Abstract

With the growth of the stainless-steel industry, the focus has moved toward making specialized steels, where Ni has proved itself as a significant ingredient. With time, Ni demand has inclined toward the energy storage sector. Observing the drastic application in several areas, Ni demand has grown multi-fold in recent years. Ni requirement was conventionally being fulfilled by the high-grade sulfidic ores, which have been facing scarcity issues for quite a long time. These issues may get suitably addressed with the introduction of lateritic ores. Lateritic ore contributes to 70% of total nickel resources. However, due to its low grades, and comparatively higher impurity constituents, it requires specific preprocessing steps prior to utilization. The present article reviews the insight into the available hydrometallurgical approaches for treating laterite ores and the separation of nickel and cobalt from hydrometallurgy routes. Caron process, a combination of pyrometallurgy and hydrometallurgy, is also well described in the review. Mineralogy aspects and the spatial distribution of laterites ore play an essential role in selecting the best-suited hydrometallurgical route, which is also discussed. The work has introduced a novel attempt where the ore genesis, corresponding hydrometallurgical processing, and the relatable post-leaching treatment are collated for better understanding.

Similar content being viewed by others

Abbreviations

- MHP:

-

Mixed hydroxide of nickel and cobalt

- MSP:

-

Mixed sulfide precipitate of nickel and cobalt

- HPAL:

-

High pressure acid leaching

- AL:

-

Atmospheric acid leaching

- HL:

-

Heap leaching

- DNi:

-

Direct nickel

- NAPL:

-

Nitric acid pressure leaching

- SS:

-

Stainless steel

- PAL:

-

Phosphoric acid leaching

- INSG:

-

International nickel study group

- HEVs:

-

Hybrid electric vehicles

- Wt.:

-

Weight

- HAL:

-

Hydrochloric acid leaching

- NAL:

-

Nitric acid leaching

- STAC:

-

Stearyl trimethyl ammonium chloride

- BNC:

-

Basic nickel carbonate

- Mt:

-

Million tonnes

- MT:

-

Metric ton

References

International Nickel Study Group – The International Nickel Study Group (INSG), [Online]. Available: https://insg.org/ [Accessed: 2022-08-07]

“Nickel Institute,” [Online]. Available: https://nickelinstitute.org/about-nickel/plating/. [Accessed 10 Nov 2021].

Nickel: Market Outlook to 2018, Roskill, London, 2014.

Stopić SR, & Friedrich BG, Hydrometallurgical processing of nickel lateritic ores, Vojnotehnički glasnik/Military Technical Courier, no. 4, 64(2016) 1033-47.

Kursunoglu S, Ichlas ZT, & Kaya M, Leaching method selection for Caldag lateritic nickel ore by the analytic hierarchy process (AHP), Hydrometallurgy, 171(2017) 179-84.

Gultom, T, & Sianipar A, High pressure acid leaching: a newly introduced technology in Indonesia, In IOP Conference Series: Earth and Environmental Science, no. 1, 413(2020) 012015.

Nasab MH, Noaparast M, & Abdollahi H, Selective precipitation of iron from multi-element PLS produced by atmospheric leaching of Ni-Co bearing laterite, International Journal of Mining and Geo-Engineering (2022). https://doi.org/10.22059/ijmge.2022.307768.594861

Safitri N, Mubarok MZ, Meidji IU, Hardi J, Jayadi H. Leaching of limonitic nickel from Sorowako with sulfuric acid at atmospheric pressure. InJournal of Physics: Conference Series, no. 1, 1763(2021) 012044.

Ilyas S, Srivastava RR, Kim H, Ilyas N, Sattar R. Extraction of nickel and cobalt from a laterite ore using the carbothermic reduction roasting-ammoniacal leaching process. Separation and Purification Technology, 232(2020)115971.

He F, Ma B, Wang C, Chen Y, Mineral evolution and porous kinetics of nitric acid pressure leaching limonitic laterite, Minerals Engineering, 181(2022) 107544.

Alvial-Hein G, Mahandra H, Ghahreman A, Separation and recovery of cobalt and nickel from end of life products via solvent extraction technique:A review, Journal of Cleaner Production, 297(2021)126592.

