Abstract

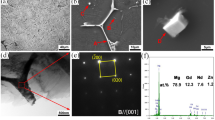

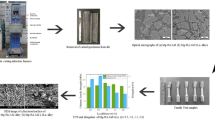

The effect of magnesium addition on the morphological, thermal, and mechanical features of conventionally and rapidly solidified Al-5.5 wt.%Zn-x wt.%Mg (x = 1, 5) samples were examined in this work. Al-5.5wt.%Zn-x wt.%Mg (x = 1, 5) samples were produced by the conventionally solidified graphite casting and rapid solidification by the melt-spinning method. The morphological and phase structures of the alloys were shown by field emission scanning electron microscopy and x-ray diffractometry. The melting temperatures were examined by differential thermal analysis in an Argon gas environment and the stress and microhardness characteristics of the conventionally solidified and melt-spun ribbons were determined by hardness and tensile strength tests. It was observed that the content of 5 wt.%Mg allowed a radical change in the conventionally solidified alloy morphologies, such as nano-sized dot shape Al12Mg17 particles and smaller sized square shaped MgZn2 particles. Moreover, the ultimate tensile strength, yield strength, and microhardness values of the rapidly solidified Al-5.5Zn-5Mg samples increased by approximately 20%. Finally, it was observed that the microstructural and mechanical properties, such as microhardness/stress values and grain size refinement, were improved with high wheel speeds.

Similar content being viewed by others

References

I. Polmear, Light Alloys: From Traditional Alloys to Nanocrystals, 4th ed., Butterworth-Hinemann, London, 2005

E. Acer, E. Cadirli, H. Erol, and M. Gunduz, Effect of Growth Rate on the Microstructure and Microhardness in a Directionally Solidified Al-Zn-Mg Alloy, Metall. Mater. Trans. A, 2016, 16, p 3484–3489

R. Ghiaasiaan, X. Zeng, and S. Shankar, Controlled Diffusion Solidification (CDS) of Al-Zn-Mg-Cu (7050): Microstructure, Heat Treatment and Mechanical Properties, Mater. Sci. Eng., A, 2014, 594, p 260–277

J.E. Hatch, Aluminum: Properties and Physical Metallurgy, Aluminum Association Inc. and ASM International, Cleveland, 1984

X. Zhang, W. Liu, S. Liu, and M. Zhou, Effect of Processing Parameters on Quench Sensitivity of an AA7050 Sheet, Mater. Sci. Eng., A, 2011, 528, p 795–802

E. Acer, E. Çadırlı, H. Erol, T. Kırındı, and M. Gündüz, Effect of Heat Treatment on the Microstructures and Mechanical Properties of Al-5.5Zn-2.5Mg Alloy, Mater. Sci. Eng., A, 2016, 662, p 144–156

P. Hidalgo-Manrique, A. Orozco-Caballero, C.M. Cepeda-Jimenez, O.A. Ruano, and F. Carreno, Influence of the Accumulative Roll Bonding Process Severity on the Microstructure and Superplastic Behaviour of 7075 Al Alloy, J. Mater. Sci. Technol., 2016, 32, p 774–782

R. Zuo, L.G. Hou, J.T. Shi, H. Cui, L.Z. Zhuang, and J.S. Zhang, The Mechanism of Grain Refinement and Plasticity Enhancement by an Improved Thermomechanical Treatment of 7055 Al Alloy, Mater. Sci. Eng., A, 2017, 702, p 42–52

D. Xu, Z. Li, G. Wang, X. Li, X. Lv, Y. Zhang, Y. Fan, and B. Xiong, Phase Transformation and Microstructure Evolution of an Ultra-High Strength Al-Zn-Mg-Cu Alloy During Homogenization, Mater. Charact., 2017, 131, p 285–297

T.G. Langdon, Twenty-Five Years of Ultrafine-Grained Materials: Achieving Exceptional Properties Through Grain Refinement, Acta Mater., 2013, 61, p 7035–7059

