Abstract

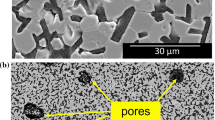

This study reports the effect of milling time on the carbon content, morphology, crystallite size, and phase evolution of pure elemental Al, Fe, Ni, Cu, Cr, Mo, Si, Co, W, V, Ta, and Ti powders during high-energy ball milling (HEBM) in toluene. The XRD results show that the HEBM of Ti resulted in the formation of TiCx, which was confirmed by Raman Spectroscopy, while milling of Ta resulted in the formation of TaCx and TaHx. In comparison, there was no carbide or hydride phase formation up to 20 hours of milling for all other elemental powders. The weight percentage of carbon in the milled powder was observed to increase progressively with milling time. Ti powder showed the highest wt pct of C followed by Ta, W, Si, Al, Cr, Fe, Mo, V, Co, Ni, and Cu, respectively. The presence of carbon could be attributed to the dissociation of toluene and erosion of tungsten carbide balls and vials. The results show that carbon pickup significantly depends on the element being milled. The D50 particle size reduced appreciably after 20 hours of milling. The crystallite size for all the powders reduced progressively with milling time and was found to be in the range of 20 to 36 nm after 20 hours of milling.

Graphical abstract

Similar content being viewed by others

References

E. Ma and M. Atzmon: Mater. Chem. Phys., 1995, vol. 39, pp. 249–67.

P.H. Shingu and K.N. Ishihara: Mater. Trans., JIM, 1995, vol. 36, pp. 96–101.

H. Bakker, G.F. Zhou, and H. Yang: Prog. Mater. Sci., 1995, vol. 39, pp. 159–241.

B.S. Murty and S. Ranganathan: Int. Mater. Rev., 1998, vol. 43, pp. 101–41.

A. Ermakov, E.E. Yurchikov, and V.A. Barinov: Phys. Met. Metall., 1981, vol. 52, pp. 50–58.

J. Wang, Z. Zheng, J. Xu, and Y. Wang: J. Magn. Magn. Mater., 2014, vol. 355, pp. 58–64.

B. Srinivasarao, C. Suryanarayana, K. Oh-Ishi, and K. Hono: Mater. Sci. Eng. A, 2009, vol. 518, pp. 100–07.

P. Susila, D. Sturm, M. Heilmaier, B.S. Murty, and V. Subramanya Sarma: J. Mater. Sci., 2010, vol. 45, pp. 4858–65.

C. Suryanarayana: Prog. Mater. Sci., 2001, vol. 46, pp. 1–184.

L. Lu and M.O. Lai: Mater. Des., 1995, vol. 16, pp. 33–39.

R.B. Schwarz and C.C. Koch: Appl. Phys. Lett., 1986, vol. 49, pp. 146–48.

A.W. Weeber and H. Bakker: Physica B, 1988, vol. 153, pp. 93–135.

J. Wang, X. Li, L.L. Shaw, H.L. Marcus, and T.B. Cameron: in Proc. International Solid Freeform Fabrication Symposium, 2001, pp. 546–52.

K.L. Edwards: Mater. Des., 2004, vol. 25, pp. 529–33.

T. Gietzelt, O. Jacobi, V. Piotter, R. Ruprecht, and J. Hausselt: J. Mater. Sci., 2004, vol. 39, pp. 2113–19.

G.M. Carter, J.L. Henshall, and R.J. Wakeman: Powder Technol., 1991, vol. 65, pp. 403–10.

V.G. Grechanyuk and E.M. Shelyakova: Soviet Powder Metall. Met. Ceram., 1986, vol. 25, pp. 359–60.

A.P. Radlinski, A. Calka, B.W. Ninham, and W.A. Kaczmarek: Mater. Sci. Eng. A, 1991, vol. 134, pp. 1346–49.

S. Sohoni, R. Sridhar, and G. Mandal: Powder Technol., 1991, vol. 67, pp. 277–86.

B.V. Velamakanni and D.W. Fuerstenau: Powder Technol., 1993, vol. 75, pp. 1–9.

A.R.C. Westwood, D.L. Goldheim, and R.G. Lye: Philos. Mag., 1967, vol. 16, pp. 505–19.

