Abstract

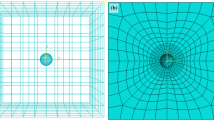

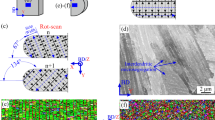

Prismatic geometries of GRCop-84 [Cu-8Cr-4Nb (at. pct)] were built with laser-powder bed fusion (L-PBF) process. The samples were sectioned parallel or perpendicular to the build direction and characterized in the as-built and after post-processing with a hot-isostatically pressing (HIP) treatment. The microstructure and phase evolutions were evaluated with optical microscopy, scanning electron microscopy (SEM), electron backscattered diffraction (EBSD), and high-temperature X-ray diffraction (HTXRD) up to 1223 K. The samples in the as-built conditions exhibited predominantly columnar epitaxial and misoriented Cu-FCC grains. The microstructure evolutions are discussed based on locations within the overall build geometry, the dynamics of small melt pool shape and sectioning effects. The above grain structure did not change significantly during post-process HIP treatment. The stability of this FCC grain structure is attributed to the formation of primary stable Cr2Nb (Laves phase) during L-PBF, even before the emergence of FCC grains from liquid. The stability of Cr2Nb in both as-built and HIPed samples were evaluated using high-temperature X-ray diffraction measurements and compared with that of gas-atomized powder. The significance of these results is discussed with reference to aerospace applications.

Similar content being viewed by others

References

Ellis DL: GRCop-84: a high temperature copper alloy for high-heat-flux applications, NASA/TM-2005-213566, (2005), https://ntrs.nasa.gov/citations/20050123582

P.R. Gradl, C.S. Protz, K. Cooper, D. Ellis, L.J. Evans, and C. Garcia: In AIAA Propulsion and Energy 2019 Forum, 2019, p 4228.

B. Blakey-Milner, P. Gradl, G. Snedden, M. Brooks, J. Pitot, E. Lopez, M. Leary, F. Berto, and A.D. Plessis: Mater. Des., 2021, vol. 209, 110008.

P.R. Gradl, C.S. Protz, K. Zagorski, V. Doshi, and H. McCallum: In AIAA Propulsion and Energy 2019 Forum, 2019, p 4390.

P.R. Gradl, C. Protz, S.E. Greene, D. Ellis, B. Lerch, and I. Locci: In 53rd AIAA/SAE/ASEE Joint Propulsion Conference, 2017, p 4670.

F. Kerstens, A. Cervone, and P. Gradl: Acta Astronaut., 2021, vol. 182, pp. 454–65.

A.H. Seltzman and S.J. Wukitch: Fusion Eng. Des., 2020, vol. 159, 111726.

D.L. Ellis and G.M. Michal: Precipitation strengthened high strength, high conductivity Cu-Cr-Nb alloys produced by chill block melt spinning. Final Report Ph.D. Thesis, Case Western Reserve University, 1989, https://ntrs.nasa.gov/citations/19900002537

D.L. Ellis, G.M. Michal GM, and N.W. Orth: Production and processing of Cu-Cr-Nb alloys. NASA-TM-102495, 1990, https://ntrs.nasa.gov/citations/19900006737

D.L. Ellis and K. Hastings: Effects of Hydrogen on GRCop-84. NASA/TM-2006-214269, 2006, https://ntrs.nasa.gov/api/citations/20060017836/downloads/20060017836.pdf

R.P. Minneci, E.A. Lass, J.R. Bunn, H. Choo, and C.J. Rawn: Int. Mater. Rev., 2021, vol. 66, pp. 394–425.

B. Dutta, S. Babu, and Bradley H Jared: Science, technology and applications of metals in additive manufacturing. Elsevier, 2019.

P.R. Gradl, S.E. Greene, C. Protz, B. Bullard, J. Buzzell, C. Garcia, J. Wood, R. Osborne, J. Hulka, and K.G. Cooper: In 2018 Joint Propulsion Conference, 2018, p 4625.

