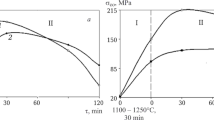

Isothermal and nonisothermal sintering are studied for castings based both on fuzed quartz suspensions with different fineness, and cast systems with a granular filler based on them. An effect is detected of considerable sintering of the test materials in the specimen heating stage (nonisothermal sintering) up to a final firing temperature of 1250°C. Depending on original specimen solid phase dispersion and particle grain size composition for the majority of materials their optimum properties are achieved after isothermal exposure for 0.5 – 1.0 h at 1250°C. Although exceeding it is accompanied by a certain reduction in porosity, it is connected with material weakening in view of the initial stage of christobalitization.

Similar content being viewed by others

References

Yu. E. Pivinskii and E. I. Sudal’tsev, Quartz Ceramics and Refractories, 2 Parts, Part1, Theoretical Bases and Production Processes (Yu. E. Pivinskii,, editor) [in Russian] Teploénergetika, Moscow (2008).

N. T. Andrianov, V. L. Balkevich, A. V. Belyakov, et al., Ceramic Chemical Technology, 2nd. Ed. (I. Ya. Guzman, editor) [in Russian], RIF Stroimetarialy, Moscow (2012).

V. S. Bakunov, E. V. Belyakov, E. S. Lukin, et al., Oxide Ceramics: Sintering and Creep [in Russian], D. I. Mendeleev RKhTU, Moscow (2007).

Y. E. Geguzin, Sintering Physics [in Russian], Nauka, Moscow (1967).

Yu. E. Pivinskii and E. I. Sudal’tsev, Quartz Ceramics and Refractories, 2 Parts, Part 2, Materials, Their Properties and Fields of Application [in Russian] Teploenergetika, Moscow (2008).

Yu. E. Pivinskii and A. G. Romashin, Quartz Ceramics [in Russian], Metallurgiya, Moscow (1974).

Yu. E. Pivinskii, “Effect of original semifinished product porosity and solid phase hydration on ceramic material sintering,” Ogneupory, No. 3, 14 – 21 (1985).

E. I. Sudal’tsev, “Properties of quartz ceramic,” Neorgan. Materialy, 20(2), 330 – 335 (1984).

Yu. E. Pivinskii, Theoretical Aspects of ceramic and Refractory Technology: in 3 Vol. Vol. 1 [in Russian], Stroizdat SpB, St. Petersburg (2003).

Yu. E. Pivinskii, Ceramic and Refractory Materials, in 3 Parts, Part 2 [in Russian], Stroizdat SpB, St. Petersburg (2003).

M. Z. Naginskii and L. A. Rechnova, Technology of Objects Made of Fuzed Quartz in Refractories for Industrial Furnaces and Boilers: Handbook [in Russian] Intermet Inzhiniring, Moscow (2000).

E. M. Grishpun and Yu. E. Pivinskii, “Twenty years epoch of cooperation,” Novye Ogneupory, No. 1, 15 – 25 (2007).

O. K. Botvinkin and A. I. Zaporozhskii, Quartz Glass [in Russian], Stroizdat, Moscow 91965).

M. V. Artamonova, M. S. Aslanova, I. M. Buzhinskii, et al., Chemical Technology of Glass and Glass Ceramic (N. M. Pavlushkin, editor) [in Russian], Stroizdat, Moscow (1983).

E. I. Sudal’tsev and A. A. Anashkina, “Analysis of methods for determining suspension fraction composition,” Novye Ogneupory, No. 4, 124 – 131 (2009).

Yu. E. Pivinskii, Rheology of Dispersed Systems, HCBS, and Ceramic Concretes. Elements of Nanotechnology and Silicate Materials Science, in 3 Vol. Vol. 3 [in Russian], Politekhnika, St. Petersburg (2012).

Yu. E. Pivinskii, F. S. Kaplan, S. G. Semikova, et al., “HCBS. Colloidal component and binder properties,” Ogneupory, No. 2, 13 – 18 (1989).

Yu. E. Pivinskii, “Thinning, plastifying and strengthening additives as effective modifiers in HCBS and ceramic concrete technology,” Refract. Indust. Ceram., 52(2), 21 – 23 (2011); 53(1), 12 – 18 (2012).

P. P. Budnikov, Yu. E. Pivinskii, and F. T. Gorobets, “Effect of sintering and crystallization of ceramic from fuzed quartz on its strength,” Dokl. Akad. Nauk SSSR, 180(6), 1411 – 1414 (1968).

P. P. Budnikov and Yu. E. Pivinskii, “Study of sintering fuzed quartz ceramic,” Zh. Prikl. Khim., No. 5, 957 – 964 (1968).

Yu. E. Pivinskii and F. T. Gorobets, “High-density fused-silica ceramics,” Refract. Indust. Ceram., 9(7/8), 509 – 516 (1968).

Yu. E. Pivinskii, “Research in the field of preparing materials based on fuzed quartz HCBS. Part 3. Study and improvement of centrifugal casting,” Novye Ogneupory. No. 3, 79 – 90 (2015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Part 1 of the article was published in Novye Ogneupory No. 7 (2014), and Parts 2 and 3 in Nos. 1 and 3 (2015).

Translated from Novye Ogneupory, No. 4, pp. 20 – 28, April, 2015.

Rights and permissions

About this article

Cite this article

Pivinskii, Y.E., Dyakin, P.V. Research in the Area of Preparing Materials Based on Fuzed Quartz HCBS. Part 4. Study of Isothermal and Nonisothermal Sintering Kinetics. Refract Ind Ceram 56, 172–179 (2015). https://doi.org/10.1007/s11148-015-9807-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-015-9807-3