Abstract

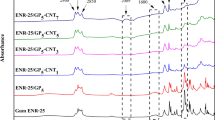

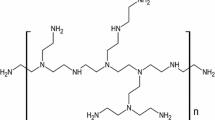

Hybrid nanocomposites, comprising epoxidized natural rubber (ENR) filled with graphene (GP) and carbon nanotubes (CNTs), were prepared via the melt mixing technique. TEM imaging confirmed the development of three-dimensional filler networks, facilitated by the π-π interaction between sp2-hybridized carbon atoms in graphene and carbon nanotubes, alongside Van der Waals forces. Moreover, a notable interaction between polar functional groups on the nanofiller surfaces and the ENR molecules emerged as a significant factor in enhancing properties. This was evidenced by the rise in bound rubber content with increasing CNT loading, amplifying reinforcing efficiency through the establishment of bridge links among rubber chains and filler networks. Temperature scanning stress relaxation (TSSR) results unveiled escalating relaxation forces, moduli, and crosslink density upon nanofiller incorporation and with increasing CNT loading. DMA results indicate elevated storage modulus and glass transition temperature (Tg), coupled with reduced coefficient of reinforcement (C-factor), indicative of an increased degree of reinforcement.

Similar content being viewed by others

Data availability

The data that support the findings of this study are avail-able from the corresponding author on reasonable request.

References

Nun-anan P, Wisunthorn S, Pichaiyut S, Nathaworn CD, Nakason C (2020) Influence of nonrubber components on properties of unvulcanized natural rubber. Polym Adv Technol 31:44–59. https://doi.org/10.1002/pat.4746

Riyajan S-A (2022) Establishment and properties of epoxidized natural rubber-graft-poly (N-vinylcaprolactam)/poly (vinyl alcohol) blend. Ind Crops Prod 177:114415. https://doi.org/10.1016/j.indcrop.2021.114415

Bokobza L (2018) Natural rubber nanocomposites: A review Nanomater 9:12. https://doi.org/10.3390/nano9010012

Mo YL, Tian YX, Liu YH, Chen F, Fu Q (2019) Preparation and properties of ultrathin flexible expanded graphite film via adding natural rubber. Chinese J Polym Sci 37:806–814. https://doi.org/10.1007/s10118-019-2264-6

La DD, Nguyen TA, Quoc VD et al (2018) A new approach of fabricating graphene nanoplates@ natural rubber latex composite and its characteristics and mechanical properties. C 4:50. https://doi.org/10.3390/c4030050

Vahidifar A, Esmizadeh E, Rostami E, Nouri Khorasani S, Rodrigue D (2019) Morphological, rheological, and mechanical properties of hybrid elastomeric foams based on natural rubber, nanoclay, and nanocarbon black. Polym Compos 40:4289–4299. https://doi.org/10.1002/pc.25290

Wang Y, Zhang H, Wu Y, Yang J, Zhang L (2005) Structure and properties of strain-induced crystallization rubber–clay nanocomposites by co-coagulating the rubber latex and clay aqueous suspension. J Appl Polym Sci 96:318–323. https://doi.org/10.1002/app.21408

Sookyung U, Nakason C, Thaijaroen W, Vennemann N (2016) Effect of organoclay loading level on mechanical properties, thermomechanical behavior, and heat build-up of natural rubber/organoclay nanocomposites. Polym Compos 37:1735–1743. https://doi.org/10.1002/pc.23346

Le M-T (2018) Influence of nanosilica in mechanical property of natural rubber composite. 2018 4th International Conference on Green Technology and Sustainable Development (GTSD). IEEE pp. 237–240. https://doi.org/10.1109/GTSD.2018.8595529

Jarnthong M, Peng Z, Lopattananon N, Nakason C (2017) Nanosilica-reinforced Epoxidized natural rubber nanocomposites: Effect of Epoxidation level on morphological and mechanical properties. Polym Compos 38:1151–1157. https://doi.org/10.1002/pc.23678

Kitisavetjit W, Nakaramontri Y, Pichaiyut S, Wisunthorn S, Nakason C, Kiatkamjornwong S (2021) Influences of carbon nanotubes and graphite hybrid filler on properties of natural rubber nanocomposites. Polym Test 93:106981. https://doi.org/10.1016/j.polymertesting.2020.106981

Wei L, Fu X, Luo M et al (2018) Synergistic effect of CB and GO/CNT hybrid fillers on the mechanical properties and fatigue behavior of NR composites. RSC Adv 8:10573–10581. https://doi.org/10.1039/C7RA12830D

Ivanoska-Dacikj A, Bogoeva-Gaceva G, Rooj S, Wießner S, Heinrich G (2015) Fine tuning of the dynamic mechanical properties of natural rubber/carbon nanotube nanocomposites by organically modified montmorillonite: A first step in obtaining high-performance damping material suitable for seismic application. Appl Clay Sci 118:99–106. https://doi.org/10.1016/j.clay.2015.09.009