K. Suzuki and Y. Kuwahara: J. Chem. Eng. Jpn., 1986, vol. 19, pp. 191–95.

S. Sheibani, A. Ataie, and S. Heshmati-Manesh: J. Alloys Compd., 2008, vol. 465, pp. 78–82.

C. Suryanarayana and E. Ivanov Dr: in Advances in Powder Metallurgy, 2013, pp. 42–68.

K. Vasanthakumar, N.S. Karthiselva, N.M. Chawake, and S.R. Bakshi: J. Alloys Compd., 2017, vol. 709, pp. 829–41.

J. Keskinen, A. Pogany, J. Rubin, and P. Ruuskanen: Mater. Sci. Eng. A, 1995, vol. 196, pp. 205–11.

B.V. Neamţu, O. Isnard, I. Chicina, C. Vagner, N. Jumate, and P. Plaindoux: Mater. Chem. Phys., 2011, vol. 125, pp. 364–69.

Z. Caamaño, G. Pérez, L.E. Zamora, S. Suriñach, J.S. Muñoz, and M.D. Baró: J. Non Cryst. Solids, 2001, vol. 287, pp. 15–19.

T. Suzuki and M. Nagumo: Scr. Metall. Mater., 1992, vol. 27, pp. 1413–18.

M. Pilar, J.J. Suñol, J. Bonastre, and L. Escoda: J. Non Cryst. Solids, 2007, vol. 353, pp. 848–50.

N.S. Anas, M. Ramakrishna, R.K. Dash, T.N. Rao, and R. Vijay: Mater. Sci. Eng. A, 2019, vol. 751, pp. 171–82.

X. Zhang, B. Chen, and Z. Wang: J. Colloid Interface Sci., 2007, vol. 313, pp. 414–22.

M. Vaidya, A. Prasad, A. Parakh, and B.S. Murty: Mater. Des., 2017, vol. 126, pp. 37–46.

R. Ravi and S.R. Bakshi: J. Alloys Compd., 2021, vol. 883, 160879.

R.A. Sekhar, S. Samal, N. Nayan, and S.R. Bakshi: J. Alloys Compd., 2019, vol. 787, pp. 123–32.

L. Raman, K. Guruvidyathri, G. Kumari, S.V.S.N. Murty, R.S. Kottada, and B.S. Murty: J. Mater. Res., 2019, vol. 34, pp. 756–66.

R. Jayasree, R.B. Mane, R. Vijay, and D. Chakravarty: Mater. Lett., 2021, vol. 292, 129618.

L.B. Mccusker, R.B. Von Dreele, D.E. Cox, D. Loue, and P. Scardi: J. Appl. Crystallogr., 1999, vol. 32, pp. 36–50.

B.D. Cullity: Elements of X-Ray Diffraction, Addison-Wesley Publishing Company Inc., Boston, 1978.

J.B. Nelson and D.P. Riley: Proc. Phys. Soc., 1945, vol. 57, p. 160.

H.-J. Fecht: Nanostruct. Mater., 1995, vol. 6, pp. 33–42.

J.X. Yang, H.L. Zhao, H.R. Gong, M. Song, and Q.Q. Ren: Sci. Rep., 2018, vol. 8, p. 1992.

B. Avar and S. Ozcan: Ceram. Int., 2014, vol. 40, pp. 11123–30.

I. Manna, P.P. Chattopadhyay, P. Nandi, F. Banhart, and H.J. Fecht: J. Appl. Phys., 2003, vol. 93, p. 1520.

B. Uhrenius: Calphad, 1984, vol. 8, pp. 101–19.

I.I. Chuev and D.Y. Kovalev: Mater. Chem. Phys., 2022, vol. 283, 126025.

N.L. Peterson: Diffusion Mechanisms in Grain Boundaries in Solids, 1982.

A.S. Bolokang, D.E. Motaung, C.J. Arendse, and T.F.G. Muller: Adv. Powder Technol., 2015, vol. 26, pp. 632–39.

T.S. Suzuki and M. Nagumo: Scr. Metall. Mater., 1995, vol. 32, pp. 1215–20.

V.N. Lipatnikov, A.A. Rempel, and A.I. Gusev: Int. J. Refract. Metals Hard Mater., 1997, vol. 15, pp. 61–64.

B.H. Lohse, A. Calka, and D. Wexler: J. Appl. Phys., 2005, vol. 97, 114912.

M.V. Klein, J.A. Holy, and W.S. Williams: Phys. Rev. B, 1978, vol. 17, p. 1546.

