Abstract

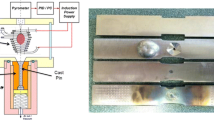

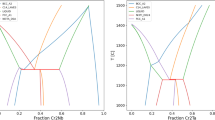

The solidification behaviour and weld solidification cracking susceptibility of high-Cr, Ni-base filler metals that are widely used, or proposed for use, in the nuclear power industry have been investigated. Two heats of ERNiCrFe-13 (filler metal 52MSS), one heat of ERNiCrFe-7A (filler metal 52M), and one heat of a modified ERNiCr-3 (filler metal 82 with higher Cr content, designated here as filler metal 52i) have been tested using both the Transvarestraint test and the Cast Pin Tear test (CPTT). The solidification behaviour in these alloys has been studied by a newly developed procedure that accurately replicates the solidification process in fusion welds of Ni-base alloys and is based on the patented technique for Single Sensor Differential Thermal Analysis (SS DTA™). Results of the solidification studies showed that filler metal 52i has the widest solidification range, followed by the two heats of filler metal 52MSS, and filler metal 52M. The filler metal 52i also has the widest eutectic temperature range. The interdendritic eutectic constituent formed in weld metal of this filler metal and filler metal 52MSS is enriched in Nb and results from the eutectic reaction of γ + L → γ + NbC at the end of solidification. Both the CPTT and the Transvarestraint test provided the same ranking of solidification cracking susceptibility among these filler metals. Both heats of 52MSS and the heat of 52i were found to be more susceptible to solidification cracking than filler metal 52M. The slightly higher resistance to solidification cracking of filler metal 52i relative to the 52MSS filler metals is attributed to crack “healing” during the final stages of solidification. This is the result of the higher fraction of eutectic liquid of filler metal 52i, as confirmed by metallographic studies. The results of this study confirm the higher solidification cracking susceptibility of high-Cr, Ni-base filler metals that contain higher Nb levels to counteract ductility-dip cracking, relative to filler metals that are Nb-free. This study has also shown that the CPTT can be used as an alternative, and reliable, tool for ranking the solidification cracking susceptibility of high-Cr, Ni-base filler metals proposed for use in nuclear power plants and other applications.

Similar content being viewed by others

References

EPRI Materials Reliability Program, Crack growth rates for evaluating primary water stress corrosion cracking of Alloy 82, 182, and 132 welds, MRP-115, Electric Power Research Institute, Palo Alto CA, 2004.

EPRI Materials Reliability Program, Technical basis for preemptive weld overlays for Alloy 82/182 butt welds in PWRs, MRP169 — Revision 1, Electric Power Research Institute, Palo Alto CA, 2008.

EPRI-NP-7085-D, Inconel weld overlay repair for low alloy steel nozzle to safe-end joint, Final Report, 1991.

Smith R.: Experiences with hot cracking in Alloy 52M overlays, Proceedings of Welding and Repair Technology for Power Plants, 8th International EPRI Conference, June 18–20, 2008, Sanibel Island, FL, 2008.

Lippold J.C. and NissleyN.E.: Ductility dip cracking in high-Cr, Ni-base filler metals, Hot Cracking Phenomena in Welds II, Springer, ISBN 978-3-540-78627-6, 2008, pp. 409-426.

Nissley N.E. and Lippold J.C.: Ductility-dip cracking susceptibility of nickel-based weld metals, Part 1: Strain-to-fracture testing, Welding Journal, 2008, vol. 87, no. 10, pp. 257s–264s.

Nissley N.E. and Lippold J.C.: Ductility-dip cracking susceptibility of nickel-based weld metals, Part 2: Microstructural Characterization, Welding Journal, 2009, vol. 88, no. 6, pp. 131s–140s.

Ramirez A.J. and Lippold J.C.: High temperature behavior of Ni-base weld metal: Part 1: Ductility and microstructural characterization, Materials Science and Engineering A, 2004, vol. 380, no. 1–2, pp. 259–271.

Ramirez A.J. and Lippold J.C.: High temperature behavior of Ni-base weld metal: Part 2: Insight into the mechanism for ductility dip cracking, Materials Science and Engineering A, 2004, vol. 380, no. 1–2, pp. 245–258.

DuPont J.N., Marder A.R., Notis M.R. and Robino C.V.: Solidification of Nb-bearing superalloys: Part II. Pseudoternary solidification surfaces, Metallurgical and Material Transactions A, 1988, vol. 29, no. 11, pp. 2797–2806.

DuPont J.N., Notis M.R., Marder A.R., Robino C.V and Michael J.R.: Solidification of Nb-bearing superalloys: Part I. Reaction sequences, Metallurgical and Material Transactions A, 1988, vol. 29, no. 11, pp. 2785–2796.

Young G.A, Capobianco T.E., Penik M.A., Morris B.W. and McGee J.J.: The mechanism of ductility dip cracking in nickel-chromium alloys, Welding Journal, 2008, vol. 87, no. 2, pp. 31s–43s.

Alexandrov B.T. and Lippold J.C.: Method and device for investigation of phase transformations in metals and alloys, United States Patent No. 7,473,028, January 6, 2009.

Alexandrov B.T., Lippold J.C., Tatman J.K. and Murray G.M.: Non-equilibrium phase transformation diagrams in engineering alloys, 8th International Trends in Welding Research Conference, ASM, Pine Mountain, GA, June 1–6, 2008.

Alexandrov B.T., Lippold J.C. and Nissley N.E.: Evaluation of weld solidification cracking in Ni-Base superalloys using the Cast Pin Tear Test, Proceedings, Hot Cracking Phenomena in Welds II, Berlin, Springer-Verlag, 2008, pp. 193–214.

Hull F.C.: Cast Pin Tear Test for susceptibility to hot cracking, Welding Journal, 1959, vol. 38, no. 4, pp. 176s–181s.

Finton T.L. and Lippold J.C.: Standardization of the Transvarestraint Test: A statistical study using austenitic stainless steels and nickel-base alloys, EWI Summary Report SR0402, January 2004.

DuPont J.N., Robino C.V. and Marder A.R.: Solidification and weldability of Ni-base superalloys, Welding Journal, 1988, vol. 77, pp. 417s–431s.

Lippold J.C., Sowards J.W., Murray G.M., Alexandrov B.T. and Ramirez A.J.: Weld solidification cracking in solid-solution strengthened Ni-Base filler metals, Proceedings, Hot Cracking Phenomena in Welds II, Berlin, Springer-Verlag, 2008, pp. 147–170.

Author information

Authors and Affiliations

Corresponding author

Additional information

Graduate Research Associate at OSU

Rights and permissions

About this article

Cite this article

Alexandrov, B.T., Hope, A.T., Sowards, J.W. et al. Weldability Studies of High-Cr, Ni-Base filler metals for power generation applications. Weld World 55, 65–76 (2011). https://doi.org/10.1007/BF03321288

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321288