Abstract

A recently proposed “Projection-based Digital Volume Correlation” (P-DVC) method is extended in this work to a cone-beam lab-tomograph in which a mechanical test is performed. This consists of a crack propagation test in an elastic-brittle gypsum specimen. Kinematic analysis is performed based on a reduced finite element modeling for which the appropriate boundary conditions and crack propagation stage are determined from the radiographs. By considering only two projections per loading step, an integrated model-based analysis of the entire test provides a full space and time identification of the kinematics, including the crack position and the determination of two material parameters. This is achieved with a drastic reduction in the acquisition time compared to classical digital volume correlation analysis. In the examples presented, the acquisition time was reduced by a factor of 350.

Similar content being viewed by others

References

Maire E (2001) On the application of X-ray microtomography in the field of materials science. Adv Eng Mater 3(8):539–546

Salvo L, Cloetens P, Maire E, Zabler S, Blandin JJ, Buffière JY, Ludwig W, Boller E, Bellet D, Josserond C (2003) X-ray micro-tomography an attractive characterisation technique in materials science. Nuclear instruments and methods in physics research section B. Beam Interac Mater Atoms 200:273–286

Salvo L, Suéry M, Marmottant A, Limodin N, Bernard D (2010) 3D imaging in material science: application of X-ray tomography. Comptes Rendus Physique 11(9):641–649

Guvenilir A, Breunig TM, Kinney JH, Stock SR (1997) Direct observation of crack opening as a function of applied load in the interior of a notched tensile sample of AlLi 2090. Acta Materialia 45(5):1977–1987

Beckmann F, Grupp R, Haibel A, Huppmann M, Nöthe M, Pyzalla A, Reimers W, Schreyer A, Zettler R (2007) In-Situ synchrotron X-Ray microtomography studies of microstructure and damage evolution in engineering materials. Adv Eng Mater 9(11):939–950

Maire E, Withers PJ (2014) Quantitative X-ray tomography. Int Mater Rev 59(1):1–43

Toda H, Maire E, Yamauchi S, Tsuruta H, Hiramatsu T, Kobayashi M (2011) In situ observation of ductile fracture using X-ray tomography technique. Acta Mater 59(5):1995–2008

Vogelgesang M, Farago T, Morgeneyer TF, Helfen L, dos Santos Rolo T, Myagotin A, Baumbach T (2016) Real-time image-content-based beamline control for smart 4D X-ray imaging. J Synchrotron Radiat 23 (5):1254–1263

Ludwig O, Dimichiel M, Salvo L, Suéry M, Falus P (2005) In-situ three-dimensional microstructural investigation of solidification of an Al-Cu alloy by ultrafast X-ray microtomography. Metall Mater Trans A 36(6):1515–1523

Uesugi K, Hoshino M, Takeuchi A, Suzuki Y, Yagi N (2012) Development of fast and high throughput tomography using CMOS image detector at SPring-8

Maire E, Le Bourlot C, Adrien J, Mortensen A, Mokso R (2016) 20 Hz X-ray tomography during an in situ tensile test. Int J Fract 200(1):3–12

Bay BK, Smith TS, Fyhrie DP, Saad M (1999) Digital volume correlation: three-dimensional strain mapping using X-ray tomography. Exper Mech 39(3):217–226

Smith TS, Bay BK, Rashid MM (2002) Digital volume correlation including rotational degrees of freedom during minimization. Exp Mech 42(3):272–278

Hild F, Bouterf A, Chamoin L, Leclerc H, Mathieu F, Neggers J, Pled F, Tomičević Z, Roux S (2016) Toward 4D mechanical correlation. Adv Model Simul Eng Sci 3(1):17

Bouterf A, Adrien J, Maire E, Brajer X, Hild F, Roux S (2016) Failure mechanisms of plasterboard in nail pull test determined by X-ray microtomography and digital volume correlation. Exper Mech 56:1427–1437

Prade F, Fischer K, Heinz D, Meyer P, Mohr J, Pfeiffer F (2016) Time resolved X-ray dark-field tomography revealing water transport in a fresh cement sample. Sci Rep 6

White RT, Najm M, Dutta M, Orfino FP, Kjeang E (2016) Communication—effect of micro-XCT X-ray exposure on the performance of polymer electrolyte fuel cells. J Electrochem Soc 163(10):F1206–F1208

Hufenbach W, Böhm R, Gude M, Berthel M, Hornig A, Ručevskis S, Andrich M (2012) A test device for damage characterisation of composites based on in situ computed tomography. Compos Sci Technol 72(12):1361–1367

