Abstract

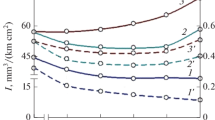

The paper compares the microstructure and tribotechnical characteristics of composite coatings of 70 wt.% Ni-20 wt.% Cr-5 wt.% Si-5 wt.% B. These coatings are produced by slip casting and unidirectional solidification. The coating composition is substantiated and coating restructuring mechanisms in the forming process are discussed. Natural composite Ni-Ni3B forms the basis of the coating. The fine lamellar eutectic, which occupies ∼50.5% of the coating, consists of Ni3B, a nickel solid solution doped with chrome and silicon, and CrB crystals. The microhardness of the coating and phase constituents are determined. The method of contact eutectic vacuum melting with controlled cooling permits obtaining the nonporous coating without slag inclusions and with homogeneous oriented structure. The mechanism of 3 to 5 times increase in the wear resistance of homogeneous nonporous coatings and their potential application in friction units of machinery are discussed.

Similar content being viewed by others

References

Proc. Int. Conf. on Modern Materials Science: Achievements and Problems, Vol. 2, Kiev (2005), pp. 515–605.

N. P. Brodnikovskii, A. V. Pauktovskii, T. L. Kurnetsova, et al., “Effect of electrospark alloying of steel 45 with ferrochromium on surface physical-chemical properties,” Prots. Lit’ya, No. 1, 101–105 (2005).

V. G. Starchak, S. D. Tsybulya, T. A. Gorbunova, et al., “Scientific principles of improving the durability, performance reliability, and safety of structural materials in corrosive environments,” Fiz. Khim. Mekh. Mater., 2, Issue 3, 738–741 (2202).

M. I. Pashechko, V. M. Golubets, and M. F. Cherepets, Formation and Friction Resistance of Eutectic Coatings [in Russian], Naukova Dumka, Kiev (1993).

V. E. Semenenko and G. P. Kovnun, “Specific features of homogeneous structures formation in heterophase metal-carbide system,” Functional Mater., 5, No. 2, 1–7 (1998).

M. V. Kindrachuk, Yu. A. Kunitsky, and O. I. Dudka, Structurization and Formation of the Tribotechnical Properties of Eutectic Coatings [in Ukrainian], Vyshcha Shkola, Kiev (1997).

V. E. Oliker and V. S. Kresanov, “Scandium-containing gamma titanium aluminide alloys and coatings for aerospace structural parts,” in: Advanced Materials and Processes for Gas Turbine (2003), pp. 293–300.

V. E. Semenenko, T. A. Kovalenko, and M. V. Tretiakov, “Effect of solidification conditions on the structure of nickel boride alloys,” Visn. Khark. Nats. Univ., Ser. Fiz.: Yadra, Chastynky, Polya, No. 619, 115–119 (2004).

F. J. Gotor, M. D. Alcala, et al., “Combustion synthesis of TiN induced by high-energy ball milling of Ti under nitrogen atmosphere,” J. Mater. Res., 17, No. 7, 16–63 (2002).

M. S. Kin and S. Watanabe, “Effect of grain size on strength, ductility and fracture in recrystallized Ni3Al doped with boron,” Trans. Jap. Inst. Mater., 38, No. 5, 235–248 (2002).

G. A. Baglyuk and L. A. Poznyak, “Powder metallurgy wear-resistant materials based on iron. Part I. Materials prepared by sintering and infiltration,” Powder Metall. Met. Ceram., 40, No. 1–2, 34–39 (2001).

V. V. Skorokhod, “Theory of the physical properties of porous and composite materials and the principles for control of their microstructure in manufacturing processes,” Powder Metall. Met. Ceram., 34, No. 1–2, 48–63 (1995).

V. I. Lutsyk and V. P Vorob’eva, “Heterogeneous design. Structural diagrams of ternary systems,” in: Material Research Society Proceeding, Vol. 804, Boston (2004), Paper 6.6.

I. M. Spiridonova and O. Yu. Bereza, “Pair phase growth in fast-cooled eutectic systems,” Metaloznav. Obrob. Met., No. 1–2, 18–23 (2002).

V. M. Azhazha, N. A. Azarenkov, V. E. Semenenkov, and V. A. Podzolkova, “Microstructure and strength of natural composites,” in: Proc. Int. Conf. on Modern Materials Science: Achievements and Problems, Vol. 1, Kiev (2005), pp. 15–16.

L. F. Kalinichenko, V. V. Lopat’ko, L. V. Zabolotny, et al., “Technique for the simultaneous friction and wear study of powder metallurgy materials, Powder Metall. Met. Ceram., 9, No. 3, 224–228 (1970).

Yu. N. Borisenko, V. T. Gritsyna, and N. A. Kasatkina, “Universal facility for measuring the adhesion of fine films,” Zavod. Lab., 49, No. 2, 55–56 (1983).

L. S. Opal’chuk and K. G. Lopat’mo, “Study of thermal saturation of steel with boron,” Metallofiz. Noveishie Tekhnol., No. 3, 39–41 (1997).

E. S. Umansky and B. A. Lyashenko, “Adhesion and cohesion strength balance of heat-resistant coatings,” in: Space Exploration in Ukraine, Issue 6, Kiev (1975), pp. 58–64.

M. O. Azarenkov, V. E. Semenenko, and M. M. Pilipenko, Modern Structural Materials: Composites, Khark. Nats. Univ., Kharkov (2004).

Author information

Authors and Affiliations

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Vol. 46, No. 1–2(453), pp. 40–47, 2007.

Rights and permissions

About this article

Cite this article

Azhazha, V.M., Semenenko, V.E. & Pilipenko, N.N. Ni-Ni3B composite coating. Powder Metall Met Ceram 46, 32–37 (2007). https://doi.org/10.1007/s11106-007-0006-8

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11106-007-0006-8