Abstract

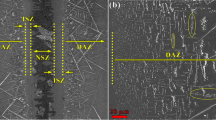

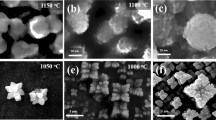

Laser powder deposition was performed on a substrate of Inconel 738 using blended powders of Mar M247 and Amdry DF3 with a ratio of 4:1 for repairing purposes. In the as-deposited condition, continuous secondary phases composed of γ-Ni3B eutectics and discrete (Cr, W)B borides were observed in inter-dendritic regions, and time-dependent nucleation simulation results confirmed that (Cr, W)B was the primary secondary phase formed during rapid solidification. Supersaturated solid solution of B was detected in the γ solid solution dendritic cores. The Kurz–Giovanola–Trivedi model was performed to predict the interfacial morphology and correlate the solidification front velocity (SFV) with dendrite tip radius. It was observed from high-resolution scanning electron microscopy that the dendrite tip radius of the upper region was in the range of 15 to 30 nm, which yielded a SFV of approx 30 cm/s. The continuous growth model for solute trapping behavior developed by Aziz and Kaplan was used to determine that the effective partition coefficient of B was approximately 0.025. Finally, the feasibility of the modeling results were rationalized with the Clyne–Kurz segregation simulation of B, where Clyne–Kurz prediction using a partition coefficient of 0.025 was in good agreement with the electron probe microanalysis results.

Similar content being viewed by others

References

J.N. DuPont, J.C. Lippold and S.D. Kiser: Welding metallurgy and weldability of nickel-base alloys, Wiley, Hoboken, N.J., 2009.

J.E. Flinkfeldt and T.F. Pedersen: Mater. Sci. Forum, 1994, vol. 163, pp. 423-428.

M. Riabkina-Fishman and J. Zahavi: Appl. Surf. Sci., 1996, vol. 106, pp. 263-267.

K. Banerjee, N.L. Richards and M.C. Chaturvedi: Metall. Mater. Trans. A, 2005, vol. 36, pp. 1881-1890.

D. Liu, J. Lippold, J. Li, S. Rohklin, J. Vollbrecht and R. Grylls: Metall. Mater. Trans. A, 2014, vol. 45, pp. 4454-4469.

L. Rickenbacher, T. Etter, S. Hövel and K. Wegener: Rapid Prototyping Journal, 2013, vol. 19, pp. 282-290.

Y. Nakao: Transactions of the Japan Welding Society, 1988, vol. 19, pp. 66-74.

C.Y. Su, C.P. Chou, B.C. Wu and W.C. Lih: J. Mater. Eng. Perform., vol. 6, pp. 619-627.

A.A. Lugan, P.A. Hilton, G.B. Melton and C. Rinaldi: In ICALEO 2006—25th International Congress on Applications of Laser and Electro-Optics, Congress Proceedings, (2006).

M.M.M. Ebrahimnia, F. Malek Ghaini and H.R. Shahverdi: Science Technology of Welding Joining, 2014, vol. 19, pp. 25-29.

B. Alexandrov, A. Hope, J. Sowards, J. Lippold and S. McCracken: Weld World, 2011, vol. 55, pp. 65-76.

J. Sowards, D. Liang, B. Alexandrov, G. Frankel and J. Lippold: Metall. Mater. Trans. A, 2012, vol. 43, pp. 1209-1222.

A.B. Goncharov, J. Liburdi and P. Lowden: Patent Application WO2014085892A1, 2012.

A.B. Goncharov, J. Liburdi and P. Lowden: Proceedings of ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, 2014.

Y. Tian, D. McAllister, H. Colijn, M. Mills, D. Farson, M. Nordin and S. Babu: Metall. Mater. Trans. A, 2014, vol. 45, pp. 4470-4483.

S. Li, Q. Wei, Y. Shi, Z. Zhu and D. Zhang: J. Mater. Sci. Technol., 2015, vol. 31, pp. 946-952.

W.J. Boettinger, L.A. Bendersky, S.R. Coriell, R.J. Schaefer and F.S. Biancaniello: Journal of Crystal Growth, 1987, vol. 80, pp. 17-25.

J.C. Baker and J.W. Gahn: Acta Metall., 1969, vol. 17, pp. 575-578.

P.M. Smith and M.J. Aziz: Acta Metall. et Mater., 1994, vol. 42, pp. 3515-3525.

M.J. Aziz: J. Appl. Phys., 1982, vol. 53, pp. 1158-1168.

M.J. Aziz, J.Y. Tsao, M.O. Thompson, P.S. Peercy and C.W. White: Phys. Rev. Lett., 1986, vol. 56, pp. 2489-2492.

P.M. Smith, R. Reitano and M.J. Aziz: In Materials Research Society Symposium Proceedings (1993), pp 749–754.

K. Eckler, R.F. Cochrane, D.M. Herlach and B. Feuerbacher: Mater. Sci. Eng., A, 1991, vol. 133, pp. 702-705.

K. Eckler, D.M. Herlach and M.J. Aziz: Acta Metall. et Mater., 1994, vol. 42, pp. 975-979.

M.J. Aziz and T. Kaplan: Acta Metall., 1988, vol. 36, pp. 2335-2347.

N.J. Harrison, I. Todd and K. Mumtaz: Acta Mater., 2015, vol. 94, pp. 59-68.

