Abstract

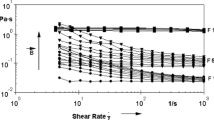

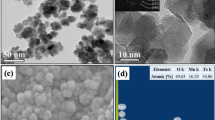

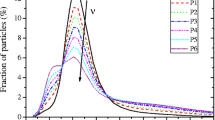

A magnetorheological fluid hybrid material (MRF122) was investigated for determining the thermal stability, rheological and morphological properties, in order to employ further these properties to design a spherical joint system that uses this fluid. To improve the rheological properties of the magnetorheological fluid, an energization program was applied, by introducing it into a magnetic field with a magnetic induction of 0.37 T, for 5 days. The thermal analysis established that MRF122 and the energized-MRF122 are stable up to 175 °C, above this temperature continuing with an oxidative decomposition of the liquid hydrocarbon mixture in which the ferromagnetic microcrystals are suspended; six exothermic stages of oxidation and structural transitions of iron and of its oxides follow. At over 900 °C, magnetite (majority) and siderite phases are formed. Rheological measurements show that the viscosity of both samples decreases with increasing shear rate, and throughout the shear rate range, the viscosity of the energized MRF122 sample is lower than that of the MRF122 sample. When the magnetic field is applied for the energization, the agglomerations of ferromagnetic nanoparticles in MRF122 probably disperse. Both fluid samples have non-Newtonian pseudo-plastic behaviour (viscosity decreases with increasing shear rate). By determining the storage modulus and the loss modulus as a function of the increasing angular frequency, the elastic properties of MRF122 decrease, while the plastic properties increase (as well as the tangent of the loss factor).

Similar content being viewed by others

References

Yao J, Zhang J, Peng Z, Zhang G. Influence of fe content and particle size of carbonyl iron powder on shear yield stress of magnetorheological fluids. Chin J Mat Res. 2014;28:955–60.

Isnikurniawan A, Kuroiwa J, Abell S, Sawada T. Investigation of cluster growth in MR fluids using ultrasonic wave propagation. J Phys Conf Ser. 2013;412:012019.

Horak W, Szczech M, Sapinski B. Magnetorheological fluids behavior in oscillatory compression squeeze: experimental testing and analysis. Acta Mech et Automat. 2019;13:221–5.

Pisuwala M, Upadhyay RV, Parekh K. Evaluation of static and dynamic yield stress for isotropic and anisotropic particle–based MR fluids: Modeling and analysis. Brazil J Phys. 2020;50:399–409.

Delivorias RP. Research on smart materials: Application of ER and MR fluid in an automotive crash energy absorber. Report no. MT04.18. Eindhoven University of Technology, Department of Mechanical Engineering, Automotive Engineering - Vehicle Safety. Eindhoven, March 16, 2004.

Mangal SK, Sharma V. Evaluation of magnetic flux density of MR Fluid by different approaches. In: Proc of the World Congress on Engineering 2016 Vol II WCE 2016, June 29–July 1, 2016, London, U.K.

Schwartz M. Smart materials. Taylor and Francis Group, Boca Raton, New York: CCR Press; 2009.

Zubieta M, Eceolaza S, Elejabarrieta MJ, Bou-Ali MM. Magnetorheological fluids: characterization and modeling of magnetization. Smart Mater Struct. 2009;18:095019.

Adjerid K. A study on the dynamic characterization of a tunable magnetorheological fluid-elastic mount in squeeze mode vibration. Thesis Master of Science in Mechanical Engineering. Virginia Polytechnic Institute and State University. 2011, Blacksburg, Virginia.

Urreta H, Aguirre G, Lopez de Lacalle LN. Hydrostatic journal bearing and pressurized seals for machine tool spindles based on active magnetic fluids: magnetorheological fluids and ferrofluids. In: Euspen’s 18th International Conference & Exhibition, Venice, IT June 2018.

Kubík M, Macháček O, Strecker Z, Roupec J, Mazůrek I. Hydraulic resistance of magnetorheological damper viscous bypass gap. In: 22nd international conference engineering mechanics 2016, Svratka, Czech Republic, 9–12 May 2016.

Kubík M, Macháček O, Mazůrek I. A study of hydraulic resistance of viscous bypass gap in magnetorheologi-cal damper. Acta Univ Agric et Silviculturae Mendelianae Brunensis. 2016;64:1199–203.

Urreta H, Leicht Z, Sanchez A, Agirre A, Kuzhir P, Magnac G. Hydrodynamic bearing lubricated with magnetic fluids. J Phys. 2009;149:012113.

Nguyen QH, Choi SB. Optimal design of a novel hybrid MR brake for motorcycles considering axial and radial magnetic flux. Smart Mater Struct. 2012;21:055003.