Oxley A, Smith ME & Caceres O, Why heap leach nickel laterites?, Minerals Engineering, 88 (2016) 53-60.

Nickel Sulfate: Outlook to 2029, 3rd edition,” Roskill, London.

Shah K, “Indian Stainless Steel Industry–Overview & Latest Updates”.

[Online]. Available: https://nickelinstitute.org/about-nickel/copper-nickel-alloys/. [Accessed 10 11 2021].

Whittington BI & Muir D, Pressure Acid Leaching of Nickel Laterites: A Review, Mineral Processing and Extractive Metallurgy Review, no. 6, 21 (2008) 527–599.

Moskalyk RR & Alfantazi AM, Nickel laterite processing and electrowinning practice, Minerals Engineering, no. 8, 15 (2002) 593-605.

Boldt Jr JR & Queneau P, The Winning of Nickel, London, (1967) 7.

[Online]. Available: https://www.statista.com/statistics/273634/nickel-reserves-worldwide-by-country/. [Accessed 11 Nov 2021].

Elias M, Nickel laterite deposits-geological overview, resources and exploitation, Giant ore deposits: Characteristics, genesis and exploration. CODES Special Publication, 4 (2002) 205-220

“Mineral commodities summary,” US Geological Survey, January 2021.

Mudd GM & Jowitt SM, A detailed assessment of global nickel resource trands and endowments, Economic Geology, 109 (2014) 1813-1841.

“Ifp energies nouvelles,” [Online]. Available: https://www.ifpenergiesnouvelles.com/article/nickel-energy-transition-why-it-called-devils-metal. [Accessed 28 March 2022].

Nurjaman F, Astuti W, Bahfie F & Suharno B, Study of selective reduction in lateritic nickel ore: Saprolite versus limonite, Materials today: Proceedings, no. 1, 44 (2021) 1488-1494.

McDonald RG & Whittington BI, Atmospheric acid leaching of nickel laterites review: Part I. Sulphuric acid technologies, Hydrometallurgy, no. 1-4, 91 (2008) 35-55.

Norgate T & Jahanshahi S, Assessing the energy and greenhouse gas footprints of nickel laterite processing, Minerals Engineering, no. 7, 24 (2011) 698-707.

Rhamdhani MA, Chen J, Hidayat T, Jak E & Hayes P, Advances in research on nickel production through the Caron process, Proceedings of EMC, (2009).

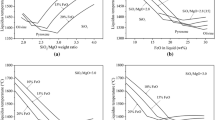

Ma B, Wang C, Yang W, Yang B & ZhangY, Selective pressure leaching of Fe (II)-rich limonitic laterite ores from Indonesia using nitric acid, Minerals Enginnering, 45 (2013) 151-158.

McCarthy F & McDonald R, Woodbridge G, Brock G & Robinson D, Iron hydrolysis in the direct nickel process, 28th International Mineral Processing Congress, (2016)

Carter RA, Leaching Laterites: Two New Processes Make Progress, Engineering and Mining Journal 215, 7 (2014) 86

Sist C & Demopoulos GP, Nickel hydroxide precipitation from aqeous sulfate media, The Journal of The Minerals, Metals & Metarials Society, 55 (2003) 42-46.

Oustadakis P, Agatzini-Leonardou S & Tsakirdis PE, Nickel and cobalt precipitation from sulphate leach liquor using MgO pulp as neutralizing agent, Minerals Engineering, no. 11, 19 (2006) 1204-1211.

Basturkcu H, Acarkan N & Gock E, The role of mechanical activation on atmospheric leaching of a lateritic nickel ore, International Journal of Mineral Processing, 163 (2017) 1-8.

Khoo JZ, Haque N, Woodbridge G, McDonald R & Bhattacharya S, A life cycle assessment of a new laterite processing technology, Journal of Cleaner Production, no. 4, 142 (2017) 1765-1777.

KURŞUNOGLU S, Extraction of nickel from a mixed nickel-cobalt hydroxide precipitate, Bilimsel Madencilik Dergisi, no. 1, 58(2019) 45-52.

McCarthy F & Brock G, Direct Nickel Test Plant Program: 2013 in Review, in ALTA 2014 NICKEL/COBALT/COPPER CONFERENCE, Perth, Australia, (2014).

