Abstract

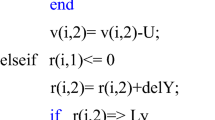

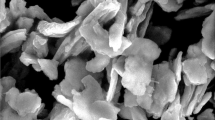

Structural deformation in the low shear rate region that is an undeformed state is investigated for the isotropic and anisotropic magnetic particle–based magnetorheological (MR) fluid. Flow curves were obtained for both MR fluids between 0.1 s−1 and 500 s−1 in the absence and in the presence of magnetic fields. A model to describe the flow behavior over the full shear rate study is proposed. The proposed model accounts for the friction contribution coming from particle-particle as well as particle-carrier interactions of anisotropic particles particularly in flake-shaped particles. The parameters derived from the fit have physical meaning, and it correlates with the observed dependency in rheology study. To get a better understanding of particle-particle friction contribution, magnetic nanoparticles were added in the MR fluid and flow behavior is studied. The study clearly demonstrates the contribution of particle-particle friction on the MR properties. The contribution of particle-carrier friction, due to the shape of the particle, is verified by comparing the result with spherical-shaped particle–based MR fluid.

Similar content being viewed by others

References

A. Khanicheh, D. Mintzopoulos, B. Weinberg, A. Tzika, C. Mavroidis, Evaluation of electrorheological fluid dampers for applications at 3-T MRI environment. IEEE-ASME Trans Mechatron. 13(3), 286–294 (2008)

S.B. Choi, D.Y. Lee, Rotational motion control of a washing machine using electrorheological clutches and brakes. Proc. Inst. Mech. Eng. Part C 219, 627–637 (2005)

J. Nikitczuk, B. Weinberg, C. Mavroidis, Control of electrorheological fluid based resisitive torque elements for use in active rehabilitation devices. Smart Mater. Struct. 16, 418–428 (2007)

X. Niu, L. Liu, W. Wen, P. Sheng, Microfluidic manipulation in lab-chips using electrorheological fluid. J. Intell. Mater. Syst. Struct. 18, 1187–1190 (2007)

Magnetorhology Advances and Applications, Ed. Norman Werely, RSC Pub (2014)

S.T. Lim, M.S. Cho, I.B. Jang, H.J. Choi, Magnetorheological characterization of carbonyl iron based suspension stabilized by fumed silica. J. Magn. Magn. Mater. 282, 170–173 (2004)

J. Goldasz, B. Sapinski, Nondimensional characterization of flow-mode magnetorheological/electrorheological fluid dampers. J. Intell. Mater. Syst. Struct. 23(14), 1545–1562 (2012)

W.P. Wu, B.Y. Zhao, Q. Wu, L.S. Chen, K.A. Hu, The strengthening effect of guar gum on the yield stress of magnetorheological fluid. Smart Mater. Struct. 15(4), N94 (2006)

S.H. Ha, M.S. Seong, S.B. Choi, Design and vibration control of military vehicle suspension system using magnetorheological damper and disc spring. Smart Mater. Struct. 22(6), 65006 (2013)

M.R. Jolly, J.W. Bender, J.D. Carlson, Properties and applications of commercial magnetorheological fluids. J. Intell. Mater. Syst. Struct. 10(1), 5–13 (1999)

B.J. Park, F.F. Fang, H.J. Choi, Magnetorheology: materials and application. Soft Matter 6(21), 5246–5253 (2010)

P.P. Phule, Magnetorheological (MR) fluids: principles and applications. Smart Mater. Bull. 2, 7–10 (2001)

J. Wang, G. Meng, Magnetorheological fluid devices: principles, characteristics and applications in mechanical engineering. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 215(3), 165–174 (2001)

W.H. Li, H. Du, N.Q. Guo, P.B. Kosasih, Magnetorheological fluids based haptic device. Sens. Rev. 24(1), 68–73 (2004)

B. Liu, W.H. Li, P.B. Kosasih, X.Z. Zhang, Development of an MR-brake-based haptic device. Smart Mater. Struct. 15(6), 1960–1966 (2006)

