Abstract

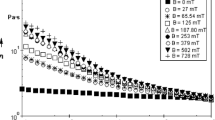

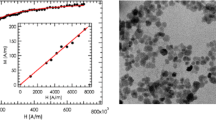

The magnetorheological behavior of three sets of ferrofluid-based magnetorheological (MR) fluids is investigated to determine the dependence of the static and dynamic yield stresses, as well as of the magnetoviscous effect on the volume fraction of magnetite nanoparticles φ and of the added Fe particles Φ Fe , at different values of the magnetic induction B in the MR cell. A wide range of the magnetic particle volume fractions were considered at the two hierarchical levels involved: at the nanometer level, φ = 2.75, 11.67, and 22.90 %, and at the micrometer level, Φ Fe = 5–40 %. Taking into account also the oleic acid monolayer coating of the magnetite nanoparticles, the hydrodynamic volume fraction of the most concentrated ferrofluid results to be 65 % and, consequently, the highest value of the effective total volume fraction of the investigated extremely bidisperse MR fluids attains 85 %. The diagrams of the static and dynamic (Bingham) yield stresses and of the magnetoviscous effect offer an adequate choice of the nanometer and micrometer range particle volume fractions to fulfill the specific requirements of high-pressure rotating seals and of various MR devices.

Similar content being viewed by others

References

Barber DE (2013) MR fluids at the extremes: high energy and low temperature performance of LORD MR fluids and devices, Ch.4 in. RSC Smart Materials 6, Magnetorheology: Advances and Applications (Ed. N. Wereley) 74–95. doi:10.1039/9781849737548.

Bica D, Potencz I, Vekas L, Giula G, Potra (Balanean) F (2000) Procedure to obtain magnetic fluids for seals. Rom Patent RO 115533:B1

Borbath T, Bica D, Potencz I, Borbath I, Boros T, Vekas L (2011) Leakage-free rotating seal systems with magnetic nanofluids and magnetic composite fluids designed for various applications. Int J Fluid Mach Syst 4:67–75

Borbáth T, Borbáth I, Günther S, Marinica O, Vékás L, Odenbach S (2014) Three-dimensional microstructural investigation of high magnetization nano–micro composite fluids using x-ray microcomputed tomography. Smart Mater Struct 23:055018

Borin DY, Zubarev AY, Chirikov DN, Odenbach S (2014) Stress relaxation in a ferrofluid with clustered nanoparticles. J Phys D Condens Matter 26:406002

Bosioc AI, Muntean S, Tanasa C, Susan-Resiga R, Vékás L (2014) Unsteady pressure measurements of decelerated swirling flow in a discharge cone at lower runner speeds. IOP Conference Series Earth Environ Sci 22:032008. doi:10.1088/1755-1315/22/3/032008

Bossis G, Volkova O, Lacis S and Meunier A (2002) Magnetorheology: fluids, structures and rheology, in: Ferrofluids: Magnetically Controllable Fluids and their Applications, Lecture Notes in Physics, ed Odenbach S., 594:202–230

Cabuil V, Bacri JC, Perzynski R, Yu R (1996) Colloidal stability of magnetic fluids. In: Berkovski B, Bashtovoy V (eds) Magnetic fluids and applications handbook. Begell House Inc., New York, Wallingford, pp. 33–56

Carlson JD, Jolly MR (2000) MR fluid, foam and elastomer devices. Mechatronics 10(4–5):555–569. doi:10.1016/S0957-4158(99)00064-1

Chin BD, Park JH, Kwon MH, Park OO (2001) Rheological properties and dispersion stability of magnetorheological (MR) suspensions. Rheol Acta 40:211–219

Durairaj R, Man LW, Ekere NN, Mallik S (2010) The effect of wall-slip formation on the rheological behaviour of lead-free solder pastes. Mater Des 31:1056–1062

Farr RS, Groot RD (2009) Close packing density of polydisperse hard spheres. J Chem Phys 131:244104

Friedman AJ and Dyke SJ (2013) Development and Experimental Validation of a New Control Strategy Considering Device Dynamics for Large Scale MR Dampers using Real Time Hybrid Simulation, Report IISL–003.

Fujita T, Yoshimura K, Seki Y, Dodbiba G, Miyazaki T, Numakura S (1999) Characterization of magnetorheological suspensions for seal. J Intell Mater Syst Struct 10:770–774

Ginder JM, Davis LC, Elie LD (1996) Rheology of magnetorheological fluids: models and measurements. Int J Mod Phys B 10:3293–3303

Iglesias GR, López-López MT, Durán JDG, González-Caballero F, Delgado AV (2012) Dynamic characterization of extremely bidisperse magnetorheological fluids. J Colloid Interface Sci 377:153–159

Iglesias GR, Ahualli S, Echávarri Otero J, Fernández Ruiz-Morón L, Durán JDG (2014) Theoretical and experimental evaluation of the flow behavior of a magnetorheological damper using an extremely bimodal magnetic fluid. Smart Mater Struct 23:085028(11pp)

Iglesias GR, Fernández Ruiz-Morón L, Durán JDG, Delgado AV (2015) Dynamic and wear study of an extremely bidisperse magnetorheological fluid. Smart Mater Struct 24:127001

Klingenberg DJ (2001) Magnetorheology: applications and challenges. AICHE J 47(2):246–249

Klingenberg DJ, Ulicny JC, Golden MA (2007) Mason numbers for magnetorheology. J Rheol 51(5):883–893

Laun HM, Schmidt G, Gabriel C, Kieburg C (2008) Reliable plate–plate MRF magnetorheometry based on validated radial magnetic flux density profile simulations. Rheol Acta 47(9):1049–1059

Laun HM, Gabriel C, Kieburg C (2010) Twin gap magnetorheometer using ferromagnetic steel plates—performance and validation. J Rheol 54(2):327