Xin DK, Nie SL, Ji H, Yin FL. Characteristics, optimal design, and performance analyses of MRF damper. Shock Vib. 2018;2018:1–17.

El Wahed AK, Wang HC. Performance evaluation of a magnetorheological fluid damper using numerical and theoretical methods with experimental validation. Front Mater. 2019;6:27.

Martins da Costa EL. Construction of a magnetorheological damper for an active suspension. Instituto Superior Técnico, Lisboa, Portugal: Technical University of Lisbon; 2018.

Tran Hai NAM, Kyoung Kwan AHN. New approach to designing an MR brake using a small steel roller and MR fluid. J Mech Sci Technol. 2009;23:1911–23.

Kim JN, Dong YZ, Choi HJ. Pickering emulsion polymerized polyaniline/zinc-ferrite composite particles and their dual electrorheological and magnetorheological responses. ACS Omega. 2020;5:7675–82.

Mangal SK, Sharma V. Multi-parameter optimization of magnetorheological fluid with high on-state yield stress and viscosity. J Braz Soc Mech Sci Eng. 2017;39:4191–206.

El Wahed AK, Balkhoyor LB. The performance of a smart ball-andsocket actuator applied to upper limb rehabilitation. J Intel Mat Syst Struct. 2018;29:2811–22. https://doi.org/10.1177/1045389X18780349.

Mangal SK, Sharma V. On state rheological characterization of MRF 122EG fluid using various techniques. Mater Today Proc. 2017;4:637–44.

Roupec J, Jeniš F, Strecker Z, Michal Kubík M, Machácek O. Stribeck curve of magnetorheological fluid within pin-on-disc configuration: an experimental investigation. Materials. 2020;13:4670.

Quoc NV, Tuan LD, Hiep LD, Quoc HN, Choi SB. Material characterization of MR fluid on performance of MRF based brake. Front Mater. 2019;6:125.

Bou-ali M, Elejabarrieta M, Zubieta M. Magnetorheological fluids: characterization and modeling of magnetization. Smart Mater Struct. 2009;18:095019.

Rudnick LR. Synthetics, mineral oils, and bio-based lubricants: chemistry and Technology. New York: Taylor and Francis Group; 2006.

Delivorias RP. Research on smart materials: Application of ER and MR fluid in an automotive crash energy absorber. Report no. MT04.18, Eindhoven: Eindhoven University of Technology; 2004.

Carlson JD. MR fluids and devices in the real world. Int J Mod Phys B. 2005;19:1463–70.

Ivănescu M, Stoian V. A sequential distributed variable structure controller for a tentacle arm. In: Proc of the IEEE-ICRA, Minneapolis, USA, 1996;4:3701-6

Vladu I, Strimbeanu D, Ivănescu, M, Bîzdoacă N, Vladu C, Florescu M. Control system for a hyper-redundant robot – INCOM’12 – Bucharest, 2012.

Vladu IC, Stoian V, Vladu I, Strîmbeanu D, Sensorial system for HYPER-REDUNDANT ARM, Sinaia, Romania, 18th International Conference on System Theory, Control and Computing (ICSTCC), 2014.

Yi SY. A robust Fuzzy logic controller for robot manipulators. IEEE Trans Syst Man Cybern. 1997;27:706–13.

Ivănescu M, Stoian V, Bîzdoacă N. A Robust FLC for Cooperative Robots, In: Pro-ceedings of CSCS12, 1999;1:281−6, Bucharest.

Thiagarajan S, Koh AS. Performance and stability of magnetorheological fluids—a detailed review of the state of the art. Adv Eng Mater. 2021;23:2001458.

Chen S, Yang J. Probing slip differential heat of magnetorheological fluids subjected to shear mode operation and its effect on the structure. Materials. 2019;12:1860.

Rabbani Y, Hajinajaf N, Tavakoli O. An experimental study on stability and rheological properties of magnetorheological fluid using iron nanoparticle core–shell structured by cellulose. J Therm Anal Calorim. 2019;135:1687–97.

Hanif H, Khan I, Shafiee S. Heat transfer exaggeration and entropy analysis in magneto-hybrid nanofluid flow over a vertical cone: a numerical study. J Therm Anal Calorim. 2020;141(5):2001–17.

Lazzara G, Cavallaro G, Di Blasi F, Lazzara G, Massaro M, Milioto S, Parisi F, Riela S, Spinelli G. Halloysite nanotubes loaded with peppermint essential oil as filler for functional biopolymer film. Carbohydrate Polym. 2016;152:548–57.

Degeratu S, Subțirelu GE, Rotaru A, Bîzdoacă NG, Rotaru P. The electro-mechanical control of element NiTi shape memory alloy strip while bending, based on thermal analysis evidence. J Therm Anal Calorim. 2021;143:3805–15.

