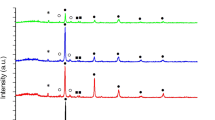

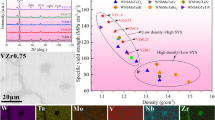

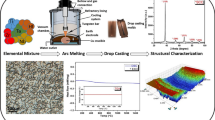

MoTaNbVxTi (x = 0.25, 0.50, and 0.75 at.%) refractory high-entropy alloys were synthesized via vacuum arc melting. The cross-sectional microstructural investigation revealed a Ti segregation tendency in the interdendritic area and a mostly homogeneous distribution of the rest elements in the dendritic parts. The calculated empirical models further verified the aforementioned microstructural evidence. Regarding the alloys’ mechanical investigation, both Vickers microhardness and Rockwell hardness estimations were escalated to values higher than those of the constituent elements, suggesting the operation of a solid solution strengthening mechanism. In terms of compression, the alteration of V content seemed to affect the alloys’ response, since the alloys with increased V content exhibited improved properties. The fracture surfaces presented cleavage/tearing characteristics, with the river-like patterns’ presence, defining their modes. In terms of their work-hardening rate, the alloys exhibited two regimes during the compression test due to possible changes in the deformation mechanisms. Finally, wear rate values verified that the harder the alloy (increased V content), the greater the wear resistance.

Similar content being viewed by others

References

Y. W. Yeh, S. K. Chen, S. U. J. Lin, et al., “Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes,” Adv. Eng. Mater., 6, 299–303 (2004).

C. Ng, S. Guo, J. Luan, et al., “Entropy-driven phase stability and slow diffusion kinetics in an Al0.5CoCrCuFeNi high entropy alloy,” Intermetallics, 31, 165–172 (2012).

S. Varalakshmi, M. Kamaraj, and B. S. Murty, “Processing and properties of nanocrystalline CuNiCoZnAlTi high entropy alloys by mechanical alloying,” Mater. Sci. Eng. A., 527, 1027–1030 (2010).

Y. Zhang, T. T. Zuo, Z. Tang, et al., “Microstructures and properties of high-entropy alloys,” Prog. Mater. Sci., 61, 1–93 (2014).

M. C. Troparevsky, J. R. Morris, P. R. C. Kent, et al., “Criteria for predicting the formation of single-phase high-entropy alloys,” Phys. Rev. X, 5, 011041-1–011041-6 (2015).

D. J. M. King, S. C. Middleburgh, A. G. McGregor, and M. B. Cortie, “Predicting the formation and stability of single phase high-entropy alloys,” Acta Mater., 104, 172–179 (2016).

O. Senkov and D. B. Miracle, “A new thermodynamic parameter to predict formation of solid solution or intermetallic phases in high entropy alloys,” J. Alloy. Compd., 658, 603–607 (2016).

M. C. Gao, J. W. Yeh, P. K. Liaw, and Y. Zhang, High-Entropy Alloys. Fundamentals and Applications, Springer (2016).

A. Shabani, M. R. Toroghinejad, A. Shafyei, and R. E. Loge, “Evaluation of the mechanical properties of the heat treated FeCrCuMnNi high entropy alloy,” Mater. Chem. Phys., 221, 68–77 (2019).

J. Gu and M. Song, “Annealing-induced abnormal hardening in a cold rolled CrMnFeCoNi high entropy alloy,” Scripta Mater., 162, 345–349 (2019).

J. T. Liang, K. C. Cheng, and S. H. Chen, “Effect of heat treatment on the phase evolution and mechanical properties of atomized AlCoCrFeNi high-entropy alloy powders,” J. Alloy. Compd., 803, 484–490 (2019).

X. Feng, K. Zhang, Y. Zheng, et al., “Effect of Zr content on structure and mechanical properties of (CrTaNbMoV)Zrx high-entropy alloy films,” Nucl. Instrum. Meth. B, 457, 56–62 (2019).

S. Elkatatny, M. A. H. Gepreel, A. Hamada, et al., “Effect of Al content and cold rolling on the microstructure and mechanical properties of Al5Cr12Fe35Mn28Ni20 high-entropy alloy,” Mater. Sci. Eng. A, 759, 380–390 (2019).

C. R. LaRosa, M. Shih, C. Varvenne, and M. Ghazisaeidi, “Solid solution strengthening theories of high-entropy alloys,” Mater. Charact., 151, 310–317 (2019).

H. Song, D. G. Kim, D. W. Kim, et al., “Effects of strain rate on room- and cryogenic-temperature compressive properties in metastable V10Cr10Fe45Co35 high-entropy alloy,” Sci. Rep., 9, 6163–6175 (2019).

J. M. Park, J. Moon, J. W. Bae, et al., “Strain rate effects of dynamic compressive deformation on mechanical properties and microstructure of CoCrFeMnNi high-entropy alloy,” Mater. Sci. Eng. A, 719, 155–163 (2018).

W. Li, G. Wang, S. Wu, and P. K. Liaw, “Creep, fatigue, and fracture behavior of high-entropy alloys,” J. Mater. Res., 33, 3011–3034 (2018).

S. H. Joo, H. Kato, M. J. Jang, et al., “Tensile deformation behavior and deformation twinning of an equimolar CoCrFeMnNi high-entropy alloy,” Mater. Sci. Eng. A, 689, 122–133 (2017).

L. Rogal, Z. Szklarz, P. Bobrowski, et al., “Microstructure and mechanical properties of Al–Co–Cr–Fe–Ni base high entropy alloys obtained using powder metallurgy,” Met. Mater. Int., 25, 930–945 (2019).