Buyukakinci E & Topkaya YA, Extraction of nickel from lateritic ores at atmospheric pressure with agitation leaching, Hydrometallurgy, no. 1-2, 97 (2009) 33-38.

Kursunoglu S, Extraction of nickel from a mixed nickel-cobalt hydroxide precipitate, Madencilik, no. 1, 58 (2019) 45-52.

Thubakgale CK, Mbaya RK & Kabongo K, A study of atmospheric acid leaching of a South African nickel laterite, Minerals Engineering, 54 (2013) 79-81.

Wang B, Guo Q, Wei G, Zhang P, Qu J & Qi T, Characterization and atmospheric hydrochloric acid leaching of a limonitic laterite from Indonesia, Hydrometallurgy, 129-130 (2012) 7-13.

Zhang P, Sun L, Wang H, Cui J & Hao J, Surfactant-assistant atmospheric acid leaching of laterite ore for the improvement of leahcing efficiency of nickel and cobalt, Cleaner production, (2019) 1-7.

Luo J, Li G, Rao M, Peng Z, Zhang Y & Jiang T, Atmospheric leaching characteristics of nickel and iron in limonitic laterite with sulfuric acid in the presence of sodium sulfite, Minerals Engineering, 78 (2015) 38-44.

Li G, Rao M, Jiang T, Huang Q & Peng Z, Leaching of limonitic laterite ore by acidic thiosulfate solution, Minerals Engineering, no. 8, 24 (2011) 859-863.

Agatzini-Leonardou S & Dimaki D, Heap leaching of poor nickel laterites by sulfuric acid at ambient temperature, Hydrometallurgy, (1994) 193-208.

Ucyildiz A, Girgin I, High pressure sulphuric acid leaching of lateritic nickel ore. Physicochemical Problems of Mineral Processing, no. 1, 53(2017) 475-88.

Rubisov DH, Krowinkel JM & Papangelankis VG, Sulphuric acid pressure leaching of laterites — universal kinetics of nickel dissolution for limonites and limonitic/saprolitic blends, Hydrometallurgy, no. 1, 58 (2000) 1-11.

Whittington BI, Johnson JA, Quan LP, McDonald RG & Muir DM, Pressure acid leaching of arid-region nickel laterite orePart II. Effect of ore type, Hydrometallurgy, 70 (2003) 47-62.

Chou EC, Queneau PB & Rickard RS, Sulfuric acid pressure leaching of nickeliferous limonites, Metallurgical Transactions B, 8 (1977) 547-554.

“Caldera Engineering,” [Online]. Available: https://www.calderaengineering.com/industries-served/high-pressure-acid-leach-and-pressure-oxidation/high-pressure-acid-leach#:~:text=High%20Pressure%20Acid%20Leach%20(HPAL,cobalt%20from%20the%20laterite%20ore.. [Accessed 21 March 2022].

Xue-yi G, Wen-tang S & Qing-hua T, Leaching behavior of metals from limonitic lateritic ore by high pressure acid leaching, Nonferrous Metals Society of China, (2011) 191-195.

Georgiou D & V. Papangelakis, Sulphuric acid leaching of limonitic laterite: chemistry and kinetics, Hydrometallurgy, (1998) 23-46.

Das GK, Anand S, Acharya S & Das RP, Characterization and acid pressure leaching of various nickel-bearing chromite overburden samples, Hydrometallurgy, no. 1-2, 44 (1997) 97-111

Johnson JA, Cashmore BC & Hockridge RJ, Optimization of nickel extraction from laterite ores by highpressure acid leaching with addition of sodium sulphate, Minerals Engineering, (2005) 1297-1303.

Loveday BK, The use of oxygen in high pressure acid leaching of nickel laterites, Minerals engineering, (2008) 533-538.

Basturkcu H & Acarkan N, Leaching behaviour of a Turkish Lateritic ore in the presence of additives, Physicochemical Problem of Mineral Processing, no. 1, 52 (2016) 112-123.

Chang Y, Zhao K & Pešić B, Selective leaching of nickel from prereduced limonitic laterite under moderate HPAL conditions- Part I: Dissolution, Journal of Mining and Metallurgy, Section B: Metallurgy, no. 2, 52 (2016) 127-134.

de Bakker J, LaMarre J, Papangelakis V, Davis B, HCl leaching and acid regeneration using MgCl2 brines and molten salt hydrates, Proceedings of The Minerals, Metals & Materials Society (TMS), (2011) Feb:521–8.

