Abstract

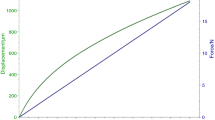

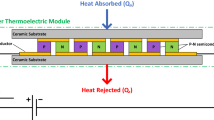

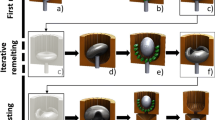

This paper presents an experimental investigation of a commercial shape memory alloy strip consisting of nickel and titanium (NiTi SMA), which correlates the thermal properties (phase transitions) with the electrical and mechanical properties of the material, allowing to be used for control applications in engineering. The bending performances of the SMA strip at different values of the activation electric current, during heating process, are also investigated. By using the differential scanning calorimetry (DSC) experiments, the thermal characteristics of the SMA strip were identified. The results of this thermal analysis were the basis for determining the equilibrium temperature, entropy and force developed by the SMA strip during the phase transformation. For the study of the SMA strip, the authors have developed an experimental platform, which uses a portable reconfigurable I/O (RIO) device and LabVIEW graphical programming environment for the measurement, testing and rapid control of parameters, and a piezo-film sensor for controlling of SMA strip movement. The real-time measurements and acquired waveforms are displayed on a PC screen, and the data associated with these waveforms are stored for later use, i.e. for applications in safety engineering like the fire extinguishing control, where very short response/activation times are required.

Similar content being viewed by others

References

Funakubo H. Shape memory alloys. New York: Gordon and Breach Science Publishers; 1987.

Otsuka K, Wayman CM. Introduction in shape memory materials. Cambridge: Cambridge University Press; 1999.

Otsuka K, Ren X. Recent developments in the research of shape memory alloys. Intermetallics. 1999;7:511–28.

Waram TC. Actuator design using shape memory alloys. 1st ed. Hamilton: Ontario Press; 1993.

Degeratu S, Bizdoaca N. Shape memory alloys: fundamentals, design and applications. Craiova: Universitaria Press; 2003.

Strittmatter J, Gümpel P, Gheorghita V. Shape memory actuators—potentials and specifics of their technical use and electrical activation. J Achiv Mater Manuf Eng. 2012;55:368–77.

Degeratu S, Rotaru P, Boncea I, Tarnita D, Alboteanu L (2018) An overview of the properties and industrial applications of shape memory alloys. In: Proceedings of the international symposium on fundamentals of electrical engineering (ISFEE), Bucharest, Romania, pp 1–6.

Liaw YC, Su YY, Lai YL, Lee SY. Stiffness and frictional resistance of a superelastic nickel-titanium orthodontic wire with low-stress hysteresis. Am J Orthod Dentofac Orthop. 2007;131(578):e12–8.

Iijima M, Brantley WA, Guo WH, Clark WAT, Yuasa T, Mizoguchi I. X-ray diffraction study of low-temperature phase transformations in nickel–titanium orthodontic wires. Dent Mater. 2008;24:1454–60.

Wang XB, Verlinden B, Van Humbeeck J. R-phase transformation in NiTi alloys. Mater Sci Technol. 2014;30:1517–29.

Wang X, Li C, Verlinden B, Van Humbeeck J. Effect of grain size on aging microstructure as reflected in the transformation behaviour of a low-temperature aged Ti–50.8 at.% Ni alloy. Scr Mater. 2013;69:545–8.

Florian G, Gabor AR, Nicolae CA, Rotaru A, Marinescu CA, Iacobescu G, Stanica N, Degeratu S, Gingu O, Rotaru P. Physical and thermophysical properties of a commercial Ni-Ti shape memory alloy strip. J Therm Anal Calorim. 2019;138:2103–22.

Cuellar EL, Mendoza EN, De Araújo CJ, Walle BCL, Otubo J, Gonzalez C. Effect of spun velocities and composition on the R-phase and thermomechanical behavior in Ti-Ni ribbons electrically heated. Mater Res. 2016;19:1132–7.

