Abstract

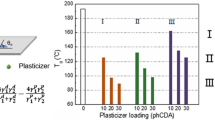

Cellulose diacetate (CDA) is a bio-based polymer of high hydrophilicity and low crystallinity for intrinsic moisture conductor. However, strong hydrogen bond induces interactions and close arrangement of CDA chains, which not only induces the difficulties for their thermal processing, but also restricts their water vapor permeability (WVP) properties. In this paper, diacetin (DA) and triacetin (TA) were chosen as green and effective plasticizers for CDA. The plasticizing CDA blends were evaluated by rheology, melt flow rate, mechanical test, Fourier transform infrared spectrometer (FTIR). The WVP of plasticized CDA film was monitored by a moisture-permeable cup. The biodegradability of CDA materials is indicated with molecular weight analyzed by gel permeation chromatography (GPC) after hydrolysis process in cellulase solution. The red shift of stretching vibrational band of carbonyl bond in FTIR demonstrates the interaction between plasticizer and CDA. The melt fluidity of CDA material increases with the increasing amount of plasticizers. The modulus and tensile strength decrease, and the elongation at break increases as a whole by blending plasticizers. DA has one more hydroxyl than TA with better compatibility with CDA. Therefore, DA brings better chain mobility of CDA chain and accordingly better improvement in moisture permeability than TA on the same load. For the CDA-DA, with the DA content increasing, the WVP is raised from 18.2 × 10–13 g·cm−1·s−1·Pa−1 to 23.6 × 10–13 g·cm−1·s−1·Pa−1. This study suggests an effective way to increase WVP of films by enhancing the chain mobility and hydrophilicity.

Similar content being viewed by others

References

Allada R, Maruthapillai A, Palanisamy K, Chappa P (2017) Moisture sorption-desorption characteristics and the corresponding thermodynamic properties of carvedilol phosphate. J Pharm Bioallied Sci 9:16–21. https://doi.org/10.4103/0975-7406.206216

Del Gaudio I, Hunter-Sellars E, Parkin IP, Williams D, Da Ros S, Curran K (2021) Water sorption and diffusion in cellulose acetate: The effect of plasticisers. Carbohyd Polym 267:118185. https://doi.org/10.1016/j.carbpol.2021.118185

Zhang XR, Zhang LZ, Pei LX (2012) Sorption, permeation and selective transport of moisture/VOCs through a CA membrane for total heat recovery. Int J Low Carbon Technol 8:64–69. https://doi.org/10.1093/ijlct/cts022

Tishchenko G, Rosova E, Elyashevich GK, Bleha M (2000) Porosity of microporous polyethylene membranes modified with polypyrrole and their diffusion permeability to low-molecular weight substances. Chem Eng J 79:211–217. https://doi.org/10.1016/s1385-8947(00)00209-6

Turan D (2021) Water vapor transport properties of polyurethane films for packaging of respiring foods. Food Eng Rev 13:54–65. https://doi.org/10.1007/s12393-019-09205-z

Al-Hassan AA, Norziah MH (2012) Starch-gelatin edible films: Water vapor permeability and mechanical properties as affected by plasticizers. Food Hydrocoll 26:108–117. https://doi.org/10.1016/j.foodhyd.2011.04.015

Peter S, Lyczko N, Gopakumar D, Maria HJ, Nzihou A, Thomas S (2022) Nanocellulose and its derivative materials for energy and environmental applications. J Mater Sci. https://doi.org/10.1007/s10853-022-07070-6

Pham B-TT, Duong T-HT, Nguyen TT, Van Nguyen D, Trinh CD, Bach LG (2021) Development of polyvinyl (alcohol)/D-glucose/agar/silver nanoparticles nanocomposite film as potential food packaging material. J Polym Res 28:410. https://doi.org/10.1007/s10965-021-02761-1

Peng JW, Li YN, Liu XL et al (2021) Cellulose film with air barrier and moisture-conducting character fabricated by NMMO. J Mater Sci 56:18313–18326. https://doi.org/10.1007/s10853-021-06499-5