Zhang H, Toda H, Qu PC, Sakaguchi Y, Kobayashi M, Uesugi K, Suzuki Y (2009) Three-dimensional fatigue crack growth behavior in an aluminum alloy investigated with in situ high-resolution synchrotron X-ray microtomography. Acta Mater 57(11):3287–3300

Roth J, Eller J, Büchi FN (2012) Effects of synchrotron radiation on fuel cell materials. J Electrochem Soc 159(8):F449–F455

Leclerc H, Roux S, Hild F (2015) Projection savings in CT-based digital volume correlation. Exp Mech 55(1):275–287

Taillandier-Thomas T, Jailin C, Roux S, Hild F (2016) Measurement of 3D displacement fields from few tomographic projections. In: SPIE Photonics Europe. International Society for Optics and Photonics, p 98960

Taillandier-Thomas T, Roux S, Hild F (2016) A soft route toward 4D tomography. Phys Rev Lett 117 (2):025501

Khalili MH (2016) Tracking and modeling small motions at grain scale in granular materials under compression by X-Ray microtomography and discrete simulations. PhD thesis, Univ. Paris Est

Roux S, Hild F, Viot P, Bernard D (2008) Three-dimensional image correlation from X-ray computed tomography of solid foam. Compos Part A: Appl Sci Manuf 39(8):1253–1265

Taillandier-Thomas T, Roux S, Morgeneyer TF, Hild F (2014) Localized strain field measurement on laminography data with mechanical regularization. Nuclear Instrum Methods Phys Res Sect B Beam Inter Mater Atoms 324:70–79

Mathieu F, Leclerc H, Hild F, Roux S (2015) Estimation of elastoplastic parameters via weighted FEMU and integrated-DIC. Exper Mech 55(1):105–119

Bertin M, HILD F, Roux S, Mathieu F, Leclerc H, Aimedieu P (2016) Integrated digital image correlation applied to elasto-plastic identification in a biaxial experiment. J Strain Anal Eng Des 51(2):118–131

Besnard G, Guérard S, Roux S, Hild F (2011) A space–time approach in digital image correlation Movie-DIC. Opt Lasers Eng 49(1):71–81

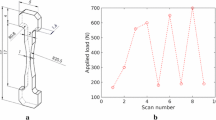

Janssen C (1977) Specimen for fracture mechanics studies on glass. Revue de Physique Appliquée 12(5):803–803

Célarié F, Prades S, Bonamy D, Ferrero L, Bouchaud E, Guillot C, Marliere C (2003) Glass breaks like metal, but at the nanometer scale. Phys Rev Lett 90(7):075504

Plaisted TA, Amirkhizi AV, Nemat-Nasser S (2006) Compression-induced axial crack propagation in DCDC polymer samples: experiments and modeling. Int J Fract 141(3-4):447–457

Fett T, Rizzi G, Guin JP, López-Cepero JM, Wiederhorn SM (2009) A fracture mechanics analysis of the double cleavage drilled compression test specimen. Eng Fract Mech 76(7):921–934

Pallares G, Ponson L, Grimaldi A, George M, Prevot G, Ciccotti M (2009) Crack opening profile in DCDC specimen. Int J Fract 156(1):11–20

Buffière J-Y, Maire E, Adrien J, Masse J-P, Boller E (2010) In situ experiments with X ray tomography: an attractive tool for experimental mechanics. Exper Mech 50(3):289–305

Van Aarle W, Palenstijn WJ, De Beenhouwer J, Altantzis T, Bals S, Batenburg KJ, Sijbers J (2015) The ASTRA Toolbox: a platform for advanced algorithm development in electron tomography. Ultramicroscopy 157:35–47

Coquard P, Boistelle R (1996) Thermodynamical approach to the brittle fracture of dry plasters. J Mater Sci 31(17):4573–4580

Meille S (2010) Etude du comportement mécanique du plâtre pris en relation avec sa microstructure. PhD thesis, INSA Lyon

He MY, Turner MR, Evans AG (1995) Analysis of the double cleavage drilled compression specimen for interface fracture energy measurements over a range of mode mixities. Acta Metall Mater 43(9):3453–3458

Acknowledgements

This work has benefited from the support of the French “Agence Nationale de la Recherche” through the “Investissements d’avenir” Program under the reference “ANR-10-EQPX-37 MATMECA”. We acknowledge Bumedijen Raka for his help in the ex situ pre-tests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jailin, C., Bouterf, A., Poncelet, M. et al. In situ μ CT-scan Mechanical Tests: Fast 4D Mechanical Identification. Exp Mech 57, 1327–1340 (2017). https://doi.org/10.1007/s11340-017-0305-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-017-0305-z