M. Furukawa, Z. Horita, M. Nemoto, R.Z. Valiev, and T.G. Langdon, Microhardness Measurements and the Hall-Petch Relationship in an Al–Mg Alloy with Sub-Micrometer Grain Size, Acta Mater., 1996, 44, p 4619–4629

S. Sabbaghianrad and T.G. Langdon, An Evaluation of the Saturation Hardness in an Ultrafine-Grained Aluminum 7075 Alloy Processed Using Different Techniques, J. Mater. Sci., 2015, 50, p 4357–4365

L. Couturier, A. Deschamps, F. De Geuser, F. Fazeli, and W.J. Poole, An Investigation of the Strain Dependence of Dynamic Precipitation in an Al-Zn-Mg-Cu Alloy, Scr. Mater., 2017, 136, p 120–123

B. Li, X.M. Wang, H. Chen, J. Hu, C. Huang, and G.Q. Gou, Influence of Heat Treatment on the Strength and Fracture Toughness of 7N01 Aluminum Alloy, J. Alloys Compd., 2016, 678, p 160–166

G. Sha and A. Cerezo, Early-Stage Precipitation in Al-Zn-Mg-Cu Alloy (7050), Acta Mater., 2004, 52, p 4503–4516

K. Wen, B. Xiong, Y. Zhang, Z. Li, X. Li, S. Huang, L. Yan, H. Yan, and H. Liu, Over-aging Influenced Matrix Precipitate Characteristics Improve Fatigue Crack Propagation in a High Zn-Containing Al-Zn-Mg-Cu Alloy, Mater. Sci. Eng., A, 2018, 716, p 42–54

L.K. Berg, J. Gjønnes, V. Hansen, X.Z. Li, M. Knutson-Wedel, G. Waterloo, D. Schryvers, and L.R. Wallenberg, GP-Zones in Al-Zn-Mg Alloys and Their Role Inartificial Aging, Acta Mater., 2001, 49, p 3443–3451

X. Wang, M. Guo, A. Chapuis, J. Luo, and J. Zhang, Effect of Solution Time on Microstructure, Texture and Mechanical Properties of Al-Mg-Si-Cu Alloys, Mater. Sci. Eng., A, 2015, 664, p 137–151

Y. He, Z. Jia, R.E. Sanders, Y. Liu, L. Ding, Y. Xing, and Q. Liu, Quantitative Study of Dissolution of Mg2Si During Solution Treatment in AA6014 Alloy, J. Alloys Compd., 2017, 703, p 272–279

Z. Chen, Y. Mo, and Z. Nie, Effect of Zn Content on the Microstructure and Properties of Super-High Strength Al-Zn-Mg-Cu Alloys, Metall. Mater. Trans. A, 2013, 44(8), p 3910–3920

M.L. Gerard and E.L. David, The Effect of Solute Content on the Slip Behavior in 7XXX Series Aluminum Alloys, Metall. Mater. Trans. A, 1981, 12A, p 2083–2091

E. Karaköse, A.M. Ibrahim, and M. Keskin, The Morphological Properties and Microhardness of As-Cast and Melt-Spun Al-5Zn-2.5Mg Alloy, J. Inorg. Organomet. Polym Mater., 2018, 28(6), p 2645–2652

F. Zupanic, G. Lojen, L. Barba, and T. Boncina, Effect of Cu on Rapidly Solidified Al-Mn-Be Alloy, Mater. Charact., 2012, 70, p 48–54

F. Zupanic, T. Boncina, A. Krizman, W. Grogger, C. Gspan, B. Markoli, and S. Spaic, Quasicrystalline Phase in Melt-Spun Al-Mn-Be Ribbons, J. Alloys Comp., 2008, 452, p 343–347

E. Karaköse and H. Çolak, Effect of Cooling Rate and Mg Addition on the Structural Evaluation of Rapidly Solidified Al-20 wt%Cu-12 wt%Fe Alloy, Mater. Charact., 2016, 121, p 68–75