Ragab S, Ahmed EN (2019) Zirconyl chloride as a novel and efficient green Lewis acid catalyst for direct acetylation of cotton cellulose in the presence and absence of solvent. J Polym Res 26:156. https://doi.org/10.1007/s10965-019-1816-3

Li H, Freeman BD, Ekiner OM (2011) Gas permeation properties of poly(urethane-urea)s containing different polyethers. J Membr Sci 369:49–58. https://doi.org/10.1016/j.memsci.2010.11.024

Sadeghi M, Semsarzadeh MA, Barikani M, Ghalei B (2010) The effect of urethane and urea content on the gas permeation properties of poly(urethane-urea) membranes. J Membr Sci 354:40–47. https://doi.org/10.1016/j.memsci.2010.02.070

Wang YX, Gupta M, Schiraldi DA (2012) Oxygen permeability in thermoplastic polyurethanes. J Polym Sci Pol Phys 50:681–693. https://doi.org/10.1002/polb.23053

Zhang XR, Zhang LZ, Liu HM, Pei LX (2011) One-step fabrication and analysis of an asymmetric cellulose acetate membrane for heat and moisture recovery. J Membr Sci 366:158–165. https://doi.org/10.1016/j.memsci.2010.09.054

Abd El-Ghaffar MA, Elawady MM, Rabie AM, Abdelhamid AE (2020) Enhancing the RO performance of cellulose acetate membrane using chitosan nanoparticles. J Polym Res 27:337. https://doi.org/10.1007/s10965-020-02319-7

Zhang Y, Fu Q (2018) Algal fouling of microfiltration and ultrafiltration membranes and control strategies: A review. Sep Purif Technol 203:193–208. https://doi.org/10.1016/j.seppur.2018.04.040

Wang CB, Li ZY, Chen JX et al (2018) Influence of blending zwitterionic functionalized titanium nanotubes on flux and anti-fouling performance of polyamide nanofiltration membranes. J Mater Sci 53:10499–10512. https://doi.org/10.1007/s10853-018-2288-2

Ma X, Wang CY, Guo HX et al (2022) Novel dopamine-modified cellulose acetate ultrafiltration membranes with improved separation and antifouling performances. J Mater Sci 57:6474–6486. https://doi.org/10.1007/s10853-022-07024-y

Jost V, Kobsik K, Schmid M, Noller K (2014) Influence of plasticiser on the barrier, mechanical and grease resistance properties of alginate cast films. Carbohyd Polym 110:309–319. https://doi.org/10.1016/j.carbpol.2014.03.096

Chaos A, Sangroniz A, Gonzalez A, Iriarte M, Sarasua JR, del Rio J, Etxeberria A (2019) Tributyl citrate as an effective plasticizer for biodegradable polymers: effect of plasticizer on free volume and transport and mechanical properties. Polym Int 68:125–133. https://doi.org/10.1002/pi.5705

Bao CY, Long DR, Vergelati C (2015) Miscibility and dynamical properties of cellulose acetate/plasticizer systems. Carbohyd Polym 116:95–102. https://doi.org/10.1016/j.carbpol.2014.07.078

Dreux X, Majeste JC, Carrot C, Argoud A, Vergelati C (2019) Viscoelastic behaviour of cellulose acetate/triacetin blends by rheology in the melt state. Carbohyd Polym 222:114973. https://doi.org/10.1016/j.carbpol.2019.114973

Keely CM, Zhang XQ, Mcbrierty VJ (1995) Hydration and plasticization effects in cellulose acetate: a solid-state NMR study. J Mol Struct 355:33–46. https://doi.org/10.1016/0022-2860(95)08865-S

Scandola M, Ceccorulli G (1985) Visoelastic properties of cellulose derivatives. 2. Effect of diethylphthalate on the dynamic mechanical relaxations of cellulose-acetate. Polymer 26:1958–1962. https://doi.org/10.1016/0032-3861(85)90174-0

Bendaoud A, Chalamet Y (2014) Plasticizing effect of ionic liquid on cellulose acetate obtained by melt processing. Carbohyd Polym 108:75–82. https://doi.org/10.1016/j.carbpol.2014.03.023