P.R. Gradl, C.S. Protz, D.L. Ellis, and S.E. Greene: Progress in additively manufactured copper-alloy GRCop-84, GRCop-42, and bimettalic combustion chambers for liquid rocket engines. In Proceedings of 70th International Astronautical Congress; 2019 Oct 21– 25, Washington, D.C, 2019, https://ntrs.nasa.gov/citations/20190033311

C. Hayes, E. Brown, and B. Kappes: In 2018 Joint Propulsion Conference, 2018, p 4624.

A.H. Seltzman and S.J. Wukitch: Fusion Sci. Technol., 2021, vol. 77, pp. 641–46.

G. Demeneghi, B. Barnes, P. Gradl, J.R. Mayeur, and K. Hazeli: Mater. Sci. Eng. A, 2021, vol. 820, p. 141511.

Paulo Rangel Rios and Dana Zöllner: Mater. Sci. Technol., 2018, vol. 34, pp. 629–38.

J.N. DuPont: ASM Handbook 6a 2011, pp. 96-114.

S. Das, D.L. Bourell, and S.S. Babu: Mrs Bull., 2016, vol. 41, pp. 729–41.

S.A. David and J.M. Vitek: Int. Mater. Rev., 1989, vol. 34, pp. 213–45.

X. Zhang, C.J. Yocom, B. Mao, and Y. Liao: J. Laser Appl., 2019, vol. 31, p. 31201.

F. Yan, W. Xiong, and E.J. Faierson: Materials, 2017, vol. 10, p. 1260.

S. Das: Adv. Eng. Mater., 2003, vol. 5, pp. 701–11.

W.J. Sames, F.A. List, S. Pannala, R.R. Dehoff, and S. Suresh Babu: Int. Mater. Rev., 2016, vol. 61, pp. 315–60.

F. Bachmann, R. Hielscher, and H. Schaeben: Solid State Phenom., 2010, vol. 160, pp. 63–68.

G.J. Butterworth and C.B.A. Forty: J. Nucl. Mater., 1992, vol. 189, pp. 237–76.

A. Plotkowski, J. Ferguson, B. Stump, W. Halsey, V. Paquit, C. Joslin, S.S. Babu, A.M. Rossy, M.M. Kirka, and R.R. Dehoff: Addit. Manuf., 2021, vol. 46, p. 102092.

D. Rosenthal: Trans. Am. Soc. Mech. Eng., 1946, vol. 68, pp. 849–65.

D. Rosenthal: Weld. J., 1941, vol. 20, pp. 220s-s234.

Øystein Grong: (No Title) 1997.

M. Haines, A. Plotkowski, C.L. Frederick, E.J. Schwalbach, and S.S. Babu: Comput. Mater. Sci., 2018, vol. 155, pp. 340–49.

B.H. Toby: J. Appl. Crystallogr., 2001, vol. 34, pp. 210–13.

B.H. Toby and R.B. Von Dreele: J. Appl. Crystallogr., 2013, vol. 46, pp. 544–49.

R.B. Von Dreele and A.C. Larson: Los Alamos Natl. Lab. Rep. LAUR, 2004, vol. 748, pp. 86–748.

M. Venkatraman and J.P. Neumann: Bull. Alloy Phase Diagr., 1986, vol. 7, pp. 462–66.

P. Nandwana, W.H. Peter, R.R. Dehoff, L.E. Lowe, and M.M. Kirka: Metall. Mater. Trans. B, 2016, vol. 47, pp. 754–62.

V. Juechter, T. Scharowsky, R.F. Singer, and C. Körner: Acta Mater., 2014, vol. 76, pp. 252–58.

S.J. Foster, K. Carver, R.B. Dinwiddie, F. List, K.A. Unocic, A. Chaudhary, and S.S. Babu: Metall. Mater. Trans. A, 2018, vol. 49, pp. 5775–98.