Liu YD, Choi HJ (2012) Carbon nanotube-coated silicated soft magnetic carbonyl iron microspheres and their magnetorheology. J Appl Phys 111:07B502

Liu YD, Hong CH, Choi HJ (2012) Polymeric colloidal magnetic composite microspheres and their magneto-responsive characteristics. Macromol Res 20(12):1211–1218

López-López MT, de Vicente J, Bossis G, González-Caballero F, Durán JDG (2005) Preparation of stable magnetorheological fluids based on extremely bimodal iron–magnetite suspensions. J Mater Res 20(4):874–881

López-López MT, Kuzhir P, Lacis S, Bossis G, González-Caballero F, Durán JDG (2006) Magnetorheology for suspensions of solid particles dispersed in ferrofluids. J Phys Condens Matter 18:S2803–S2813

Mezger TG (2002) The Rheology Handbook, Curt R. Vincentz Verlag, Hannover

Ngatu GT, Wereley NM (2007) Viscometric and sedimentation characterization of bidisperse magnetorheological fluids. IEEE Transac Magn 43(6):2474–2476

Park BJ, Fang FF, Choi HJ (2010) Magnetorheology: materials and application. Soft Matter 6:5246–5253

Ramos J, Klingenberg DJ, Hidalgo-Álvarez R, de Vicente J (2011) Steady shear magnetorheology of inverse ferrofluids. J Rheol 55(1):127–152

Rankin PJ, Horvath AT, Klingenberg DJ (1999) Magnetorheology in viscoplastic media. Rheol Acta 38:471–477

Russell WB, Saville DA, Schowalter WR (1989) Colloidal dispersions, Cambridge Univ. Press, Cambridge

Shah K, Phu Do X and Choi S-B (2014) Rheological properties of bi-dispersed magnetorheological fluids based on plate-like iron particles with application to a small-sized damper, Journal of Applied Physics 115:203907–203907-10. doi:10.1063/1.4879681

Susan-Resiga D, Vékás L, Bica D (2010) Flow behaviour of extremely bidisperse magnetizable fluids. J Magn Magn Mater 322(20):3166–3172. doi:10.1016/j.jmmm.2010.05.055

Susan-Resiga D, Socoliuc V, Boros T, Borbáth T, Marinica O, Han A, Vékás L (2012) The influence of particle clustering on the rheological properties of highly concentrated magnetic nanofluids. J Colloids Interface Sci 373:110–115

Susan-Resiga D, Vékás L (2014) Yield stress and flow behavior of concentrated ferrofluid based magnetorheological fluids: the influence of composition. Rheol Acta 53:645–653

Vékás L, Bica D, Avdeev MV (2007) Magnetic nanoparticles and concentrated magnetic nanofluids: Synthesis, properties and some Applications. Particuology 45:43–49

Vékás L (2008) Ferrofluids and magnetorheological fluids. Smart Mater Micro/Nanosyst Book Series Adv Sci Technol 54:127–136. doi:10.4028/www.scientific.net/AST.54.127

de Vicente J, Klingenberg DJ, Hidalgo-Álvarez R (2011) Magnetorheological fluids: a review. Soft Matter 7:3701–3710

Viota JL, González-Caballero F, Durán JDG, Delgado AV (2007) Study of the colloidal stability of concentrated bimodal magnetic fluids. J Colloid Interface Sci 309:135–139

Viota JL, Duran JDG, Delgado AV (2009) Study of the magnetorheology of aqueous suspensions of extremely bimodal magnetite particles. Eur Phys J E 29:87–94

Volkova O, Bossis G, Guyot M, Bashtovoi V, Reks A (2000) Magnetorheology of magnetic holes compared to magnetic particles. J Rheol 44(1):91–104

Wang X, Gordaninejad F (2006) Study of magnetorheological fluids at high shear rates. Rheol Acta 45:899–908

Wereley NM, Chaudhuri A, Yoo J-H, John S, Kotha S, Suggs A, Radhakrishnan R, Love BJ, Sudarshan TS (2006) Bidisperse magnetorheological fluids using Fe particles at nanometer and micron scale. J Intell Mater Syst Struct 17:393–401. doi:10.1177/1045389X06056953

Yang Y, Li L, Chen G (2009) Static yield stress of ferrofluid-based magnetorheological fluids. Rheol Acta 48:457–466

Yoshimura A, Prud’homme RK (1988) Wall-slip corrections for coquette and parallel disk viscometer. J Rheol 32:53–67

Zhou JZQ, Fang T, Luo G, Uhlherr PHT (1995) Yield stress and maximum packing fraction of concentrated suspensions. Rheol Acta 34:544–561

Zhu X, Jing X, Cheng L (2012) Magnetorheological fluid dampers: a review on structure design and analysis. J Intell Mater Syst Struct 23(8):839–873. doi:10.1177/1045389X12436735

Acknowledgments

This work was supported by the SEMNAL MRD research project (contract nr. 77/2014-PNII-UEFISCDI) and by the Research Program LLM-CCTFA 2013-2015 of the Romanian Academy. The ferrofluid carriers and the nano–micro composite MR fluid samples were prepared by Florica Balanean, Research Ass. (RCESCF-University Politehnica Timisoara, Timisoara, Romania). The authors are indebted to Dr. Vlad Socoliuc (CFATR) for valuable discussions and to Dipl.-Phys. Oana Marinica, PhD fellow, for magnetization measurements and data interpretation concerning the most concentrated samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Susan-Resiga, D., Vékás, L. Ferrofluid-based magnetorheological fluids: tuning the properties by varying the composition at two hierarchical levels. Rheol Acta 55, 581–595 (2016). https://doi.org/10.1007/s00397-016-0931-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-016-0931-x