Krainoi A, Boonkerd K (2022) Novel hybrid natural rubber nanocomposites with carbon nanotube and cellulose nanofiber for strain-sensitive sensor. Ind Crops Prod 187:115455. https://doi.org/10.1016/j.indcrop.2022.115455

Krainoi A, Kummerlöwe C, Nakaramontri Y et al (2020) Novel natural rubber composites based on silver nanoparticles and carbon nanotubes hybrid filler. Polym Compos 41:443–458. https://doi.org/10.1002/pc.25378

Thongkong N, Wisunthorn S, Pichaiyut S, Nakason C, Kiatkamjornwong S (2020) Natural rubber nanocomposites based on hybrid filler of zinc nanoparticles and carbon nanotubes: Electrical conductivity and other related properties. EXPRESS Polym Lett 14. https://doi.org/10.3144/expresspolymlett.2020.93

Shahamatifard F, Rodrigue D, Park K, Frikha S, Mighri F (2021) Natural rubber nanocomposites: Effect of carbon black/multi-walled carbon nanotubes hybrid fillers on the mechanical properties and thermal conductivity. Polym Plast Tech M 60:1686–1696. https://doi.org/10.1080/25740881.2021.1930044

Rattanasom N, Saowapark T, Deeprasertkul C (2007) Reinforcement of natural rubber with silica/carbon black hybrid filler. Polym Test 26:369–377. https://doi.org/10.1016/j.polymertesting.2006.12.003

Bakošová D, Bakošová A (2022) Testing of rubber composites reinforced with carbon nanotubes. Polymers 14:3039. https://doi.org/10.3390/polym14153039

Duan X, Cheng S, Li Z et al (2022) Flexible and environmentally friendly graphene natural rubber composites with high thermal conductivity for thermal management. Compos A Appl Sci Manuf 163:107223. https://doi.org/10.1016/j.compositesa.2022.107223

Siriwas T, Pichaiyut S, Susoff M, Petersen S, Nakason C (2023) Graphene-filled natural rubber nanocomposites: Influence of the composition on curing, morphological, mechanical, and electrical properties. EXPRESS Polym Lett 17. https://doi.org/10.3144/expresspolymlett.2023.61

Li H, Yang L, Weng G, Xing W, Wu J, Huang G (2015) Toughening rubbers with a hybrid filler network of graphene and carbon nanotubes. J Mater Chem A 3:22385–22392. https://doi.org/10.1039/C5TA05836H

Salaeh S, Kao-ian P (2022) Conductive epoxidized natural rubber nanocomposite with mechanical and electrical performance boosted by hybrid network structures. Polym Test 108:107493. https://doi.org/10.1016/j.polymertesting.2022.107493

Shojaie S, Vahidifar A, Naderi G, Shokri E, Mekonnen TH, Esmizadeh E (2021) Physical Hybrid of Nanographene/Carbon Nanotubes as Reinforcing Agents of NR-Based Rubber Foam. Polymers 13:2346. https://doi.org/10.3390/polym13142346

Hu H, Zhao L, Liu J et al (2012) Enhanced dispersion of carbon nanotube in silicone rubber assisted by graphene. Polym 53:3378–3385. https://doi.org/10.1016/j.polymer.2012.05.039

Matsuo T, Inaba A, Yamamuro O et al (2002) Rubber elasticity in the introductory thermodynamics course. J Therm Anal Calorim 69:1015–1020. https://doi.org/10.1023/A:1020697115165

Geethamma V, Sampath V (2019) Rubber as an aid to teach thermodynamics: The discovery by a blind scientist. Resonance 24:217–238. https://doi.org/10.1007/s12045-019-0772-x

Vennemann N, Bökamp K, Bröker D (2006) Crosslink density of peroxide cured TPV. Macromol Symp, Wiley Online Library pp. 641–650. https://doi.org/10.1002/masy.200651391

Barbe A, Bökamp K, Kummerlöwe C, Sollmann H, Vennemann N, Vinzelberg S (2005) Investigation of modified SEBS-based thermoplastic elastomers by temperature scanning stress relaxation measurements. Polym Eng Sci 45:1498–1507. https://doi.org/10.1002/pen.20427

Siriwas T, Pichaiyut S, Susoff M, Petersen S, Nakason C (2023) Enhancing curing, mechanical and electrical properties of epoxidized natural rubber nanocomposites with graphene and carbon nanotubes hybrid fillers. J Mater Sci 1–20. https://doi.org/10.1007/s10853-023-09003-3

Mark J (1982) Rubber elasticity. Rubber Chem Technol 55:1123–1136. https://doi.org/10.5254/1.3535918