Zanaboni E (2008) One way and two way-shape memory effect: thermo-mechanical characterization of Ni–Ti wires. PhD Thesis, University of Pavia, Faculty of Engineering, Pavia.

Brantley WA. Orthodontic wires. Orthodontic materials: scientific and clinical aspects. Stuttgart: Thieme; 2001.

Duerig TW, Melton KN, Stockel D, Wayman CM, editors. Engineering aspects of shape memory alloys. London: Butterworth-Heinemann; 1990.

Morawiec H (2008) Structure formation and its effect on properties of shape memory alloys. In: Physics of advanced materials, Winterschool, Thesaloniki, Greece.

Machado LG, Savi MA. Medical applications of shape memory alloys. Braz J Med Biol Res. 2003;36:683–91.

Wu MH, Schetky LMD (2000) Industrial applications for shape memory alloys. In: Proceedings of the international conference on shape memory and superelastic technologies, Pacific Grove, California, pp 171–82.

Songa G, Ma N, Li HN. Applications of shape memory alloys in civil structures. Eng Struct. 2006;28:1266–74.

Suzana Dănoiu S, Rotaru P, Degeratu S, Rizescu S, Bîzdoacă NG. Shape memory alloy-based smart module structure working under intense thermo-mechanical stress. J Therm Anal Calorim. 2014;118:1323–30.

Degeratu S, Alboteanu L, Rizescu S, Coman D, Bîzdoacă NG, Cărămidă C. Active solar panel tracking system actuated by shape memory alloy springs. In: Proceedings of the IEEE international conference on applied and theoretical electricity, Craiova, Romania, 2014, pp 1–5.

Degeratu S, Tarniță D, Căramidă C, Boncea I, Alboteanu L, Stăicuș M. Experimental investigation of a barrier structure based on a shape memory alloy actuator. In: Proceedings of OPTIM & ACEMT international conference, Brasov, Romania, 2017, pp 17–25.

Bellouard Y. Shape memory alloys for microsystems: a review from a material research perspective. Mat Sci Eng A. 2008;481:582–9.

Duerig TW, Melton KN. Applications of shape memory in the USA. In: Proceedings of 1st Japan international SAMPLE symposium, Japan, 1989, pp. 195–200.

Menna C, Auricchio F, Asprone D. Applications of shape memory alloys, Chapter 13. In: Shape memory alloy engineering. Butterwort Heinemann, London, 2015.

Schetky LMD, Coley D. Shape memory alloy torsion tube actuators for trailing edge trim tab control on helicopter rotors. In: Proceedings of the 2. international conference on shape memory and superelastic technologies, Pacific Grove, CA, USA; 1997, pp. 299–303.

Bîzdoacă NG, Petrişor A, Bîzdoacă E, Diaconu I, Degeratu S. Shape memory alloy tendons actuated tentacle - robotic structure models and control. In: Proceedings of the 5th international conference on informatics in control, automation and robotics, ICINCO, Funchal Madeira, Portugalia; 2008, pp. 77–80.

Hartl DJ, Lagoudas DC. Aerospace applications of shape memory alloys. J Aerosp Eng Part G. 2007;221:535–52.

Degeratu S, Rotaru P, Rizescu S, Bîzdoacă NG. Thermal study of a shape memory alloy (SMA) spring actuator designed to insure the motion of a barrier structure. J Therm Anal Calorim. 2013;111:1255–62.

Degeratu S, Rotaru P, Bîzdoacă NG, Manolea G, Petropol GS, Tont D. Evaluation of the characteristics of a shape memory alloy cantilever actuator using thermal analysis. In: Proceedings of international conference on materials science, Bucarest, Romania, 2008.

Florian G, Gabor AR, Nicolae CA, Iacobescu G, Stănică N, Mărășescu P, Petrișor I, Leulescu M, Degeratu S, Gângu O, Rotaru P. Physical properties (thermal, thermomechanical, magnetic, and adhesive) of some smart orthodontic wires. J Therm Anal Calorim. 2018;134:189–208.