O. Senkov, C. Woodward, and D. Miracle, “Microstructure and properties of aluminum-containing refractory high-entropy alloys,” JOM, 66, 2030–2042 (2014).

M. Annasamy, N. Haghdadi, A. Taylor, et al., “Dynamic recrystallization behaviour of AlxCoCrFeNi high entropy alloys during high-temperature plane strain compression,” Mater. Sci. Eng. A, 745, 90–106 (2019).

R. Carroll, C. Lee, C. W. Tsai, et al., “Experiments and model for serration statistics in low-entropy, medium-entropy, and high-entropy alloys,” Sci. Rep., 5, 16997 (2015).

H. Y. Yasuda, K. Shigeno, and T. Nagase, “Dynamic strain aging of Al0.3CoCrFeNi high entropy alloy single crystals,” Scripta Mater., 108, 80–83 (2015).

M. Seifi, D. Li, Z. Yong, et al., “Fracture toughness and fatigue crack growth behavior of as-cast high-entropy alloys,” JOM, 67, 2288–2295 (2015).

K. V. S. Thurston, B. Gludovatz, A. Hohenwarter, et al., “Effect of temperature on the fatigue-crack growth behavior of the high-entropy alloy CrMnFeCoNi,” Intermetallics, 88, 65–72 (2017).

M. A. Hemphill, T. Yuan, G. Y. Wang, et al., “Fatigue behavior of Al0.5CoCrCuFeNi high entropy alloys,” Acta Mater., 60, 5723–5734 (2012).

P. Y. Chen, C. Lee, S. Y. Wang, et al., “Fatigue behavior of high-entropy alloys: A review,” Sci. China Tech. Sci., 61, 168–178 (2018).

S. Yang, Z. Liu, and J. Pi, “Microstructure and wear behavior of the AlCrFeCoNi high-entropy alloy fabricated by additive manufacturing,” Mater. Lett., 261, 127004 (2020).

J. K. Xiao, H. Tan, Y. Q. Wu, et al., “Microstructure and wear behavior of FeCoNiCrMn high entropy alloy coating deposited by plasma spraying,” Surf. Coat. Technol., 385, 125430 (2020).

Y. Zhang, S. G. Ma, and J. W. Qiao, “Morphology transition from dendrites to equiaxed grains for AlCoCrFeNi high-entropy alloys by copper mold casting and Bridgman solidification,” Metall. Mater. Trans. A, 43, 2625–2630 (2012).

A. Ludwig, I. Wagner, J. Laakmann, and P. R. Sahm, “Undercooling of superalloy melts: basis of a new manufacturing technique for single-crystal turbine blades,” Mater. Sci. Eng. A, 178, 299–303 (1994).

X. Yang and Y. Zhang, “Prediction of high-entropy stabilized solid-solution in multi-component alloys,” Mater. Chem. Phys., 132, 233–238 (2012).

O. N. Senkov, J. M. Scott, S. V. Senkova, et al., “Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy,” J. Alloy. Compd., 509, 6043–6048 (2011).

X. Yang, Y. Zhang, and P. K. Liaw, “Microstructure and compressive properties o NbTiVTaAlx high entropy alloys,” Procedia Engineer., 36, 292–298 (2011).

J. Joseph, N. Stanford, P. Hodgson, and D. M. Fabijanic, “Tension/compression asymmetry in additive manufactured face centered cubic high entropy alloy,” Scripta Mater., 129, 30–34 (2017).

D. H. Xiao, P. F. Zhou, W. Q. Wu, et al., “Microstructure, mechanical and corrosion behaviors of AlCoCuFeNi-(Cr,Ti) high entropy alloys,” Mater. Design, 116, 438–447 (2017).

D. Hull, “Interpretation of river line patterns on indentation generated fracture surfaces with comments on the fractal characteristics,” J. Mater. Sci. Lett., 15, 651–653 (1996).

J. T. Fan, L. J. Zhang, P. F. Yu, et al., “A novel high-entropy alloy with a dendrite-composite microstructure and remarkable compression performance,” Scripta Mater., 159, 18–23 (2019).

A. Rohatgi, K. S. Vecchio, and G. T. Gray, “The influence of stacking fault energy on the mechanical behavior of Cu and Cu-Al alloys: Deformation twinning, work hardening, and dynamic recovery,” Metall. Mater. Trans. A, 32, 135–145 (2001).

N. Kumar, Q. Ying, X. Nie, et al., “High strain-rate compressive deformation behavior of the Al0.1CrFeCoNihigh entropy alloy,” Mater. Design, 86, 598–602 (2015).

S. I. Rao, C. Varvenne, C. Woodward, et al., “Atomistic simulations of dislocations in a model BCC multicomponent concentrated solid solution alloy,” Acta Mater., 125, 311–320 (2017).

S. P. Wang, E. Mac, and J. Xu, “Notch fracture toughness of body-centered-cubic (TiZrNbTa)–Mo high entropy alloys,” Intermetallics, 103, 78–87 (2018).

M. M. Khruschov, “Principles of abrasive wear,” Wear, 28, 69–88 (1974).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 6, p. 124, November – December, 2021.

Rights and permissions

About this article

Cite this article

Poulia, A., Mathiou, C., Georgatis, E. et al. Microstructural Verification, Mechanical and Wear Analysis of MoTaNbVxTi Refractory High-Entropy Alloys. Strength Mater 53, 1011–1022 (2021). https://doi.org/10.1007/s11223-022-00368-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-022-00368-5