R.K. Sidhu, O.A. Ojo and M.C. Chaturvedi: Metall. Mater. Trans. A, 2007, vol. 38, pp. 858-870.

C.A. Schneider, W.S. Rasband and K.W. Eliceiri: Nature Methods, 2012, vol. 9, pp. 671-675.

D. Drouin, A.R. Couture, D. Joly, X. Tastet, V. Aimez and R. Gauvin: Scanning, 2007, vol. 29, pp. 92-101.

G.P. Dinda, A.K. Dasgupta and J. Mazumder: Mater. Sci. Eng., A, 2009, vol. 509, pp. 98-104.

F. Xu, Y. Lv, Y. Liu, B. Xu and P. He: Physics Procedia, 2013, vol. 50, pp. 48-54.

O.A. Ojo, N.L. Richards and M.C. Chaturvedi: Metall. Mater. Trans. A, 2006, vol. 37, pp. 421-433.

T.B. Massalski, H. Okamoto and A.S.M. International: Binary alloy phase diagrams, ASM International, Materials Park, Ohio, 1990.

G. Shao and P. Tsakiropoulos: Acta Metall. et Mater., 1994, vol. 42, pp. 2937-2942.

H. Jones: Philosophical Magazine B: Physics of Condensed Matter; Electronic, Optical and Magnetic Properties, 1990, vol. 61, pp. 487-509.

V.M. Azhazha, V.E. Semenenko and N.N. Pilipenko: Powder Metall. Met. Ceram., 2007, vol. 46, pp. 32-37.

C.W. Bale, P. Chartrand, S.A. Degterov, G. Eriksson, K. Hack, R. Ben Mahfoud, J. Melançon, A.D. Pelton and S. Petersen: Calphad, 2002, vol. 26, pp. 189-228.

F. Spaepen and D. Turnbull: in Laser Annealing of Semiconductors, J.M.P.W. Mayer, ed., Academic Press, New York, 1982, pp. 15–42.

S. Kou: In Welding Metallurgy, John Wiley & Sons, Inc., New York, pp. 37–64.

W. Kurz and D.J. Fisher: Acta Metall., 1981, vol. 29, pp. 11-20.

M.H. Burden and J.D. Hunt: J. Cryst. Growth, 1974, vol. 22, pp. 109-116.

S.A. David and J.M. Vitek: Int. Mater. Rev., 1989, vol. 34, pp. 213-245.

W.W. Mullins and R.F. Sekerka: J. Appl. Phys., 1964, vol. 35, pp. 444-451.

D.E. Hoglund, M.J. Aziz, S.R. Stiffler, M.O. Thompson, J.Y. Tsao and P.S. Peercy: J. Cryst. Growth, 1991, vol. 109, pp. 107–12.

W. Kurz, B. Giovanola and R. Trivedi: Acta Metall., 1986, vol. 34, pp. 823-830.

W.J. Boettinger and S.R. Coriell: in Science and Technology of the Undercooled Melt, P.R. Sahm, H. Jones and C.M. Adam, eds., Springer, New York, 1986, pp. 81–109.

E. Scheil: Z. Metallkd., 1942, vol. 34, pp. 70-72.

H.D. Brody and M.C. Flemings: Trans. AIME, 1966, vol. 236, pp. 615-623.

T.W. Clyne and W. Kurz: Metall. Trans. A, 1981, vol. 12, pp. 965-971.

D. Heard: Ph.D. Thesis, McGill University, Montreal, QC, 2013.

A. Lal, R.G. Iacocca and R.M. German: Journal of Materials Science, 2000, vol. 35, pp. 4507-4518.

Acknowledgment

The authors would like to acknowledge the support from Liburdi Turbine Service, particularly Dr. Alexandre Gontcharov and Dr. Paul Lowden for sample preparation and technical support. The authors would also like to acknowledge the McGill University Doctoral Award (MEDA) and NSERC for financial support. Finally the authors would like to thank Mr. Nicolas Brodusch for technical assistance and Dr. Manas Paliwal for fruitful discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 12, 2015.

Appendix A. Calculation of dendrite tip radius

Appendix A. Calculation of dendrite tip radius

The equation to estimate dendrite tip radius, as developed by Kurz and Fisher,[40] was calculated using Eq. [A.1]

where R is dendrite tip radius, λ is dendrite arm spacing, G is temperature gradient, and ΔT′ is the temperature difference between dendrite tip and non-equilibrium solidus, and

where T L and T S are liquidus and solidus temperature, respectively, ΔT* is tip undercooling and expressed in equation (A.3) at RSP,

where m is the slope of the liquidus line in the phase diagram and can be described as Eq. [11] for RSP, C0 is the nominal solute concentration, p is the complementary partition coefficient and displayed as 1 − k, k is effective partition coefficient, and

where V is SFV, γ is the Gibbs–Thompson coefficient, D is diffusion coefficient, and ΔT 0 = T L − T S.

Rights and permissions

About this article

Cite this article

Tian, Y., Gauvin, R. & Brochu, M. Microstructure Evolution and Rapid Solidification Behavior of Blended Nickel-Based Superalloy Powders Fabricated by Laser Powder Deposition. Metall Mater Trans A 47, 3771–3780 (2016). https://doi.org/10.1007/s11661-016-3505-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3505-8