DYNALLOY, Inc. FLEXINOL® Actuator Ribbon technical and design data. Available online: https://www.dynalloy.com/tech_data_ribbon.php.

DYNALLOY, Inc. Introduction To FLEXINOL® Actuator Wire. Online: https://www.dynalloy.com/flexinol.php.

Gugat JL, Krantz MC, Gerken M. Two-dimensional versus three-dimensional finite-element method simulations of cantilever magnetoelectric sensors. IEEE Trans Magn. 2013;49:5287–93.

LEM products: current transducers, voltage transducers. Available online: https://www.lem.com/en.

Doering Ed. NI myRIO Project Essentials Guide; 2016. Available online: http://www.ni.com/myrio/project-guide.

NI myRIO-1900: User Guide and Specifications. Online: http://www.ni.com/pdf/manuals/376047c.pdf.

Piezo film sensor without leads. Available online: https://www.te.com/usa-en/product-CAT-PFS0004.html.

Qin Q, Peng H, Fan Q, Zhang L, Wen Y. Effect of second phase precipitation on martensitic transformation and hardness in highly Ni-rich NiTi alloys. J Alloys Comp. 2018;739:873–81.

Degeratu S, Rotaru P, Manolea G, Manolea HO, Rotaru A. Thermal characteristics of Ni–Ti SMA (shape memory alloy) actuators. J Therm Anal Calorim. 2009;97:695–700.

Tong Y, Gu H, James RD, Qi W, Shuitcev AV, Li L. Novel TiNiCuNb shape memory alloys with excellent thermal cycling stability. J Alloys Comp. 2019;782:343–7.

Najafi M, Mirzadeh H, Alibeyki M. Tempering of deformed and as-quenched martensite in structural steel. J Min Metall Sect B Metall. 2019;55:95–9.

Yates SJ, Kalamkarov AL. Experimental study of helical shape memory alloy actuators: effects of design and operating parameters on thermal transients and stroke. Metals. 2013;3:123–49.

Voncina M, Kores S, Ernecl M, Medved J. The role of Zr and T6 heat treatment on microstructure evolution and hardness of AlSi9Cu3(Fe) diecasting alloy. J Min Metall Sect B Metall. 2017;53(3B):423–8.

Demidova E, Belyaev S, Resnina N, Shelyakov A. Influence of the holding temperature on the kinetics of the isothermal B2 → B19′ transformation in TiNi-based shape memory alloy. J Therm Anal Calorim. 2020;139:2965–70.

Kök M, Durğun SB, Özen E. Thermal analysis, crystal structure and magnetic properties of Cr-doped Ni–Mn–Sn high-temperature magnetic shape memory alloys. J Therm Anal Calorim. 2019;136:1147–52.

Canbay CA, Aziz S, Özkul İ, Dere A. The effect of e/a ratio on thermodynamic parameters and surface morphology of Cu–Al–Fe–X shape memory alloys. J Therm Anal Calorim. 2020;139:823–9.

Kök M, Al-Jaf AOA, Çirak ZD, Qader IN, Özen E. Effects of heat treatment temperatures on phase transformation, thermodynamical parameters, crystal microstructure, and electrical resistivity of NiTiV shape memory alloy. J Therm Anal Calorim. 2020;139:3405–13.

Ercan E, Dagdelen F, Qader IN. Effect of tantalum contents on transformation temperatures, thermal behaviors and microstructure of CuAlTa HTSMAs. J Therm Anal Calorim. 2020;139:29–36.

Golmakani MH, Vahdati khaki J, Babakhani A. Formation mechanism of Fe-Mo master alloy by aluminothermic reduction of MoS2-Fe2O3 in the presence of lime. J Min Metall Sect B Metall. 2018;54(2):233–41.

Holjevac Grgurić T, Manasijević D, Kožuh S, Ivanić I, Anžel I, Kosec B, Bizjak M, Govorčin Bajsic E, Balanovic L, Gojic M. The effect of the processing parameters on the martensitic transformation of Cu-Al-Mn shape memory alloy. J Alloys Comp. 2018;765:664–76.