Zhang ZM, Jiang PP, Liu DK et al (2021) Research progress of novel bio-based plasticizers and their applications in poly(vinyl chloride). J Mater Sci 56:10155–10182. https://doi.org/10.1007/s10853-021-05934-x

Nisha Y, Minna H (2021) Degradable or not? Cellulose acetate as a model for complicated interplay between structure, environment and degradation. Chemosphere 265:128731. https://doi.org/10.1016/j.chemosphere.2020.128731

Boulven M, Quintard G, Cottaz A, Joly C, Charlot A, Fleury E (2019) Homogeneous acylation of Cellulose diacetate: Towards bioplastics with tuneable thermal and water transport properties. Carbohyd Polym 206:674–684. https://doi.org/10.1016/j.carbpol.2018.11.030

Phuong VT, Verstichel S, Cinelli P, Anguillesi I, Coltelli MB, Lazzeri A (2014) Cellulose acetate blends -effect of plasticizers on properties and biodegradability. J Renew Mater 2:35–41. https://doi.org/10.7569/jrm.2013.634136

Kwon SH, Lee CJ, Choi HJ, Chung KH, Jung JH (2019) Viscoelastic and mechanical behaviors of magneto-rheological carbonyl iron/natural rubber composites with magnetic iron oxide nanoparticle. Smart Mater Struct 28:045012. https://doi.org/10.1088/1361-665X/ab0018

Sun HX, Mao ZP, Zhang J (2020) Fabrication of damping material over broad temperature range: blending amorphous styrene-butadiene-styrene triblock copolymer with semi-crystalline syndiotactic 1,2-polybutadiene. J Vinyl Addit Technol 26:336–347. https://doi.org/10.1002/vnl.21748

Mao ZP, Sun HX, Zhang J (2021) Selective distribution of SrTiO3 in co-continuous composites: An effective method to improve the dielectric and mechanical properties. Compos Part A-Appl S 143:106312. https://doi.org/10.1016/j.compositesa.2021.106312

Mao ZP, Jiang TK, Zhang XQ, Jiang GD, Zhang J (2020) Co-continuous phase structure formed in melt processing inducing shear bands to prevent crack propagation: Significant improvement in impact toughness of PMMA. Polym Test 85:106425. https://doi.org/10.1016/j.polymertesting.2020.106425

Zhang LZ, Wang YY, Wang CL, Xiang H (2008) Synthesis and characterization of a PVA/LiCl blend membrane for air dehumidification. J Membr Sci 308:198–206. https://doi.org/10.1016/j.memsci.2007.09.056

Chen G, Zhang XS, Wang JH, Zhang SB (2007) Synthesis and characterization of soluble poly(amideimide)s bearing triethylamine sulfonate groups as gas dehumidification membrane material. J Appl Polym Sci 106:3179–3184. https://doi.org/10.1002/app.26819

Garcia MA, Martino MN, Zaritzky NE (2000) Lipid addition to improve barrier properties of edible starch-based films and coatings. J Food Sci 65:941–947. https://doi.org/10.1111/j.1365-2621.2000.tb09397.x

Hazrati KZ, Sapuan SM, Zuhri MYM, Jumaidin R (2021) Effect of plasticizers on physical, thermal, and tensile properties of thermoplastic films based on Dioscorea hispida starch. Int J Biol Macromol 185:219–228. https://doi.org/10.1016/j.ijbiomac.2021.06.099

Liu L, Gong DC, Bratasz L, Zhu ZY, Wang CM (2019) Degradation markers and plasticizer loss of cellulose acetate films during ageing. Polym Degrad Stab 168:108952. https://doi.org/10.1016/j.polymdegradstab.2019.108952

Acknowledgements

We are grateful to Industry Prospect and Common Key Technology of Suqian Science and technology plan (No. H201815) for financial support of this work. We give great thanks to a project funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no competing financial interests or personal relationship that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hu, S., Wu, P., Zhao, Y. et al. Effects of plasticizers on the properties of breathable cellulose diacetate films. J Polym Res 29, 404 (2022). https://doi.org/10.1007/s10965-022-03251-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03251-8