R.M. Shalaby, M. Kamal, E.A.M. Ali, and M.S. Gumaan, Microstructural and Mechanical Characterization of Melt-Spun Process Sn–3.5Ag and Sn-3.5Ag-xCu Lead-Free Solders for Low Cost Electronic Assembly, Mater. Sci. Eng., A, 2017, 446, p 690

M. Kamal, A. El-Bediwi, A.R. Lashin, and A.H. El-Zarka, Room-Temperature Indentation Creep and the Mechanical Properties of Rapidly Solidified Sn-Sb-Pb-Cu Alloys, J. Mater. Eng. Perform., 2016, 25, p 2084–2090

L.L. Dobrzyńska, P. Ochin, A. Góral, M. Faryna, and J. Dutkiewicz, The Microstructure of Rapidly Solidified Al-Zn-Mg-Cu Alloys with Zr Addition, Solid State Phenom., 2010, 163, p 42–45

E.M. Ahmed, Microstructure Properties of Rapidly Solidified Al-Zn-Mg-Cu Alloys, Indian Journal of Materials Science, 2014, Article ID 353698.

K.M. Youssef, R.O. Scattergood, K.L. Murty, and C.C. Koch, Nanocrystalline Al-Mg Alloy with Ultrahigh Strength and Good Ductility, Scr. Mater., 2006, 54, p 251–256

L.A. Jacobson and J. McKittrick, Rapid Solidification Processing, Mater. Sci. Eng. Rep., 1994, 11, p 355–408

E. Karaköse, M. Yildiz, and M. Keskin, Response of Mg Addition on the Dendritic Structures and Mechanical Properties of Hypoeutectic Al-10Si (Wt. Pct.) Alloys, Metall. Mater. Trans. B, 2016, 47(4), p 2468–2478

Y. Xu, L. Ke, Y. Mao, Q. Liu, J. Xie, and H. Zeng, Formation Investigation of Intermetallic Compounds of Thick Plate Al/Mg Alloys Joint by Friction Stir Welding, Materials, 2019, 12, p 2661

E. Karaköse and M. Keskin, Effect of Mn Additions on the Microstructure and Microhardness of As-Cast and Rapidly Solidified Mg-5Ni-5Cu Alloy, J. Non Cryst. Solids, 2013, 367, p 70–81

H. Liang, S.L. Chen, and Y.A. Chang, A Thermodynamic Description of the Al-Mg-Zn System, Metall. Mater. Trans. A, 1997, 28, p 1725–1734

ASM International, ASM Handbook Volume 2, Properties and Selection: Nonferrous Alloys and Special Purpose Materials, ASM International, Cleveland, 1990

C. Pang, H. Luo, Z. Zhang, and Y. Ma, Precipitation Behavior and Grain Refinement of Burnishing Al-Zn-Mg Alloy, Prog. Nat. Sci. Mater. Int., 2018, 28, p 54–59

G. Chen, L. Chen, G. Zhao, and C. Zhang, Microstructure Evolution During Solution Treatment of Extruded Al-Zn-Mg Profile Containing a Longitudinal Weld Seam, J. Alloys Compd., 2017, 729, p 210–221

S. Abdi, M. Samadi Khoshkhoo, O. Shuleshova, M. Bönisch, M. Calin, L. Schultz, J. Eckert, M.D. Baró, J. Sortd, and A. Gebert, Effect of Nb Addition on Microstructure Evolution and Nano Mechanical Properties of a Glass-Forming Ti-Zr-Si Alloy, Intermetallics, 2014, 46, p 156–163

J. Zuo, L. Hou, J. Shi, H. Cui, L. Zhuang, and J. Zhang, Enhanced Plasticity and Corrosion Resistance of High Strength Al-Zn-Mg-Cu Alloy Processed by an Improved Thermomechanical Processing, J. Alloys Compd., 2017, 716, p 220–230

