulß: Steel Res. Int., 2009, vol. 80, pp. 39-49.

K. Asim, K. Sripichai, and J. Pan: Int. J. Fatigue., 2014, vol. 61, pp. 283-96.

G. Marulo: Master Degree in Vehicle Engineering, University of Pisa, Pisa, Italy, 2014, pp. 25-32.

G. Marulo, J. Baumgartner, and F. Frendo: Int. J. Fatigue., 2017, vol. 96, pp. 142-51.

N. Matsumoto, Y. Kawahito, K. Nishimoto, and S. Katayama: J. Laser Appl., 2017, vol. 29, pp. 012003-1-8.

H. Ohtani, S. Okaguchi, Y. Fujishiro, and Y. Ohmori: Metall. Trans. A., 1990, vol. 21, pp. 877-88.

H.K.D.H. Bhadeshia: Acta Metall., 1980, vol. 28, pp. 1103-14.

W. D. Callister Jr., and D. G. Rethwisch: Materials Science and Engineering: An Introduction, 8th ed., Wiley, New York 2009, pp. 199-233.

J. Hu, Y. N. Shi, X. Sauvage, G. Sha, and K. Lu: Science, 2017, vol. 355, pp. 1292–6.

Acknowledgments

The work was supported by the National Natural Science Foundation of China (Grant Numbers 51475282, 51105240); the “Shu Guang” Project of Shanghai Municipal Education Commission and Shanghai Education Development Foundation (Grant Number 13SG54); and the Graduate Innovation Project (Grant Number 17KY0515).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 6, 2017.

Rights and permissions

About this article

Cite this article

Li, B., Xu, P., Lu, F. et al. Microstructure Characterization of Fiber Laser Welds of S690QL High-Strength Steels. Metall Mater Trans B 49, 225–237 (2018). https://doi.org/10.1007/s11663-017-1153-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-1153-z