Wang H-Z, Zhao Y-D, Ma Y-H, Gao Z-Y. Effect of low-energy proton on the microstructure, martensitic transformation and mechanical properties of irradiated Ni-rich TiNi alloy thin films. Int J Minerals Metall Mater. 2020;27(4):538–543.

Holjevac Grgurić T, Manasijević D, Kožuh S, Ivanić I, Balanović L, Anžel I, Kosec B, Bizjak M, Knežević M, Gojić M. Phase transformation and microstructure study of the as-cast Cu-rich Cu-Al-Mn ternary alloys. J Min Metall Sect B Metall. 2017;53(3):413–22.

Samal S, Tyc O, Heller L, Šittner P, Malik M, Poddar P, Catauro M, Blanco I. Study of interfacial adhesion between nickel-titanium shape memory alloy and a polymer matrix by laser surface pattern. Appl Sci. 2020;10:2172.

Salzbrenner RJ, Cohen M. Thermodynamics of thermoelastic martensitic transformations. Acta Metall. 1979;27:739–48.

Wayman CM, Tong HC. On the equilibrium temperature in thermoelastic martensitic transformations. Scripta Metall. 1977;11:341–3.

Kaya I, Ozdemir Y, Kaya E, Keskin ME. The heating–cooling rate effect on thermal properties of high nickel-rich NiTi shape memory alloy. J Therm Anal Calorim. 2020;132:817–22.

Degeratu S, Bizdoaca N G, Manolea G, Diaconu I, Petrisor A, DegeratuV. Practical aspects regarding the design of intelligent systems using the shape memory alloy spring. In: Proceedings of the international conference EMESEG, Heraclion, Crete, Greece, 2008, pp. 226–31.

G. Ramanathan G, Panoskaltsis V, Mullen R, Welsch GE. Experimental and computational methods for SMAs. In: Proceedings of the 15th ASCE engineering mechanics conference, Columbia University, New York, 2002.

Lee HJ, Lee JJ. Evaluation of the characteristics of a shape memory alloy spring actuator. Smart Mater Struct. 2000;9:817–23.

Eshghinejad A, Elahinia M. Exact solution for bending of shape memory alloy superelastic beams. In: Proceedings of the ASME conference on smart materials adaptive structures and intelligent systems, Scottsdale, USA, 2011, pp. 1–8.

Beam deflection during cantilever bending, University of Cambridge. https://www.doitpoms.ac.uk/tlplib/thermal-expansion/derivation1.php.

Cantilever Beam - Point Load at Free End, STRUCT. Available online: https://structx.com/Beam_Formulas_022.html.

Experiment: Measurement of Young’s modulus, University of Cambridge. https://www.doitpoms.ac.uk/tlplib/thermal-expansion/expt1.php.

Novák V, Šittner P, Dayananda GN, Braz-Fernandes FM, Mahesh KK. Electric resistance variation of NiTi shape memory alloy wires in thermomechanical tests: Experiments and simulation. Mat Sci Eng A. 2008;481:127–33.

Cuéllar LE, Guénin G, Morin M. Behaviour of strain-resistivity coupled measurements of Ti–Ni–Cu wires during thermal cycling under constant stress. Mat Sci Eng A. 2004;378:115–8.

Gheorghita V, Guempel P, Ceron AE, Strittmatter A. Controlling the stroke of shape memory actuator wires. In: Katalinic B, editor. Danube Adria Association For Automation & Manufacturing. Vienna: International Scientific Book; 2011. p. 563–72.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Degeratu, S., Subțirelu, G.E., Rotaru, A. et al. The electro-mechanical control of element NiTi shape memory alloy strip while bending, based on thermal analysis evidence. J Therm Anal Calorim 143, 3805–3815 (2021). https://doi.org/10.1007/s10973-020-10172-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10172-5