Lakshmanan VI, Sridhar R, DeLaat R, Chen J, Halim MA, Roy R, Extraction of nickel, cobalt and iron from laterite ores by mixed chloride leach process, InNi-Co 2013, Springer, Cham (2013) 97-106

Li G, Zhou Q, Zhu Z, Luo J, Rao M, Peng Z & Jiang T, Selective leaching of nickel and cobalt from limonitic laterite using phosphoric acid: An alternative for value-added processing of laterite, Journal of Cleaner Production, 189 (2018) 620-626.

Sukla LB & Panchanadikar V, Bioleaching of lateritic nickel ore using a heterotrophic micro-organism, Hydrometallurgy, 32 (1993) 373-379.

Mohapatra S, Bohidar S, Pradhan N, Kar RN & Sukla LB, Microbial extraction of nickel from Sukinda chromite overburden by Acidithiobacillus ferrooxidans and Aspergillus strains, Hydrometallurgy, no. 1, 85 (2007) 1-8.

Behera SK, Panda SK, Pradhan N, Sukla LB & Mishra BK, Extraction of nickel by microbial reduction of lateritic chromite overburden of Sukinda, India, Bioresource Technology, 125 (2012) 17-22.

Biswas S, Dey R, Mukherjee S & Benerjee PC, Bioleaching of Nickel and Cobalt from Lateritic Chromite Overburden Using the Culture Filtrate of Aspergillus niger, Applied Biochemistry and Biotechnology, 170 (2013) 1547-1559.

Biswas S, Chakraborty S, Chaudhary M, Banerjee MG … & Dey R, Optimization of process parameters and dissolution kinetics of nickel and cobalt from lateritic chromite overburden using organic acids, Journal of Chemical Technology & Biotechnology, no. 10, 89 (2014) 1491-1500.

Bohidar S, Mohapatra S & Sukla LB, Nickel recovery from chromite overburden of Sukinda using fungal strains, International Journal of Intergrative Biology, no. 2, 5 (2009) 103-107.

Behera SK, Panda PP, Singh S, Pradhan N …. & Mishra BK, Study on reaction mechanism of bioleaching of nickel and cobalt form lateritic chromite overburdens, International Biodeterioration and Biodegradation, no. 7, 65 (2011) 1035-1042.

Behera SK & Sukla LB, Microbial extraction of nickel from chromite overburdens in the presence of surfactant, Transactions of Nonferrous Metals Society of China, no. 11, 22 (2012) 2840-2845.

Esther J, Panda S, Behera SK, Sukla LB, Pradhan N & Mishra BK, Effect of dissimilatory Fe(III) reducers on bio-reduction and nickel–cobalt recovery from Sukinda chromite-overburden, Bioresource Technology, 146 (2013) 762-766.

Biswas S, Samanta S, Dey R, Mukherjee S & Benerjee PC, Microbial leaching of chromite overburden from Sukinda mines, Orissa, India using Aspergillus niger, International Journal of Minerals, Metallurgy, and Materials, no. 8, 20 (2013) 705-712.

Valix M, Usai F & Malik V, Fungal bio-leaching of low grade lateritic ores, Minerals Engineering, no. 2, 14 (2001) 197-203.

Le L, Tang J, Ryan D & Valix M, Bioleaching nickel laterite ores using multi-metal tolerant Aspergillus foetidus organism, Minerals Engineering, no. 12, 19 (2006) 1259-1265.

Tzeferis PG, Leaching of a low grade hematitic laterite ore using fungi and biologically produced acid metabolites, International Journal of Mineral Processing, no. 3-4, 42 (1994) 267-283.

De Graff JE, The treatment of lateritic nickel ores — a further study of the Caron process and other possible improvements. Part I. Effect of reduction conditions, Hydrometallurgy, no. 1, 5 (1979) 47-65.

Safitri N, Mubarok Z, Winarko R & Tangela Z, Recovery of nickel and cobalt as MHP from limonitic ore leaching solution: Kinetics analysis and precipitate characterization, AIP conference proceedings 1964, 2018.