S. Urbonaite, L. Hälldahl, and G. Svensson: Carbon N Y, 2008, vol. 46, pp. 1942–47.

P. Pachfule, D. Shinde, M. Majumder, and Q. Xu: Nat. Chem., 2016, vol. 8, pp. 718–24.

R. Yuan, Y. Dong, R. Hou, L. Shang, J. Zhang, S. Zhang, X. Chen, and H. Song: Chem. Eng. J., 2023, vol. 454, 140418.

M.T. Timko, A.R. Maag, J.M. Venegas, B. McKeogh, Z. Yang, G.A. Tompsett, S. Escapa, J. Toto, E. Heckley, and F.T. Greenaway: RSC Adv., 2016, vol. 6, pp. 12021–31.

S. Zhang, Y. Cui, B. Wu, R. Song, H. Song, J. Zhou, X. Chen, J. Liu, and L. Cao: RSC Adv., 2014, vol. 4, pp. 505–09.

O.M. Kanunnikova, V.V. Aksenova, and G.A. Dorofeev: Mater. Sci. Forum, 2020, vol. 989, pp. 532–36.

H. Wipf, M.V. Klein, and W.S. Williams: Physica Status Solidi b, 1981, vol. 108, pp. 489–500.

M. Schoenitz, X. Zhu, and E.L. Dreizin: Scr. Mater., 2005, vol. 53, pp. 1095–99.

X.P. Niu, L. Froyen, L. Delaey, and C. Peytour: Scripta Metall. Mater., 1994, vol. 30, pp. 13–18.

J.L. Iturbe-García and B.E. López-Muñoz: Adv. Nanopart., 2014, vol. 03, pp. 159–66.

S. Semboshi, N. Masahashi, and S. Hanada: Met. Mater. Int., 2004, vol. 10, pp. 45–53.

S.R. Shatynski: Oxid. Met., 1979, vol. 13, pp. 105–18.

K. Vasanthakumar and S.R. Bakshi: Ceram. Int., 2018, vol. 44, pp. 484–94.

M.B. Rahaei, A. Kazemzadeh, and T. Ebadzadeh: Powder Technol., 2012, vol. 217, pp. 369–76.

B. Ghosh and S.K. Pradhan: Mater. Chem. Phys., 2010, vol. 120, pp. 537–45.

H.L. Chiang and L.X. Zeng: J. Alloys Compd., 2018, vol. 748, pp. 861–70.

X. Wang and Q. Zhang: Powder Technol., 2020, vol. 371, pp. 55–63.

G.A. Bowmaker: Chem. Commun., 2013, vol. 49, pp. 334–48.

L.L. Ye and M.X. Quan: Nanostruct. Mater., 1995, vol. 5, pp. 25–31.

J.S. Benjamin: Sci. Am., 1976, vol. 234, pp. 40–49.

J. Ye, J. He, and J.M. Schoenung: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 3099–3109.

S. Cheng, E. Ma, Y.M. Wang, L.J. Kecskes, K.M. Youssef, C.C. Koch, U.P. Trociewitz, and K. Han: Acta Mater., 2005, vol. 53, pp. 1521–33.

A.H. Cottrell: The Mechanical Properties of Matter, 1964.

C.L. Chen and C.L. Huang: Int. J. Refract. Metals Hard Mater., 2014, vol. 44, pp. 19–26.

X.-T. Luo, C.-J. Li, and G.-J. Yang: J. Alloys Compd., 2013, vol. 548, pp. 180–87.

M.S. El-Eskandarany, K. Aoki, and K. Suzuki: J. Less Common Met., 1990, vol. 167, pp. 113–18.

D. Oleszak and P.H. Shingu: J. Appl. Phys., 1996, vol. 79, pp. 2975–80.

K. Tanaka and T. Mori: Acta Metall., 1970, vol. 18, pp. 931–41.

A. Pragatheeswaran, R. Ravi, and S.R. Bakshi: Adv. Powder Technol., 2019, vol. 30, pp. 2759–67.

F.L. Zhang, C.Y. Wang, and M. Zhu: Scr. Mater., 2003, vol. 49, pp. 1123–28.

Acknowledgments

The authors would like to acknowledge funding from Ministry of Human Resources Development under the Institute of Eminence scheme for carrying out the work (Grant No. SB20210993MMMHRD008470). Authors would like to thank Ms. Ramya S. for helping with carbon analysis experiments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Behera, K.K., Pradeep, K.G. & Bakshi, S.R. Effect of High-Energy Ball Milling in Toluene on the Morphology, Phase Evolution, and Contamination for Some Elemental Powders. Metall Mater Trans A 55, 303–319 (2024). https://doi.org/10.1007/s11661-023-07250-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07250-2