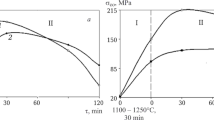

The effect of nonisothermal heating temperature in the range 1100 – 1500°C on shrinkage indices and and degree of cristobalitization is studied for quartz steel-pouring refractory specimens with a ceramic concrete structure. Cristobalite formed at elevated temperature has a reduced (150 – 220°C) transition temperature into the low-temperature form. Quartz steel-pouring refractories with a ceramic concrete structure have good thermal shock resistance, and in contrast to corundum-graphite refractories, requiring preliminary high-temperature heating, may operate without the latter (“cold start”).

Similar content being viewed by others

References

Yu. E. Pivinskii E. M. Grishpun, and A. M. Gorokhovskii, “Development of technology, manufacture, and service of molded and unmolded refractories based on HCBS,” Novye Ogneupory, No. 5, 29 – 39 (2015).

Yu. E. Pivinskii and P. V. Dyakin, “Research in the area of preparing materials based on fuzed quartz HCBS. Part 1. Comparative evaluation and distinguishing features of quarts ceramic and refractory technology,” Refract. Indust. Ceram., 55(4), 311 – 317 (2014).

Yu. E. Pivinskii, “Research in the area of preparing materials based on fuzed quartz HCBS. Part 2. Quartz steel–pouring refractories,” Refract. Indust. Ceram., 56(1), 20 – 25 (2015).

Yu. E. Pivinskii, “Research in the field of preparing materials based fuzed quartz HCBS. Part 3. Study and improvement of centrifugal molding processes,” Novye Ogneupory, No. 3, 79 – 90 (2015).

Yu. E. Pivinskii, I. B. Volchek, and E. V. Rozhkov, Inventor’s Cert. 165289, Method for molding ceramic objects, Claim 04.03.89, Publ. 02.08.91, Byul. No. 21.

I. B. Volchek, Yu. E. Pivinskii, E. M. Grishpun, and E. V. Rozhkov, Inventor’s Cert. 1628460, Method for molding steel-pouring nozzles, Claim 07.31.89, Publ. 10.15.90.

Yu. E. Pivinskii, E. M. Grishpun, and E. V. Rozhkov, Patent 2122534, Method for preparing cast steel-pouring refractory, Claim. 0.24. 97, Publ. 11.27.98, Byul. No. 33.

Yu. E. Pivinskii, E. M. Grishpun, E. V. Rozhkov, and M. Z. Naginskii, Patent 21009714, Method for manufacturing quartz steel-pouring refractories, Claim 02.27.97, Publ. 02.23.98, Byul. No. 12.

Yu. E. Pivinskii, E. M. Grishpun, E. V. Rozhkov, and M. Z. Naginskii, Patent 21009713, Method for preparing ceramic concrete steel-pouring nozzles, Claim. 02.27.97, Publ. 04.23.98, Byul. No. 12.

Yu. E. Pivinskii and E. M. Grishpun, Patent 2272012, Method for manufacturing quartz steel-pouring refractories, Claim. 08.22.05, Publ. 03.20.06, Byul. No. 8.

Yu. E. Pivinskii, E. M. Grishpun, and E. V. Rozhkov, Patent 2153481, Method for preparing ceramic concrete steel-pouring refractories, Claim 06.18.98, Publ. 07.27.00, Byul. No. 21.

Yu. E. Pivinskii and P. V. Dyakin, “Research in the field of preparing materials based on fuzed quartz HCBS. Part 4. Study of isothermal and nonisothermal sintering kinetics,” Novye Ogneupory, No. 4, 20 – 28 (2015).

Yu. E. Pivinskii and P. V. Dyakin, “Research in the field of preparing materials based on fuzed quartz HCBS. Part 5. Effect of sintering on material porosity and strength,” Novye Ogneupory, No. 6, 47 – 55 (2015).

Yu. E. Pivinskii and P. V. Dyakin “Research in the field of preparing materials based on fuzed quartz HCBS. Part 6. Effect of firing temperature on material sintering and christobalitization,” Novye Ogneupory, No. 7, 22 – 31 (2015).