Mubarok MZ & Lieberto,a* J, Precipitation of Nickel Hydroxide from Simulated and Atmospheric-Leach Solution of Nickel Laterite Ore, Procedia Earth and Planetary Science, (2013) 457-464.

Williams C, Hawker W, Vaughan JW, Selective leaching of nickel from mixed nickel cobalt hydroxide precipitate, Hydrometallurgy, 138(2013) 84-92.

Virnig MJ & MacKenzie MJ, Process for the recovery of nickel, US Patent, 5,976,218 (1999).

Price MJ and Reid JG, Separation and recovery of nickel and cobalt in ammoniacal systems, US Patent, 5,174,812 (1992).

Donegon S, Direct solvent extraction of nickel at Bulong operations,” Minerals Engineering,19 (2006) 1234-1245.

Dreisinger DB & Cooper WC, The solvent extraction separation of cobalt and nickel using 2-ethylhexylphosphonic acid mono-2-ethylhexyl ester, Hydrometallurgy, no. 1, 12 (1984) 1-20.

Hatch WR, Cobalt ion echange process, U.S. Patent, 4,042,665 (1977).

Suetsuna A & Lio T, Process for separating and recovering nickel and cobalt, US Patent, US4004990 (1974)

Owusu G, Oxidation-precipitation of Co from Zn-Cd-Co-Ni sulphate solution using Caro's acid, Hydrometallurgy, no. 1, 48 (1998) 91-9.

Nishimura T & Umetsu Y, Separation of cobalt and nickel by ozone oxidation, Hydrometallurgy, no. 1-3, 30 (1992) 483-497.

Jebbink P, Stefan R, Neff D & Tomlinson M, Expanding the cobalt recovery circuit at the Thompson nickel refinery, The Journal of The Minerals, Metals & Materials Society, no. 10, 58 (2006) 37-42.

Van den Steen J, Kalala Polloni B & Shungu T, Developmnet of cobalt sulfate solution purification by sulfides precipitation, The Metallurgy Society, (1988) 493-504.

Boldt Jr. JR & Queneau P (Ed.), The winning of nickel, Longmans Canada Limited, Toronto, (1967) 290-387.

Chaudhary AJ, Donaldson JD, Grimes SM, Yasri NG, Separation of nickel from cobalt using electrodialysis in the presence of EDTA, Journal of Applied Electrochemistry, no.4, 30(2000) 439-45.

Cheng CY, Boddy G, Zhang W, Godfrey M …& Wang W, Recovery of nickel and cobalt from laterite leach solutions using direct solvent extraction: Part 1—selection of a synergistic SX system, Hydrometallurgy, no.1,104(2010) 45-52.

Agacayak T, Zedef V, Leaching of a Turkish lateritic nickel ore in nitric acid solution. In Mine Planning and Equipment Selection, Springer, Cham (2014) 1039-1045.

Agacayak T, Zedef V, Aras A, Kinetic study on leaching of nickel from Turkish lateritic ore in nitric acid solution, Journal of Central South University, no. 1 23(2016) 39-43.

Agatzini-Leonardou S, Oustadakis P, Dimaki D, Zafiratos J …& Drougas J, Heap Leaching of Greek Low-Grade Nickel Oxide Ores by Dilute Sulphuric Acid at a Pilot-Plant Scale, Materials Proceedings, no. 1,5(2021) 65.

MacCarthy J, Addai-Mensah J & Nosrati A, Atmoshperic acid leaching of siliceuos goethitic Ni laterite ore: Effect of solid loading and temperature, Minerals engineering, 69 (2014) 154-164..

Ma B, Yang W, Yang B, Wang C & Zhang Y, Pilot-scale plant study on the innovative nitric acid pressure leaching technology for laterite ores, Hydrometallurgy, 155 (2015) 88-94.

Acknowledgements

The authors are thankful to the management of Tata Steel Ltd., Jamshedpur, for the support and permission to publish this review.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pandey, N., Tripathy, S.K., Patra, S.K. et al. Recent Progress in Hydrometallurgical Processing of Nickel Lateritic Ore. Trans Indian Inst Met 76, 11–30 (2023). https://doi.org/10.1007/s12666-022-02706-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02706-2