Vennemann N, Wu M, Heinz M (2012) Thermoelastic properties and relaxation behavior of S-SBR/silica vulcanizates. Rubber World 246:18–23

Norbert V (2012) Characterization of thermoplastic elastomers by means of temperature scanning stress relaxation measurements. Thermoplast Elastomers 1:347–370. https://doi.org/10.5772/35976

Wolff S, Wang M-J, Tan E-H (1993) Filler-elastomer interactions. Part VII. Study on bound rubber. Rubber Chem Technol 66:163–177. https://doi.org/10.5254/1.3538304

Aziz M, Halim FA, Jaafar J (2014) Preparation and characterization of graphene membrane electrode assembly. J Teknol 69:11–14. https://doi.org/10.11113/jt.v69.3388

Aguilar-Bolados H, Lopez-Manchado MA, Brasero J, Avilés F, Yazdani-Pedram M (2016) Effect of the morphology of thermally reduced graphite oxide on the mechanical and electrical properties of natural rubber nanocomposites. Compos B Eng 87:350–356. https://doi.org/10.1016/j.compositesb.2015.08.079

Kuilla T, Bhadra S, Yao D, Kim NH, Bose S, Lee JH (2010) Recent advances in graphene based polymer composites. Prog Polym Sci 35:1350–1375. https://doi.org/10.1016/j.progpolymsci.2010.07.005

Yang G, Feng X, Wang W, OuYang Q, Liu L, Wu Z (2021) Graphene and carbon nanotube-based high-sensitive film sensors for in-situ monitoring out-of-plane shear damage of epoxy composites. Compos B Eng 204:108494. https://doi.org/10.1016/j.compositesb.2020.108494

Nakaramontri Y, Nakason C, Kummerlöwe C, Vennemann N (2016) Enhancement of electrical conductivity and filler dispersion of carbon nanotube filled natural rubber composites by latex mixing and in situ silanization. Rubber Chem Technol 89:272–291. https://doi.org/10.5254/rct.15.84848

Nun-anan P, Wisunthorn S, Pichaiyut S, Vennemann N, Nakason C (2018) Novel approach to determine non-rubber content in Hevea brasiliensis: Influence of clone variation on properties of un-vulcanized natural rubber. Ind Crops Prod 118:38–47. https://doi.org/10.1016/j.indcrop.2018.03.011

Yangthong H, Pichaiyut S, Jumrat S, Wisunthorn S, Nakason C (2019) Mechanical, thermal, morphological, and curing properties of geopolymer filled natural rubber composites. J Appl Polym Sci 136:47346. https://doi.org/10.1002/app.47346

Baranwal K, Stephens H (2001) Basic Elastomer Technology, Rubber Division. Akron, OH: Am Chem Soc

Zhang S, Lin L, Deng H et al (2012) Synergistic effect in conductive networks constructed with carbon nanofillers in different dimensions. EXPRESS Polym Lett 6. https://doi.org/10.3144/expresspolymlett.2012.17

Kruželák J, Sýkora R, Hudec I (2016) Sulphur and peroxide vulcanisation of rubber compounds–overview. Chem Pap 70:1533–1555. https://doi.org/10.1515/chempap-2016-0093

Hanzlik R. Correlating cure kinetics and physical properties with accelerator variations in a model SBR compound

Pimolsiriphol V, Saeoui P, Sirisinha C (2007) Relationship among thermal ageing degradation, dynamic properties, cure systems, and antioxidants in natural rubber vulcanisates. Polym Plast Technol Eng 46:113–121. https://doi.org/10.1080/03602550601152861

Chen J, Gui X, Wang Z et al (2012) Superlow thermal conductivity 3D carbon nanotube network for thermoelectric applications. ACS ACS Appl Mater Interface 4:81–86. https://doi.org/10.1021/am201330f

Srinivasan N, Bökamp K, Vennemann N (2005) New test method for the characterisation of filled elastomers. KGK. Kautsch Gummi Kunstst 58:650–655

Kim P, Shi L, Majumdar A, McEuen PL (2001) Thermal transport measurements of individual multiwalled nanotubes. Phys Rev Lett 87:215502. https://doi.org/10.1103/PhysRevLett.87.215502

Bhattacharya AB, M. Gopalan A, Chatterjee T, Vennemann N, Naskar K (2021) Exploring the thermomechanical properties of peroxide/co-agent assisted thermoplastic vulcanizates through temperature scanning stress relaxation measurements. Polym Eng Sci 61:2466–2476. https://doi.org/10.1002/pen.25772

Pichaiyut S, Nakason C, Vennemann N (2012) Thermoplastic elastomers-based natural rubber and thermoplastic polyurethane blends. Iran Polym J 21:65–79. https://doi.org/10.1007/s13726-011-0006-x

Leblanc JL (2002) Rubber–filler interactions and rheological properties in filled compounds. Prog Polym Sci 27:627–687. https://doi.org/10.1016/S0079-6700(01)00040-5