G. Chen, L. Chen, G. Zhao, C. Zhang, and W. Cui, Microstructure Analysis of an Al-Zn-Mg Alloy During Porthole Die Extrusion Based on Modeling of Constitutive Equation and Dynamic Recrystallization, J. Alloys Compd., 2017, 710, p 80–91

N. Takata, T. Okano, A. Suzuki, and M. Kobashi, Microstructure of Intermetallic-Reinforced Al-Based Alloy Composites Fabricated Using Eutectic Reactions in Al-Mg-Zn Ternary System, Intermetallics, 2018, 95, p 45–48

X. Yongqian, Z. Lihua, L. Shujian, and W. Xintong, Effect of Stress-Aging Treatments on Precipitates of Pre-retrogressed Al-Zn-Mg-Cu Alloy, Rare. Metal. Mater. Eng., 2017, 46(2), p 355–362

C. Meng, D. Zhang, L. Zhuang, and J. Zhang, Correlations Between Stress Corrosion Cracking, Grain Boundary Precipitates and Zn Content of Al-Mg-Zn Alloys, J. Alloys Compd., 2016, 655, p 178–187

K. Zhang, J.Q. Chen, P.Z. Ma, and X.H. Zhang, Effect of Welding Thermal Cycle on Microstructural Evolution of Al-Zn-Mg-Cu Alloy, Mater. Sci. Eng., A, 2018, 717, p 85–94

L. Wu and W.G. Ferguson, Modelling of Precipitation Hardening in Casting Aluminium Alloys, Aluminium Alloys, Theory and Applications, T. Kvackaj, Ed., Intech, Rijeka, 2011, p 307–330

A. Deschamps, G. Fribourg, Y. Bréchet, J.L. Chemin, and C.R. Hutchinson, In Situ Evaluation of Dynamic Precipitation During Plastic Straining of an Al-Zn-Mg-Cu Alloy, Acta Mater., 2012, 60(5), p 1905–1916

M. Dumont, W. Lefebvre, B. Doisneau-Cottignies, and A. Deschamps, Characterisation of the Composition and Volume Fraction of η′ and η, Precipitates in an Al-Zn-Mg Alloy by a Combination of Atom Probe, Small-Angle X-Ray Scattering and Transmission Electron Microscopy, Acta Mater., 2005, 53(10), p 2881–2892

E. Karaköse and M. Keskin, Structural Investigations of Mechanical Properties of Al Based Rapidly Solidified Alloys, Mater. Des., 2011, 32(10), p 4970–4979

K. Park, J. Park, and H. Kwon, Effect of Intermetallic Compound on the Al-Mg Composite Materials Fabricated by Mechanical Ball Milling and Spark Plasma Sintering, J. Alloys Compd., 2018, 739, p 311–318

M. Furukawa, A. Utsunomiya, K. Matsubara, Z. Horita, and T.G. Langdon, Influence of Magnesium on Grain Refinement and Ductility in a Dilute Al-Sc Alloy, Acta Mater., 2001, 49(18), p 3829–3838

Y. Wang, X. Zeng, and W. Ding, Effect of Al-4Ti-5B Master Alloy on the Grain Refinement of AZ31 Magnesium Alloy, Scr. Mater., 2006, 54(2), p 269–273

Acknowledgments

This study was financed by Erciyes University Research Fund, Grant No. FYL-2017-7348 and Çankırı Karatekin University Research Fund, Grant No: FF200217B31.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Karaköse, E., Çolak, H. & Keskin, M. The Effect of Magnesium Additions on Microstructural, Thermal, and Mechanical Properties of Rapidly Solidified Al-5.5wt.%Zn-x wt.%Mg (x = 1, 5) Alloys. J. of Materi Eng and Perform 29, 7308–7320 (2020). https://doi.org/10.1007/s11665-020-05246-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05246-2