J.A. Dantzig and M. Rappaz: Solidification: -Revised & Expanded, EPFL Press, Lausanne, 2016.

M. Rappaz, S.A. David, J.M. Vitek, and L.A. Boatner: Metall. Trans. A, 1990, vol. 21, pp. 1767–82.

S.A. David, S.S. Babu, and J.M. Vitek: Jom, 2003, vol. 55, pp. 14–20.

J.C. Villafuerte, H.W. Kerr, and S.A. David: Mater. Sci. Eng. A, 1995, vol. 194, pp. 187–91.

M. Maalekian, H. Azizi-Alizamini, and M. Militzer: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 608–22.

Ge. Wang, H. Ouyang, C. Fan, Q. Guo, Z. Li, W. Yan, and Z. Li: Mater. Res. Lett., 2020, vol. 8, pp. 283–90.

R. Viswanathan and C.L. Bauer: Acta Metall., 1973, vol. 21, pp. 1099–1109.

R.A. Vandermeer, D. Juul Jensen, and E. Woldt: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 749–54.

M.A. Tschopp and D.L. McDowell: Philos. Mag., 2007, vol. 87, pp. 3871–92.

J.R. Porter and F.J. Humphreys: Met. Sci., 1979, vol. 13, pp. 83–88.

F.J. Humphreys and M.G. Ardakani: Acta Mater., 1996, vol. 44, pp. 2717–27.

T. Watanabe: J. Phys. Coll., 1988, vol. 49, pp. C5-507-5–519.

J. Raplee, J. Gockel, F. List III., K. Carver, S. Foster, T. McFalls, V. Paquit, R. Rao, D.W. Gandy, and S.S. Babu: Sci. Technol. Weld. Joining, 2020, vol. 25, pp. 679–89.

Ellis, D.L., Misra, A.K. and Dreshfield, R.L., 1994. Effect of Hydrogen Exposure on a Cu‐8 Cr‐4 Nb Alloy for Rocket Motor Applications. Hydrogen Effects in Materials (No. NASA-TM-106429).

B.D. Cullity and S.R. Stock: Elements of X-ray Diffraction, 3rd ed. Prentice Hall, Upper Saddle River, NJ, 2001.

A.R. Denton and N.W. Ashcroft: Phys. Rev.A, 1991, vol. 43, p. 3161.

K. Hono and S. S. Babu: In Physical Metallurgy (Fifth Edition), ed. David E. Laughlin and Hono Kazuhiro Elsevier: Oxford, 2014, pp 1453–1589.

T.F. Kelly and M. Miller: Rev. Sci. Instrum., 2007, vol. 78, p. 031101.

David L Ellis, Dennis J Keller, and Michael Nathal: 2000.

Acknowledgments

The authors would like to acknowledge the Manufacturing and Materials Joining Innovation Center (Ma2JIC), made possible through awards NSF IIP-1540000 (Phase I) and NSF IIP-1822186 (Phase II) from the National Science Foundation Industry University Cooperative Research Center program (IUCRC). RPM also acknowledges the financial support of Oak Ridge National Laboratory’s Graduate Opportunities (GO!) Program. A portion of this research used resources at the High Flux Isotope Reactor, a DOE Office of Science User Facility operated by the Oak Ridge National Laboratory. This paper describes objective technical results and analysis. Any subjective views or opinions that might be expressed in the paper do not necessarily represent the views of the National Aeronautics and Space Administration (NASA) or the United States Government. M. Haines and S. S. Babu’s contribution to this research is partially supported by the US Department of the Navy Office of Naval Research under ONR award number N00014-18-1-2794. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the Office of Naval Research.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Minneci, R.P., Haines, M.P., Gradl, P.R. et al. Characterization and Rationalization of Microstructural Evolution in GRCop-84 Processed by Laser-Powder Bed Fusion (L-PBF). Metall Mater Trans A 55, 1377–1396 (2024). https://doi.org/10.1007/s11661-024-07315-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-024-07315-w