P. Chen, X.X. Bai, L.J. Qian, S.B. Choi, A magneto-rheological fluid mount featuring squeeze mode: analysis and testing. Smart Mater. Struct. 25(5), 55002 (2016)

S.B. Choi, Y.M. Han, Magnetorheological Fluid Technology: Applications in Vehicle Systems (CRC press, New york, 2012)

J. Park, G.H. Yoon, J.W. Kang, S.B. Choi, Design and control of a prosthetic leg for above-knee amputees operated in semi-active and active modes. Smart Mater. Struct. 25(8), 85009 (2016)

W. Kordonski, A. Shorey, Magnetorheological (MR) jet finishing technology. J. Intell. Mater. Syst. Struct. 18(12), 1127–1130 (2007)

S. Jha, in Alpha Science International Ltd., ed. by V. K. Jain. Introduction to Micromachining (Oxford, 2010), pp. 5.1–5.21

A. Sidpara, V.K. Jain, Experimental investigations into forces during magnetorheological fluid based finishing process. Int. J. Mach. Tools Manuf. 51(4), 358–362 (2011)

A. Ghaffari, S. Hashemabadi, M. Ashtiani, A review on the simulation and modeling of magnetorheological fluids. J. Intell. Mater. Syst. Struct. 26, 881–904 (2015)

Bingham E. C., Fluidity and Plasticity (McGraw Hill New York) (1922)

W. Herschel, R. Bulkley, Consistency measurements of gum benzene solutions. Kolloid Z 39, 291–300 (1926)

T.C. Papanastasiou, Flows of materials with yield. J. Rheol. 31, 385–404 (1987)

Y.P. Seo, Y. Seo, Modeling and analysis of electrorheological suspensions in shear flow. Langmuir 28, 3077–3084 (2012)

Y.P. Seo, S. Han, J. Choi, A. Takahara, H.J. Choi, Y. Seo, Adv. Mater., 1704769 (2018)

R.V. Upadhyay, Z. Laherisheth, S. Kruti, Rheological properties of soft magnetic flake shaped iron particle based magnetorheological fluid in dynamic mode. Smart Mater. Struct. 23, 015002 (2014)

Z. Laherisheth, K. Parekh, R.V. Upadhyay, Role of inter-particle force between micro and nano magnetic particles on the stability of magnetorheological fluid. AIP Adv. 7, 025206 (2017)

J.M. Ginder, L.C. Davis, L.D. Elie, Rheology of magnetorheological fluids: models and measurements. Int. J. Mod. Phys. B 10, 3293–3303 (1996)

F.F. Fang, H.J. Choi, M.S. John, Magneto rheology of soft magnetic carbonyl iron suspension with single-walled carbon nanotube additive and its yield stress scaling function. Colloid Surf. A 351, 46–51 (2009)

G.R. Iglesias, M.T. Lopez-Lopez, J.D. Duran, F. Gonzalez-Caballero, A.V. Delgado, Dynamic characterization of extremely bidisperse magnetorheological fluids. J. Colloid Interface Sci. 377, 153 (2012)

M.T. Lopez-Lopez, P. Kuzhir, S. Lacis, F. Gonzalez-Caballero, J.D. Duran, G. Bossis, Magnetorheology for suspensions of solid particles dispersed in ferrofluids. J.Phys: Condesed Matter 18, S2803 (2006)

R. Rosensweig, Magnetorheological particle clouds. E. J. Magn. Magn. Mater. 479, 301–306 (2019)

J.A. Ruiz-Lopez, R. Hidalgo-Alvarez, J. de Vicente, Towards a universal master curve in magnetorheology. Smart Mater. Struct. 26, 054001 (2017)

Funding

The authors are thankful to Charotar University of Science and Technology for financial help to MP.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pisuwala, M., Upadhyay, R.V. & Parekh, K. Evaluation of Static and Dynamic Yield Stress for Isotropic and Anisotropic Particle–Based MR Fluids: Modeling and Analysis. Braz J Phys 50, 399–409 (2020). https://doi.org/10.1007/s13538-020-00755-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13538-020-00755-w