Yu. E. Pivinskii, T. I. Litovskaya, O. N. Samarina, et al., “Centrifugal casting of ceramics. Main parameters and regularities of the process,” Refractories, 32(11), 551 – 558 (1991).

Yu. E. Pivinskii, T. I. Litovskaya, O. N. Samarina, et al., “Centrifugal casting of ceramics and properties of the castings,” Refractories, 33(3), 138 – 143 (1992).

Yu. E. Pivinskii and E. I. Suzdal’tsev, Quartz Ceramics Refractories in 2 Vol., Vol. 1. Theoretical Bases and Production Processes (Yu. E. Pivinskii, editor) [in Russian], Teploénergetik, Moscow (2008).

Yu. E. Pivinskii and E. I. Suzdal’tsev, Quartz Ceramics Refractories in 2 Vol., Vol. 2. Materials, Their Properties and Fields of Application (Yu. E. Pivinskii, editor) [in Russian], Teploenergetik, Moscow (2008).

Yu. E. Pivinskii, Ceramics and Refractory Materials, in 3 Vol., Vol. 2 [in Russian], Stroizdat SpB, St Petersburg (2003).

Yu. E. Pivinskii, Rheology of Dispersed Systems, HCBS, and Ceramic Concretes. Elements of Nanotechnology and Silicate Material Science, Sel. Work in 3 Vol [in Russian], Politekhnika, St. Petersburg (2012).

E. M. Grishpun and Yu. E. Pivinskii, “Twenty year epoch of cooperation,” Novye Ogneupory, No. 1, 15 – 25 (2007).

Yu. E. Pivinskii, A. M. Gorokhovskii. A. V. Makarov, “Record-breaking durability of quartz protecting tubes for steel teeming tested under service conditions,” Refract. Indust. Ceram., 46(1), 27 – 28 (2005).

T. I. Litovskaya, Yu. E. Pivinskii, F. S. Kaplan, et al., “Features of the thermophysical properties a highly concentrated ceramic binder suspension-base unfired quartz ceramic,” Refractories, 30(11/12), 701 – 705 (1990).

24. Yu. E. Pivinskii, Theoretical Aspects of Ceramic and Refractory Technology: Sel. Work Vol. 1 [in Russian], Stroizdat SpB, St Petersburg (2003).

Yu. E. Pivinskii and A. G. Romashin, Quartz Ceramics [in Russian], Metallurgiya, Moscow (1974).

I. E. Nishanova, R. Ya. Popil’skii, and I. Ya. Guzman, “Preparation of quartz glass objects by ceramic technology,” in: High-Temperature Materials, Coll. Work [in Russian], Metallurgiya, Moscow (1966).

Yu. E. Pivinskii, N. G. Kotova, and F. S. Kaplan, “Highly concentrated suspensions of nontransparent fused quartz and materials based on them,” Refractories, 27(5), 318 – 323 (1986).

Yu. E. Pivinskii, Chemistry and Technology of Silicate and Refractory Nonmetallic Materials [in Russian], Nauka, Leningrad (1989).

Yu. E. Pivinskii, Ceramic Binders and Ceramic Concretes [in Russian], Metallurgiya, Moscow (1990).

Author information

Authors and Affiliations

Corresponding author

Additional information

1Part 1 of the article was published in Novye Ogneupory No. 7 (2014), and parts 2 – 6 in Nos. 1, 3, 4, 6, and 7 (2015).

Translated from Novye Ogneupory, No. 9, pp. 16 – 24, September 2015.

Rights and permissions

About this article

Cite this article

Pivinskii, Y.E., Dyakin, P.V. Research in the Area of Preparing Materials Based on Fuzed Quartz HCBS. Part 7. Study of Centrifugally Molded Refractory Sintering and Cristobalitization1 . Refract Ind Ceram 56, 476–482 (2016). https://doi.org/10.1007/s11148-016-9872-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-016-9872-2