Song L, Li Z, Chen L, Zhou H, Lu A, Li L (2016) The effect of bound rubber on vulcanization kinetics in silica filled silicone rubber. RSC Adv 6:101470–101476. https://doi.org/10.1039/C6RA20063J

Jyoti J, Singh BP, Arya AK, Dhakate S (2016) Dynamic mechanical properties of multiwall carbon nanotube reinforced ABS composites and their correlation with entanglement density, adhesion, reinforcement and C factor. RSC Adv 6:3997–4006. https://doi.org/10.1039/C5RA25561A

Hameed N, Sreekumar P, Francis B, Yang W, Thomas S (2007) Morphology, dynamic mechanical and thermal studies on poly (styrene-co-acrylonitrile) modified epoxy resin/glass fibre composites. Compos A: Appl Sci Manuf 38:2422–2432. https://doi.org/10.1016/j.compositesa.2007.08.009

Pothan LA, Oommen Z, Thomas S (2003) Dynamic mechanical analysis of banana fiber reinforced polyester composites. Compos Sci Technol 63:283–293. https://doi.org/10.1016/S0266-3538(02)00254-3

Marcovich NE, Reboredo MM, Aranguren M (1998) Mechanical properties of woodflour unsaturated polyester composites. J Appl Polym Sci 70:2121–2131. https://doi.org/10.1002/(SICI)1097-4628(19981212)70:11%3C2121::AID-APP5%3E3.0.CO;2-Z

Pe JCGP, Gerdeen JC, Lord HW, PE RARP, Rorrer RA (2005) Engineering design with polymers and composites. CRC Press

Zhang C, Dan Y, Peng J, Turng LS, Sabo R, Clemons C (2014) Thermal and mechanical properties of natural rubber composites reinforced with cellulose nanocrystals from southern pine. Adv Polym Technol 33. https://doi.org/10.1002/adv.21448

Saji J, Khare A, Choudhary R, Mahapatra S (2014) Visco-elastic and dielectric relaxation behavior of multiwalled carbon-nanotube reinforced silicon elastomer nanocomposites. J Polym Res 21:1–13. https://doi.org/10.1007/s10965-013-0341-z

Kader M, Kim K, Lee Y-S, Nah C (2006) Preparation and properties of nitrile rubber/montmorillonite nanocomposites via latex blending. J Mater Sci 41:7341–7352. https://doi.org/10.1007/s10853-006-0792-2

Devi LU, Bhagawan S, Thomas S (2010) Dynamic mechanical analysis of pineapple leaf/glass hybrid fiber reinforced polyester composites. Polym Compos 31:956–965. https://doi.org/10.1002/pc.20880

Dinesh KB, Kim J (2023) Mechanical and Dynamic Mechanical Behavior of the Lignocellulosic Pine Needle Fiber-Reinforced SEBS Composites. Polymers 15:1225. https://doi.org/10.3390/polym15051225

Krainoi A, Kummerlöwe C, Nakaramontri Y, Vennemann N, Pichaiyut S, Wisunthorn S, Nakason C (2018) Influence of critical carbon nanotube loading on mechanical and electrical properties of epoxidized natural rubber nanocomposites. Polym Test 66:122–136. https://doi.org/10.1016/j.polymertesting.2018.01.003

Hayeemasae N, Ismail H, Khoon TB, Husseinsyah S, Harahap H (2016) Effect of carbon black on the properties of polypropylene/recycled natural rubber glove blends. Prog Rubber Plast Recycl Technol 32:241–252. https://doi.org/10.1177/147776061603200404

Funding

We gratefully acknowledge the support of financial by the National Research Council of Thailand (NRCT) (Grant No. NRCT-RGJ63019-159). Furthermore, Faculty of Science and Industrial Technology, Prince of Songkla University Surat Thani campus and University of Applied Science, Osnabrück, Germany are highly acknowledged for access to facilities and equipment.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conficts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Three-dimensional filler networks were created in the ENR-25 matrix.

• The π-π interaction between sp2-hybridized carbon atoms in GP and CNT along with the Van der Waals forces caused formation of filler networks.

• Increasing bound rubber content, relaxation modulus, and crosslink density was found with increasing CNT loadings in the ENR-25/GP5-CNTx nanocomposites.

• The glass transition temperature (Tg) increased with a reduction in the coefficient of reinforcement with increasing loadings of CNT, indicating an enhancement of the degree of reinforcement.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Siriwas, T., Pichaiyut, S., Susoff, M. et al. Optimizing the thermomechanical and thermal performance of epoxidized natural rubber hybrid nanocomposites using graphene and carbon nanotubes. J Polym Res 31, 118 (2024). https://doi.org/10.1007/s10965-024-03962-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-024-03962-0