Corbu AR, Rotaru A, Nour V. Edible vegetable oils enriched with carotenoids extracted from byproducts of sea buckthorn (Hippophae rhamnoides ssp. sinensis): the investigation of some characteristic properties, oxidative stability and the effect on thermal behavior. J Therm Anal Calorim. 2020;142:735–47.

Rotaru A. Thermal and kinetic study of hexagonal boric acid versus triclinic boric acid in air flow. J Therm Anal Calorim. 2017;127:755–63.

Carabet CA, Moanță A, Pălărie I, Iacobescu G, Rotaru A, Leulescu M, Popescu M, Rotaru P. Physical, thermal and biological properties of yellow dyes with two azodiphenylether groups of anthracene. Molecules. 2020;25:5757.

Rotaru A, Brătulescu G, Rotaru P. Thermal analysis of azoic dyes: part I. Non-isothermal decomposition kinetics of [4-(4-chlorobenzyloxy)-3-methylphenyl](p-tolyl) diazene in dynamic air atmosphere. Thermochim Acta. 2009;489:63–9.

Leulescu M, Rotaru A, Pălărie I, Moanță A, Cioateră N, Popescu M, Morîntale E, Bubulică MV, Florian G, Hărăbor A, Rotaru P. Tartrazine: physical, thermal and biophysical properties of the most widely employed synthetic yellow food-colouring azo dye. J Therm Anal Calorim. 2018;134:209–31.

Leulescu M, Pălărie I, Moanță A, Cioateră N, Popescu M, Morîntale E, Văruț MC, Rotaru P. Brown HT Physical, thermal and biophysical properties of the food azo dye. J Therm Anal Calorim. 2019;136:1249–68.

Leulescu M, Rotaru A, Moanță A, Iacobescu G, Pălărie I, Cioateră N, Popescu M, Criveanu MC, Morîntale E, Bojan M, Rotaru P. Azorubine: physical, thermal and bioactive properties of the widely employed food, pharmaceutical and cosmetic red azo dye material. J Therm Anal Calorim. 2021;143:3945–67.

Pascu CI, Gheorghe Ș, Rotaru A, Nicolicescu C, Cioateră N, Roșca AS, Sârbu D, Rotaru P. Ti-based composite materials with enhanced thermal and mechanical properties. Ceram Int. 2020;46:29358–72.

Nenițescu CD. Organic chemistry, vol. 1. Bucharest: Technical Publishing House; 1960.

Hammond EG, Johnson LA, Murphy PA. SOYBEAN | Grading and Marketing. In Encyclopedia of Grain Science, Amsterdam, The Netherlands: Elsevier, 2004; 155–9.

Pometescu N, Negrea M, Rotaru P. The anomalous particle flux induced by electromagnetic turbulence. Plasma Phys Control Fusion. 1998;40:1383–98.

Nguyen QH, Choi SB. Selection of magnetorheological brake types via optimal design considering maximum torque and constrained volume. Smart Mater Struct. 2012;21:015012.

Negrea M. Diffusion of stochastic magnetic field lines with average poloidal component. Plasma Phys Control Fusion. 2019;61:065004.

O’Flynn TD, Hogan SA, Daly DFM, O’Mahony JA, McCarthy NA. Rheological and solubility properties of soy protein isolate. Molecules. 2021;26:3015.

Adachi M, Chunying H, Utsumi S. Effects of designed sulfhydryl groups and disulfide bonds into soybean proglycinin on its structural stability and heat-induced gelation. J Agric Food Chem. 2004;52:5717–23.

Heirman G, Hendrickx R, Vandewalle L, Van Gemert D, Feys D, De Schutter G, Desmet B, Vantommec J. Integration approach of the Couette inverse problem of powder type self-compacting concrete in a wide-gap concentric cylinder rheometer: Part II. Influence of mineral additions and chemical admixtures on the shear thickening flow behaviour. Cement Concrete Res. 2009;39:171–81.

Morel M, Martinez F, Mosquera E. Synthesis and characterization of magnetite nanoparticles from mineral magnetite. J Magn Magn Mater. 2013;343:76–81.

Hurlbut CS, Klein C. Manual of mineralogy. 20th ed. Hoboken: Wiley; 1985.

Pârvu G. Minerals and rocks. Bucharest: Scientific and Encyclopedic Publishing House; 1983.

Acknowledgements

The authors express their gratitude and thanks to the Mr. Eng. Albert Istvan, the director of SC ROFAROM SRL, the representative of Anton Paar in Romania, for his support in performing rheological measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sârbu, D., Bîzdoacă, N.G., Cioateră, N. et al. Thermal stability, rheological and morpho-structural properties of the magnetorheological fluid MRF122 employed in spherical joint mechanisms. J Therm Anal Calorim 148, 1289–1308 (2023). https://doi.org/10.1007/s10973-022-11461-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11461-x